55-702441 Logistics and Enterprise Information Systems Assignment Sample

Module code and Title: 55-702441 Logistics and Enterprise Information Systems Assignment Sample

Introduction

The main objective of every business is to gain maximum profit by conducting operating activities. Main determinant factors to the profit maximization are having maximum revenue while managing the cost of production. Earning revenue is dependent on the market situation and customers’ reaction to the business organization. Due to this reason the company cannot control the revenue generating process.

Due to this reason, it is essential to ensure that the cost of the operating process is maintained at the lowest level since it is controllable by a business organization. Raw material is one of the main aspects or cost factors in an operating factor. Material resource planning helps a business to minimize the usage of materials in the production line. It also ensures that there is no wastage of materials while maintaining a smooth supply of raw materials without facing the problem of shortage.

This report has shown the material resource planning for the side lamp and headlamp production process in Automotive Spare parts Ltd. It has provided a background of Automotive Spare parts Ltd while identifying their business operation process. It has also identified the problems that this company faces and the solutions that can be taken. In the end a conclusion has been provided to summarize the key factors of this project.

Background of the company

Automotive Spare parts Ltd operates in the spare part manufacturing industry. The main focus of this company is to produce side lamps and head lamps for their customers. Automotive Spare parts Ltd mainly focuses on B2B style business. Under the B2B business model they do not sell their products directly to the end users.

Rather they supply their products to 75 Automobile stores and repair shops. Among all customers, it has been seen that “Moonbird silver” is the largest car dealer of the region which purchases products from Automotive Spare parts Ltd (Ren and Shi, 2021).

As for the history of Automotive Spare parts Ltd, it can be found that Johnny Bennett is the founder of the business. Mr. Johnny Bennett started his first manufacturing in his personal garage.

As a result of this humble start of Automotive Spare parts Ltd, the main motto of the business is to work hard to produce good quality products. Their objective is to ensure customers satisfaction by providing service and good quality products so that their loyalty can be ensured while attracting new customers.

The main products that Automotive Spare parts Ltd produces are the side lamps and headlamps. In recent years the automobile industry has seen a certain uprise within a short time span. However even with the market upside the market fluctuates rapidly. Due to this reason it can be seen that business faces high demand and due to this fails to supply as per the demand. On the other hand it has also seen lower demands in certain months (Qu et al. 2019).

In these low demand months, companies were producing more than their actual customer demand. Due to this reason it can be seen that their finished product stock was increasing as well as the cost of manufacturing without generating sufficient revenue.

Due to this reason it became essential to strategize their Case study shows that companies intended to provide training to their employees for making sure that the material resource planning process can be handled properly. However after one year the process was dropped because there were problems regarding the matter of customer satisfaction. Multiple complains were coming from customers regarding the shipment quality.

Problem statement

Case study has reflected that many complaints were received from the customer’s side on the subject of shipment. It has been identified that the system of the company to handle their shipments and supply chain is not working properly. The business is however only able to handle their inventory records and BOM files. However the lack of connection between inventory management process and production department creates a knowledge gap.

Inventory management process fails to identify the need of a raw material and due to this purchase of raw material within a time does not take place in the manufacturing process hence lowering customer satisfaction level. To handle this type of issues it can be business is planning to extend their business output measurement process so that material handling process can be improved. It has also been identified that Automotive Spare parts Ltd does not have a mankind planning which is also creating issues in the production line (Basl, 2018).

By analyzing these departmental faults it can also be suggested that Automotive Spare parts Ltd is facing connectivity problems between departments. For example, marketing departments are taking a high volume of orders which the operating department is failing to deliver hence reducing customer satisfaction. Human resource department is also not handling employees properly so that their potentials can be used according to the business requirement.

Production

Jacob has suggested using pre MRP informal system to improve their production logistics. It can be seen that due to the lack of order, management were forced to over produce just to ensure that workers are working as per their daily schedule. However, this week they failed to meet the demand of the customers due to the high demand. From this it can be identified that the production and demand are fluctuating due to the market situation.

The main reason for failing to supply as per demand can be identified as the shortage of raw materials in inventory (Bouzida et al. 2021). It can be suggested that Automotive Spare parts Ltd needs to plan their material management process accordingly. They also need to create connections between every department so that departments can work together to handle a surge in demand by working collaboratively.

Purchasing

Jayna spring is the purchase manager of Automotive Spare parts Ltd. She is also responsible to ensure that the inventories of the business are maintained within a safe limit so that the production process can be conducted smoothly. However, in the case study it has been seen that the purchase department is facing problems.

Due to the lack of information, the purchasing department failed to maintain a smooth inventory supply. As a result, this whole company is facing problems. For example they failed to provide proper supplies to the customers hence creating dissatisfaction among them.

Analysis

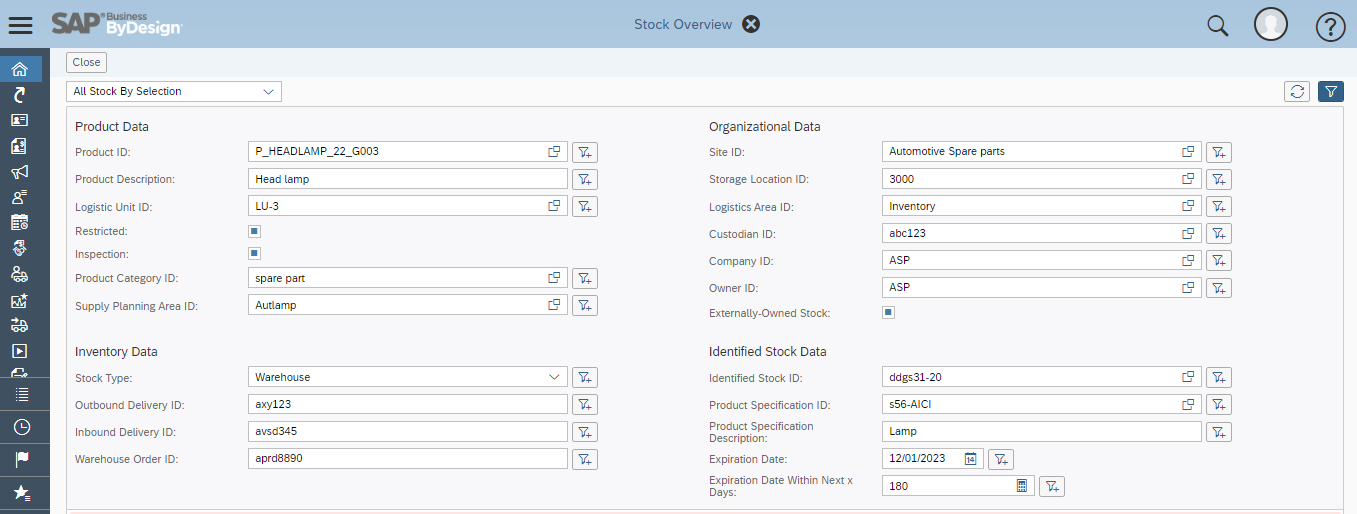

Figure: Stock overview (Source: SAP Design by business)

Figure: Stock overview (Source: SAP Design by business)

In the problem statement it has been observed that businesses are having problems managing their stocks. For this reason SAP has been designed to ensure that inventory management can be conducted properly. In the above, figure a product with a particular raw material example has been shown. If all the raw materials are recorded in such a manner then businesses will be able to manage their inventory properly (Vernadat et al. 2018).

SAP will provide notification when the stock goes below the safety margin. It also shows notification when a stock crosses its expiry date. Maintaining this two time factor helps a business to ensure the smooth operating process along with the quality of the produced product. Maintaining the expiry date helps the business to ensure that they are not using any raw materials that are not in a proper condition. It helps the business to avoid quality related issues.

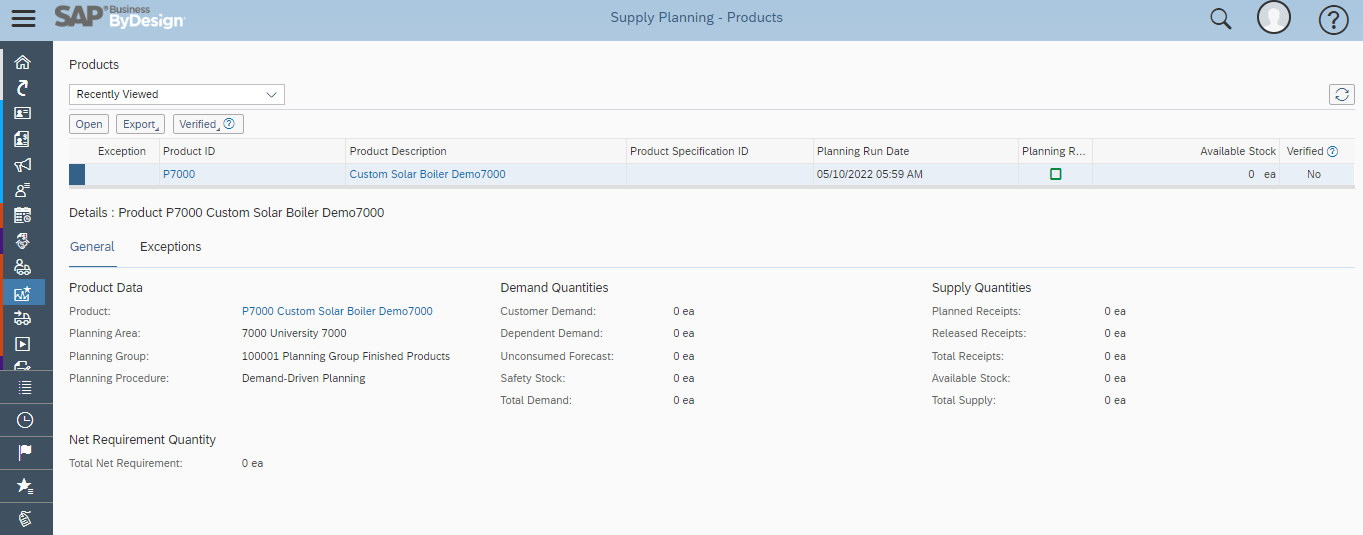

Figure: Supply planning of products (Source: SAP Design by business)

Figure: Supply planning of products (Source: SAP Design by business)

Similar to the production process, planning of supply is also an important factor. Planning the supply process enables Automotive Spare Components Ltd to provide maximum customer satisfaction. This process helps a business to ensure that an order is supplied with the promised time. In the above figure, supply planning has been created. In the above process it can be seen that supply receipt time has been shown (Masudin et al. 2021).

This ensures that Automotive Spare parts Ltd can create their supply stagy before time for example, arranging transportation medium, shipment time etc. Managing this helps the business to ensure that their customers are satisfied and they are receiving their products within their expected time.

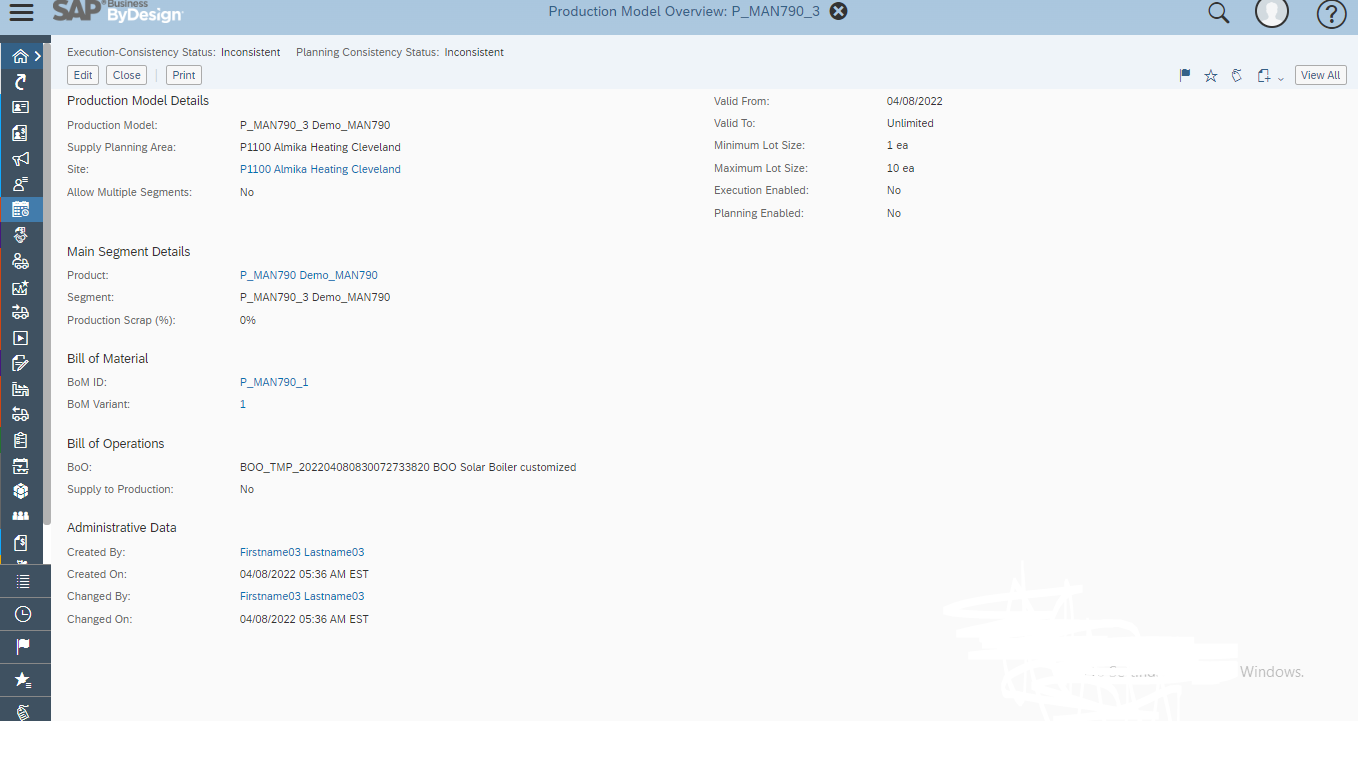

Figure: production model overview (Source: SAP Design by business)

Figure: production model overview (Source: SAP Design by business)

Quality check is another key factor where it comes to meeting customer satisfaction. To ensure that customers are satisfied Automotive Spare parts Ltd needs to check the quality of their every manufactured product. In the above a production model overview can be seen.

This type of model overview ensures that the product that is being shipped to the customer has gone through the quality check (Wambui, 2021). In other words it can be said that production model overviews are created by the quality checking department.

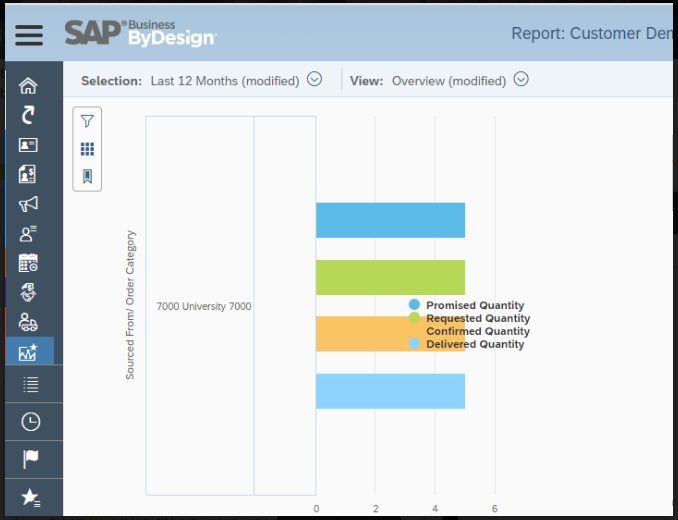

Figure: Customer delivery report (Source: SAP Design by business)

Figure: Customer delivery report (Source: SAP Design by business)

After delivering the product it is essential to check that all the products that were meant to be delivered have actually reached the customer. To ensure this fact, customer delivery statistics reports can be made. It identifies all the steps that a product has gone through for the delivery process. In the above example, it can be seen that the report has identified promised quantity and requested quantity. It ensures that business is delivering as per the promise made. It has also identified the confirmed quantity (Dzwigol et al. 2021).

This aspect identifies the amount that the customer actually agreed to purchase. In the last, the actual delivered quantity has been identified. For maintaining a pepper business operation it is essential to maintain the values of all these variables at the same point. This ensures that the business is delivering products as per customer’s requirement.

From the above analysis it can be understood that SAP is an important platform for the material management process (Kitsios et al. 2019). It shows that if Spare parts Ltd implement the SAP platform properly then they will be able to improve their business process. It can be identified that SAP has helped Spare parts Ltd to manage their customer satisfaction level also by delivering products within time. From this it can be sad that SAP is an all in one platform, helping the total business management process.

Conclusion

One of the most important features or cost considerations in an operational factor is raw material. Material resource planning assists a company in reducing material utilization in the production line. It also guarantees that no materials are wasted while ensuring a steady supply of raw materials without experiencing a shortage. Automotive Spare Components Ltd is a company that manufactures spare parts. This company’s major focus is on producing side and head lighting for their clients.

Automotive Spare Parts Ltd’s motto is to work hard in order to manufacture high-quality products. Their goal is to achieve client pleasure by delivering excellent service and high-quality products, ensuring customer loyalty while also attracting new consumers. Side lights and headlamps are the primary products of Automotive Spare Parts Ltd. In recent years, the vehicle sector has experienced a significant uptick in a very short period of time. On the other side, several months have witnessed lesser demand.

Companies were generating more than their real client need during these months of low demand. According to the findings of the case study, several complaints about shipment were received from customers. Analyzing departmental faults further suggests that Automotive Spare Parts Ltd is experiencing departmental connection issues. The buying section appears to be having difficulties. The buying department was unable to maintain a steady inventory supply due to a lack of data. It has been observed that this type of solution can be solved by Using SAP. Due to this reason, it should be recommended.

Reference List

Journals

Dzwigol, H., Trushkina, N., Kvilinskyi, O.S. and Kvilinskyi, O.S., 2021. Green logistics as a sustainable development concept of logistics systems in a circular economy (Doctoral dissertation, Proceedings of the 37th International Business Information Management Association (IBIMA)).

Kitsios, F., Kamariotou, M., Madas, M.A., Fouskas, K. and Manthou, V., 2019. Information systems strategy in SMEs: critical factors of strategic planning in logistics. Kybernetes.

Masudin, I., Lau, E., Safitri, N.T., Restuputri, D.P. and Handayani, D.I., 2021. The impact of the traceability of the information systems on humanitarian logistics performance: Case study of Indonesian relief logistics services. Cogent Business & Management, 8(1), p.1906052.

Qu, Y., Ming, X., Ni, Y., Li, X., Liu, Z., Zhang, X. and Xie, L., 2019. An integrated framework of enterprise information systems in smart manufacturing system via business process reengineering. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 233(11), pp.2210-2224.

Ren, X. and Shi, X., 2021, September. Research on Integration Path of Modern Apprenticeship and Certificate Information Systems for Computer Assisted Logistics Education. In 2021 4th International Conference on Information Systems and Computer Aided Education (pp. 1955-1957).

Stankov, I. and Tsochev, G., 2020. Vulnerability and protection of business management systems: threats and challenges. Problems of Engineering Cybernetics and Robotics, 72, pp.29-40.

Velychko, O., Velychko, L., Butko, M. and Khalatur, S., 2019. Modelling of strategic managerial decisions in the system of marketing logistics of enterprise. Innovative Marketing, 15(2), pp.58-70.

Vernadat, F.B., Chan, F.T., Molina, A., Nof, S.Y. and Panetto, H., 2018. Information systems and knowledge management in industrial engineering: recent advances and new perspectives. International Journal of Production Research, 56(8), pp.2707-2713.

Wambui, R.S., 2021. Logistics Management Practices, Logistics Information Systems, Logistics Service Quality and Customer Satisfaction of Selected Shippers in Kenya (Doctoral dissertation, University of Nairobi).

Zheng, K., Zhang, Z. and Song, B., 2020. E-commerce logistics distribution mode in big-data context: A case analysis of JD. COM. Industrial Marketing Management, 86, pp.154-162.

Know more about UniqueSubmission’s other writing services: