Project Risk Evaluation Assignment Sample

Patch 1

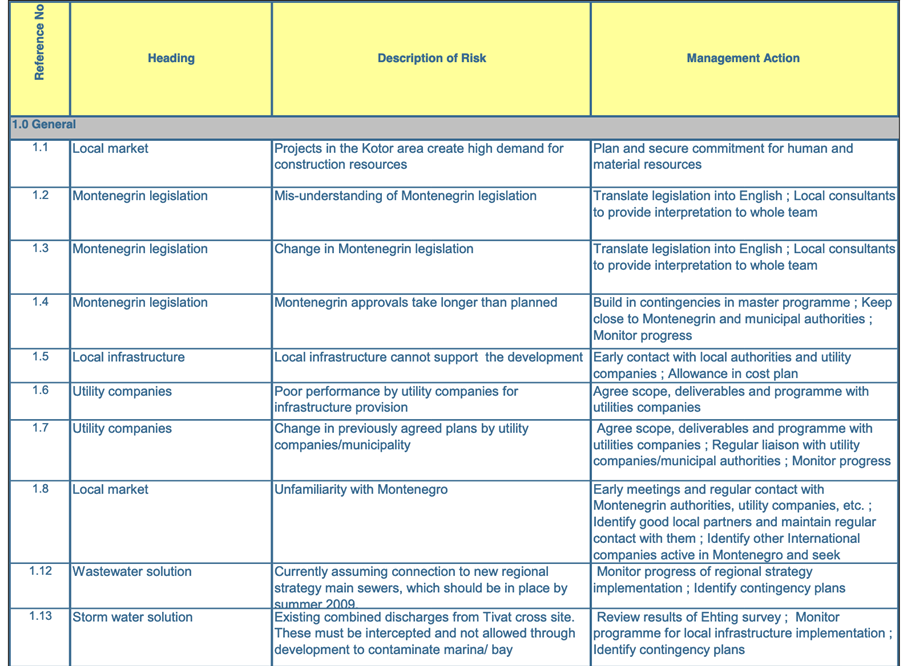

As a result of its development, the longevity of a building and the uniqueness of its product have both increased, making it a potentially dangerous construction. There are a number of critical processes that must be followed in order to limit construction risks throughout the design, procurement, and construction stages. Risk management strategies are developed, risks are distributed to different project participants, and risks are monitored as they are executed.

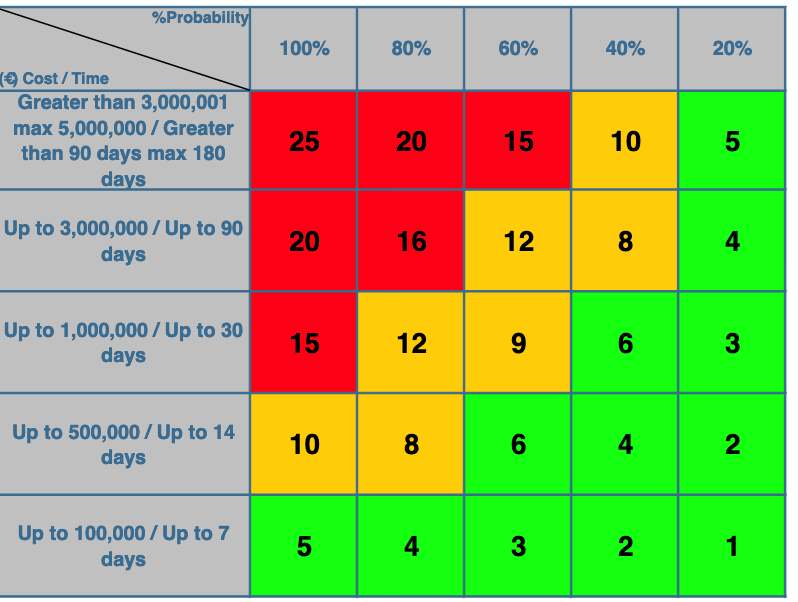

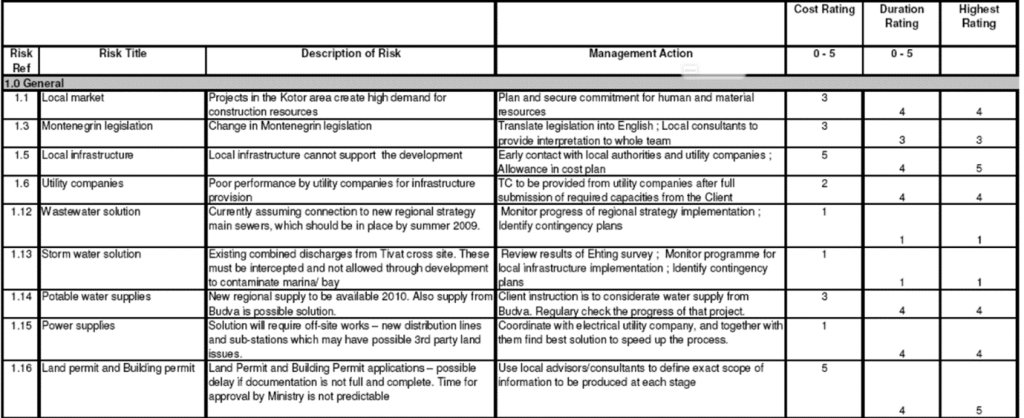

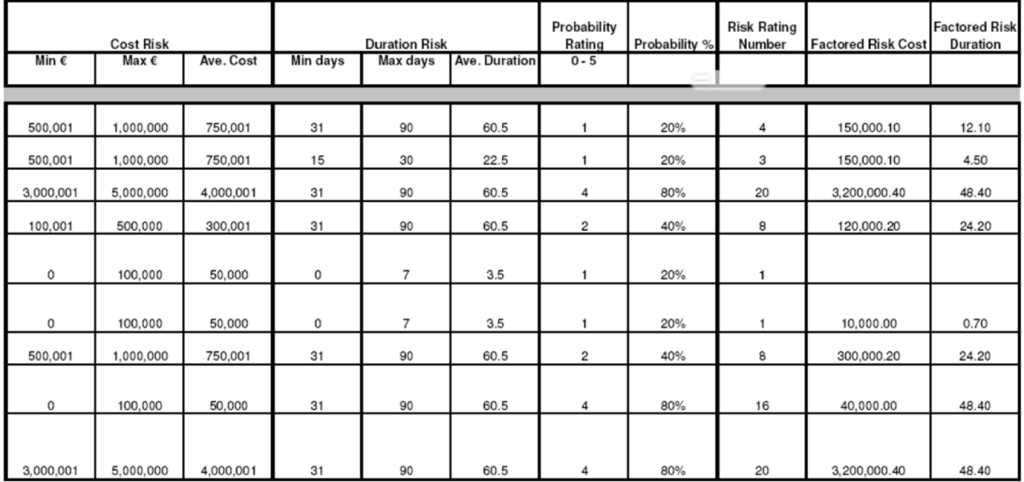

This article will go into great detail on the cost and duration risks associated with a project, as well as the overall budget contingency, in the context of project management, in this article. On the basis of the statistical data collected for the project, general remarks and recommendations will be made. There will also be a standardised method of assessing risk that will be implemented.

The ultimate goal of project management in the construction industry is the elimination of project-related hazards at every step of the project’s lifecycle. Construction projects that are productive and long-lasting rely largely on appropriate risk management approaches and processes to be successful. Recognizing and managing risk as early in the process as feasible is crucial.

Because the quality of the end product is often dictated by the conditions of the contract, it is vital to keep costs and schedules under control throughout building projects. Regular risk analysis is required in order to standardise risk overview management and ensure that it is carried out in an organised manner.

Incorporating a systematic approach to risk analysis into decision-making allows decision-makers to account for risks and their effects in their contingency plans while also developing risk-reduction approaches for use inside their organisations. Various issues, including but not limited to the host country’s economic policies and political instability, environmental, health and safety (EHS) problems, and so on, have the potential to jeopardise the project’s progress.

It is possible that a project’s timeline and budget may be exceeded due to a lack of risk management, as well as its general quality and safety, if this does not occur. In each construction project, regardless of its scale, risk management is a vital and needed component of the decision-making process. In recognition of the reality that the effect of risk varies depending on the situation, various countries have developed a range of methods to risk management [18].

Over the last few decades, scholars have been investigating the causes and effects of risk in an attempt to identify risk factors. Previous studies have been primarily focused with identifying general risk factors and impacts rather than with determining average impact levels for individual building lifecycles.

A variety of approaches were used in the research, which was carried out in a number of different countries.

Patch 2

It should be noted that there is one drawback to the treatment. Risk may be reduced by using integrated methodologies, such as the fuzzy analytical hierarchy process and an index of relative importance [19], which can assist reduce uncertainty. A common source of mistake in this technique to assessment is the imprecision with which it is carried out [14].

Fuzzy logic and interpretive structural modelling are critical components to take into consideration while evaluating risks in an efficient manner. It took only a few hours to model a system using a computer software programme, and the system was completed in record time. The relevance of the relationship between the components of a complex system is not taken into consideration when this approach is used to analyse the system. In order to predict the likelihood of a construction project being delayed [21,22], one may use a Bayesian belief network.

In order to make the determination, this network takes into account the interactions between the components of the system. With the use of causal loop diagrams and simulation-based scheduling, SD may be used to estimate the likelihood of a schedule delay, which provides a number of benefits over conventional scheduling approaches. Though effective in risk assessment, System Dynamics and Bayesian Belief Networks have limitations in terms of the structural linkages that may be conveyed by the models they use. The models of various experts may vary if, for example, the architecture of connections and assumptions differs across them.

22-24″ [22, 24] is a phrase that means “22-24.” Because of the intricacy of the components, Structural Equation Modeling (SEM) was employed to study their interrelationships using a technique known as causal connections, which was developed at the University of California. In this technique, there is a flaw in that it does not take into account risk pathways during the creative process, nor does it take into account the constantly changing behaviour of risk factors. There are a variety of ways that may be utilised to deal with challenges relating to limitations.

It is still necessary to consider gaining a better understanding of construction project risk, as well as more effective risk management [27]. This is owing to the fact that the risk associated with building projects is dynamic and complex. There are still substantial gaps in the research, despite the fact that several of the methodologies outlined above may be used to predict the likelihood of timetable delays in the future.

Beginning at the very beginning of the development lifecycle, there are restrictions to the methods by which risk impact levels may be monitored. More than half of the study has been devoted to determining the effect of variables on particular construction activities, rather than the correlations and rankings of various components, as previously stated.

In this study, a hybrid model for assessing delay risk in construction projects is developed using a combined FCE and TOPSIS method, with the purpose of filling a knowledge vacuum in the area of construction project management.

When it comes to reducing the impact of scheduling risk on their operations, managers may choose to use hybrid models that include decision-making approaches. The FCE and TOPSIS integrated model, which extends beyond the identification of components and their interactions to include the study of their linkages, may be beneficial in the context of building construction projects.

Patch 3

Developing an idea for and carrying out a research.

Using FCE and TOPSIS is essential when trying to choose and rank a range of items with frequently disparate and unrelated attributes [28]. However, they may also be beneficial when faced with a restricted number of options. [28] While the integrated model has the advantage of being more flexible in terms of anticipating the usual level of delay risk associated with building activities, this flexibility also helps it to provide better outcomes and aid users in making better choices as a consequence of this flexibility.

Figure 1 depicts an approach for assessing the risk of schedule delay by combining models from the FCE and TOPSIS frameworks in a single diagram. 2018 The number 10 is represented by the letter x. For the purpose of being of service to others. Three out of the fourteen studies were found to be missing in a systematic method for incorporating the dynamic and complex nature of construction project risk, which was proven to be true in three of the fourteen research. [27].

Nonetheless, even with the use of the approaches indicated above, there are still certain restrictions to the investigation’s scope. Beginning at the very beginning of the development lifecycle, there are restrictions to the methods by which risk impact levels may be monitored. More than half of the study has been devoted to determining the effect of variables on particular construction activities, rather than the correlations and rankings of various components, as previously stated.

It is being developed, with the support of FCE and TO PSIS, a model for measuring the risk of project delays in the construction industry. When it comes to reducing the impact of scheduling risk on their operations, managers may choose to use hybrid models that include decision-making approaches.

It is necessary to take chances with one’s health and safety while working in the construction sector. Consider possible risks such as sound, temperature, radiation, vibration and changes in barometric pressure while planning your next adventure. When working in the construction sector, it is not unusual for workers to be required to work through the night or in inclement weather, depending on the circumstances. Barometric pressure and radiation extremes, both ionising and non-ionizing, may be found on the globe, as can extremes in temperature and humidity.

Technology that has transformed the construction business into a mechanical one has also increased the amount of noise that employees must endure at their places of employment. For example, engines of various types (such as those used in vehicles, air compressors, and cranes), together with a broad range of other noisemakers (such as winches, nail guns, and pneumatic hammers) are instances of this.

Debris generated during demolition operations generates a tremendous volume of noise as a result of the devastation that happens throughout the demolition process. It has an impact on people who are near by and may cause hearing damage as a consequence of the noise. It also conceals other sounds that are required for communication and public safety.

Pneumatic hammers and earth-moving machines are among the types of equipment that expose workers to both whole-body and segmental vibratory exposure.

As a result of the fact that so much of the construction work is done outside, where both heat and cold hazards are most likely to occur, heat and cold hazards are common in the construction industry.

Roofing contractors, in addition to the heat created by physical effort, are subjected to both convective and radiative heat loads when working with pots of tar, which means that they are exposed to both forms of heat while doing their jobs. While operating the machinery in issue, a heavy equipment operator may be compelled to work in an enclosed cab with no windows or air conditioning, in close proximity to a hot engine, and in extreme temperatures. Because they do not have a cover over their heads, open-cab drivers have very little protection from the elements.

Due to the tightness of their suits, workers in protective gear such as those participating in hazardous waste cleaning may be unable to take a break from the heat caused by intensive physical activity since their suits are preventing them from breathing. If there is little water or shade available, heat exhaustion may be aggravated. The frigid weather forces construction employees to labour long hours in subzero conditions, putting them at risk of injury.

In addition to the sun and electric arc welding, UV radiation is produced by a range of other sources, the most prevalent of which are the environment and the environment’s environment. If individuals are exposed to ionising radiation when conducting x-ray inspection of welds or while operating equipment such as flow metres that use radioactive isotopes, they should seek medical attention immediately.

As lasers have grown in popularity over the last several years, it is possible that they may cause catastrophic damage, especially to the eyes if the laser beam is caught by an object.

Injuries to construction workers are most often caused by strains and sprains, which may be quite uncomfortable to experience. In addition to trauma, recurrent forceful acts, painful postures, and overexertion can all result in musculoskeletal disorders that are extremely uncomfortable to deal with on a regular basis (such as tendinitis, carpal tunnel syndrome, and low back pain). Someone losing their balance, falling into open holes, or otherwise being injured while working on scaffolding or ladders is very unusual.

Examining the Possibilities for Risks and Threats

Pathogenic germ contact, exposure to biologically generated toxins, and animal attacks are all examples of biological risks, but there are several more. Those who work in the excavation industry are at risk for the lung illness histoplasmosis, which is caused by a common soil fungus and may be deadly if not treated quickly.

It is possible for workers to get infected with infectious diseases such as influenza or tuberculosis (TB), which may result in sickness or death as a result of the rapid turnover in the workforce. Malaria, yellow fever, and Lyme disease are all preventable diseases that can be contracted by working in areas where these infections and their insect vectors are prevalent. Malaria, yellow fever, and Lyme disease are all preventable diseases that can be contracted by working in areas where these infections and their insect vectors are prevalent.

Malaria, yellow fever, and Lyme disease are all preventable diseases that can be contracted by working in areas where these infections and their insect vectors are prevalent. Malaria, yellow fever, and Lyme disease are all preventable diseases that can be contracted by working in areas where these infections and their insect vectors are prevalent. Even while certain types of wood dust have been proved to be carcinogenic in animals, others have been shown to cause allergy reactions in people.

When a building project creates a nuisance or encroaches on the habitat of an animal, the animal may respond by attacking the construction project in order to protect its own territory. Wasps, fire ants, and snakes, to name a few of the organisms that can fall into this group, are among the most dangerous.

Getting into contact with other individuals comes with it certain risks.

There are a lot of possible risks in the social structure of the industrial sector. As a result, many aspects of construction workers’ jobs, such as the state of the economy and the weather, are out of their hands since they have little control over these external variables. For the same reasons, a large number of individuals are under a significant lot of pressure to increase their level of productivity.

A common need for many construction projects is that employees live in labour camps that are located far away from their families and homes, making it difficult for them to establish strong social networks. As a result of the enormous workload and lack of management that exists in the construction business, employees in other sectors are more prone than those in the construction industry to feel stress. In some way, these dangers affect all construction workers, and no profession is free from the dangers they pose.

Patch 4

When one knows exactly what it takes on in a particular profession or activity, it is easy to measure exposure. This may be problematic since, owing to a paucity of resources on the work site, it may not always be readily accessible to personnel (e.g., MSDSs). Due to technological improvements in computer and communication technologies, this information may now be collected and transmitted with reasonable simplicity.

Risk Management in the Workplace: Preventing and Managing Risks

While it comes to construction employees, workplace hazards are presented in a variety of forms, and these variances must be taken into consideration when monitoring and measuring their exposure to these dangers. As is customary in the industrial hygiene field, the 8-hour time-weighted average is used as the basis for industrial hygiene assessments and exposure limits.

It follows as a result of this that the construction sector does not get the same advantages from controls and exposure constraints that other industries do. However, rather of calculating the number of shifts worked, it is feasible to assess exposure based on the activities that are carried out. The application of this approach may enable the identification and quantification of certain occupations, as well as of the dangers connected with certain professions. Everything from welding to painting to plumbing installation might be considered a feasible professional route to follow in the construction industry.

As long as these activities are documented, it is feasible to create exposure profiles that are based on information about tasks that have been performed or that are near enough to completion to be exposed to have been finished. Because of our awareness of exposure that is based on our work obligations, task-based regulation may become a reality.

It is important to note that the quantity of danger present, as well as the frequency and length with which the work is completed, all have an influence on exposure.

There are a variety of options for minimising exposure to hazardous compounds, including decreasing the concentration of the material, reducing the amount of time spent working, and increasing the frequency of the activities carried out.

Attempts to control exposure frequency or duration via administrative interventions are less practicable in the construction sector owing to the fact that exposure is already erratic. It is most efficient to reduce the concentration of the substance in order to minimise exposure. The provision of appropriate training and counselling may also aid in the reduction of exposure to dangerous chemicals.

Although it is not always feasible to reduce exposure concentrations, it is possible to take into consideration the source, surrounding environment, and individuals who are exposed to the danger. Control methods that are more effective and efficient when they are implemented closer to the source are more common. Controls to reduce the concentration of work-related hazards may be divided into three categories: administrative, physical, and technical.

Administrative controls are the most common kind of controls used to reduce the concentration of work-related risks. The most successful techniques of minimising exposure to hazardous materials include engineering controls at the point of production, environmental controls that remove the risk from the environment, and personal protective equipment for employees.

When a risk is identified, it is feasible to trace its origin. Modifications to the primary cause of danger are the most effective means of shielding workers from possible risks. Alternatively, if a more dangerous chemical is not readily available, a less harmful chemical may be substituted. a vitreous substance that is impermeable to air flow

With the use of certain equipment, it is possible to use environmental control to remove a hazardous item from the environment or to protect the source of a hazardous chemical that is in the air or that constitutes a physical threat to someone.

When using LEV, it is possible to collect fumes, vapours, and dust via the use of ventilation ducts and a dust cowl, which may help to limit the amount of pollutants discharged into the environment and save money. Any LEV would need to be movable and adjustable in order to deal with changing job circumstances and the construction of the building, so that it could be moved and adapted as needed.

Truck-mounted dust collectors with fans and filters, independent power sources, flexible ducting, and transportable water supplies have all been deployed on several project sites to provide LEV for a wide variety of hazardous operations, including demolition and demolition demolishment, among others.

Sound, ultraviolet (UV) radiation from arc welding, and infrared radiant (IR) heat from hot things, to mention a few potential risks, may all be efficiently mitigated with the use of proper shielding materials. The use of plywood sheets may serve to offer insulation against infrared and ultraviolet radiation, and the use of materials that absorb and reflect sound may aid in the reduction of noise pollution in certain situations.

References

Anysz, H. and Buczkowski, B., 2019. The association analysis for risk evaluation of significant delay occurrence in the completion date of construction project. International Journal of Environmental Science and Technology, 16(9), pp.5369-5374.

Changwei, Y., Zonghao, L., Xueyan, G., Wenying, Y., Jing, J. and Liang, Z., 2019. Application of BP neural network model in risk evaluation of railway construction. Complexity, 2019.

Chen, H., Luo, X., Zheng, Z. and Ke, J., 2019. A proactive workers’ safety risk evaluation framework based on position and posture data fusion. Automation in Construction, 98, pp.275-288.

Deng, X., Xu, T. and Wang, R., 2018. Risk evaluation model of highway tunnel portal construction based on BP fuzzy neural network. Computational Intelligence and Neuroscience, 2018.

Lin, S.S., Zhang, N., Zhou, A. and Shen, S.L., 2022. Risk evaluation of excavation based on fuzzy decision-making model. Automation in Construction, 136, p.104143.

Ma, G. and Wu, M., 2019. A Big Data and FMEA-based construction quality risk evaluation model considering project schedule for Shanghai apartment projects. International Journal of Quality & Reliability Management.

Wang, T., Gao, S., Li, X. and Ning, X., 2018. A meta-network-based risk evaluation and control method for industrialized building construction projects. Journal of Cleaner Production, 205, pp.552-564.

Wang, W., Liu, X., Ma, Y. and Liu, S., 2021. A new approach for occupational risk evaluation of natural gas pipeline construction with extended cumulative prospect theory. International Journal of Fuzzy Systems, 23(1), pp.158-181.

WU, T.Y., LIANG, K.Y. and SONG, L.L., 2018. Research on Construction Risk Evaluation of Mountainous Expressway Based on CIM Model. Highway.

Know more about UniqueSubmission’s other writing services: