MOD007697 Operations Management Sample

1.0 Introduction

“Elite Print Service” is the part of “The Elite group”, the company is the leading organization in pre-press as well as technology market. The company has the mission that is to grow as a world class organization by supplying the full production services that is for improving as well as corporations the value of the produced product as well as the services by developing the efficiency as well as the quality of communication process.

The company operates on various fields of communication sector that are promotional print, imaging networks, corporate literature, flexible as well as the rigid packaging and flexible packaging, advertising, academic journals and labels. The company has over 250 employees who are specialists in color printing in calendars, gift wrap, book jackets, folders, greeting cards, as well as the posters.

The customer of the company is mainly supplying retailers as well as the creative publisher but the company wanted to step forward in the supermarket for achieving the vision as well as to retain its market value in rapidly changing market conditions. The study is based on models as well as the risk that can be evaluated for doing the business in supermarkets as well as the method for the improvement of the condition of the company on entering the supermarket business in printing technology.

2.0 Analysis

2.1 External performance objective for A&B business

There are various objectives of external performance for doing the business with A&B business. There are many reasons present for differing them with existing customers. The main reason for the difference is that the A&B Company is the company which leads on the supermarket and the company ESP has the chance for entering the supermarket through the A&B business. The A&B is the big supply retailer of supermarkets (Carlin, 2019).

If the company supplies their product to the retailer then they have a chance to enter the supermarket with their excellent reputation in responsiveness as well as quality and with their sales effort. The company will also face a huge profit after successfully dealing with the retailer. The retailer gives a huge order to the company and the company has to place the order in very less time while retaining its good quality.

Hence the company faced the new challenges to produce the product in a very less time as well as the specification of the product. The retailer has the demand of special paper as well as the different embossing and the colors that are primarily red as well as green and some of the cards have to be designed by metallic ink and the card will be designed with the blocking of gold foil.

The major issues are also with the technical capability to deliver the card on time as well as with proper quality. The special papers are arranged from suppliers. These are the reasons for the difference between the retailer and the other existing customers.

2.2 Input-process-output model

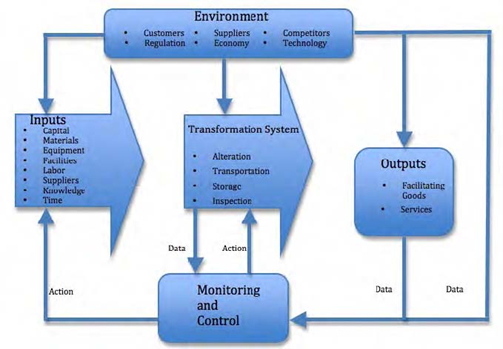

The “input process output model” can be explained as a function; graph that detects the input as well as the output and processing task that is essential for the transportation of the input as an output. The model also configures the storage that may occur in a particular process. The input presents the data flow as well as the materials in particular methods from outside.

The output is the material as well as the data that is flowing out of the transformation process. The model has 5 diagrams. The first diagram is the input and the input diagram contains the different parameters of the company like capital time, labor, equipment, suppliers, facilities, knowledge as well as the materials (Ezennaya, 2017). The environment block is also present in the model and the model is counting the various characteristics such as technology, regulation, customers, competitor’s suppliers as well as the economy.

Apart from that, there was the block of the transportation system that is contained with the inspection, alteration, strategic as well as transportation. The monitoring as well as the control diagram also there. In the output diagram the parameters are service and the facilitating goods.

The advantages of the model is it gives a framework for the conceptualizing team and the model has also the influence on the different factors like performance of the team as well as the productivity of the team and also with the help of the model the company can increase the performance of the company. Hence it is a very efficient method for improving the performance of a company in short period of time.

Figure 1: Input-process-output Model

(Source: opentextbooks.org.hk/ditatopic/7027)

2.3 Operation 4V

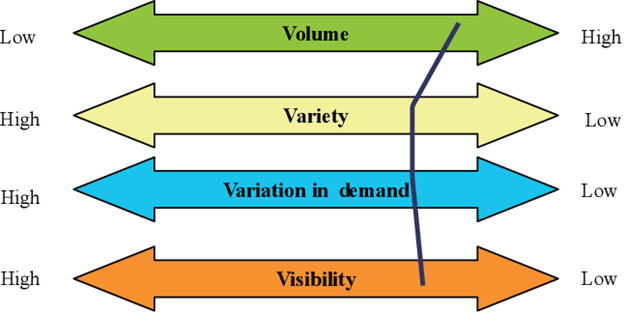

In operation 4V, the four factors are included: volume, variety, variation and variability.

Volume

The volume can be defined as the production volume which is needed for the satisfaction of a specific product on overall demand. This indicates the number of items or the units which are produced. The volume is categorized by the high volume as well as the low volume.

Volume is the important tool because it indicates the buying parameter of the buyer in a product. By7 the help of the volume the company can determine the selling price as well as the selling patterns. It also helps in determining the new strategies of a company.

Variety

This parameter is related with the variety of the goods as well as the services of a company that is produced and also sold to the customer. The variety is all about the diversity of manufacturing products. Selling the diversity of the product will help the company into increasing the sales as well as the profit margin. The high quality of any good gives the flexibility to maximize the services as it has the ability to fulfill the requirement of the customer.

Figure 2: Operation 4V

(Source: drvidyahattangadi.org/what-are-the-4-vs-of-operations-management/)

Variation

Variation can be defined as a change of the demand of a customer in a certain period of time for the external factor. It is very difficult to predict the various variations as it depends upon the different external functions (Galas, 2019). There are variation inputs as well as the variation drivers are present. It takes plenty of experience as well as maturity to predict the variation.

Visibility

Visibility can be explained as the chain where all the processes of a company are combined together. The service industry is concentrated on visibility than the manufacturing process but in the printing sector the company has to concrete on the visibility of the manufacturing process as well as the quality and service of the manufactured products.

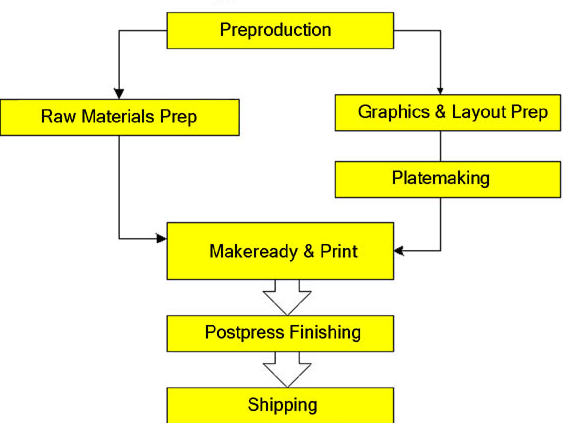

2.4 Business Process Mapping

This mapping process can be explained as an effective technique for the visualization of the process steps that is followed from start to end. With the help of the techniques the stakeholders of a company get a clear view of functioning of the company. In this process the use of different flowcharts, symbols as well as the chart is done for underrating as well as mapping the process of a particular industry.

This is useful because with the help of this the production procedure has a particular sequence for the completion of the production (Gautam, and Gautam, 2020). Apart from that it can give a clear concept of the predictable process by which the company is running as well as the method of the running process to achieve sustainable growth. Another importance of the mapping is that it can offer a transparent view of the mistakes and the performance of the employee.

Figure 3: Business Process Mapping

(Source: offsetpressman.blogspot.org/2018/08/the-offset-printing-process-flowchart.html)

3.0 Potential Risk and Rewards

3.1 Potential Risk

There are different types of risk present in the EPS to accept the order from the retailer company as well as for handling the products with appropriate quality on time to the retailers. The risks are

Risk on delivering the products

The ESP Company has the risk of delivering the products on time. The order was placed by the retailer for a very short time and the order is in huge amounts. The company has to palace the order successfully as well as with its good quality. So it is a challenge to the company to9 deliver the order on time. Hence it has the risk to the company of on-time delivery. If the company cannot place the order the company has the risk of its reputation and sales effort.

Risk on market change

The company has the risk of market change also. The company is doing their business with small retailers as well as creative publishers and with the supplying retailer also. In time the company has to place the order for them also whereas the company has to place the border of big retailers at the same time. So the company needs to concentrate on both the customer to retain its market condition for both the market.

Risk on Product quality

The company has the risk on product quality also because for quick delivery or for quick manufacturing of the products there was a high chance to low the quality of the products. The other reason for the poor quality of the product is that the company will make the various things which were not produced by them before so there was a little chance for reducing the poor quality (Horsfall, and Etuk, 2018). The different products like the special paper as well as the unusual matt finish and the supply of metallic inks and the foil of gold blocking has the minimum experience on it so there was the high chance of reducing the quality of product. The recruitment of the new employee who are not experienced with this work which has to be done for finishing the order also played an important factor for reducing the product quality.

Apart from that the company has the risk on Technical factor and also in the manufacturing process that is the company has to manufacture more than double of their production while maintaining its quality in very less time. The company has the risk on the employee also.

To achieve the product goal as well as manufacture of the product the company have to begin the shift system as well as the employee have to work on Saturday as well as on Sundays also. The A&B Company has the specifications of their ordered product like they ordered for the special paper, metallic link as well as the colors and embossed and blocking of gold foil.

Few of the order items are not practiced by the company so the company has to hire the new employee or transport the items to the designer for making the different items of the product. Hence it was the risk of accepting the order from A&B business.

3.2 Rewards

There are different benefits present if the company accepted the offer of the big retailer company A&B business. By accepting the offer for the retailer company the EPS can get a chance to enter the supermarket of printing industry as the EPS Company is dealing with the small retailer company, creative publisher as well as the suppliers.

If the company cracks the deal then the company faces new opportunities with the supermarket that is they will be a part of the larger selling industry by selling cards or designing the book cover or any printed packaging (Lauer, and Koyama, 2019). The EPS company is reputed for responsiveness as well as quality as well as it has the better sales effort in their traditional base and if the company enter the supermarket the business of the company will grow sustainable as well as it will step forward toward the mission of the company that is doing business worldwide with its better quality as well as service.

Apart from that there are other benefits also that is if the product is placed then the different new technology of printing system as well as the new methods and the components also be used in the company for satisfy the demand of the customer that will also be possible if the company is agreed to accept the offer form the retailer company of supermarket. Hence the quality as well as the services will be better than previous of the company which has the direct connection of sustainable enhancement of the company.

4.0 Process to Handle the Order of A&B Business

There are different types of ways present to improve as well as to handle the order of the A&B business. The ways are

Technical improvement

To fulfil or to deliver the order in time the improvement of ability of the machinery is very essential. By the enhancement of the capabilities of machinery the production of the various products as well as the die-cutting or folding or printing, bindery process will improve rapidly.

If the machinery of the company is better than the speed of various steps of printing technology will be done rapidly like embossing or guillotine. If the lithographic printer is in use of the company the speed of manufacturing or producing will increase rapidly. Hence the improvement of techniques are very important.

Improvement in production

The other most important factor is the enhancement in the production. The production can be improved by the use of proper machinery as well as by maintaining the product quality.

The different types of machinery are used by the company for the improvement of production and the suppliers supply the best material for enhancing the quality of the produced material (Riordan, 2021.). If the new employee or the part time employee join then the speed of the production will also be speeded up. The use of different machinery and also the recruit of experienced employee can enhance the production of the company. [Referred to Appendix 1]

Save time and space

Another way to improve and handle the order of the retailer is to save the time as well as the space of the card. The card is designed in such a way that the paper of the card will not be wasted so that cost reduction of any paper is also done and the design also sophisticated on the card and the die cutting as well as guillotine also done in very less time (Parhami, 2019).

Another way to save the time for the production is the shifting of the employee and the rotational shift of the employee so that the pressure of the workload of the employee can be minimized. It will help the fruitful production of the company. The rotation work on Saturday and also on Sunday will help to save the time when the work pressure is more for handling then order. If the extra payment is done for the extra work the employee will be very pleased and that also has a direct impact on production.

Adding New Suppliers

The old suppliers of the company is supplied the usual material of the production and the regular order is also very big for the company .if the company add the new suppliers for both for the old usual material as well as for the specified material so that the time in supply will less and the variation of the material will be shown by the process which leads the company to make varieties of products. The new suppliers are taken by the company for handling the product of the retailer.

Recruiting new employee

Recruitment of new employees is an essential factor to handle the order. The new recruit employee has the new ideas or the design that will be very helpful for the modification of the design as well as the product and the new employee also can assist with the production process so that the process can undergo a very quick process that can be helpful to the quick delivery of the products. If the company recruits the experienced employee then the company has to be beneficial not only in the production system as well as for the creative design of the product also.

Modification in product variety

Modification of the product variety is also a major factor. To handle the order of the bog retailer the modification of the varieties in product is an essential factor. The specifications of the products of the retailer are different from the usual variety of the products made by the company (Quiñones Melgoza, 2020).

The specification is present in the paper or the embossed or in the gold foil blocking in the card and there was the use of matt links and metallic inks and in the color also. Hence they have to modify their variation of product to fully fill the demand of the retailer company.

Improvement in management factors

The other way to handle the order is the improvement of the management factors that is the personnel of the management have to be more concerned about the factors which are the obstacles of delivering the product on time. The management has to look at the different systems of the company so that the production of the company continues without any interference. The management has to take care of their own field of work sincerely so that any type of interference in the production system as well as the delivery system does not occurred.

5.0 Conclusion

The section is the summarization part of the study. By reading the section the reader will understand the factor of the external performance of EPS Company for doing the business with A&B business which is the big retailer company of supermarkets and the theoretical models of improving the performance of the company is also discussed in the study.

The different risks of the company like the production risk, quality risk as well as the risk of market change are also thoroughly discussed in the study. The difference in methods of improving performance like the 4V variable or input-process-output model and the mapping of business models is also discussed in the topic.

The different benefits if the company accepts the deal with the big retailer company of the supermarket is also discussed that the company will help the company to achieve a sustainable growth and it also took a forward step to the mission of the company, which is to be a worldwide printing industry. Apart from that, the different recommendation that is used for handing the order of the retailer company is also briefly elaborate in the study. The study is useful for the reader who want to understand the different factors of printing industry.

Reference List

Cao, S., Yang, Y., Wei, X., Jian, T., Rehan, A., Zhang, P. and Xiang, X., 2021, July. Cloud-based Approach for Prevention Mainten

Carlin, M., 2019. Celestin Freinet: The Printing Press and Student Work.

Ezennaya, N.P., 2017. Employee participation in decision making and its impact on productivity: an appraisal of government printing press and two other private publishing firms in Enugu (Doctoral dissertation).

Galas, E.M., 2019. Development Of An Online Printing Press Production And Sales Management System Using Software Engineering Workbenches.

Gautam, A. and Gautam, 2020. A., EVALUATION OF THE METHODS USED FOR OPTIMISING THE CONSUMPTION OF PRINTING SUBSTRATES IN SHEET-FED OFFSET PRINTING PRESS. EPRA International Journal of Multidisciplinary Research (IJMR), p.10.

Horsfall, O.A.H. and Etuk, S., 2018. OUTSOURCING SERVICES AND OPERATIONAL PERFORMANCE OF SELECT PRINTING PRESS COMPANIES IN PORT-HARCOURT, NIGERIA. Brief Description Publication Name: British Journal of Management and Marketing Studies, p.12.

Ibrahim, A.A., Hakim, S.A., El Gewely, M.S. and Wassif, G.O., 2019. Occupational exposures and health profile among workers in an Egyptian printing press. Egyptian Journal of Community Medicine, 37(4), pp.75-83.

Lauer, C. and Koyama, M., 2019. The Engine of Immortality: The Printing Revolution and the Movable-Type Printing Press as a Deep Cause of the Industrial Revolution.

Parhami, B., 2019, August. Evolutionary changes in Persian and Arabic scripts to accommodate the printing press, typewriting, and computerized word processing. In Tugboat (Proc. 40th Annual Meeting of the TeX Users Group, Palo Alto, CA, August) (Vol. 40, No. 2, pp. 179-186).Press, I.P., Mechanization of the Printing Press. Disrupting Society, p.83.

Quiñones Melgoza, J., 2020. The Latin Classics at the Beginnings of Printing Press in Mexico (1577-1605). Nova tellus, 38(1), pp.193-200.

Riordan, K., 2021. On world literature’s frontier: Jules Verne and the portable printing press. Nineteenth-Century Contexts, 43(1), pp.35-54.

Rishi, J.P., Srinivas, T.R., Ramachandra, C.G. and Ashok, B.C., 2018, June. Implementing the Lean Framework in a Small & Medium & Enterprise (SME)–Acase Study in Printing Press. In IOP Conference Series: Materials Science and Engineering (Vol. 376, No. 1, p. 012126). IOP Publishing.

Rizzuto, F.J., Trinh, T. and Sleiman, H.F., 2020. Molecular Printing with DNA Nanotechnology. Chem.

Ruiz Baldiviezo, G.A., USES OF FUTURE INDICATIVE BY SPORT PRINTING PRESS OF LA PAZ (Doctoral dissertation, Universidad Mayor de San Andrés. Facultad de Humanidades y Ciencias de la Educación. Carrera de Lingüística e Idiomas.).

Spasova, A., 2019. THE PRINTING PRESS THROUGH THE EYES OF THE REVIVAL PUBLICIST.

Williams, I., 2020. Law, Language and the Printing Press in the Reign of Charles I: Explaining the Printing of the Common Law in English. Law and History Review, 38(2), pp.339-371.

Zhang, J., Wu, J., Wang, Y., Li, K., Ma, L.E. and Zhao, F., 2018. Fault Diagnosis in Printing Press Roller Bearing Based on Spectrum Kurtosis and Improved EEMD. In Applied Sciences in Graphic Communication and Packaging (pp. 545-552). Springer, Singapore.

Appendices

Appendix 1: Process of Printing

(Source:visual.ly/community/Infographics/other/5-types-printing-process)

Know more about UniqueSubmission’s other writing services: