7ENT1060 Operations Management Assignment Sample

DESIGNING OPERATIONS

Introduction

Nestle’s organizational approach is heavily informed by the execution of diet, fitness, and wellness policies. The approach is explicitly designed to help people who want a healthier lifestyle. These activities are structured by the realistic contributions of creativity, which the organization actively pushes by leading research and development. The whole scenario facilitates the continuing processing of the enterprise’s food and drinks portfolio. Furthermore, Nestle is continuously exploring the role of nutritional treatments for improving people’s health and lifestyles in research and development activities. Through these events, the organization focuses more on raising awareness of its health and wellness issues amongst people from various cultures.

Designing Operations

The corporate strategy of Nestle is therefore focused primarily on an effort to have a positive effect on the activities of various companies throughout the world. Nestle perseveres by exchanging different perspectives on the global issues of nutrition, health, and wellness, developing superior relationships with other leading firms, and engaging officials, key leaders, and stakeholders from a particular geographical location of the organization operations to achieve this specific target (S. and Hosseinnia, 2018).

Product & Service Design

Adequate use of the resources and minimization of the optimum waste rate during the product life cycle is highly essential to Nestle’s product and service design. It is acknowledged that Nestle is the world’s largest fast-moving consumer goods company. The major part of the organizational contribution of the organization is dedicated to creating and maintaining the ecosystem through the production and conception of the commodity. The goal of Nestle’s products is to include food and drink consumer segments around the world by creating a full range of goods in various categories. Faster and more cost-effective, life cycle assessments are the commonly used technique for the company, to carry out a comprehensive review of goods with environmental consequences. The main obstacle in this process, however, is the increased participation of costs and time, as the process takes several months to complete.

The method of the company’s product design should also be carried out in more economic ways to evaluate the environmental consequences and to quantify them. It is one of Nestle’s unique fields where it faces major challenges as the company constantly works hard to build a faster and more economical effort (Melo, 2020).

Process Design

One of Nestle’s key goals is to adjust to the individual product packaging process such that consumers of all ages are reduced in difficulty.

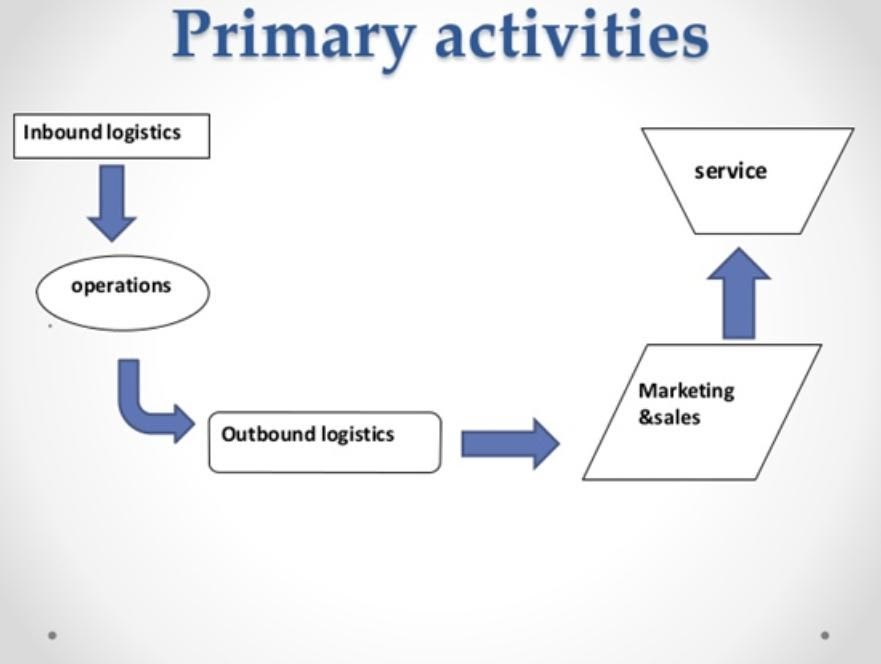

In the product packaging business, Nestle is one of the first companies in the food and beverage field to take a tailored approach to recognize environmental challenges. From the overall understanding, it is suggested that Nestle’s process design phase is characterized by its comprehensive structure, packaging, and nutritional values of its clients. A diagram may be used to further categorize the process design of the organization listed.

Planning & Control

Taking into account the concept of an organization, an entity uses various inputs such as resources and capital for its processing and production of results in the form of products and services. It can be suggested from the general knowledge that the choice of effective planning and management mechanisms affects the achievement of short or long-term objectives needs consideration by the organization and the assessment of the implications of the activities.

Innovation and Improvement

As stated by Lezcano et al. (2020), for an organization to maintain the lead in the identified market and succeed in response to the needs of the market’s customers, continuous improvement is important. The primary goal of Nestle is the enhancement of the company goods by the maintenance of process innovation, as practices have been the heart of the company’s operation for more than 150 years.

Supply Chain

Nestle’s supply chain aspect is driven by the creation of a broad forum for co-operating supply chain experts. By the successful inputs of the supply chain, the organization hits the original competitive advantage.

Nestle’s supply chain management is a blend of art and science, which allows the organization to achieve superior corporate goals. The business recognizes the unique need for raw components to manufacture the goods or services with the aid of the process. Nestle’s core business of supply chain management is driven by the useful efforts of important stakeholders such as vendors, manufacturers, distributors, dealers, customers, and producers.

Quality Management

In order to ensure the safe and safe use of consumers, Nestle operations are committed to ensuring quality and safety in the manufacturing process. Over the years customer quality and safety are key issues in building key quality control strategies for the organization. The same principle extends to the whole company’s portfolio, from food and drink goods through to services and systems.

The complete quality management approach is the continuous process of reducing or eliminating blurring in the assembly, streamlining the management of the shop networks, improving customer meetings, and ensuring that employees are reliant upon their growth. Total quality control seeks to take responsibility for the overall quality of the finished product or service to all parties in the manufacturing process. Absolute quality control is a theory of management and company activities aimed at using an organization’s human and physical capital to achieve its objectives. There are eight concepts in this theory (Huskaj et al., 2020). A customer-centric organization is the first concept. This theory shows that the company is customer-centered and therefore current and potential customer needs must be understood, customer requirements met and expectations surpassed (Liao et al., 2019).

The next key leadership, leadership, gives the company a mission, guidance, and internal climate. You must encourage others to engage in achieving the goals of the organization. The phase method is the third principle. It is the desired outcome, if relevant resources and activities are handled as a procedure, all the more proficiently. The fourth concept includes people, the core of an organization is people at all levels, and their total engagement allows their talents to be used for the benefit of the organization. The fifth theory is the management system strategy.

The Quality Control Method of Nestlé begins on farms. We work with farmers for a long time to improve their milk quality by enabling farmers to develop special quality controls such as cooling and automated milking systems. A special collection centers each day Nestlé collects fresh milk from the farmers and on-site tests the milk to confirm its consistency. The more we pay the farmer for the better quality of milk! special laboratory is available in every Nestlé factory in the world. Our Laboratory tests for the best quality, including an alcohol test to assess bacterium levels and a visual test to ensure cleanliness, shall be carried out directly at the time of arriving in the Valsayne factory milk of Nestlé. The Laboratory uses fat content, bacterial stress, and other critical questions regarding consistency to assess samples. Nestlé factory accepts only milk that fulfills Food and Drug requirements.

When goods are withdrawn from the manufacturing line they are kept in a special warehouse called the Incubator. Days are detained with milk; three days with juices and beverages. The Nestlé Laboratory performs additional quality controls on each batch during this time. Only after these final quality control checks have been passed, Nestle’s goods shall be sold to shops and supermarkets

When the Laboratory accepts milk, it undergoes many quality assurance procedures. All foreign matter is extracted and then pasteurized to destroy harmful bacteria. Milk then passes through the separation process and is standardized in order to satisfy all fresh milk composition specifications. Sterilization, which destroys bacteria and other species while preserving the nutritional value of the milk, follows. The milk is finally homogenized to make sure it does not split.

Locations strategy and layout strategies

Nestle’s raw stock is made up of milk. The raw material is processed in silos. The large tanks used to store milk are Silos. The inventories of their raw materials cannot be kept for a longer time and in bulk condition. Up to 596000 liters of milk can be processed at the farm. The five silos for the handling of the milk are all capable of different. The milk will remain without losing quality for a period of 36 hours.

Job is not too large in-process inventories. All they put into production stop production after production is finished if no unusual breakdown occurs. The unpacked inventory of products can be regarded as a WIP stock. In Bins the condensed milk is kept. Beakers are the larger boxes that store milk powder until it is packaged. Then the milk is packed in an automated factory. Butter is kept in large bathrooms (Alkhred et al., 2018).

Conclusion

The company has a separate department responsible for the procurement of the equipment and its supply by the management. A centralized material management system is in operation. Operational managers are responsible for all tasks. In addition, a shop manager also supervises the management of the products.

Nestle is using Continuous Analysis, the whole computer system, to monitor the inventory. Thus, they monitor their inventory continuously. In addition to keeping notes, the store officer makes trips to the warehouses to see the actual materials situation. The officer can always check the stock. The management and the auditing personnel are also tracking the inventory and its records so as to reduce the possibility of failure or manipulation.

References

Alkhred, F., Nohuddin, P.N., Zainol, Z. and Zakaria, O., 2018. Sharing explicit knowledge: designing a peacekeeping operation databank. Advanced Science Letters, 24(2), pp.956-960.

Liao, H., Jiang, L., Lev, B. and Fujita, H., 2019. Novel operations of PLTSs based on the disparity degrees of linguistic terms and their use in designing the probabilistic linguistic ELECTRE III method. Applied Soft Computing, 80, pp.450-464.

Huskaj, G., Iftimie, I.A. and Wilson, R.L., 2020, June. Designing Attack Infrastructure for Offensive Cyberspace Operations. In ECCWS 2020 20th European Conference on Cyber Warfare and Security (p. 473). Academic Conferences and publishing limited.

Lezcano, C., Noguera, J.L.V., Pinto-Roa, D.P., García-Torres, M., Gaona, C. and Gardel-Sotomayor, P.E., 2020. A multi-objective approach for designing optimized operation sequence on binary image processing. Heliyon, 6(4), p.e03670.

Nakhla, M., 2018. Designing extended overall equipment effectiveness: application in healthcare operations. International Journal of Management Science and Engineering Management, 13(4), pp.227-236.

Monteiro, G.P., Hopkins, A. and e Melo, P.F.F., 2020. How do organizational structures impact operational safety? Part 2–Designing structures that strengthen safety. Safety science, 123, p.104534.

Tripathi, S.B., Narzary, A., Toppo, R., Goswami, M. and Sen, B., 2018, June. Designing Efficient Configurable QCA Nano Circuit for Morphological Operations in Image Processing. In Journal of Physics: Conference Series (Vol. 1039, No. 1, p. 012028). IOP Publishing.

Yousefinezhad, S., Kermani, S. and Hosseinnia, S., 2018. Designing an Inverter-based Operational Transconductance Amplifier-capacitor Filter with Low Power Consumption for Biomedical Applications. Journal of medical signals and sensors, 8(1), p.53.

Zakirnichnaya, M.M. and Kulsharipov, I.M., 2017, October. Wedge gate valves selecting essentials in pipeline systems designing based on permissible operation parameters. In IOP Conference Series: Earth and Environmental Science (Vol. 87, No. 8, p. 082055). IOP Publishing.

Know more about UniqueSubmission’s other writing services:

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.