MOD007698 Supply Chain Management Sample

I. Introduction

AbTech, a company with headquarters in Boston, Massachusetts, United States, was able to manufacture LCD touch screen glass that is thinner by reusing obsolete smartphones and tablets. During his time as a doctorate student at MIT, AbTech CEO Jonathan Furness founded the company and was recognised with a number of accolades and honours for his innovative research. Jonathan has invested the previous five years on recruiting engineers, chemists, and researchers in order to develop his idea into a high-volume manufacturing company. In 2018, Jonathan was able to get $3 million in funding from a US bank in exchange for a 25% stock stake in the company(Pournader,2021).

In a developing business park is a cutting-edge storage facility known as AbTech. It has a total area of 100,000 square metres. Because of the very high water requirements of the ultrasonic treatment apparatus, water storage tanks were placed in the surrounding area. Because manufacturing often uses up all of the available water sources, it may take several days to refill the tanks because of the incoming water supply, or it may take several days for the water that was ordered to arrive at the location.

The study team is looking at the possibility of a production slowdown being caused by the unanticipated clogging of sand filters as of right now. It is imperative that the high cost of the sand itself be taken into consideration while searching for options to replace sand filters. There is a wait time of four weeks from Europe, and AbTech does not presently have any inventory available. Because of the time constraints involved in sustaining production, air freighting the sand is an option that comes at a higher cost.

II. Analysing the situation

SCOR Model

| Reliability | Consistency | Efficiency |

| The facility will be able to create the same number of touch screen displays once it is fully operational, and it will be able to dismantle between 100 and 150 e-waste phones or tablets per hour | . It would be difficult for a single firm to produce the roughly one thousand e-waste pieces that are required per hour. | AdTech has been approached by a major Italian e-waste provider regarding the possibility of forming a European collaboration to solve the problem of excessive hoarding of mobile phones. |

| A significant original equipment manufacturer (OEM) has been conducting a campaign in which they offer affordable contracts in exchange for “free” phones | At Italian manufacturers, there is a mountain of electronic garbage that is continuing to expand. Jonathan from AdTech is keen to send all of the eWaste to the United State | but the bank is reluctant owing to worries about the logistics and the present condition of manufacturing and supply chain management. Jonathan is eager to export all of the eWaste to the United States. |

. s,

The screens are also being evaluated for a long-term sale to a firm in Africa, which aims to employ them in the construction of a mobile phone that can be purchased for just $5, in order to satisfy the rising demand in Africa. Although AbTech’s board of directors is very generous, it might be difficult to figure out how to fulfil requests from customers who are not known to the company(Suryanto,2018).

II.1 Situation analysis using ….Framework

There is a very high cost associated with putting this strategy into action, in addition to considerable hazards to both the operations and the efficiency of the business(Waters,2020).

II.2 The company capabilities

SWOT Analysis

| Strength

The bank has proposed that the board of directors of AdTech study the potential of engaging into a strategic partnership or outsourcing some areas of the company’s supply chain. Both of these options are being considered by the bank(Helo,2022). |

Weakness

The board of directors of AdTech is opposed to the practise of outsourcing, and the company is now making efforts to purchase its own fleet of cars, trucks, and an extra workhouse that may be used as a warehouse |

| Opportunities

It is vital to include precautions in any scheme of this sort to avoid having several incentives work against one another and render the strategy ineffective. |

Threats

They have to be constructed at a variety of points throughout the value chain, and they have to take into consideration the interests of all relevant stakeholders. After then, and only then, will they have the ability to influence behaviour in a manner that is to the overall good of society. |

Porters Model

- Competition in the industry

The vast majority of electronic gadgets are incapable of biodegradation; as a result, the metals, chemicals, polymers, and flame retardants that these devices contain, such as lead, cadmium, mercury, arsenic, and brominated flame retardants, have the potential to infiltrate the food chain. In addition, during the process of informal recycling of electronic waste, potential sources of pollution can include the open burning of coated wire, the heating of printed circuit boards in order to remove electronic components, and the use of acid baths in order to extract gold. All of these activities are done in order to remove electronic components.

- Potential of new entrants into the industry

For this reason, electronic waste poses a huge concern not just for the long-term survival of society as a whole, but also especially for the electronics sector. The problem has been getting more attention as a result of recent news stories that have focused on the possible effects that it could have on the health of children and adolescents.

- Power of suppliers

The makers, merchants, users, parties responsible for disposal, and governments each have specific duties to fulfil at various stages of the lifespan of an electronic device in order to improve the management of electronic waste at various stages of the lifecycle of an electronic device. In addition, funding is provided by non-governmental organisations (NGOs), as well as the media.

- Power of customers

People and businesses who engage in recycling and appropriate waste management should be rewarded monetarily as an incentive by their respective governments. This is one method that governments may use to promote activities such as recycling. They can even establish stricter rules and regulations to penalise irresponsible behaviour regarding the disposal of electronic waste; manufacturers can design products with longer lifecycles; and the media can assist by drawing attention to the consequences of failing to properly manage e-waste. These measures can all be taken to reduce the amount of electronic waste that ends up in landfills.

- Threat of substitute products

During the Creator AbTech that took place in Shanghai, one of the items that was addressed by the many stakeholders was a way for the formalised public collecting of data from end customers. This action was taken in order to guarantee that electronic trash is recycled and disposed of in the most effective manner. E-waste may be given a resale value by using a system that assigns a price to it, and there is also a programme that allows for the exchange of old products in return for new ones. Both of these things are possible via the use of a system that assigns a price to it.

III. Supply chain Strategy

According to the results of the study, there seems to be a trend toward managing the present situation of electronic waste through legislative action and government compliance. This is shown by the fact that there is a movement toward managing the current situation. The technical advances that were achieved by businesses with a forward-thinking mindset made it feasible for a management strategy to be developed for electronic waste(Aslam,2021). When seen via the prism of Porter’s Diamond, the role of the government may be understood to be dualistic, including elements of both a facilitator and an inhibitor in equal measure. Even if the government may not be able to make some industries more competitive on its own, it can certainly provide a helping hand by pushing firms to perform to the best of their ability and encouraging other businesses to do the same(Khan,2021).

III.1 So what is your product?

The hazardous snowball of electronic garbage has now reached the stage where it has the potential to be categorised as a catastrophe. The supply chain is under increasing amounts of pressure to become more ecologically friendly as a result of laws such as ROHS, REACH, and WEEE (WEEE). These tips make it easier for companies to get a knowledge of reverse logistics. Reverse logistics refers to the process of returning consumer goods to their original manufacturer or retailer for the purpose of service, warranty repair, or disposal(Asamoah,2021).

III.1.1 Competitor analysis

In order to evaluate, manage, recondition, and remarket electronics in a way that is considered acceptable, one requires knowledge of both the sell and the goods themselves, as well as access to high-tech facilities and a safe reverse supply chain. It is crucial to have a grasp of market values at different periods in time in order to retain quality, security, traceability, and price at optimum levels.

III.1.2 Macro economics of the industry (case study)

Consumers are showing an increased interest in actions such as recycling, reusing, and repairing previously owned goods. Businesses have shifted their attention toward environmental sustainability practises in response either to internal value evaluations or to external laws. The ecologically responsible business practises of corporations are singled out through programmes that are aimed to promote environmental sustainability. This strategy boosts the company’s bottom line by resulting in increased sales and provides the business with excellent public relations opportunities.

III.1 The objectives of your strategy

This should follow the same structure of your analysis, did you pick Porter value chain? So, the objectives should come up with solutions to fixed what you highlighted in the analysis (Wong,2020)

III.2 Designing the supply chain

The procedure that is employed by nonformal units for the extraction of metals involves heating or burning PCBs that have been immersed in acidic or alkaline solutions prior to the extraction process. As a direct consequence of these practises, both the natural environment and the workforce are placed in jeopardy. Even while recycling electronic devices has grown increasingly common in recent years, the vast majority of recycling centres will only accept items that are still capable of performing their intended function. Green Peace International has offered figures indicating that anywhere from 25 to 75 percent of electrical and electronic equipment that is brought into Africa is in such a horrible shape that it is unable to be used(Gölgeci,2020).

III.3 The suggested strategies tactics

Using a framework known as the Triple Triangle, we were able to dissect the many stages that make up the global value chain. The purpose of putting Bangladesh in a position of strategic advantage should be included into the business practises of every kind of organisation, from those that manufacture cellphones to those that are in charge of the management of electronic trash. This is a goal that each and every company ought to have in common with one another. The data that we have suggests that incompetence is widespread, and it is not just on the side of customers who do not dispose of unwanted products with the right degree of care. One example of this kind of incompetence is consumers who do not properly recycle unwanted items. Over the course of the last several years, Bangladesh has seen an increase in the number of businesses that are responsible for the processing of electronic waste. These developments have provided a boost to the smartphone industry and have also made new chances for collaboration amongst a variety of businesses accessible(Gurtu,2019).

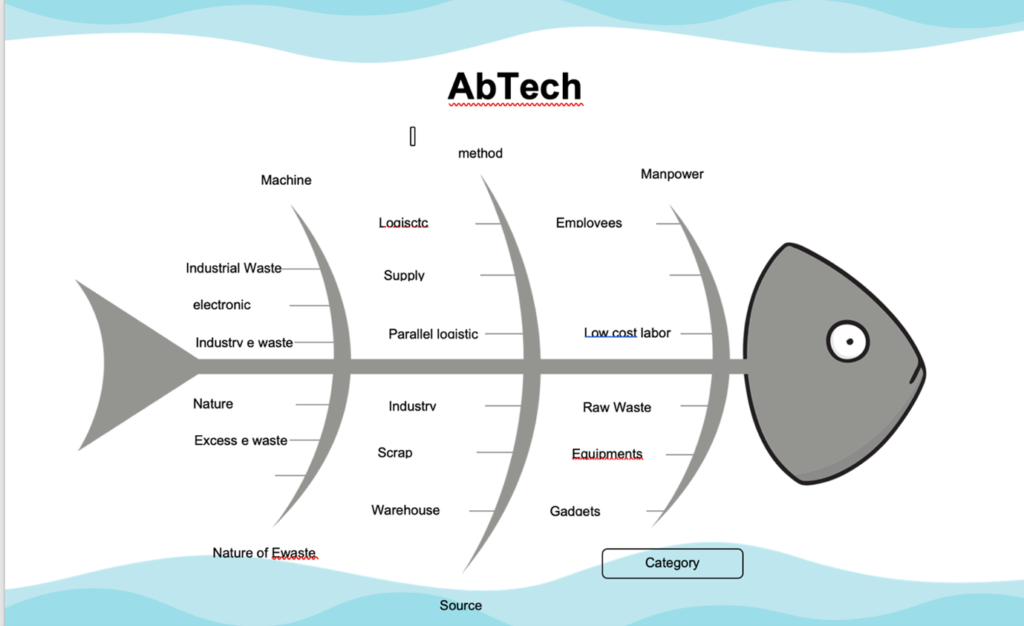

Fishbone Diagram

Fishbone Diagram

(Source: Created by learner)

III.3.1 The advantages and disadvantages to supply chain outsourcing

There is still a large quantity of previously unknown local information out there. According to the results of Alam and Bahauddin, the current system for the management of electronic trash in Bangladesh is made up of a broad variety of small businesses that are spread out over the nation and are mostly reliant on the black market. Inadequate regulation and policy, uncertainty and reluctance on the side of companies to handle critical problems, and the difficulty in maintaining correct inventory are only a few of the obstacles that the firm has to overcome in order to be successful. Other obstacles include: M. Alam & M. Bahauddin (2015).

III.3.2 Risk management

In order to do this, it is necessary to have an understanding of the market. Because of this, it is possible to integrate component standards with testing and certification requirements as well as market possibilities. The partner in the reverse supply chain has to be informed about how to meet all of the certification and sourcing standards if the refurbished product is going to be resold via trusted channels. There has been a rise in the demand for reverse logistics service programmes that can accomplish these goals while simultaneously cutting margins as a result of departments and organisations placing a larger focus on their essential competencies.

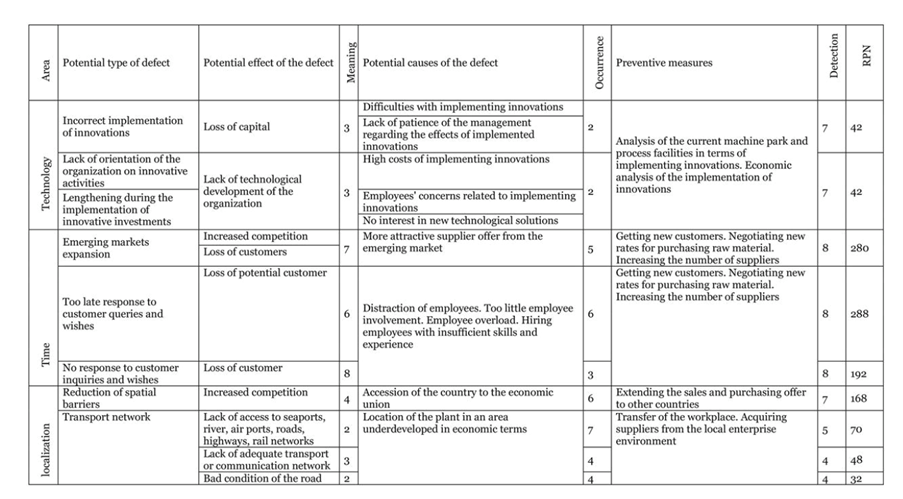

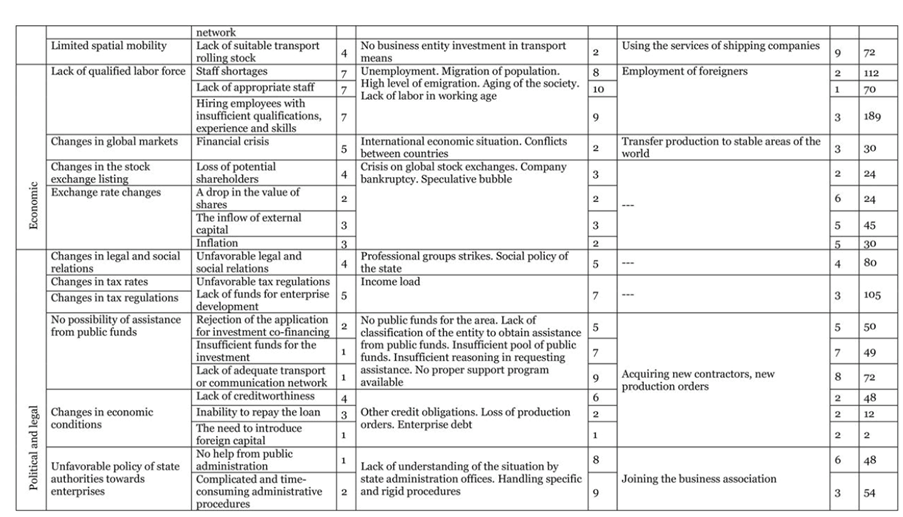

Failure mode effect Analysis

The FMEA risk analysis is utilised as the basis for research in supply chain management in the heavy industrial sector. The research was carried out during the years of 2016 and 2019. The investigation focused on nine companies in the private sector that are involved in the production, trade, and processing of steel. The entities were used to form three groupings, each of which consisted of three economic entities. The first group consisted of companies that dealt in steel. The following category included Polish companies involved in the steel industry. In conclusion, there is a cluster of companies that specialise in steel processing. The FMEA risk analysis has been produced based on information gathered from various corporate entities and a study of the industry.

The FMEA analysis that is included in the study focuses on an examination of the industry rather than on the process or product that is currently being utilised. This first application of the FMEA risk analysis. A risk assessment pertaining to supply chain management has not been compiled by the sector as of yet.

III.3.3 Impact of future technologies in sharing information throughout the supply chain

Not only does this article present an international and local perspective on the subject of electronic waste, but it also highlights the crucial role that education plays in conquering the challenges that Bangladesh is now experiencing. As a result of the rising cost of labour, many developed nations are unable to afford the expense of treating their own electronic waste and are obliged to transport it to other countries in order to have it processed elsewhere (where the labour cost is comparatively low and the environmental laws are not enforced so strictly). One of the most fascinating facts is that the cost of managing rubbish in Nigeria is twenty-six times less expensive than it is in the United States. This is one of the most amazing figures. Because of the manner in which they are carried out, the practises that are followed in third-world countries are fraught with a number of moral and ethical issues, despite the fact that they are viable from a purely economic point of view.

IV. Conclusion and recommendations

In the field of reverse logistics, companies are faced with the responsibility of developing and meticulously managing supply networks. Businesses are obligated to comply with standards that prescribe the appropriate recycling of electronic waste and, in some cases, data wiping requirements that prohibit the disposal of sensitive electronic equipment. Both of these types of requirements are intended to prevent the improper disposal of electronic waste. In order to safeguard the natural world, certain regulations and standards have been put into place. Laptops may be recycled by dropping them off at a drop box located in a store(Cousins,2019).

It is reasonable to presume that sensitive information is stored in every electronic device, whether it be on the hard disc of a computer or on the pager that a doctor carries with them. Companies that operate in the financial, medical, or government sectors are responsible for ensuring the correct disposal of data and components as well as their complete destruction. Only laboratories that have been given accreditation are permitted to carry out secure destruction operations such as deleting data, destroying documents, and other methods that are recognised by the industry. These labs give certification for the disposal of items once they have been destroyed. It is absolutely necessary, in order to have a successful programme for the management of electronic waste and an efficient one for sustainability, to choose the procedures for disposal that are the most suitable for the waste being disposed of, as well as partners in the reverse supply chain that can be trusted the most.

It is in the greatest financial interest of a firm to determine whether or not it is viable to salvage and resell the components of a product in order to maximise their profits. In the modern manufacturing business, it is imperative that profit margins be razor thin and that inventory levels be kept to a minimum. Utilizing reverse logistics might make it feasible to expand profit margins by reselling high-quality old components in well-established marketplaces. This would be accomplished by selling the components secondhand. Televisions, video game consoles, personal computers, and mobile phones are just examples of the types of electronics that may be refurbished and then resold. In certain cases, a damaged electronic device’s hard drive, central processor unit, or screen may be evaluated and then resold after being repaired. It is possible to delete, shred, and dispose of unneeded components and equipment in an ecologically friendly way, most of the time without the need for a landfill. This may be accomplished by several methods.

Everyone is touched, not only in the context of economics, but also by the sustainability of supply chains. If businesses are made responsible for the harm they do, the human and environmental costs of activities such as recycling at home and disposing of technological trash in landfills would be decreased. Firms do not necessarily need to depend exclusively on natural resources in order to mine; rather, they may utilise current equipment that has been updated with the appropriate components and materials. This allows the companies to avoid the need to rely solely on natural resources. Even though the idea of reverse logistics has been around for some time, the advantages it offers are only now beginning to become apparent as the business process continues to develop and evolve. Not only does this make our supply chains more efficient, but it also makes us better stewards of the environment.

References

Asamoah, D., Agyei-Owusu, B., Andoh-Baidoo, F.K. and Ayaburi, E., 2021. Inter-organizational systems use and supply chain performance: Mediating role of supply chain management capabilities. International journal of information management, 58, p.102195.

Aslam, J., Saleem, A., Khan, N.T. and Kim, Y.B., 2021. Factors influencing blockchain adoption in supply chain management practices: A study based on the oil industry. Journal of Innovation & Knowledge, 6(2), pp.124-134.

Cousins, P.D., Lawson, B., Petersen, K.J. and Fugate, B., 2019. Investigating green supply chain management practices and performance: The moderating roles of supply chain ecocentricity and traceability. International Journal of Operations & Production Management.

Gölgeci, I. and Kuivalainen, O., 2020. Does social capital matter for supply chain resilience? The role of absorptive capacity and marketing-supply chain management alignment. Industrial Marketing Management, 84, pp.63-74.

Gurtu, A. and Johny, J., 2019. Potential of blockchain technology in supply chain management: a literature review. International Journal of Physical Distribution & Logistics Management.

Helo, P. and Hao, Y., 2022. Artificial intelligence in operations management and supply chain management: An exploratory case study. Production Planning & Control, 33(16), pp.1573-1590.

Khan, S.A.R., Yu, Z., Golpira, H., Sharif, A. and Mardani, A., 2021. A state-of-the-art review and meta-analysis on sustainable supply chain management: Future research directions. Journal of Cleaner Production, 278, p.123357.

Pournader, M., Ghaderi, H., Hassanzadegan, A. and Fahimnia, B., 2021. Artificial intelligence applications in supply chain management. International Journal of Production Economics, 241, p.108250.

Suryanto, T., Haseeb, M. and Hartani, N.H., 2018. The correlates of developing green supply chain management practices: Firms level analysis in Malaysia. International Journal of Supply Chain Management, 7(5), p.316.

Tsai, F.M., Bui, T.D., Tseng, M.L., Ali, M.H., Lim, M.K. and Chiu, A.S., 2021. Sustainable supply chain management trends in world regions: A data-driven analysis. Resources, Conservation and Recycling, 167, p.105421.

Waters, D., 2019. Supply chain management: An introduction to logistics. Bloomsbury Publishing.

Wong, L.W., Tan, G.W.H., Lee, V.H., Ooi, K.B. and Sohal, A., 2020. Unearthing the determinants of Blockchain adoption in supply chain management. International Journal of Production Research, 58(7), pp.2100-2123.

Know more about UniqueSubmission’s other writing services: