7PJMN018W Agile Project Management Sample

1. Introduction

The construction industry is one of the primary players that play a major role in the development of any country. This especially happens on a mass scale in developing countries. Whereas, in the developed countries construction plays a major role for developing as well as shaping up of different sectors.

Kanban technology that was developed first in Japan has now become a hot choice among various project managers especially for big projects like construction work. Construction is part of development processes all over the world. These days due to a rapid pace of development across various sectors construction projects have also started getting imbibed with that quicker deadlines.

The Kanban process has become an important part of the Construction process these days to help projects get completed within this schedule. Kanban method uses cards that help to reduce project backlogs and reduce various cases of accidents that may crop up in a particular project. This process has thus been an increasing choice across this industry in the current times.

This industry needs faster adaptations as well as quicker completion in these current times than before. Thus the combination of Agile methodology along with that of Kanban tends to be an important solution for construction projects to be completed on time desirably.

2. Main Body

2.1 Kanban Principles

The Kanban principle mainly tends to focus upon taking away various defects that may come up in a product in a gradual manner. Kanban principle seeks to learn from every mistake that generates a defect to fine-tune it with the production process. Defects cannot be eliminated in any production procedure but with the help of Kanban, this can be reduced to the lowest level.

Kanban is now considered a major part of agile methodology as it tends to allow a lot of flexibility. As per the opinion of Liu and Shi (2017), Kanban thus tends to mean in general a procedure of learning on the go. Thus Agile which also seeks to modify a certain project as per requirements of that time tends to use more of Kanban methodology to find out the places which require a change for the better.

As per the opinion of Lei (2017), initially project management and its various associated software had been mainly based upon usage of Waterfall methodology. This however got replaced by that of agile methodology in construction as well as that of other industries in order to be better adapt to flexibility.

Figure 1: Kanban cards in Kanban methodology

(Murtazova and Aliyev, 2021)

Kanban seeks to ensure that goods are produced in such a way that there are no wastages as such. As per the opinion of Murtazova and Aliyev (2021), thus this is an important methodology for the Just In Time (JIT) technique as well. Just In Time means that goods are produced in such a way that they become ready fresh from the factory when a requirement is generated.

Thus for ensuring this method a proper analysis of different market conditions along with various competencies of a firm has got to be understood. A proper analysis can ensure the generation of a proper demand forecast. The forecast also makes it possible to understand different areas that need improvement as well. Then finally Kanban is applied to eliminate these defects to reach desired goals.

Large projects like that of Construction and other such sectors tend to use this method because there has got to be a certain level of flexibility that has got to be there in these projects.

Kanban is an effective tool of a lean production control system that helps to meet up project goals without wastage of time. Kanban is a Japanese term that means visual cards. This method uses these cards to create an effective communication across any work process to mainly reduce delays, reparations as well as any other major problem in a work process.

Kanban helps to maintain the material flow system of any work through a “pull replenishment” logic system. Kanban is essentially a part of the Just in Time (JIT) approach which says that goods that are demanded should be produced just when they are required. Kanban actually tends to focus upon various subsections of a particular work structure to understand which is to be completed before which one. Kanban principle uses cards to make these work structures more visible among people who are engaged in this particular task.

Advantages of Kanban

Kanban has been extremely beneficial for reducing heavy inventory costs as well as that of backlog time across different projects. Kanban has to be implemented from the very beginning in order to ensure its integration in a particular project. According to the opinion of Ćirić and Gračanin (2017), Kanban cards have been helpful to reduce various Work-in-progress scenarios that create backlogs across projects.

Kanban mainly specifies tasks in such a way that there is smooth completion of various interconnected tasks. This has reduced the Work-In-Progress scenario to a minimum thereby helping projects to meet deadlines. Actually, Kanban helps to create an effective communication level across various stakeholders through communication through cards. These cards clearly mention the time, quality, quantity, deadline as well as various associated people for a particular work. This makes it easier for everyone to understand tasks and their responsibilities to drive work forward.

Kanban Operation System

Kanban is essentially a project control mechanism that makes various associated people aware of regarding demands of a particular work. Besides, there is an efficient control mechanism to check work structure through this system. In the Kanban method, various visual cards of daily work structures are to be upgraded on a daily basis. Besides, there is also a checking mechanism to be implemented at the end of each week.

- Based upon a weekly schedule a project plan is prepared for a particular week by the last person (pull schedule).

- According to this work schedule ordering, receipts are printed for various workers for each day.

- Safety instructions regarding any previous mishap or other associated delays are included in these cards. This helps to make the team aware to reduce the recurrence of such problems in the future (John, 2018).

- A project manager or field engineer picks up kanban cards for a particular day and distributes these among various team members to drive work processes forward.

- Then comes the receipt kanban during each workday in which the progress status of a particular task is filled by the project head.

- Kanban verification and cross-checking is done in this stage to compare the work status with that of desired project goals

- In the end, reasons for delays are found out along with accidents that may have been caused in this stage.

Different varieties of Kanban

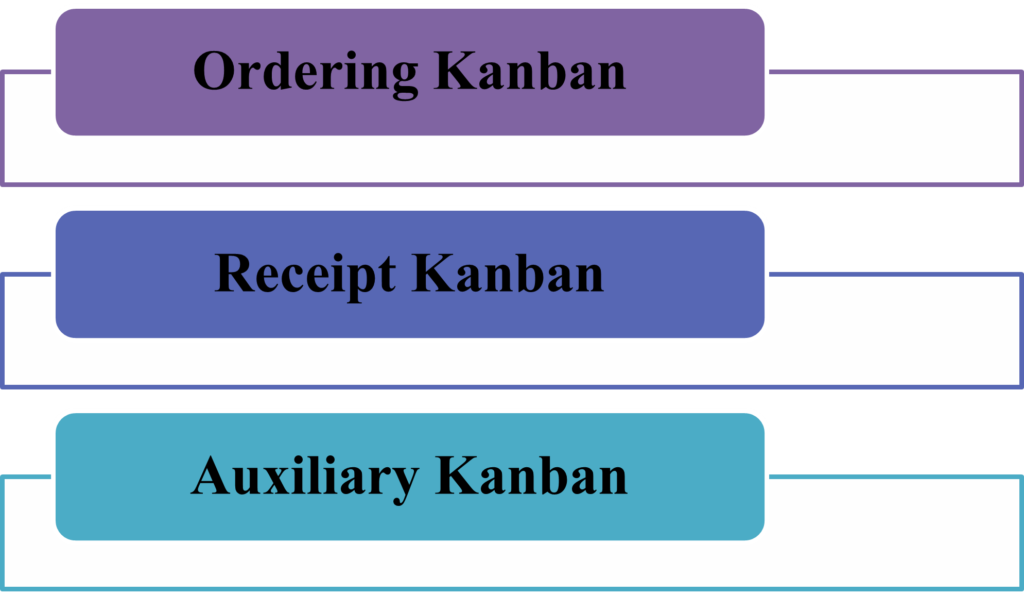

The ordering Kanban- These job cards actually are made by the controller who hands these down to that of the field engineer or Project Manager. These cards actually include various definitions of certain tasks that are to be completed.

According to the opinion of Papadakis and Tsironis (2018), each card contains specifications of the names of people who are responsible for a particular job, nature of the job, quality demanded as well as start and end dates. Resource allocation, as well as safety measures, is also given through these cards for a particular week. Percent Plan Completion (PPC) module is integrated along with Kanban to check the progress of a particular task against the preset objectives.

Figure 2: Different types of Kanban.

(Source: Lalmi et al. 2021)

The Receipt Kanban – This method is more useful when work is in progress. The Kanban cards that were initially ordered come back with numerous information regarding the actual date of completion of a task, reasons for the delay, accidents if any, excess requirements if any, and various other information. The project controller then visits the worksite to find out the real reasons for various delays and uses various control mechanisms that are first for this scenario.

The Auxiliary Kanban– Sometimes in project requirements of certain additional tasks may get generated. As per the opinion of Lalmi et al. (2021), in this scenario, it is not possible to leave a task behind and concentrate upon a new job as all tasks are preplanned and interconnected. In these cases, a separate Kanban module called Auxiliary Kanban is implemented to carry on this additional task without hampering the progress of the current project

2.2 Usage of Kanban in the Construction Industry

The construction industry falls in the category of major projects that are essential to ensure development. As per the opinion of Innella et al. (2019), construction logistics are relying more upon the usage of Kanban in this current time to reduce huge costs that may be incurred due to defects in its demand and supply procedures. Kanban is also used in the construction industry because certain small defects can be life-threatening for some.

According to the opinion of Saltz and Heckman (2020), agile methodology is increasingly replacing various other methodologies in different sectors starting from that of academics to that of Construction industry in order to drive efficiency. Besides, a misinterpretation of a certain requirement at the exact time can create a huge stoppage in the project work as well.

This thus prevents a big project with numerous stakeholders to meet the deadlines. Kanban is most preferred by business organisations in the manufacturing of automobile industry. There are several benefits of this framework while an organisation improves not in their company to manufacturer to deliver to final consumers of the product. There is another strategy than can be applicable in this context is hybrid Kanban.

It is implementation of the push system which is referred in case of predetermination of schedule along with the associated downstream requirement (Leonardo et al. 2017). The simulation method in hybrid implementation within a manufacturing industry can be considered as one of the strategic application of the above mentioned methodologies.

It supports a business organisation to develop an optimum level strategy and develop a manufacturing process that consists of low production cost as well as improving efficiency of production. Besides, it supports manufacturing companies to adopt any changes.

That is arisen due to the development of the production process as well as developing an effective supply chain system. As opined by Babalola and Ezema, (2019), supply chain system is an important factor for any organisation to improve performance of organisation as well as more satisfied customers of company. Besides, the automobile industry is growing and developing business in the current business market. Kanban framework supports minimising risk in business processes as well as improving efficiency of SCM.

The factor of giving more focus on continuous delivery of a project is most important in case of Kanban framework. Project managers in constructionindustry often get certain advantage of delivering their projects on time with the application of Kanban strategy.

In case of an organization which is centralised, is governed by a single authority while in the decentralised organization there are boards and association dealing with the strategic movement (Thürer et al. 2019). In taking the decisions, a decentralised organization is more affective.

The construction industry is associated with the building of various structures of diverse sizes that tend to serve different purposes. However, a construction project generally tends to have a similar basic work structure that has various associated subsidiary tasks.

There generally tends to be a need for a huge amount of man and materials to complete any construction work. This has however got to be sorted out by an efficient manager who can ensure reliability to this particular project to ensure completion. As per the opinion of Ahmed and Mohammed (2018), in a construction project, there is usually a field manager who tends to investigate the progress of a particular construction project from the on-site location.

Previously, this field-in-charge used to plan various tasks while working on a particular project. But currently, after the implementation of Kanban methodology work can be sorted out quite easily daily. Kanban and scrum are the greatest mechanism in case of manufacturing farm and supporting alignment is in this case is not similar for both the methods.

Kanban is more fluid in nature where methodologies give the generalized mechanism in conduction of all the operation (Alqudah and Razali, 2017). On the other hand Scrum is simpler and short techniques associated with the manufacturing methodologies.

Initially, there is a huge and very important phase where planning is done keeping in mind various subtasks that are associated with that of a project. Important among these are fixing raw material requirements, sorting out manpower needs, and checking up on financial requirements.

As per the opinion of Burton et al. (2021), construction is generally broken down into numerous phases starting from that laying down the foundation, preparing the brickwork and steelwork, and finally following by completion of the project. In the construction fieldwork, daily work targets are set out to achieve daily targets which are controlled through a project. Usage of various kinds of ordering as well as receiving cards has helped to increase workflow.

Coloured Kanban cards tend to allocate different daily job requirements in such a manner that it becomes easy to understand different job requirements by different stakeholders.

Current situation of the Construction industry

The construction industry is expected to grow at an alarming rate in recent years because of a general rise of different kinds of developmental projects all over the world. There is however a general rise to complete projects within shorter periods than before. Due to this situation, there has been increasing pressure upon various employees associated with this kind of work.

Thus this has also created a rise in cases of various kinds of accidents in this industry as well. Implementation of Kanban methodology has helped a lot to reduce these problems through the creation of a proper instructional format through cards. According to the opinion of Masood and Farooq (2017), traditional operations management procedures are used to create problems specifically to help manage bulk amounts of work.

Moreover due to a general emergence of various kinds of designs in the field of construction work, in some major constructional jobs flexibility has become a necessity. Agile methodology helps create a proper scenario for adoption to these kinds of project structures as it ensures flexibility, but this is not enough. Implementation of Kanban along with that of Agile is considered as a perfect combination to drive project goals.

Improvements in the Construction industry through the implementation of Kanban

Visibility- Kanban has increased visibility in this industry. There is thus currently a need to communicate everything through words. This has helped to reduce the wastage of time a lot. Workers now can concentrate more on their work and communicate only for those cases in which they are facing difficulty in understanding tasks (Lukianov and Primak, 2019).

Production- kanban has helped the construction industry by creating a proper understanding regarding those tasks which are to be prioritized. The fact that foundational tasks are to be followed by steelwork is properly mentioned in Kanban cards for easy functioning processes.

Progress Monitoring- kanban has been extremely helpful for progress monitoring by field engineers as well as project controllers. As per the opinion of Vallon et al. (2019), several receipt cards in kanban measure the total number of tasks that have been completed.

This is then compared with the various orders that have come out in total for a project to understand the gap that is remaining in a particular project. This kind of monitoring helps to find out the current stage of a particular project and thereby make strategic decisions to complete this task on time.

2.3 Case study of kanban with an U.K based organisation

Balfour Beatty is one of the topmost construction companies in the UK which follows the Kanban framework to deliver its projects to clients. As opined by Sarhan and Fawzia, (2017), kanban framework is highly focused on the increased productivity of a certain project. Project managers in construction industry are often seen to apply the Kanban methodology to increase overall productivity.

In the construction industry, wastage of products is highly common due to which most of the top brands in the country focus on implementing the kanban framework. As stated by Kosasih and Sriwana, (2019), team member’s focus gets enhanced to a certain extent once the project managers in the construction industry implement kanban framework.

Increased efficiency is a factor that is required to be maintained in the construction industry and Kanban framework create opportunities for the contractors to become more efficient. As stated by Omar and Alaidaros, (2020), the kanban framework also prescribed that an organisation may improve their performance through implementing digital gadgets in the production process. Latest technology is an important factor for the development of the whole organisation.

There are numerous organizations that operate around the U.K and its surrounding areas that deal with construction and its associated products. As per the opinion of Alaidaros et al. (2020), Software Project management for managing projects spread across various constructional works are recurrently applying Kanban, a common project management methodology of the Agile format.

Now the fact is that the U.K now being one of the top-level developed countries is seen as a requirement of constant up-gradation of various structures. As per the opinion of Zenga et al. (2019), unlike developing countries, developed countries do not need a huge development of major infrastructure projects. This tends to happen as these countries already have various major infrastructures installed within them.

In the United Kingdom, there are numerous companies like that of Balfour Beatty, Kier group, and various companies who have been major players across this sector. Balfour Beatty is considered a key player in this scenario in the United Kingdom who has driven forward some of the major construction projects.

Balfour Beatty’s previous operational procedures were previously based upon traditional ones. This has however got changed in recent times to meet the fast deadlines of various client projects. Balfour Beatty started with a focus only upon lean management systems to derive advantages from better efficiency in certain constructional techniques.

This scenario has however changed after the introduction of the kanban methodology across their different projects. According to the opinion of Innella et al. (2019), Kanban has helped various companies to divide their basic work structures into different important components at the start of project work. Then it has also helped to control the progress of various running projects through a control room from their headquarters.

Previously managing different diverse tasks used to be very difficult as there used to be a problem as to understand which task was to be focused upon by this company to ensure better quality. Furlow is a household name in United Kingdom that applies kanban method to properly create visual instructions for various employees. Collato is another organization that seeks to create flexibility in day to day projects through agile.

Balfour Beatty now is mainly concentrated upon allocating various tasks to its different site engineers. This company however tends to concentrate mainly upon portions likes that of finances, resources, manpower planning, and seeing the project progress through control mechanisms. This has saved a lot of time for this organization to not be involved with various routine jobs only. As per the opinion of Powell (2018), various construction organizations are now even able to take up more projects than they could have previously dreamt of.

Kanban methodology is applied not only in the onsite locations but also incorporate the offices of this company. Various kanban cards that come up from different sites are allocated to various managers who tend to look after different projects. Thus the operations manager in charge of a project can look up kanban cards coming from different places and understand the current conditions of various construction projects.

Moreover, there is a reduced need to constantly call project and field managers to supply information regarding particular projects. Thus these days’ project managers can view various approaches and situations of a particular project just by looking at the kanban cards.

Thus site engineers are also more at peace as they know that they may be called only if defects tend to arise in a particular job. According to the opinion of Houti et al. (2017), stakeholders associated with various organizations of both the on-site as well as off-site members can understand a project much better if work is followed in this system.

Balfour Beatty previously used to receive various reports of employee frustration in terms of increasing work pressure. This used to originate because of the increase in the number of various projects.

The current use of the kanban mechanism has improved communication levels across these employees and has reduced their grievances as well. Allocation of daily jobs used to involve a huge analysis of various work constraints on part of project managers. This has got hugely reduced as these days a simple analysis of previous day’s work is enough to make one understand about current requirements from a particular day’s job.

This has further helped to integrate construction work in such a way that there remains hardly any difficulty to complete allocated work on time. These construction projects that have been able to use kanban in its projects are now basking upon the fruits of their success.

This draft is conducted to develop the impact of different frameworks in the manufacturing industry as well as other manufacturing industries. Besides this draft is also discussed the process of development of the Tesla company from their starting to become a global automotive industry for organisation.

Tesla is treated their business without having sufficient design for their cars and other vehicles. Besides this draft is also prescribed a kanban framework for development of this whole business process through considering different components and factors that play prime role to develop an effective SCM. It can be concluded from the above discussion that Kanban has acted as a major trump card for various companies operating across the construction industry. Construction falls within the big projects category and haven thus has a lot of tasks that are embedded within it.

Operations management procedure adopted in the previous eras is increasingly becoming inapplicable as per the current scenario. A rapid increase in construction work has made it a necessity to use such a method that helps to incomplete these projects in time. Agile methodology is extremely helpful to control a project by imbibing flexibility within it as projects of these times tend to demand more frequent n modifications.

Integration of Kanban methodology along with that of Agile is thus an optimal solution to help reach project objectives quite smoothly and on time. The modifications that are to be included in a particular project can be integrated through the usage of Auxiliary Kanban methodology that makes special allocation for completion of these additional tasks simultaneously as well.

References

Ahmed, M.N. and Mohammed, S.R., 2018. Agile Quality Management Framework in Construction Projects (AQMFCP). International Journal of Engineering and Technology (UAE), 7(20), pp.307-309. Available at: https://www.researchgate.net/profile/Mohammed-Neamah-3/publication/332140307_Agile_Quality_Management_Framework_in_Construction_Projects_AQMFCP/links/5ecf8f2f4585152945187ec2/Agile-Quality-Management-Framework-in-Construction-Projects-AQMFCP.pdf

Ahmed, M.N. and Mohammed, S.R., 2019. Developing a Risk Management Framework in Construction Project Based on Agile Management Approach. Civil Engineering Journal, 5(3), pp.608-615. Available at: https://scholar.archive.org/work/sdsxwwibqzdc5pmsrmtkfzgbae/access/wayback/https://www.civilejournal.org/index.php/cej/article/download/1252/pdf

Alaidaros, H., Omar, M. and Romli, R., 2020. Improving the progress monitoring task of agile Kanban Method: An enhanced theoretical framework and its implication. International Journal of Scientific & Technology Research, 9(1), pp.611-615. Available at: http://repo.uum.edu.my/28279/

Alqudah, M. and Razali, R., 2017, November. A comparison of scrum and Kanban for identifying their selection factors. In 2017 6th International Conference on Electrical Engineering and Informatics (ICEEI) (pp. 1-6). IEEE. Available at: https://ieeexplore.ieee.org/abstract/document/8312434/

Babalola, O., Ibem, E.O. and Ezema, I.C., 2019. Implementation of lean practices in the construction industry: A systematic review. Building and Environment, 148, pp.34-43. Available at: https://core.ac.uk/download/pdf/322886976.pdf

Burton, E., Edwards, D.J., Roberts, C., Chileshe, N. and Lai, J.H., 2021. Delineating the implications of dispersing teams and teleworking in an Agile UK construction sector. Sustainability, 13(17), p.9981. Available at: https://www.mdpi.com/1259848

Ćirić, D. and Gračanin, D., 2017. Agile project management beyond software industry. In Proceedings of the XV International Scientific Conference on Industrial Systems (pp. 332-337). Novi Sad: Faculty of Technical Sciences. Available at: https://iim.ftn.uns.ac.rs/is17/papers/60.pdf

Ezcan, V., Goulding, J.S. and Arif, M., 2020. Redefining ICT embeddedness in the construction industry: maximizing technology diffusion capabilities to support agility. Building Research & Information, 48(8), pp.922-944. Available at: https://www.tandfonline.com/doi/abs/10.1080/09613218.2019.1709786

Grangel, R. and Campos, C., 2019. Agile model-driven methodology to implement corporate social responsibility. Computers & Industrial Engineering, 127, pp.116-128). Available at: https://www.sciencedirect.com/science/article/pii/S0360835218305928

Houti, M., El Abbadi, L. and Abouabdellah, A., 2017. E-Kanban the new generation of traditional Kanban system, and the impact of its implementation in the enterprise. In Proceedings of the International Conference on Industrial Engineering and Operations Management (pp. 1261-1270). Available at: https://www.researchgate.net/profile/Mariam-Houti/publication/321945900_E-Kanban_the_new_generation_of_traditional_Kanban_system_and_the_impact_of_its_implementation_in_the_enterprise/links/5a3a80c6aca2728e698aa090/E-Kanban-the-new-generation-of-traditional-Kanban-system-and-the-impact-of-its-implementation-in-the-enterprise.pdf

Innella, F., Arashpour, M. and Bai, Y., 2019. Lean methodologies and techniques for modular construction: chronological and critical review. Journal of Construction Engineering and Management, 145(12), p.04019076. Available at: https://ascelibrary.org/doi/abs/10.1061/(ASCE)CO.1943-7862.0001712

Innella, F., Arashpour, M. and Bai, Y., 2019. Lean methodologies and techniques for modular construction: chronological and critical review. Journal of Construction Engineering and Management, 145(12), p.04019076. Available at: https://ascelibrary.org/doi/abs/10.1061/(ASCE)CO.1943-7862.0001712

John, B., 2018. Framework of agile management’s sprint planning in construction projects–AFD method. International Journal for Advance Research and Development, 3(5), pp.88-93. Available at: https://www.ijarnd.com/manuscript/framework-of-agile-managements-sprint-planning-in-construction-projects-afd-method/

Kosasih, W., Sriwana, I.K., Sari, E.C. and Doaly, C.O., 2019, May. Applying value stream mapping tools and kanban system for waste identification and reduction (case study: a basic chemical company). In IOP Conference Series: Materials Science and Engineering (Vol. 528, No. 1, p. 012050). IOP Publishing. Available at: https://iopscience.iop.org/article/10.1088/1757-899X/528/1/012050/pdf

Lalmi, A., Fernandes, G. and Souad, S.B., 2021. A conceptual hybrid project management model for construction projects. Procedia Computer Science, 181, pp.921-930. Available at: https://www.sciencedirect.com/science/article/pii/S187705092100291X

Lei, H., Ganjeizadeh, F., Jayachandran, P.K. and Ozcan, P., 2017. A statistical analysis of the effects of Scrum and Kanban on software development projects. Robotics and Computer-Integrated Manufacturing, 43, pp.59-67. Available at: https://www.sciencedirect.com/science/article/pii/S0736584515301599

Leonardo, D.G., Sereno, B., da Silva, D.S.A., Sampaio, M., Massote, A.A. and Simões, J.C., 2017. Implementation of hybrid Kanban-CONWIP system: a case study. Journal of Manufacturing Technology Management. Available at: https://www.emerald.com/insight/content/doi/10.1108/JMTM-03-2016-0043/full/html

Liu, J. and Shi, G., 2017. Quality control of a complex lean construction project based on KanBIM technology. EURASIA Journal of mathematics, science and technology education, 13(8), pp.5905-5919. Available at: https://www.ejmste.com/article/quality-control-of-a-complex-lean-construction-project-based-on-kanbim-technology-4997

Lukianov, P.D.D. and Primak, P.D.Y., 2019. Transfer of project management technologies from information technology to construction industry. In 4th International Scientific and Practical Conference “Project, Program, Portfolio Management. РЗМ-2019»-ONPU (pp. 47-51). Available at: https://www.researchgate.net/profile/Dmytro-Lukianov/publication/343750174_Transfer_of_project_management_technologies_from_information_technology_to_construction_industry/links/5f3da420458515b7292f629e/Transfer-of-project-management-technologies-from-information-technology-to-construction-industry.pdf

Masood, Z. and Farooq, S., 2017. The benefits and key challenges of agile project management under recent research opportunities. International Research Journal of Management Sciences, 5(1), pp.20-28. Available at: https://www.researchgate.net/profile/Zahid-Masood/publication/316239082_The_Benefits_and_Key_Challenges_of_Agile_Project_Management_under_Recent_Research_Opportunities/links/5911cd1ea6fdcc963e6d0ea3/The-Benefits-and-Key-Challenges-of-Agile-Project-Management-under-Recent-Research-Opportunities.pdf

Murtazova, K. and Aliyev, S., 2021. Current state and development prospects of the construction industry. Nexo Revista Científica, 34(02), pp.916-925. Available at: https://camjol.info/index.php/NEXO/article/view/11619

Omar, M., Alaidaros, H. and Romli, R., 2020. An Improved Software Project Monitoring Task Model of Agile Kanban Method: A Practitioners’ Perspective. International Journal on Advanced Science, Engineering and Information Technology, 10(2), pp.548-554. Available at: http://repo.uum.edu.my/28276/1/IJASEIT%2010%202%202020%20548%20554.pdf

Papadakis, E. and Tsironis, L., 2018. Hybrid methods and practices associated with agile methods, method tailoring and delivery of projects in a non-software context. Procedia computer science, 138, pp.739-746. Available at: https://www.sciencedirect.com/science/article/pii/S1877050918317447

Powell, D.J., 2018. Kanban for lean production in high mix, low volume environments. IFAC-PapersOnLine, 51(11), pp.140-143. Available at: https://www.sciencedirect.com/science/article/pii/S2405896318313727

Saltz, J. and Heckman, R., 2020. Exploring which agile principles students internalize when using a kanban process methodology. Journal of Information Systems Education, 31(1), p.51. Available at: http://jise.org/Volume31/n1/JISEv31n1p51.html

Sarhan, J.G., Xia, B., Fawzia, S. and Karim, A., 2017. Lean construction implementation in the Saudi Arabian construction industry. Construction Economics and Building, 17(1), pp.46-69. Available at: https://search.informit.org/doi/pdf/10.3316/informit.763708036719779

Thürer, M., Fernandes, N.O., Stevenson, M., Qu, T. and Li, C.D., 2019. Centralised vs. decentralised control decision in card-based control systems: comparing kanban systems and COBACABANA. International Journal of Production Research, 57(2), pp.322-337. Available at: https://www.tandfonline.com/doi/abs/10.1080/00207543.2018.1425018

Vallon, R., Strobl, S., Ras, M., Bernhart, M. and Grechenig, T., 2019, May. Distributed Kanban with Limited Geographical Distance: Analyzing Lean Principles Pull, Work in Progress and Kaizen. In ENASE (pp. 210-217). Available at: https://www.scitepress.org/Papers/2019/76263/76263.pdf

Zenga, N., Yea, X., Pengb, X. and Königa, M., 2019. Applying Kanban System in Construction Logistics for Real-time Material Demand Report and Pulled Replenishment. In Proceedings of the 36th International Symposium on Automation and Robotics in Construction (ISARC) (pp. 1018-1025). Available at: https://www.researchgate.net/profile/Ningshuang-Zeng/publication/334128450_Applying_Kanban_System_in_Construction_Logistics_for_Real-time_Material_Demand_Report_and_Pulled_Replenishment/links/5d9068de299bf10cff1836d4/Applying-Kanban-System-in-Construction-Logistics-for-Real-time-Material-Demand-Report-and-Pulled-Replenishment.pdf

Know more about UniqueSubmission’s other writing services: