MOD007698 SUPPLY CHAIN ANALYSIS

1. Introduction

In the age of globalisation, employees, investors, customers and other stakeholders have put increasing pressure on companies to demonstrate greater social responsibilities along with environmental stewardship. Focusing on usage of suitable supply chain strategies in business performance management and handling the pressures with care helps many businesses to fulfil sources of unnecessary demands and strengthen operational activities as well. Development of these suitable supply chain strategies on operational services helped companies to start measurable environmental and social actions that impacted on goods or services. This study sheds light on evaluation of a business consultation report regarding suitable supply chain strategies adopted by AbTech Innovate e-Waste in their operational business performance management. Likewise, Risk management models like Fish bone analysis and FMEA model have been described to indicate potential risk references faced by this company in business operation management. Therefore, it has been summarised that application of situational analysis, SWOT analysis, and Risk management related framework in this study provides detailed information of suitable supply chain strategies adopted by AbTech Innovate e-Waste. These analyses would also effective to derive their operational business performance management of AbTech Innovate e-Waste.

2. Analysis of the Situation

SWOT Analysis

| Strength | Weakness |

| ● “AbTech Innovate e-Waste” has developed a new thinner LCD touch screen glass oriented off recycling old mobile phones and tablets in their business performance management.

● US based start-up company AbTech had potentially expanded their business process into Europe and Mexico by developing strong partnerships with multiple e-waste companies in US. |

● Due to lack of required suitable supply chain strategies the overall expansion of the business had disrupted and resulted in direct impact of business performance management.

● CEO felt that they would not have required supply chain strategies along with a plan which is required for expansion of the business. |

| Opportunity | Threat |

| ● Supply sense, demand sense, decision or commitment, supply responses and demand responses are considered as five general capabilities in strategies supply chain management.

● AbTech had developed five major end-to-end supply chain capabilities such as investment process, E-waste regulations in US, demand in products, pressure in AbTech team and production facilities along with overseas expansions. |

● Due to lack of regulatory approaches in the recycling production process, expansion of business into Mexico for this company had been difficult.

● Due to financial pressure, investment policy of this company had disrupted and increased risk associated with managing suppliers along with delivering products within higher standards. |

Table 1: SWOT Analysis

(Source: Created by author)

Case Study Overview

The minute analysis of the case study revealed the pre-existing CEO of this concerned company, Jonathan Furness, had started their business after completing a PHD at MIT and achieved multiple awards regarding outstanding research. In the last five years, the CEO had built a well-maintained team of engineers, researchers, and scientists for transitioning the concept of off recycling mobile phone production into a higher volume in organisation. Meanwhile, in 2018, the concerned CEO achieved over $3 million investment from a US bank and got 25% share of the business in return. However, the In this context, the CEO of this company had decided to focus on multiple global OEM’s processes from recycling the aspects of e-waste into the final products. In terms of analysing the overview of the case study, it has also been observed that the AbTech Company faced potential investment process, pressures from e-Waste regulation, higher demand of products and production facilities. These types of pressures have created potential impact on supply chain operations and increased interest from different companies. Product differentiation and competitive ones have been increased in this stage within the business performance management. However, due to stronger US government regulations on e-waste production and recycling processes, this company faced potential issues in manufacturing process that lead to operational processes in business. In this regard, this company needs to develop suitable planning and strategies related to supply chain management to optimise the operation management and develop expansion of business into Mexico or Europe with reference to strong partnership of multiple e-waste companies.

Current capabilities within supply chain management

Development of integrated capabilities in supply chain management enabled end-to-end supply chain strategies within the business performance management. Ramaswamy (2022) stated that, in the business process, supply chain leaders need to make active focus on strategic planning and capabilities to translate mission, vision and objectives of business. Integration of effective capabilities within end-to-end supply chain management helps to codify as well as articulate business planning. However, Pettit et al. (2019) contradicted that due to lack of complexity in supply chain planning and strategies, development of resilience in supply chain management has been disrupted and hindered integrated priority actions as well. In the initial phase of scoping towards strategic planning in supply chain capabilities, a top-down approach has developed to critically understand both internal and external context in supply chain operations. Min et al. (2019) suggested that development of end-to-end capabilities in supply chain operations helps a business process to drill down the details and introduce supply chain strategies, priorities, and capabilities. However, On the other hand, in increasing capabilities of supply chain management into product demand, this company had experienced potential issues in management of eWaste. E-waste suppliers involved in collecting random times which were already being stocked ready for a drop off. In this regard, staff of that American Start-up company faced consequences and failed to fulfil queries of customers.

Potential pressures on meeting demand of customers and maintaining quality of products or services, AbTech Company had also faced consequences in management of production demand and failed to resolve potential staff leaving situations due to poor working environment. Esmaeilian et al. (2022) stated that in the age of globalisation and digitalisation, it has been necessary to adopt technological advances in business operation management for improving supply chain capabilities. Using block chain technologies in supply chain operations has not only improved operations but also increased capacity of warehouse spaces. However, during expansion of business AbTech company faced potential issues in production facilities due to lack of required spaces in warehouse facilities and large amounts of production process had randomly stopped which had directly impacted on business process. Under these consequences in end-to-end supply chain management capabilities, this company needs to develop suitable supply chain strategies and integrated planning to reduce such operational capabilities during the global expansion process.

Opportunities for future growth in AbTech Innovate

In terms of analysing supply chain management capabilities, AbTech Company faced potential issues in management in operational activities which damage the overall business process. According to Mosteanu et al. (2020), development of strategic planning in supply chain operations had helped to resolve issues in business operation management and aid to current expansion of business. Likewise, AbTech would introduce proper business cases and funding policies to reduce issues in financial resources over the last five years of the business investment process. Introducing “Zero Emission Waste by 2050” in the business process by AbTech would be effective to expand the business into multiple developing countries like Mexico. Enforcing regulatory approaches in business provides suitable opportunities for future growth in AbTech Innovate Solutions. Moreover, manufacturing technologies adopted by AbTech Innovate under global patent provide suitable opportunities towards international expansion.

3. Supply Chain Strategies

Product and Competitor Analysis

Based on a report of “Waste Collection Services in US, 2021”, it has been found that over 8352 businesses have been associated with E-waste collection services throughout the US. Likewise, 2.2% of waste collection services in US make potential growth in their existing business process (IBISWORLD, 2022). In case of global comparison, the leading waste management company in US is considered as “Waste Management Inc” which generated higher revenue in business by 17.39 billion US dollars in 2021. Apart from this, “Republic Services” is also considered as potential competitors of AbTech in US marketplace. However, In North American Waste Management market, growth of this business expansion has been expected to reach 230 billion US dollars by 2027 (STATISTA, 2022). In-depth analysis of the waste management market in US revealed a strong competitive position for AbTech Innovation E-waste in US marketplace. Based on a proposed case study, it has also been indicated that due to inadequate investment policy, AbTech faced potential pressures from the investment bank during acceptance of new contracts for growing the business expansion process to next five years. Due to global massive potential and short-term competitions in US market, this company faced potential difficulties in expansion of business. Moreover, in case of product demand, this company has also run recent competitions while winning holidays for people who returned their old phones along with tablets. The staffs of this company were inundated with enquiries while actively handling the business performance and product demands.

Objective of strategy

Triggers to changes:

|

||

| Objective

(Strategic goals for supply chain) |

Strategy

(Design the supply chain) |

Tactics

(Re-optimise around the new strategy) |

| ● American start-up company AbTech Innovate is currently under financial pressure from investment banks to accept new contracts and expand the business in upcoming 5 years.

|

● Technological idea of AbTech dwells with new thinner LCD touch screen glass based on recycling old mobile phones and tablets. In terms of expanding international procurement, this organisation had entered partnership with several e-waste organisations of Mexico and Europe. | ● In terms of enhancing awareness regarding the e-waste recycling concept, AbTech would need to enhance digital marketing across USA, which can further be supported by manual and automated customer service. |

Table 2: Framework to Design supply chain

(Source: Created by Author)

Designing of Strategy

Opportunities for establishing global supply chain

As per the given case study, manufacturing technology adopted by AbTech is under global patent, thereby devoid of any short-term competition, which can provide opportunities for global expansion. As observed by Durand and Milberg (2020), global patents held by organisations enhance reliability of particular business operations, which in return offers access to quality suppliers and distributor networks. Interlinking these aspects with the provided case study, AbTech can scale up unlimited recycling, where touch screen technology can provide easy access for recycling guidance to users.

US investment bank providing financial support to AbTech has identified that production unit and supply chain remains uncontrolled, which may result in loss of reputation and termination of new contracts. Ardito et al. (2019) explained that, a start-up firm’s organisational structure holds importance in earning reliable reputation, thereby enabling partnership from existing reputed companies. It can be confirmed that, immediate backlog of orders and integrated inventory management needs ro be installed for gaining opportunities in new distributor contracts. In terms of improving inventory control and order management, consultants of Abtech can refer to renowned theoretical ideas developed by Michael Porter and frameworks such as SCOR for framing agile concepts.

Advantages and Disadvantages of supply chain outsourcing

Supply Chain outsourcing conducted through observation of both Value Chain Model and SCOR framework may possess certain opportunities and limitations in building procurement networks. Interlinking outbound logistics with form infrastructure, assists organisations into adequate financial investment and resource management (Alvstam et al. 2020). For instance, AbTech can be recommended to lessen the reluctance if entering a partnership in case of outsourcing networks. Owing to the perspective that production delays have resulted in order cancellation, AbTech can accordingly design partnered outbound logistics with FedEx Shipment and expand operations internationally. However, Jones et al. (2019) had stated that, absence of culture component during international expansion is considered as a major barrier of Value Chain Model. For example, partnership proposals with Italian production houses may create cross-cultural barriers of language miscommunication, resulting in further delay of production from European sectors.

Benefits of SCOR framework lies in enhancing coordination between suppliers and reducing management costs through an improved adaptability concept. noted that, improved responsiveness between organisation and suppliers presented by SCOR framework, reduces risks of inventory delays and production malfunctions. Application of SCOR framework for AbTech’s business would likely to reduce manufacturing cost and help the business to satisfy the production proposal of making low cost mobile phones in Africa. Yildiz and Ahi (2022) argued with the fact that SCOR frameworks generally propose standard process functions, which when applied in warehousing may fail to comprehend complex situations. Hence, implementation of general SCOR framework would likely reduce agility of Abtech frameworks in ongoing Covid-19 pandemic.

Supply Chain Theories

Porter’s Value Chain Model

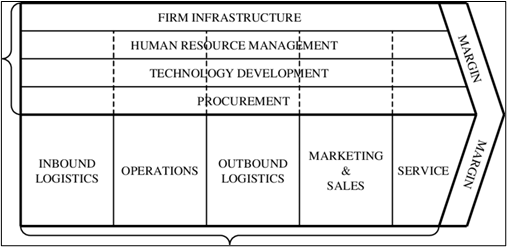

Figure 1: Porter’s Value Chain Model

(Source: Inspired by Bienhaus and Haddud, 2018)

Supply Chain Management functions as the pillar holding an organisation’s structure, by networking through manufacturers, sellers, distributors, and consumers. Michael Porter had proposed a “Value Chain Model”, stating about a firm’s internal and external supply chain needs Bienhaus and Haddud (2018). Since 2018, human resources of AbtEch have involved scientists, engineers and researchers residing in USA to complete the proposed idea of e-Waste generation.

Based on the above segregation of internal organisational structure and business vision, AbTech would need to frame external supply chain initiatives accordingly. As opined by Linkov et al. (2020), “inbound logistics”, “operations”, “outbound logistics”, “marketing and sales” and “service” firm external value chains. Aligning these aspects with AbTech it can be stated that, inbound logistics would need to focus more on domestic American networks, owing to risks of pandemic lockdowns. On the other hand, European partnership in Italy can drive opportunities for outbound logistics in connected regions and even enhance direct exporting chances.

SCOR (Supply Chain Operations Reference)

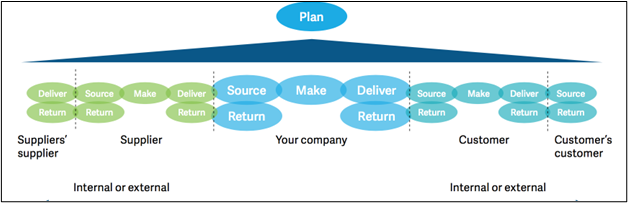

Figure 2: SCOR Framework

(Source: Inspired by Ehie and Ferreira, 2019)

Supply Chain Operations Reference Model (SCOR) Model initiated by organisations, interlinks supplier sources and consumer networks functioning in a market. SCOR Model concentrates on an organisation’s plan to satisfy internal and external supply chain functions, where suppliers form internal missions and consumers frame the external (Ehie and Ferreira, 2019). Implementation of SCOR Model benefits organisations in understanding how supply chain objectives can be repeated and realigned as per market situation, thereby maintaining a circular concept. For example, as per AbTech current production issues, the organisation would need to enhance plan of enhancing production volume to 1000 e-Waste per hour. In terms of initiating this plan, more factories across Boston and franchise partnership with small local e-Waste recycling units needs to be undertaken. Gaining a stronghold in local SME recycling units, would likely enhance authority of mobile and tech repairing companies. On the other hand, AbTech can collaborate with packaging waste recycling units across Boston, along with other logistics chains such as FedEx. Distribution of packaging and a part of logistics burden to other organisations would likely enhance scheduling for AbTech and improve order management.

Comparison of Merits and Demerits in Agile, Hybrid and Lean Supply Chain Strategies

| Options to compare | Agile | Lean | Hybrid |

| Merits | ● Agile Supply Chain Management prioritises adaptability in procurement and logistics activities.

● Supply chain adaptability assists organisations to change as per economic and environmental situations within a shorter time-frame. |

● Lean supply chain management focuses towards reducing waste and operational costs.

● Efficient and streamlined operations are proposed in lean supply chain management. |

● Hybrid Supply Chain Management helps in reducing operational costs by improving adaptability in decision-making. |

| Demerits | ● Excessive reliability on market forecasting often results in false assumptions.

● Repetitive nature of observation adopted in lawn supply chain induces rigidity in procurement or logistics. |

● Shorter time period observed for agile supply chain management results in excessive operational pressure.

● High rate of adaptability can be subjected to frequent changes which can be hard to control and maintain. |

● Presence of both lean and agile management characteristics often results in opinion related clashes.

● Conflicts between corporate departments and units can simultaneously occur due to excessive administrative pressure. |

Table 3: Comparison between Agile, Lean and Hybrid Supply Chain

(Source: Inspired by Salleh and Nohuddin, 2019)

Risk Management

Fish Bone Analysis

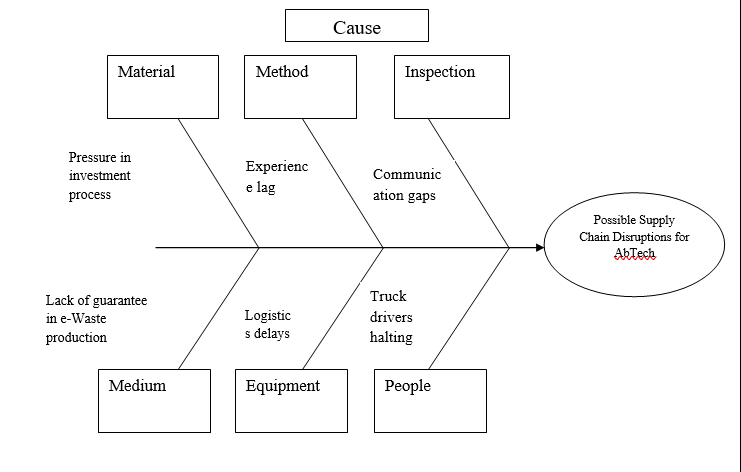

Figure 3: Fish Bone Analysis for AbTech

(Source: Created by Author)

FMEA Model

| Consequences | Probability | |||||||||

| Severity | Classifications | Safety | Production | Team development | Environmental aspects | 1

<1% Remote |

2

1% – 5% Extremely unlikely |

3

5%- 25% Very unlikely |

4

25% – 50% Unlikely |

5

>50% likely |

| 5 | Disastrous | Potential pressure in investment process | Increasing demand from different companies. | Lack of strong financial team.

|

Rapid changing protocols on US government in recycling production process. | 5 | 10 | 15 | 20 | 25 |

| 4 | Catastrophic | Lack of experience in management of suppliers | Higher level of competition in e-waste production process. | Inadequate space in warehouse. | Potential climate change situation in Mexico. | 4 | 8 | 12 | 16 | 20 |

| 3 | Major | Delivery lower quality and standard of products | Potential staff leaving situations. | Potential shortage of shipping and packages in container. | Lack of sustainable e-waste development process. | 3 | 6 | 9 | 12 | 15 |

| 2 | Serious | Rumour in US governmental regulations | Consequences in production process. | Less stock of displays in e-waste generation of phone. | Due to higher price of both products and productions. | 2 | 4 | 6 | 8 | 10 |

| 1 | Moderate | Lack of guarantee in production of e-waste products | Issues in developing contract with other companies. | Lack of potential issues in tracking orders. | Lack of cost implemented strategies | 1 | 2 | 3 | 4 | 5 |

Table 4: FMEA Model

(Source: Created by author)

Impact of future technologies in information sharing

Usage of future technologies in information sharing processes in supply chain operations helps to develop the process of global expansion in business in recent days. Islam and Huda (2019) suggested that development material flow analysis in information sharing process in supply chain operation management helps to develop manufacturing and increase end-to-end supply chain capabilities. Based on a proposed case study, it has been observed that AbTech Innovate has faced issues in investment pressures. In this regard, enforcing a strong management team with suitable supply chain strategies helps to increase aspects of current production and ensures delivery of products with higher qualities. Introducing a strong financial team in the business process helps AbTech to set up banking personnel’s and maintains general operations. Apart from this, adopting manufacturing technologies during the production process helps to increase future growth of business and increase production of e-waste of phones by 1000 per hour from 100 to 150 through an effective manner.

In terms of analysing future technologies for information sharing, AbTech Innovate purchased a production assembly line to reduce shortage of packages along with containers. In this regard, touch screens just fit with warehouses and generate the process of selling of products by E-commerce sites. Furthermore, in the case of developing technologies for information sharing, developing contracts with major E-waste suppliers in Italy toward European Partnership to manage over stocking of mobile phones efficiently. Finally, development of long-term planning in AbTech helps to sell the phone at lower prices as per growing demand in Africa.

Building Supply Chain networks from manufacturers to end customers

The given case study had identified that the Italian supplier e-waste stock would tend to rapidly grow in upcoming years, which would likely provide future growth opportunities to AbTech. However, owing to the existing issues of limited production capacity, international logistics connected with Italian warehouses may face untimely contract termination. In terms of attaining strongholds within the Italian warehouses, AbTech could observe either “Franchisee” form of partnerships. Alon et al. (2021)noted that, franchisee partnerships allow business to gain domestic support, without complete financial or operational investment. On the other hand, partnership with leading electric vehicle manufacturers such as Tesla would enhance chances of reducing CO2 emissions during transportation. However, partnership with Tesla may receive lesser chances, due to the former’s major ventures with only large scaled renowned forms. Additionally, selling networks of mobile phones in Africa can both function in a hybrid structure where propositions of physical and offline stores can be in a ratio of 70:30. Hybrid sales strategy would likely to assist AbTech in integrated order management for mobile phones specifically sold in Africa.

Conclusion and Recommendations

Conclusion

This study dwells with the case study of American start-up company AbTech, for developing an industry feasible supply chain planning. Scenario Analysis of AbTech presented in this study identified major issues of production delays, lack of adequate outsourcing management and absence of suitable international insight. Based on identified risks experienced by AbTech, relevant theoretical frameworks such as SCOR Model and Porter’s Value Chain Model were prescribed. Analysis conducted through the presented frameworks had identified opportunities for domestic partnership in logistics and packaging along with introduction of franchisee partnership in target market.

Recommendations

Sustainability perspective of start-up company AbTech can be improved through effective application of “Blockchain Technology.” As observed by Rejeb et al. (2019), blockchain is a distributed ledger technology, consisting of a growing list of ledgers known as blocks and are connected through cryptography. Blockchain Technology is primarily utilised for digitalisation of supply chain functions across international networks and reducing the burden of manual inventory management. Application of blockchain would likely assist AbTech towards enhancing integration in supply chain functions, where digitalisation would reduce paper works and ensure environmental sustainability. On the other hand, automation in inventory management would lessen manual involvement, thereby risks of manual error and costs of recruiting additional workers would simultaneously decrease.

References

Alon, I., Apriliyanti, I.D. and Henríquez Parodi, M.C. (2021), “A systematic review of international franchising”, Multinational Business Review, Vol. 29 No. 1, pp. 43-69.

Althaf, S., Babbitt, C.W. and Chen, R., (2021). The evolution of consumer electronic waste in the United States. Journal of Industrial Ecology, 25(3), pp.693-706.

Alvstam, C., Ivarsson, I. and Petersen, B. (2020), “Are multinationals and governments from emerging economies configuring global value chains in new ways?”, International Journal of Emerging Markets, Vol. 15 No. 1, pp. 111-130.

Ardito, L., Petruzzelli, A.M., Panniello, U. and Garavelli, A.C. (2019), “Towards Industry 4.0: Mapping digital technologies for supply chain management-marketing integration”, Business Process Management Journal, Vol. 25 No. 2, pp. 323-346.

Bienhaus, F. and Haddud, A. (2018), “Procurement 4.0: factors influencing the digitisation of procurement and supply chains”, Business Process Management Journal, Vol. 24 No. 4, pp. 965-984.

Durand, C. and Milberg, W., (2020). Intellectual monopoly in global value chains. Review of International Political Economy, 27(2), pp.404-429.

Ehie, I. and Ferreira, L.M.D., (2019). Conceptual development of supply chain digitalization framework. IFAC-PapersOnLine, 52(13), pp.2338-2342.

Esmaeilian, B., Sarkis, J., Lewis, K. and Behdad, S., (2020). Blockchain for the future of sustainable supply chain management in Industry 4.0. Resources, Conservation and Recycling, 163, p.105064.

IBISWORLD (2022), Waste Collection Services in the US, Available at: ttps://www.ibisworld.com/industry-statistics/number-of-businesses/waste-collection-services-united-states/ [Accessed on 16th November, 2022]

Islam, M.T. and Huda, N., (2019). Material flow analysis (MFA) as a strategic tool in E-waste management: Applications, trends and future directions. Journal of Environmental Management, 244, pp.344-361.

Jones, L., Demirkaya, M. and Bethmann, E., (2019). Global value chain analysis: concepts and approaches. J. Int’l Com. & Econ., p.1.

Linkov, I., Carluccio, S., Pritchard, O., Ní Bhreasail, Á., Galaitsi, S., Sarkis, J. and Keisler, J.M. (2020), “The case for value chain resilience”, Management Research Review, Vol. 43 No. 12.

Linkov, I., Carluccio, S., Pritchard, O., Ní Bhreasail, Á., Galaitsi, S., Sarkis, J. and Keisler, J.M. (2020), “The case for value chain resilience”, Management Research Review, Vol. 43 No. 12.

Min, S., Zacharia, Z.G. and Smith, C.D., (2019). Defining supply chain management: in the past, present, and future. Journal of Business Logistics, 40(1), pp.44-55.

Mosteanu, N.R., Faccia, A., Ansari, A., Shamout, M.D. and Capitanio, F., (2020). Sustainability integration in supply chain management through systematic literature review. Calitatea, 21(176), pp.117-123.

Pettit, T.J., Croxton, K.L. and Fiksel, J., (2019). The evolution of resilience in supply chain management: a retrospective on ensuring supply chain resilience. Journal of Business Logistics, 40(1), pp.56-65.

Prasetyo, P. and Dzaki, F., (2020). Institutional performance and new product development value chain for entrepreneurial competitive advantage. Uncertain Supply Chain Management, 8(4), pp.753-760.

Ramaswamy, V., (2022). Embracing a Co-Creation Paradigm of Lived-Experience Ecosystem Value Creation. In The Routledge Companion to Corporate Branding (pp. 95-110). Routledge.

Rejeb, A., Keogh, J.G. and Treiblmaier, H., (2019). Leveraging the internet of things and blockchain technology in supply chain management. Future Internet, 11(7), p.161.

Roy, J.J., Rarotra, S., Krikstolaityte, V., Zhuoran, K.W., Cindy, Y.D.I., Tan, X.Y., Carboni, M., Meyer, D., Yan, Q. and Srinivasan, M., (2022). Green recycling methods to treat lithium‐ion batteries E‐waste: a circular approach to sustainability. Advanced Materials, 34(25), p.2103346.

Salleh, N.M. and Nohuddin, P.N., (2019). Comparative study between lean six sigma and lean-agile for quality software requirement. International Journal of Advanced Computer Science and Applications, 10(12).

STATISTA (2022), Leading waste management companies in the United States 2021, by revenue, Available at: https://www.statista.com/statistics/1046508/us-canada-ranking-waste-haulers-by-revenue/ [Accessed on 16th November, 2022]

Yildiz, K. and Ahi, M.T., (2022). Innovative decision support model for construction supply chain performance management. Production Planning & Control, 33(9-10), pp.894-906.

Know more about UniqueSubmission’s other writing services: