7ENT1129 Advanced Materials and Manufacturing Technology Assignment Sample

Effects of Air Temperature and Relative Humidity on Coronavirus Survival on Surfaces

Introduction

The development of the new product is always an essential and special topic for the manufacturing companies usually when it was designated to become the main focus for the corporates in next few years. This develops the energy in higher levels for generating attention in the internal as well as external levels along with engaging every company’s workforce starting from strategy making team to product launching team. In the biomedical sector the successful developed new product mainly determines the company’s background along with evaluating the position in the market for over next few years. However, all the strategy along with its derivatives mainly contributed to the product success but it should be evaluated properly using certain methods because the failure may occur from any side of the overall team which may lead to aggressive pricing of the newly launched product. The aggressive pricing in the biomedical industry may disrupt the overall competition in the market within the same time. It can also lead to destroying the product’s perceived value and deteriorating the margins rate for several other manufacturers (Simeon, et al, 2020). The perfect methods of strategy along with implementation was not only enough for gaining the position in the biomedical device market, it needs backup with the required amount of optimum inventory model along with forecasting model for supply strategy. The inaccurate priority given to the resources generally leads to the shortage of the product, client frustration in a subsequent manner along with increasing in delayed time which provides a platform for other competitors to enter the market with their own newly manufactured product.

Although if the biomedical manufacturing companies were confident with their newly developed product for launching, they should analyse that their product should be top notch in technology along with it should be efficient for next generation operational conditions for treatment. The launching of the new product was very expensive so the companies need to avoid the failure for making their workflow cost effective. While launching several challenges occurred so try to overcome those challenges many strategies were developed by the companies for minimizing these mistakes (Rivera, 2020).

Some common issues identified in launching of new product

Developing an innovative technical product with the current situation in the health industry is an essential point in the initial stage but it isn’t determined that the product was launched successfully and conquered in the markets. Several common issues were identified by the respective companies which may stand in the direction of launching a new product success mode. They are:

- The landscape in the competitive market and resulting in the position of the new product especially when it was not developed firstly in the sector which means several competitors were previously launched that product so the company’s needs and significant shift in the product with respect to the previous one which was available in the market.

- The changes in the making of the decision in the modern developing era with respect to the purchasing of the product along with its facilities provided in the health care may result in breaking the situation of the buyers which was mainly shifting to the economic buyers’ options (Dayton, et al, 2020).

- The requirements of the clinical evidence along with the reimbursement may increase the impact on the launching process and commonly leads to the loner and costlier activities with undetermined outcomes.

- The new developed products in the biomedical industry were launched in the landscape of macroeconomics in nature with determination of the potential high constraint of the budget along with successive prioritization with the help of financial difficulties which possibly occur internally.

- At last, the companies need to visualize their implementation plan which was executed during launching of a product from end-to-end mode.

Blue Ocean Strategy to Position and Price of launching product

Once the launching of the newly developed product was accessed in the market with respect to its technical background then it times to design the modern identity of the value to the products in terms of pricing, process for healing, action of speed or delivery system for therapy.

The methodology of the blue ocean strategy was considered as the best way for analyzing and representing the values which were proposed to the product and along with it clarifies that the product is innovative or not as per the current situation (Christodoulou and Langley 2020). The value of BOS curves were very effective, descriptive and clear for showing the key competitor rate along with it provides advantages to the companies in focusing on their communication, sales and marketing strategies for defining the supply chain values. After the assessment of the product along with creating a modern value to the product with the help of a framework which contains four sections seems to eliminate, raise, reduce, create is shown below. The curves within the framework mainly show that the position of the product with their key competitor in the market segment along with evaluating the benefits lies in between the strategy along with selecting the aspect for giving up from the strategy for making a decision in healthy mode.

Previously, while implementation of this approach helps major biomedical devices manufacturing companies in attaining their position in the market within its industry. For cardiology procedures the drug eluting stent helps in increasing the values toward the customers as well as for patients by following methods :

- Increasing the success rate of the intervention.

- Increasing in the prices of the unitary products

- Creation of the new component for the products with combination of the new platform.

- Minimizing in the overall cost of the treatment due to the decreasing in the re-stenosis incidents in the healthcare system.

From the above strategy for pricing of the new launched product is playing a critical role in the strategy process again the BOS was offered an evidence-based solution in analytical mode (Bilal and Iqbal 2020).

The based pricing value strategy mainly analyzes the perceived value with the help of the final customers which include several professionals of the healthcare system along with the reaction of patients. After this approach is performed then the comparison with the equivalent model of costing will be executed while mapping with the alternative treatment cost with several required therapies for specifying the indications and finally justify the overall premium cost with some benefits provided to the new launched product. This blue ocean approach helps in designing the prices of the product and its attaining position in the market for reflecting the appropriate benefits to the clients. The main aim of this approach was to match the prices with the perceived value with respect to the customers along with patients and healthcare professionals.

Nanocomposites to develop a treatment for health purpose

Compatible materials for medical implants

Depending on the end-user i.e., for what purpose the device is designed for example fracture, density, wear resistance, elasticity etc, materials (such as ceramics, polymers or metals and composites related to them) must be properly selected and engineered accordingly to associate biocompatibility with certain properties to be implemented as implants. As metals possess a high ductility and exceptional strength they have been used from a very earlier time. Mostly, metals which exhibit extremely high corrosion resistance property such as CoCr alloys, alloys of Ti, stainless steel are broadly used in industries. In order to enhance the biocompatibility of metals with tissues of organs, further functionalization of the surface is highly required. For example, to achieve bone compatibility implants are coated with hydroxyapatite. Some novel metals like Pt, Au and Ag are considered for the application of density as they contain ductility and castability.

In tissue engineering, many technologies related to biocompatible device implementation is used. To develop the technology of tissues engineering polymer which have properties like biocompatibility and biodegradability are used on a huge basis. They are also used in the development process of regenerative medicine. Some examples of these polymers are gelatine, chitosan, collagen and heparin. However human body is not very responsive in nature to these materials and these materials get degraded over the course of time. Because of their non-toxicity, biocompatibility, biodegradability, and significant mechanical properties, aliphatic polyesters such as polylactide, polycaprolactone (PCL), polyglycolide, and their copolymers are commonly used as non-permanent scaffolds. PEG (poly (ethylene glycol)) is a well-known biocompatible polymer with hydrophilicity and solubility in a wide variety of solvents, which makes it easy to produce. While poly (vinyl alcohol) (PVA) and poly (acrylic acid) (PAA) have been used in the past, their non-degradability prohibits them from being used in implants. Because of their high mechanical ability, polyurethanes have also been researched.

Their biodegradability can be enhanced by the addition of some segment of hydrolysable polymers like PCL. In addition, the establishment of the biocompatibility of some polymers which are conductive in nature has been completed already. For example, the biocompatibility of polyaniline, polypyrene, polythiophene and their relative derivatives has been established. As a result, it increases their applicability to tissues that are simulated electrically like bone, cardiac cells, nerve cells etc. However, all these materials are hydrophobic in nature, non-degradable and show low mechanical functionalities and as consequence requiring the development of a design of composites that will have attributes that are multifunctional.

Based on the intended use, these bulk materials have their own set of advantages and disadvantages. Combining these materials with nanomaterials will strengthen or fine-tune their mechanical or functional properties. Based on the environmental conditions of the desired system, different types of nanomaterials may be used for biomedical applications. Nanocomposites are described as a matrix (most commonly polymers) with unique structural properties that are drugged with fillers with parameters less than 100 nm. Fillers change the matrix’s structural properties or incorporate features, such as electrical properties, biocompatibility, and so on. The use of nanoscale fillers is especially intriguing for amplifying the extent of changes in composite properties. The problem lies in dispersing them correctly into matrices in order to optimise the properties while limiting their accumulation.

Nanocomposites in the development of Nano-filters which are built by metals

Metallic nanofillers may be used in biomedical processes to improve tissue electrochemical performance or antimicrobial properties. For musculoskeletal tissue engineering, the insertion of gold nanoparticles into intracellular matrixes (ECM) demonstrated the reinforcement of cellularity by strengthening the ECM thereby reducing inflammation. Silver nanoparticles are also well known for their antimicrobial activities, especially as an alternative to antibacterial agents. Bhowmick and Koul developed a PVA-based hydrogel that could maintain a microbial atmosphere for 96 hours after being drugged with Ag nanoparticles. This hydrogel proved to be a promising applicant for wound dressing and microbial control. Likewise, magnetic particles (Fe2O3) have been polymerized into bio-based polyurethane backbones, culminating in a composite with antimicrobial and magnetic and optical properties. The use of graphene oxide as an intermediary to strengthen PCL drugged with silver was stated. In contrast to PCL doped with Ag nanoparticles separately, PCL composites with both graphene and silver demonstrated an improvement in matrix multiplication, electron mobility, stable release of Ag ions, and non-toxicity with living organisms.

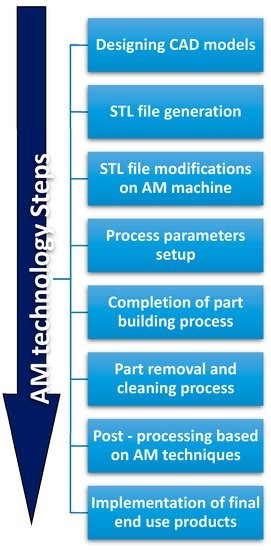

Figure 1: Steps involved in AM technology

The health industry is one of the second strongest industries, accounting for about 10% of many developing countries’ gross domestic product (GDP). As a result, the medical sector will be a significant component of a country’s economy, potentially creating a financing demand. In particular, the AM procedure is more suitable for the healthcare industry than other sectors because complicated biocompatible materials can be therapeutically fabricated with limited restrictions and a high degree of flexibility can be achieved. To reap the full benefits of AM strategies, many considerations such as repeatability, efficiency, and a smooth layout must be considered. Patients with irregular anatomy, complicated injuries, or neoplasms with whom conventional procedures are incompatible may benefit from handcrafted tools and patient-specific implants. Furthermore, if bioprinting techniques can be used to create scaffolds for cellular materials, precise surface morphology for a bio-implant and joint restoration may be achieved.

Conclusion

The increasing issues regarding health care have demanded immediate solutions to address those issues. New finding of nanotechnology was coming out as revolutionary occurrences. Nanomaterials have been used in human history in curing implants of medical fields from a few decades back. However, there existed many challenges in developing the compatibility of the nanocomposites with growing technologies of AM from time to time in the specification for medical applications of niche. Many opportunities are opened up in researches in various fields due to the current findings of the uses of biocompatibility of nanocomposites. The new findings and discoveries can be implemented to develop new curable technologies in different fields of engineering ranging from biotechnological engineering to mechanical engineering. By using the knowledge of engineering new 3D models can be designed to develop suitable nanomaterial devices for process optimization and requirements of design and geometry which will enable the rapid development of new devices which can easily tackle new attack of viruses and bacteria.

References

Al Thaher, Y., Satoof, A., Kamal, A., Almani, D., Shaban, D., Kassab, G., Surchi, H., Abu-Qtaish, H., Fatouh, J. and Ajaleh, S.A., 2021. Instrumental analytical techniques for physicochemical characterization of bio-nanomaterials. In Handbook on Nanobiomaterials for Therapeutics and Diagnostic Applications (pp. 133-150). Elsevier.

Bilal, M. and Iqbal, H.M., 2020. Biologically active macromolecules: Extraction strategies, therapeutic potential and biomedical perspective. International journal of biological macromolecules, 151, pp.1-18.

Christodoulou, I. and Langley, P.A., 2020. A gaming simulation approach to understanding blue ocean strategy development as a transition from traditional competitive strategy. Journal of Strategic Marketing, 28(8), pp.727-752.

Dayton, H., Smiley, M.K., Forouhar, F., Harrison, J.J., Price-Whelan, A. and Dietrich, L.E., 2020. Sensory domains that control cyclic di-GMP-modulating proteins: A critical frontier in bacterial signal transduction. In Microbial cyclic di-nucleotide signaling (pp. 137-158). Springer, Cham.

Gang, O., 2020. Soft Matter And Biomaterials On The Nanoscale: The Wspc Reference On Functional Nanomaterials-Part I (In 4 Volumes) (Vol. 20). World Scientific.

García-Mayagoitia, S., Pérez-Hernández, H., Medina-Pérez, G., Campos-Montiel, R.G. and Fernández-Luqueño, F., 2020. Bio-nanomaterials in the air pollution treatment. In Nanomaterials for Air Remediation (pp. 227-248). Elsevier.

Menossi, M., Ollier, R.P., Casalongué, C.A. and Alvarez, V.A., Essential Oils‐loaded Bio‐nanomaterials for Sustainable Agricultural Applications. Journal of Chemical Technology & Biotechnology.

Rivera, C.P., 2020. Preparing early career biomedical undergraduates through investigations of stakeholder needs: A qualitative analysis. In American Society for Engineering Education Annual Conference & Exposition. Virtual Conference.

Simeon-Dubach, D., Roehrl, M.H., Hofman, P. and Puchois, P., 2020. Enhancing cooperation between academic biobanks and biomedical industry: better mutual understanding and new collaborative models are needed. Biopreservation and biobanking, 18(2), pp.144-149.

Velu, R., Calais, T., Jayakumar, A. and Raspall, F., 2020. A comprehensive review on bio-nanomaterials for medical implants and feasibility studies on fabrication of such implants by additive manufacturing technique. Materials, 13(1), p.92

Know more about UniqueSubmission’s other writing services: