TC 60059E Construction Management Sample

1) A) Quality management

Part 1

Construction management is one type of controlling process that includes different segments such as planning, scheduling, budgets, and execution of projects. In order to develop the improvement program, this study discusses two different procedures tools, and techniques such as TQM, six sigma, and other procedures to develop the construction management structures in their respective project. This paper is also trying to develop the quality of their respective products by adopting TQM management and six sigma process tools such as Tallyfy, Value-Stream Mapping, fishbone diagram, Kanban System, Pareto Chart, Process Mapping, and Project charters.

In order to develop the TQM management system through Tallyfy tools that can support them to manage their workflow and project quality by including the automation process. Tallyfy is a software or cloud-based BPM solution that can integrate all the tasks, press, and other documents without adding any kinds of coding, complexity, flow charts, and other attributes which can help them to maintain suitable business performance.

| Merits | Demerits |

| · It can improve the tracking system that can guide them to reduce some kinds of human errors in their respective execution of the projects.

· It can provide the flexibility of workflow development at any place or with any stakeholders of the company. · It can also provide assistance to prepare the blueprint of their respective projects (Sabirova et al. 2019). · Developing the monitoring process and reducing the wastage amounts · It can also handle this respective task by including the auto-pilot systems. · It can also allow the company to develop its API systems through developing its UI system which can assist them to maintain a suitable business structure. |

· The dashboards of this application are limited

· Not following some procedures such as sometimes it does not provide the specific names of the projects and slowing down UI systems. · Apart from that it can also increase the risk of data leaking due to storing the private’s data of the company · It can also increase the budget of the company and any kind of technical issues can stop the whole project’s progress. |

Table 1: Tallyfy tools’ advantages and disadvantages

(Source: self-developed)

Through this software or tools, the project management can maintain flexibility which can help them to maintain their business performances by developing their decision-making process, workflow managing, and other attributes. Through this application, the project manager can develop flexibility in their respective monitoring process that can reduce their waste of material and improves their overall business performance. As argued by Babalola et al. (2019), this software can also increase the risk of maintaining confidentiality in data management systems which can affect their brand image and leak about their respective strategies.

The fishbone diagram is another tool and technique for developing construction management projects. It is a diagram that can provide a visual look and cause that makes it can support the project manager to identify the different kinds of problems in the respective business progress. Through this process, managers can provide details about the effects of the amount of fish in the diagram that can help them to identify the effects on their respective colleagues.

| Metrics | Demerits |

|

|

Table 2: Fishbone diagram advantages and disadvantages

(Source: self-developed)

The value stream online process is a technique that is used for developing the lean manufacturing process for the guidance of the team’s members to maintain the optimal process in the entire organization of this company.

| Metrics | Demerits |

|

|

Table 3: Value-Stream Mapping advantages and disadvantages

(Source: self-developed)

The Kanban System is one kind of Japanese process for developing the inventory control management system. It is mainly used for just-in-time (JIT) manufacturing processes and tracking the production and controls process which can help them to manage the overall business structures. It has some rules such as don not using defective products, products as per customer demand, and other attributes.

| Metrics | Demerits |

|

|

Table 4: Kanban systems advantages and disadvantages

(Source: self-developed)

The project manager can also use different tools and techniques such as Pareto Chart to enhance the TQM and six sigma continuous processes for improving the construction project management process. This is a bar chart and it is used as a cause analysis tool with 7 initial qualities for developing construction management systems. As suggested by Črešnar et al. (2020), the length of the graphs represents the cost or frequency. Through this process, managers can visually identify the most important situations or less important situations which can help them to manage their project management system.

| Metrics | Demerits |

|

|

Table 5: Pareto Chart advantages and disadvantages

(Source: self-developed)

These tables show the different positive sides and negative sides that can help the project manager to identify appropriate tools and techniques for developing their respective TQM and six sigma continuous processes.

Part 2

This chapter of this paper is discussing the quality culture of the Royal BAM Group Company through using effective tools and techniques of TQM and the six sigma continuous programs that can enhance their overall business progress.

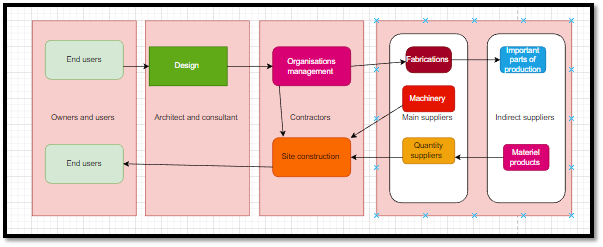

Figure 1: Process map of Royal BAM Group Company for maintaining the quality cultures

(Source: Self-developed)

In this case, This Company is trying to develop its overall business performance by enhancing the development of this company’s respective press maps can help them to maintain the quality of its respective projects. In this case, the project is dividing its process into several stages based on the role and responsibility of their respective stakeholders that can help them to maintain suitable business progress. As suggested by Harris et al. (2019), this process consists of the role of owners providing the details of their respective projects that can help them to identify their structures and implements their design based on their client demands that can support them to maintain sustainable business performance. In order to develop this designing process, the company used BIM models with automation techniques that can help them to maintain an effective quality and provides a high-quality project to their respective client which can help them to maintain suitable business structures.

After that, they are consulting with contractors about the process of organization management and construction and other attributes based on their respective designs and provide some detail with their respective consultants or architect that can help them to enhance the overall business progress. During this site construction, they can develop their suppliers for providing their respective resources that can assist them to maintain the quality of their respective projects which can assist them to enhance their respective projects’ performances. They are also developing some processes that can assist them to maintain suitable business structures by taking the help of their direct suppliers for their respective parts or products. Through the contribution of all stakeholders, they can complete their site construction, and then they can handle over to their users to the whole project (Wang et al. 2020).

1)b) Risk Management

| Costs | Charges | Estimated | % Complete | Projected | Change |

| 2-Jul | 8,754,516 | 65,863,092 | 13.292 | 66,545,263 | 682,171 |

| Billings | Contract | Gross Bill | % Billed | Profit | |

| 1-Jul | 67,511,602 | 9,276,621 | 13.741 | 966,339 | |

| Payables | Paid | Open | Retention | Labor | Total |

| 1-Jul | 6,719,103 | 1,300,089 | 391,671 | 343,653 | 8,754,516 |

| Receivable | Net Bill | Received | Retention | Open | |

| 2-Jul | 8,761,673 | 7,209,344 | 514,948 | 2,067,277 | |

| Cash Position | Paid | Received | Position | ||

| 7,062,756 | 7,209,344 | 146,588 |

Table 6: Budget allocation for the piling

(Source: Self-developed)

| Equipment type | Equipment cost (1,000) | The factor for ancillary items | |

| 150,000 bbl | 600,000 bbl | 150,000 bbl | |

| Furnace | $3,000 | $10,000 | 0.32 |

| Tower | 2,000 | 6,000 | 0.42 |

| Drum | 1,500 | 5,000 | 0.42 |

| Pumps, etc. | 1,000 | 4,000 | 0.54 |

| Total costs | 168000 | ||

Table 7: Total cost plan allowance for the piling

(Source: Self-developed)

In this case, the earthworks subcontractor is trying to prepare a project management system by developing estimations of costs that assist them to maintain suitable business structures. As suggested by Abdel-Hamid and Abdelhaleem (2019), this process consists of the pile foundation process through proper methods such as developing the budget based on monthly outcomes and costs balance allowance that can help them to maintain the quality of their respective business structures. A Pile foundation is one kind or process that can be defined as a long cylindrical material that can prepare through steel or concretes that is mainly used for supporting structures.

Moreover, is also used for transferring the load to their corresponding structures to the desired depth through the skin friction process. This process consists of different types such as friction piling, sheets piles, load piles, end-bearing piles, and other attributes based on the function. In this case, the earthworks subcontractor is trying to develop a ground foundation for a large project by developing the Fiction pile concepts that can help them to implement sustainable projects. This process transfers the load through soils and friction forces to the corresponding material that can help them to improve the overall project’s structures. In this case, the company is trying to provide a bid amount for developing this project by identifying their respective factors such as a type of material such as steel, concrete, and other attributes that can help them to maintain suitable business structures. As opined by Farhangi and Karakouzian (2020), this process can also contain a cost allowance process that can depend on some factors such as base circles diameters, depth, steel length, and other attributes which can improve the overall project performance. Through these details, they can develop their overall business strictures by developing these projects and implementing sustainable construction structures. Through this

References

Abdel-Hamid, M. and Abdelhaleem, H.M., 2019. Improving the Construction Industry Quality Using the Seven Basic Quality Control Tools. Journal of Minerals and Materials Characterization and Engineering, 7(06), p.412. DOI: https://doi.org/10.1201/b10260

Babalola, O., Ibem, E.O. and Ezema, I.C., 2019. Implementation of lean practices in the construction industry: A systematic review. Building and Environment, 148, pp.34-43. DOI: https://doi.org/10.1016/j.buildenv.2018.10.051

Bastas, A. and Liyanage, K., 2018. Sustainable supply chain quality management: A systematic review. Journal of cleaner production, 181, pp.726-744. DOI: https://doi.org/10.1016/j.jclepro.2018.01.110

Borkovskaya, V., Degaev, E. and Burkova, I., 2018. Environmental economic model of risk management and costs in the framework of the quality management system. In MATEC web of conferences (Vol. 193, p. 05027). EDP Sciences. DOI: https://doi.org/10.1051/matecconf/201819305027

Črešnar, R., Potočan, V. and Nedelko, Z., 2020. Speeding up the implementation of industry 4.0 with management tools: Empirical investigations in manufacturing organizations. Sensors, 20(12), p.3469. DOI: https://doi.org/10.3390/s20123469

Farhangi, V. and Karakouzian, M., 2020. Effect of fiber reinforced polymer tubes filled with recycled materials and concrete on structural capacity of pile foundations. Applied Sciences, 10(5), p.1554. DOI: https://doi.org/10.3390/app10051554

Gunasekaran, A., Subramanian, N. and Ngai, W.T.E., 2019. Quality management in the 21st century enterprises: Research pathway towards Industry 4.0. International journal of production economics, 207, pp.125-129. DOI: https://doi.org/10.1016/j.ijpe.2018.09.005

Harris, F., McCaffer, R., Baldwin, A. and Edum-Fotwe, F., 2021. Modern construction management. John Wiley & Sons.

Mizuno, S., 2020. Management for quality improvement: The seven new QC tools. Productivity press. DOI: https://doi.org/10.4324/9781003070450

Sabirov, O.S., Suyunov, Y.B., Aslonov, A.F.O., Subhonov, M.R.O. and Kamilov, A.Q.O., 2021. Improvement of Ways to Develop the Textile Industry on the Basis of Resource-Technology. International Journal of Modern Agriculture, 10(2), pp.1868-1877. DOI: https://doi.org/10.1108/ECAM-12-2020-1082

Sabirova, S., Vasiliev, V.A. and Chernogorskiy, S.A., 2019, October. Choosing a quality management method. In IOP Conference Series: Materials Science and Engineering (Vol. 666, No. 1, p. 012043). IOP Publishing. DOI: https://doi.org/10.1088/1757-899X/666/1/012043

Wang, Z., Wang, T., Hu, H., Gong, J., Ren, X. and Xiao, Q., 2020. Blockchain-based framework for improving supply chain traceability and information sharing in precast construction. Automation in construction, 111, p.103063. DOI: https://doi.org/10.1016/j.autcon.2019.103063

Know more about UniqueSubmission’s other writing services: