BSS051-6 GLOBAL LOGISTICS AND SUPPLY CHAIN MANAGEMENT ASSIGNMENT SAMPLE

Module code and Title: BSS051-6 GLOBAL LOGISTICS AND SUPPLY CHAIN MANAGEMENT ASSIGNMENT SAMPLE

Introduction

Sustainability in the supply chain defines a business organization’s efforts to contemplate the human and environmental effects of their product’s journey through the “supply chain”. The supply chain of a semiconductor business ranges from sourcing raw materials to manufacturing, storage, delivery, and each “transportation link” between the buyer and producers. The subject of this research is sustainable SCM that’s objective is to reduce environmental harm from aspects like waste production, weather consumption, and energy usage, while having a “positive impact” on the communities and people in and across their business operations.

As illustrated by Baliga et al. (2020), while traditional SCM concentrates on the reliability, cost, and speed of operations, “sustainable SCM” has the objectives of upholding societal and environmental values. It means labeling worldwide issues such as corruption, fair labor practices, human rights, deforestation, water security, and climate change.

The purpose of this report is to extract the relevant data about the selected semiconductor manufacturing company – “Taiwan Semiconductor” and analyze relevant literature on sustainable “supply chain management” of it. As per the information at Taiwansemi (2022), it can be identified that the semiconductor supply chain engages many various processes and steps. These are all required to keep it effective and functioning.

In order to make a “sustainable future”, supply chains need to perform for the improvement of production procedures and the standard to minimize the ecological effect and safeguard “labor rights”. The major points of this research contain relevant data about “Taiwan Semiconductor”, a Relevant Literature Review on Sustainable SCM, Evaluation and Critical Analysis of Taiwan Semiconductor’s current performance with a conclusion.

Recommendations based on the current performance of Taiwan Semiconductor have been provided in this report for the improvement of sustainable supply chain management. It can be identified that the four major principles are continuous development, audit participation, risk assessment, and code compliance.

Relevant information about Taiwan Semiconductor

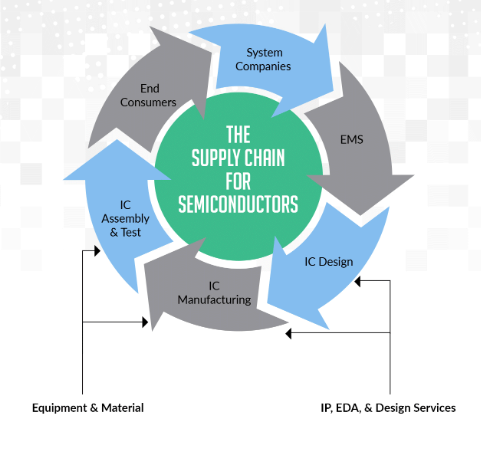

The supply chain of Taiwan Semiconductor begins with “system companies”, and travels through Integrated Circuit or IC assembly and test, IC manufacturing, design, and EMS. Thereafter it circles back to “system companies” based on sustainable SCM. According to the views of Das and HM (2022), business organizations are required to concentrate on the economy, social practices, and environmental procedures.

In this context, business organizations across the globe have taken measures to reduce their “carbon emissions“, waste cut back, and develop the conditions of labor. It can be identified that Taiwan Semiconductor observes multifaceted events by tracking the sustainability measures in its supply chain management systems (Taiwansemi, 2022). For instance, the company has recycled materials and products, prioritized renewable energy, and encouraged larger communal responsibility among the distributors.

Fernandez-Vazquez et al. (2022) stated that semiconductor businesses are abv to use predefined protocols and intelligence in order to make sure that semiconductor products are not being transferred unnecessarily. For instance, ensuring goods are sent from the nearest supply center as opposed to one “on the other side” of the nation. Apart from this, Mohammed et al. (2022) illustrated that the supply chain is liable for the bulk of their “ecological effect” for most business organizations. Therefore, sustainable supply chain management often engages in energy-intensive manufacturing and transportation as products are created and moved across the world by their variable nature.

As commented by Shahiet al. (2021), the complexity of semiconductor distributor connection and border crossings also make it challenging for the suitability of the supply chain. For that reason, Taiwan Semiconductor can often snake the greatest contrast by making transformations to their “supply chain” rather than other “business operations”. Thus, it can hinder the visibility into significant “operational considerations” like conditions of labor at a distributor’s factory which is far away.

Status of Taiwan Semiconductor’s supply chain

According to the information in Taiwan Semi (2022), the company has achieved global popularity as the “cutting edge” of innovation without crucial “promotional spending”. It is one of the most significant components of a greatly integrated “supply chain” that fabricates the globe’s “Fourth Most-traded” type of products, after automobiles and refined and crude oil. Taiwan became the first nation to develop the world’s “most advanced microchips“. Therefore, it becomes a “choke point” in the competition between China and the United States which wants to upend the supply chain of complex semiconductors.

As cited by Wang and Ge (2022), TSMC or “Taiwan Semiconductor Manufacturing Corporation” has a success story with a “geopolitical dimension”. It adheres to a defense against the growingly “truculent policies” of Beijing based on its current performance. Yu et al. (2022) stated that these business connections are becoming strained as the “US-China techno-nationalists imperatives”. It, therefore, put the place of Taiwan in the worldwide technology ecosystem under “unprecedented public” demand. Moreover, TSMC is dedicated to operating a “positive cycle” in the supply chain and sector.

Sustainable SCM of Taiwan Semiconductor

Koberg and Longoni (2019) commented that semiconductor businesses like Taiwan Semiconductor offer the “sustainable development” of their supply chain. It is done to ensure that respectful and dignified labor relations, safe working ambiance, and operation in line with the “code of ethics” can be built within the company. According to Tawiansemi (2022), the company facilitates ecological protection through its achievements, targets, and strategies. It can be found that all distributors of the company are needed to comply with the Business Conduct and Code of Ethics and to come after the controls on conflict-free minerals and human rights.

Taiwan Semiconductor’s sustainable SCM has regional supply chain optimization. As said by Paliwalet al. (2020), it supports fostering the core capability of regional distributors, safeguarding the rights of “entry-level local labor” and growing their regional sourcing. The strategy of Sustainable SCM of Taiwan Semiconductor is to cooperate with distributors for conserving water and electricity and minimize waste. Taiwan Semiconductor has achieved all first-tier distributors by signing the “TSMC supplier code of conduct” at the rate of completion – 100% (Taiwansemi, 2022). On the other hand, the company has accomplished the “sustainability management self-evaluation questionnaire” at a rate of completion of 100%.

Relevant literature review on the topic

Understanding the Supply Chain Management (SCM)

Supply chain management refers to the practice of coordinating “sourcing”, “inventory management”, “production” and “transportation” among the participants within the supply chain of “Taiwan Semiconductor” to maximize their “operational efficiency” and ensure “customer satisfaction”. Supply chain management proves helpful for organizations like “Taiwan Semiconductor” which falls under the chemical industry by saving their cost and money and providing them with a competitive edge.

As per the views of Kuoet al. (2022), Supply chain management (SCM) focuses on the cost, reliability as well as speed as well as management of the supply chain within the organization so that the aims and objectives of the organization are met. Consider another example where “Outdoor apparel” gears up its effectiveness as a retail firm through proper maintenance of Supply chain management. However, it needs to be noted that in terms of management of the supply chain the firms are subjected to certain challenges like “lack of visibility” of the network of supply and increased cost for managing the supply chain.

Benefits of supply chain management for “Taiwan Semiconductor”

“Taiwan Semiconductor ” is one of the famous firms in the chemical industry that can draw significant advantages through their aim of managing the supply chain. The benefits associated with the maintenance of SCM for “Taiwan Semiconductor” are mentioned below:

Collaboration of suppliers:

The collaboration with the suppliers gets enhanced as a result of better SCM. Thai ensures that the organization namely “Taiwan Semiconductor” gets access to their needed resources so that its operation can go on in an uninterrupted manner (Wong and Lee, 2022). Collaboration with suppliers also helps in maintaining flexibility within the organization which helps in ensuring sustainability under a volatile market.

Better control of quality:

The case of “Taiwan Semiconductor ” deals with several suppliers that fight and witness a clash of interests. Here comes the need for supply chain management that helps in maintaining the interest of all the supplies associated with the organization (Tsung-Chun et al. 2019). This helps the chemical firm,“Taiwan Semiconductor ” to maintain the quality or standards of their products like the microchips that they produce and even more (Taiwan Semi, 2022).

Shipping optimizations:

It needs to be mentioned that as “Taiwan Semiconductor ” operates over a vast area the costs of logistics seem to rise beyond control for them. “Supply chain management” minimizes the number of separate channels for distributions. As per the opinion of Li et al. (2019), “Taiwan Semiconductor ” makes use of “logistic specialists” under their supply chain in order to reduce their cost of operation and thereby offer the customers products at low cost and thereby attain a competitive advantage.

One of the most significant challenges that are being faced by such firms is the large number of suppliers who ship independently which increases the cost of operation as well as leads to inefficiency within the operation which can be avoided only through SCM.

Minimizes the overhead or inventory costs.

Proper supply chain management within an organization like “Taiwan Semiconductor” is also helpful in the sense that they do not need to maintain inventories. As stated by Him (2022), they can do it by cutting the overhead costs associated with security or storage. However, lean inventory on the contract increases the pressure on the distribution channels and reduces the resilience of their supply chain stock.

Improves the chances of risk mitigation:

Supply chain management offers an organization such as “Taiwan Semiconductor ” to have clear visibility of the “supply chain” from end-to-end. This helps in the detection of the issues within the supply chain or in furniture the issues that may arise and thereby adopting steps in advance to restrict those issues (Bao-Guang Chang and Kun-Shan Wu, 2022).

Supply chain management also assures development in the standard of products, demand planning, supply planning, and procurement of resources as well as proves helpful in terms of better distribution and manufacturing by a firm. This quality control offered by SCM helps in boosting the cash flow and also helps in attaining agility within the business.

Focusing zones for “Taiwan Semiconductor” to produce semiconductors.

In reality, the semiconductor or chips produced by “Taiwan Semiconductor ”is not very easy. The experts call it the process of“voodoo magic” as a result of the complexities in the production process. As mentioned by Mastel (2022), innovation and market research are the means through which the performance of an organization can be improved by the maintenance of the supply chain. The semiconductor manufacturing process includes almost 600 steps which require specialized engineers with unique capabilities. As per the statement ofB

ao-Guang Chang and Kun-Shan (2021), the technology of“Taiwan Semiconductor ” is the strength of the organization. As per the understanding of Hao-Chun et al. (2022), one of the major competing countries of Taiwan in terms of semiconductor production is China but they are not up to the standard followed by Taiwan. As a result of the strong capabilities within the OEM water manufacturing and as a result of the complete industry “Supply chain” Taiwan attains a competitive advantage over their competitors (Baligaet al. 2020). They earn around US$115 billion which is a dominating figure in terms of semiconductor firms falling under the chemical industry.

As per the comment of Mastel (2022), the main zones where “Taiwan Semiconductor ” focus on the research, and their design in terms of the production of the microchips that are helpful in communication used mostly in communicating devices like televisions, radios and many more. “Taiwan Semiconductor ” is the simple answer for the customers as within proper supply chain management they offer their customers their products at cheaper prices compared to the lists of their competitors.

As opined by Panpatil and Kant (2022), Green supply chain management is the means through which “Taiwan Semiconductor ” can manage its supply chain in an eco-friendly way and stay helpful in the long run. It chooses to operate at an international level and thus this supply chain seems best to operate under a differentiated environment.

Evaluation and critical analysis of the company’s current performance

Key challenges faced in managing the supply chain and logistics of “Taiwan Semiconductor.”

The key challenges faced by “Taiwan Semiconductor ” in terms of their operation go to Data latency which arises as a result of various tasks using varied parameters for planning. The different tasks under this are related to power, and efficiency, as well as task binning related to wafer-die (Corbett and Narayanan, 2022). They also include issues like Customer-specific needs. It is challenging for“Taiwan Semiconductor ” to offer their customers varied materials, shipment sizes and many more based on varied demands from the customers due to changes in preferences over time (Taiwan Semi, 2022).

Front-end (FE) output needs added manufacturing steps like assembling testing and blending models. These are associated with issues like these processes are related to complexities associated with the supply chain as well as turning efficient capacity planning. As per the views of Cousins et al. (2019), FE cycle times take around 6- 8 weeks however on the contrary BE cycle times take a much shorter time like 1-2 weeks. That means deferring inventory at various manufacturing periods needs additional planning.

Restricted end-to-end supply chain visibility and planning is tough and is subjected to a learning process which is time taking and challenging for a firm like “Taiwan Semiconductor. ”

Compare and contrast the SCM strategy of “Taiwan Semiconductor” with its main competitors.

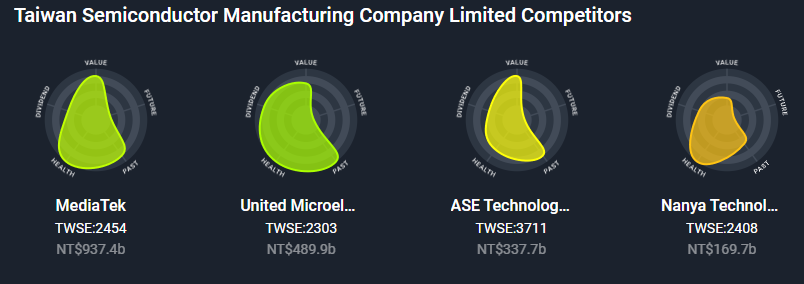

The top four conductors of “Taiwan Semiconductor” are “United Microelectronics, MediaTek, ASE Technology Holding and Nanya Technology”. It is presented below in the figure with the amount of revenue they earn.

Figure 1: Competitors of “Taiwan Semiconductor” (Source: Simple wall, 2022)

Figure 1: Competitors of “Taiwan Semiconductor” (Source: Simple wall, 2022)

The supply chain for “Taiwan Semiconductor ” as well as most of their competitors looks like the figure presented below. However, there are certain differences among the firms.

Figure 2: Supply chain for semiconductors (Source: Tsmc, 2022)

Figure 2: Supply chain for semiconductors (Source: Tsmc, 2022)

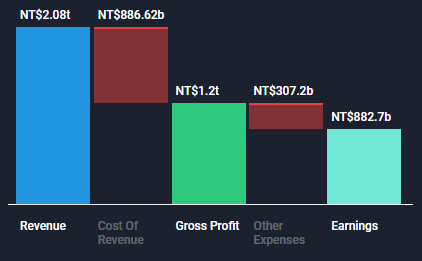

The competitors of “Taiwan Semiconductor” follows are “Continuous Flow, Fast chain, Efficient Chain, Custom-configured and flexible” whereas “Taiwan Semiconductor” seem to follow an “Agile supply chain” strategy (Ayman et al. 2021). This has provided quite effective in registering highly successful businesses and providing them with a competitive position in terms of the chemical industry in terms of the production of semiconductor chips. Proper supply chain management within the organization has helped them in growing their earnings by 56% compared to the previous year. The performance of “Taiwan Semiconductor” can be captured with the help of the bar graph presented below.

Figure 3: Performance of “Taiwan Semiconductor” (Source: Simple wall, 2022)

Figure 3: Performance of “Taiwan Semiconductor” (Source: Simple wall, 2022)

The graph states that earnings per share for the firm is 34.04 which captures a gross margin of 57.30%. The net profit margin for this firm is 42.51% and its debt-equity ratio is 31.5%. The price-to-earnings ratio of “Taiwan Semiconductor”

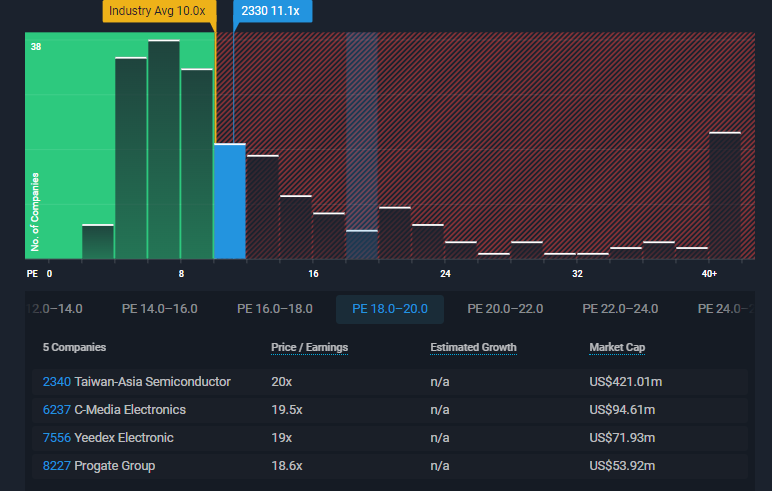

To its competitors, SCM helps them in benign superpower in this industry. The price-earnings ratio has been presented below in graphical form.

Figure 4: Comparing and contrasting the performance of “Taiwan Semiconductor” compared to its competitors. (Source: Simple wall, 2022)

Figure 4: Comparing and contrasting the performance of “Taiwan Semiconductor” compared to its competitors. (Source: Simple wall, 2022)

The pictorial presentation clearly states that Price to earnings ratio is maximum in the case of “Taiwan Semiconductor” compared to their competitors which adds a competitive advantage to them.

Summary

Supply Chain Sustainability accounts for the effort adopted by the company to consider the impact of the overall journey of the product. The journey of a product starts with raw materials and then reaches production, storage and finally delivery of the product. It also includes the transportation cost of the product in the process. The study includes an analysis of products developed by Taiwan Semiconductor and thus highlights the development of the industry in the global market. The business target of Taiwan Semiconductor is to serve a large base of global customers. Different products of the brand range from mobile devices to high-computing automotive electronics.

Discussion on different benefits of supply chain management of Taiwan Semiconductor reflects on the necessary changes made. It also includes the identification of different sectors of the business responsible for the overall improvement. The Supply Chain of a semiconductor business plays an influencing role in determining the overall success of business in the long run.

Technological improvement in the business process of Taiwan Semiconductor plays an important role in bringing innovation within the work process. The study analyses different issues relevant to the supply chain process such as developing an understanding of key challenges of the industry. The study successfully sheds light on the key factors hampering the supply chain work process and thus evaluates necessary solutions for the business as well.

The report also extracts relevant data in terms of the changes occurring within the business process and thus improves the cost management process. Discussion on benefits of the supply chain management process is an important zone that highlights changes adopted in the sector. The study highlights different factors such as “inventory management”, “production process” and “customer satisfaction” to determine the overall progress of the chosen industry. The study is all about comparing and contrasting different supply chain strategies that help industry to compete with main competitors of business.

Conclusion

The study concludes that the process of Supply chain management is an important aspect that ultimately determines the performance of a particular product in the international market. The study sheds light on different benefits associated with the supply chain management process of Taiwan Semiconductor.

Different workings of Supply Chain management include assessment of cost of product. Since supply chain management works range from identification of raw materials to evaluation of cost of raw materials of the product, it helps in developing a rough estimate of the overall cost of the product. The study also concludes that evaluation of different benefits highlights the significant improvement made within the product development process.

The study helps in inferring that supply chain management operation helps in devising strategies for saving costs and thus catering scope for improvement and increasing chance of profit. The study concludes from the literature review section that current performance of the company is good.

Development of understanding of this benefit is an important aspect as it sheds light on the overall performance of a product in a competitive market. Evaluation of company performance highlights the strategies adopted to mitigate challenges affecting business performance. Sustainability within a supply chain management process helps in evaluation of different consequences of the product on environment or human lives.

The study concludes that the main approach of the chosen semiconductor manufacturing company is to improve the overall product manufacturing process and also to evaluate new strategies that can increase visibility of products in the market. Development of understanding of the supply chain work process helps to understand the work strategy of competitors of the business. Development of understanding about the competitors of the business is an important aspect as it is responsible for bringing changes in the product promotion strategy. The study infers that adoption of the right solution reduces challenges in the work process.

Recommendation

Taiwan Semiconductor mainly targets to serve a huge base of global customers. The work of the business is to maintain a high level of capacity utilization and profitability from healthy investment. One of the primary advantages of this aspect is creation of scope for generation of healthy returns for the business. However, this aim also creates a big disadvantageous issue which is correct estimation of customer needs.

Lack of understanding regarding changing need of customers can pose a big damage to the whole process. The study highlights significant innovations occurring in various segments of the supply chain management process. The main target of the study is to identify challenges and suggest improvements on the basis of them to improve the overall performance of chosen business. Multifaceted events occurring within the business segment of Taiwan Semiconductor focus on incorporation of more renewable energy sources. It also highlights cutting costs on the transportation process.

As the current status of the company reflects its global success, it is important to manage challenging factors that can impact the future growth and development process. Identification of a proper solution can ultimately result in improving the existing business scenario.

A few recommendations made to mitigate challenges within business are:

Recommendation 1: Dividing business into segments and determining priority.

| Specific | Measurable | Achievable | Relevant | Time-bound |

| Clear division of business into different segments helps in maximizing visibility and thus improving finance process. | Dividing business into significant segments accounts for an important process that helps in improving the overall capacity of the business. | Division of business into segments also helps in dividing teams on the basis of inventory system and thus distribution of finances accordingly. | Maximization of visibility creates scope for supporting new ways of work and also helps in identifying priorities of micro-segments as well. | 6 months |

Table 1: Recommendation 1

Recommendation 2: Incorporation of a SWAT team to evaluate the supply chain scenario.

| Specific | Measurable | Achievable | Relevant | Time-bound |

| SWAT team helps in devising ponds and strategies to effectively manage multiple intervention process | Orchestration of effective responses is an important formula that helps in undertaking multiple interventions in the business | Improvement in planning helps in understanding priorities about different segments of business and thus orchestrating responses effectively | Development of actionable insights can help in improving the condition of the supply chain scenario | 8 months |

Table 2: Recommendation 2

Reference List

Ayman, B.A., Alfar, N.A. And Alhyari, S., 2021. The Effect Of Supply Chain Quality Management On Supply Chain Performance: The Indirect Roles Of Supply Chain Agility And Innovation. International Journal Of Physical Distribution & Logistics Management, 51(7), Pp. 785-812.

Baliga, R., Raut, R. and Kamble, S. 2020, “The effect of motivators, supply, and lean management on sustainable supply chain management practices and performance: Systematic literature review and modeling”, Benchmarking, vol. 27, no. 1, pp. 347-381.

Baliga, R., Raut, R. And Kamble, S., 2020. The Effect Of Motivators, Supply, And Lean Management On Sustainable Supply Chain Management Practices And Performance: Systematic Literature Review And Modeling. Benchmarking, 27(1), Pp. 347-381.

Bao-Guang Chang And Kun-Shan Wu, 2021. The Nonlinear Relationship Between Financial Flexibility And Enterprise Risk-Taking During The Covid-19 Pandemic In Taiwan’s Semiconductor Industry. OeconomiaCopernicana, 12(2), Pp. 307-333.

Bao-Guang Chang And Kun-Shan Wu, 2022. Concave Effect Of Financial Flexibility On Semiconductor Industry Performance: Quantile Regression Approach. Technological And Economic Development Of Economy, 28(4), Pp. 948-978.

Corbett, C.J. And Narayanan, S., 2022. Special Issue Of 0rw1s34rfesdcfkexd09rt2production And Operations Management1rw1s34rfesdcfkexd09rt2 “Diversity, Equity, And Inclusion In Operations And Supply Chain Management”. Production And Operations Management, 31(4), Pp. 1895-1897.

Cousins, P.D., Lawson, B., Petersen, K.J. And Fugate, B., 2019. Investigating Green Supply Chain Management Practices And Performance: The Moderating Roles Of Supply Chain Ecocentricity And Traceability. International Journal Of Operations & Production Management, 39(5), Pp. 767-786.

Das, S. and HM, K.H. 2022, “Impact of sustainable supply chain management and customer relationship management on organizational performance”, International Journal of Productivity and Performance Management, vol. 71, no. 6, pp. 2140-2160.

Fernandez-Vazquez, S., Rosillo, R., de la Fuente, D. and Puente, J. 2022, “Blockchain in sustainable supply chain management: an application of the analytical hierarchical process (AHP) methodology”, Business Process Management Journal, vol. 28, no. 5, pp. 1277-1300.

Hao-Chun, L., Xu, Y., Lu, T. And Chun-Jung, H., 2022. A New Approach To Constructing Confidence Intervals For Population Means Based On Small Samples. Plos One, 17(8),.

He, Z., 2022. Analysis On The Development Of Semiconductor Manufacturing Process. Journal Of Physics: Conference Series, 2295(1), Pp. 012009.

Koberg, E. and Longoni, A., 2019. A systematic review of sustainable supply chain management in global supply chains. Journal of cleaner production, 207, pp.1084-1098.

Kuo, C., Yu, J. And Chang, F., 2022. Revenue Recognition And Channel Stuffing In The Taiwanese Semiconductor Industry. International Journal Of Disclosure And Governance, 19(3), Pp. 352-361.

Li, X., Holsapple, C.W. And Goldsby, T.J., 2019. The Structural Impact Of Supply Chain Management Teams: Supply Chain Agility Development In Multidivisional Firms. Management Research Review, 42(2), Pp. 290-310.

Mastel, G., 2022. Thoughts On Pelosi’s Taiwan Visit. The International Economy, 36(3), Pp. 36-39.

Mohammed, A.S., Madhavan, M. and Chaichana, T. 2022, “The Effects of Innovation Adoption and Social Factors between Sustainable Supply Chain Management Practices and Sustainable Firm Performance: A Moderated Mediation Model”, Sustainability, vol. 14, no. 15, pp. 9099.

Paliwal, V., Chandra, S. and Sharma, S., 2020. Blockchain technology for sustainable supply chain management: A systematic literature review and a classification framework. Sustainability, 12(18), p.7638.

Panpatil, S.S. And Kant, R., 2022. Green Supply Chain Management Implementation: Modeling The Green Supply Chain Practices (Gscps). Journal Of Advances In Management Research, 19(3), Pp. 389-413.

Shahi, S.K., Shiva, A. and Dia, M. 2021, “Integrated sustainable supply chain management and firm performance in the Indian textile industry”, Qualitative Research in Organizations and Management, vol. 16, no. 3, pp. 614-635.

Simplywall, 2022 available at: https://simplywall.st/stocks/tw/semiconductors/twse-2408/nanya-technology-shares[Accessed on 29th October, 2022]

Taiwansemi, 2022, Corporate Information, Available at: https://www.taiwansemi.com/en/about/company-profile [Accessed on 29th October, 2022]

Tsmc, 2022 available at: https://www.tsmc.com/english/aboutTSMC/dc_infographics_supplychain[Accessed on 29th October, 2022]

Tsung-Chun, C., Dong-Qiang, G., Hsiao-Min, C. And Wei, T., 2019. Effects Of R&D Intensity On Firm Performance In Taiwan’s Semiconductor Industry: Znanstveno-StrucniCasopis. EkonomskaIstrazivanja, 32(1),.

Wang, D. and Ge, G. 2022, “Development of a Sustainable Collaborative Management Strategy for Green Supply Chains in E-Business: Collaborative Management Strategy of Green Supply Chain Considering Sustainable Development”, Information Resources Management Journal, vol. 35, no. 3, pp. 1-21.

Wong, C. And Lee, K., 2022. Evolution Of Innovation Systems Of Two Industrial Districts In East Asia: Transformation And Upgrade From A Peripheral System And The Role Of The Core Firms, Samsung And Tsmc. Journal Of Evolutionary Economics, 32(3), Pp. 955-990.

Yu, Z., Waqas, M., Tabish, M., Tanveer, M., Haq, I.U. and Khan, S.A.R. 2022, “Sustainable supply chain management and green technologies: a bibliometric review of literature”, Environmental science and pollution research international, vol. 29, no. 39, pp. 58454-58470.

Bibliography

Ali, Z., Gongbing, B. And Mehreen, A., 2019. Predicting Supply Chain Effectiveness Through Supply Chain Finance: Evidence From Small And Medium Enterprises. International Journal Of Logistics Management, 30(2), Pp. 488-505.

Aslam, H., Blome, C., Roscoe, S. And Azhar, T.M., 2018. Dynamic Supply Chain Capabilities: How Market Sensing, Supply Chain Agility And Adaptability Affect Supply Chain Ambidexterity. International Journal Of Operations & Production Management, 38(12), Pp. 2266-2285.

Ayman, B.A., Alfar, N.A. And Alhyari, S., 2021. The Effect Of Supply Chain Quality Management On Supply Chain Performance: The Indirect Roles Of Supply Chain Agility And Innovation. International Journal Of Physical Distribution & Logistics Management, 51(7), Pp. 785-812.

Cadden, T., Mcivor, R., Cao, G., Treacy, R., Yang, Y., Gupta, M. And Onofrei, G., 2022. Unlocking Supply Chain Agility And Supply Chain Performance Through The Development Of Intangible Supply Chain Analytical Capabilities. International Journal Of Operations & Production Management, 42(9), Pp. 1329-1355.

Muafi, M. And Sulistio, J., 2022. A Nexus Between Green Intelectual Capital, Supply Chain Integration, Digital Supply Chain, Supply Chain Agility, And Business Performance. Journal Of Industrial Engineering And Management, 15(2), Pp. 275-295.

Ngoc, H.D. And Quang-An Ha, 2021. The Links Between Supply Chain Risk Management Practices, Supply Chain Integration And Supply Chain Performance In Southern Vietnam: A Moderation Effect Of Supply Chain Social Sustainability. Cogent Business & Management, 8(1),.

Piprani, A.Z., Jaafar, N.I., Ali, S.M., Mubarik, M.S. And Shahbaz, M., 2022. Multi-Dimensional Supply Chain Flexibility And Supply Chain Resilience: The Role Of Supply Chain Risks Exposure. Operations Management Research, 15(1-2), Pp. 307-325.

ZeplinJiwa, H.T., Siagian, H. And Ferry, J., 2021. Impact Of Internal Integration, Supply Chain Partnership, Supply Chain Agility, And Supply Chain Resilience On Sustainable Advantage. Sustainability, 13(10), Pp. 5460.

Zhu, S., Song, J., Hazen, B.T., Kang, L. And Cegielski, C., 2018. How Supply Chain Analytics Enables Operational Supply Chain Transparency: An Organizational Information Processing Theory Perspective. International Journal Of Physical Distribution & Logistics Management, 48(1), Pp. 47-68.

Know more about UniqueSubmission’s other writing services: