BSS052-6 Project and Operations Management Assignment Sample

Module code and Title: BSS052-6 Project and Operations Management Assignment Sample

Introduction

Operation management (OM) is indicated as the process of supervising, controlling and planning the areas of manufacturing and production. It also helps the business to deliver proper products and services demanded by the customers and increase brand position within the market. The current report will be highlighting OM decision areas of Apple, an American multinational technology company headquartered in California, US.

The company produces several technical products such as Apple watch, iPad, iPhone, AirTag, Apple TV, Macbook and many others. Current activities of the company in managing its OM decision areas will be highlighted alongside comparison of Apple with Dell based on 4V’s. Lastly, ways of improving operational performance will also be discussed in the report below.

Findings and analysis

Critical examination of three OM decision areas of Apple

OM decision areas highly align with strategic management within an organisation that in turn assist in creating high ease alongside flexibility within business operations. As per Barnes (2018) OM decision areas includes quality management, location, goods and services, process and capacity design, human resource management, scheduling, supply chain management, inventory management, strategy and maintenance. Concerning this, three OM decision areas of Apple including quality management, inventory management and process and capacity design will be evaluated.

Quality management of Apple

Management of quality is one of the most significant areas of OM. It is because, Alzoubi et al. (2022) stated that high quality within products and services is required in order to satisfy customers and maintain operational excellence. As Apple produces premium quality products, therefore, quality is one of the key requirements of the company. From the reports of the company, it can be observed that principles of total quality management are highly followed by Apple in order to manage its quality (Ovide, 2021).

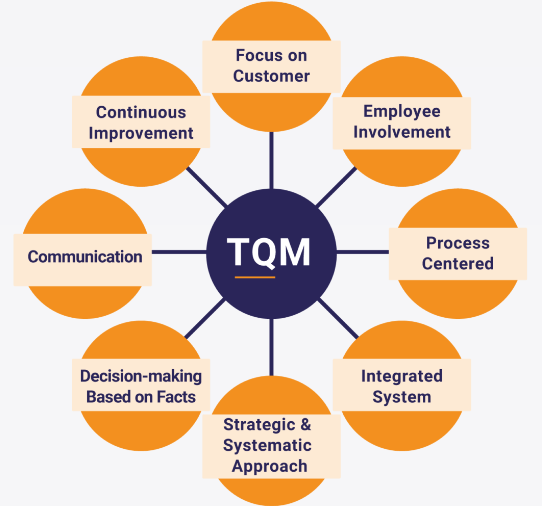

TQM is a method that includes managerial and technological aspects for the accomplishment of quality requirements alongside objectives of business. Eight principles are included in this model such as employee involvement, customer focus, integrated system, strategic and systematic approach, continuous improvement, proper communication, taking decisions based on real facts and process centre system (Abbas, 2020).

Figure 1: Total Quality Management (Source: Abbas, 2020)

Figure 1: Total Quality Management (Source: Abbas, 2020)

In consideration to the methods of TQM, Apple uses four basic tools to control its quality such as pareto chart, histogram, effect diagram and control chart (Rostamkhani and Ramayah, 2022). The principles of TQM followed by Apple helped the company to create a culture of open innovation. Apart from that, the company has also been observed to be successful in the reduction of waste within supply chain management through the implementation of this model (Apple, 2022).

Moreover, principles of continuous improvement along with process centred and integrated systems also enable Apple to create a balance between efficiency and responsiveness within the domain. For instance, the service of Apple such as ‘Find My’ mainly allows users to find lost devices while ‘AirDrop’ service of Apple allows users to transfer files to other users through Apple gadgets (Hansen and Podolny, 2020). Additionally, products of Apple are also having a rich ecosystem that ensures task uniformity and continuity.

In consideration to the principles of TQM Apple also follows a people-centred philosophy, which in turn helps the company to build high product value. Henceforth, Apple is highly facilitated by quality management approaches within the domain.

Inventory management of Apple

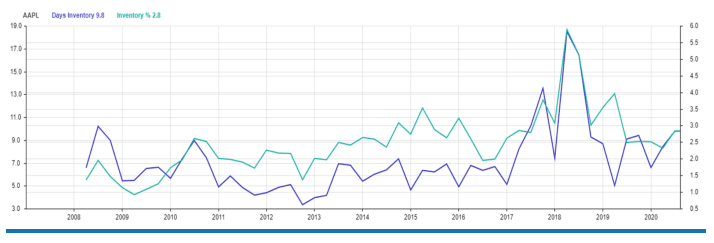

Proper management of the supply chain helps a company to manage or maintain its inventory. According to Canetta et al. (2018), inventory management assists in shaping the areas of production and maintaining proper demand and supply within the market. From the reports of Apple it can be observed that product revenue in 2020 decreased by 11% while the inventory of the company dropped by 3% (Martins, 2020).

This indicates that Apple has been managing its supply champion tightly through the strategy of Research and Development (R&D), concept testing, proper management of warehousing, manufacturing along with quarterly reviews. The figure below states that a 3% bump within inventory has been observed in the third quarter of 2020 (Martins, 2020).

As a result of this, certain strategies of inventory management are followed by Apple to manage its production and supply level. Apple seems to be following the notion of cutting down on warehousing while reducing inventory and making the suppliers compete between themselves.

Figure 2: Inventory stock over of Apple (Source: Martins, 2020)

Figure 2: Inventory stock over of Apple (Source: Martins, 2020)

As technology manufacturers are unable to manage high stock of product due to technological advancement along with comparative nature, therefore, Apple follows the strategy of keeping very low inventory in their hand (Shrum, 2021). In order to manage its inventory, Apple seems to be following the strategy of maintaining proper relationships with suppliers and maintaining one central warehouse of the company.

Most importantly, it can also be observed that Apple follows the strategy of led distribution and contract manufacturing to manage its inventory (Neowin, 2022). Apart from that, the First In First Out (FIFO) system is also used by Apple to manage its inventory and is also considered to be the leader in managing inventory in the current scenario.

According to Utami et al. (2018), FIFO method indicates selling the item first that arrives first. In consideration to the strategies used by Apple in managing its inventory, 2021 indicated 62.03% rise in inventory indicating an amount of $6.58 billion from 2020 that indicated an amount of $4.061 billion further depicting 1.1% decline from the previous year (Macrotrends, 2022). However, the decline in 2022 value by 24.83% depicts a high need for proper inventory management strategy by Apple.

Process and capacity design strategy of Apple

Capacity and process design also play a crucial role in OM decision areas. Proper capacity designing seems to be increasing the capability of the organisation in delivering products as per consumers’ demand. It also indicates implementation of proper process that further helps in implementing proper value within organisational products and services.

Considering the scenario of Apple, it can be observed that strategies of Human Resource Management (HRM) within the domain of the company include proper support along with encouragement and motivation of the workforce. Surya et al. (2021) stated that proper encouragement alongside motivation of the workforce tends to increase the capacity for effective product designing and development.

Additionally, Apple is also observed to be working in close collaboration with the suppliers for ensuring adequate capacity and efficient processes within the decision areas of OM. For instance, suppliers of Apple are given proper guidelines in terms of process design and the company also maintains Suppliers Code of Conduct in order to optimise the HRM. Moreover, Apple also strives for the aspects of innovation in order to facilitate process and capacity efficiently (Hansen and Podolny, 2020). Henceforth, it can be stated that Apple follows a proper capacity and process designs strategy for managing its operation.

Comparing and contrasting Apple with Dell

Apple is considered to be one of the leading firms in the technology sector with a wide range of products and services. However, Dell is also an American company that deals with developing, selling, repairing and manufacturing computers and other similar services (Dell, 2022). As Dell is one of the biggest competitors of Apple in the current scenario, therefore, 4V’s will be used below to compare and contrast Apple with Dell. 4V’s helps in evaluating volume, variety, visibility and variation of a company in order to analyse the current operating notion.

Volume dimension

Volume of Dell is high as compared to Apple in the current scenario. It is because Dell focuses on repeating the procedure in terms of making computers daily along with adopting systemisation and specialisation through the model of direct sales and Build-To-Order strategies (Apple, 2022). On the other hand Apple focuses on low production as the company is involved in dealing with its product issues on an urgent basis while producing and designing limited quantities of high quality and well designed products for suiting the needs of the customers effectively (Dell, 2022). Therefore, the volume dimension is better in Dell as compared to Apple.

Variety dimension

Variety dimension in both the companies seems to be low in the current scenario. It is because Apple produces alongside designs limited but targeted products to its customers. Moreover, it is also focused on producing innovative services and products with high quality that limits the area of variety within the company (Apple, 2022). On the other hand, Dell is also having a low level of variety because it is also involved in investing in the R & D field for satisfying the needs of customers and increasing the quality of product lines (Dell, 2022). Henceforth, both the companies are involved in increasing product quality by implementing innovation and neglecting variety aspects within its product line.

Variation in demand dimension

Variation in demand is high within Apple as compared to Dell in the current scenario. It is because the business process followed by Apple is highly aligned with high variation within the demand for Apples product. As demands of consumers keep changing in consideration to latest technology trends within the market, therefore, the company faces a variety of demands and produces its products accordingly (Mint, 2020).

On the other hand, Dell seems to be following a Build-To-Order strategy which creates low variation in demand and the organisation is focused on producing laptops or PCs according to consumer demand where no lofty in the demand variation can be observed (Parvez et al. 2018). Henceforth, demand variation is high in Apple as compared to Dell.

Visibility dimension

Visibility is one of the most important factors for companies for gaining consumers trust in the market. In consideration to Apple, internal working processes are not visible to the customers. However, the platforms designed by Apple or end products of the company are highly visible to customers, thereby indicating high visibility of the company in the current scenario (Ferrari, 2019). On the other hand, Dell seems to be having low aspects of visibility. It is because Dell adopts the process of centralisation and standardisation within its stages of production.

As a result of this, the company is not observed to be exposing its internal operations related to its computer production to the customers and just deals with taking the order and providing an estimated date of delivery (Dell, 2022). Henceforth, it can be stated that the aspect of visibility is high in Apple as compared to Dell in the current scenario.

Ways of improving operational performance

From the report of Apple, it can be observed that the company is facing issues within its inventory management that seems to be decreasing the inventory by 3% along with its revenue in the same year. However, Liu et al. (2022) argued that Apple also seems to be having a tight policy of supply chain that prevented high loss within the inventory and helped in managing its operating notion.

As Apple is a technological company and deals with technological advancements within its operations, therefore, the company can implement Radio-frequency identification (RFID) for managing its inventory. According to Cui et al. (2019), RFIS is considered to be a technology that helps in enhancing the management of inventory through the use of radio waves.

In this technology every item within the inventory is separated by unique RFID tags that help in storing alongside scanning the product easily. This technology is also effective in increasing the level of productivity as tags within the materials or products can be analysed automatically that implements high speed within the operating system.

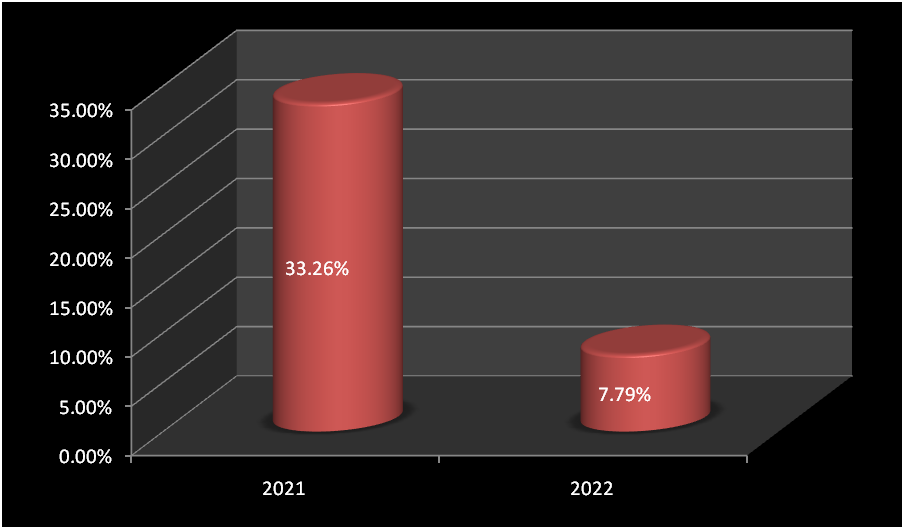

Figure 3: Increasing rate of Apple’s revenue margin (Source: Influenced by Macrotrends, 2022)

Figure 3: Increasing rate of Apple’s revenue margin (Source: Influenced by Macrotrends, 2022)

As Apple seems to be having issues in managing its inventory, therefore, implementation of RFID technology can be effective for the company in managing its inventory and improving operational efficiencies. On the other hand, revenue of the company seems to be having an increasing curve, but the rate of revenue decreased in the current years. For instance, 2021 reported a 33.26% increase in revenue margin of Apple, further indicating an amount of $365.817 billion (Macrotrends, 2022).

However, the rate of increase in revenue margin seems to be decreasing in 2022 as the stated year reported 7.79% increase in the revenue margin with an amount of $394.328 billion (Macrotrends, 2022). As a result of this, it can be observed that the low increasing rate of Apple’s revenue reflects improper performance notion within the company.

In consideration to this, Apple can implement training and development programs within the organisation. As per Bag et al. (2020), training and development programs within an organisation helps in developing the skills and knowledge of the employees. It also helps in maintaining proper values of operations and accomplishing organisational objectives effectively.

Through the program of training and development, Apple can be effective in guiding its employees regarding the production of proper values within products and services. Moreover, it will also be effective to create an awareness regarding the organisational objectives while increasing speed and efficiencies within the process (Younas et al. 2018).

Through high skilled employees, Apple can be effective in mitigating the challenge of low increasing rate of revenues in the market and build operational efficiencies as well. Henceforth, this strategy can be effective for Apple in improving operating notion.

Moreover, Apple also seems to be facing the issues of faulty products within the market that is further creating a sense of dissatisfaction among the customers. In respect to this, it can be recommended that implementation of control and checking of quality initiative before manufacturing alongside launching it in the market can be helpful for Apple in solving performance issues.

Villalba-Diez et al. (2019) evaluated that effective checks of products and services before the stage of manufacturing can be highly beneficial in pointing out the defaults within the phones that can create issues in later stages. As a result of this, Apple can be beneficial in creating positive influence on customers while can also be effective in maintaining its market position. Henceforth, the stated strategies can be effective in improving operational efficiencies within Apple.

Conclusion

From the current report, it can be concluded that Apple is a technological company dealing with several products such as Apple Watch, iPad, iPhone, Macbook and others. Quality of Apple is managed through the principles of TQM while Apple also seems to be managing its inventory through LIFO method. However, the company’s inventory seems to be reflecting a decreasing rate that further depicts the need of managing inventory properly.

However, process and capacity design of the company is managed through employee motivation, proper relationship with suppliers and innovation. Comparing Apple with Dell, low volume is observed within Apple along with high variation in demand and high visibility. Variety dimension seems to be equal in both the companies.

Lastly, Apple seems to be facing issues of improper inventory management along with improper performance and decreasing rate of revenue margin. In consideration to this, implementation of RFID Technology along with training and development programs and control and quality checking before the stages of manufacturing can be beneficial for Apple to increase its operational efficiency.

Reference list

Abbas, J., 2020. Impact of total quality management on corporate green performance through the mediating role of corporate social responsibility. Journal of Cleaner Production, 242, p.118458.

Alzoubi, H.M., Ahmed, G. and Alshurideh, M., 2022. An empirical investigation into the impact of product quality dimensions on improving the order-winners and customer satisfaction. International Journal of Productivity and Quality Management, 36(2), pp.169-186.

Apple, 2022. Apple at Work, Apple. Available at: https://www.apple.com/in/business/ [Accessed on 25 November 2022]

Bag, S., Wood, L.C., Xu, L., Dhamija, P. and Kayikci, Y., 2020. Big data analytics as an operational excellence approach to enhance sustainable supply chain performance. Resources, Conservation and Recycling, 153, p.104559.

Barnes, D., 2018. Operations management: an international perspective. Bloomsbury Publishing.

Canetta, L., Barni, A. and Montini, E., 2018, June. Development of a digitalization maturity model for the manufacturing sector. In 2018 ieee international conference on engineering, technology and innovation (ICE/ITMC) (pp. 1-7). IEEE.

Cui, L., Zhang, Z., Gao, N., Meng, Z. and Li, Z., 2019. Radio frequency identification and sensing techniques and their applications—A review of the state-of-the-art. Sensors, 19(18), p.4012.

Dell, 2022. Dell PowerVault ME5 Series Administrator’s Guide, Dell. Available at: https://www.dell.com/support/manuals/en-us/powervault-me5024/me5_series_ag/size-representations?guid=guid-116f636e-2124-4674-bd8f-ba46b3f769f8&lang=en-us [Accessed on 25 November 2022]

Dell, 2022. Discover All Dell Products, Dell. Available at: https://www.dell.com/en-in/lp/discover-dell-products [Accessed on 25 November 2022]

Dell, 2022. Get the visibility and control you need to achieve consistent, high-quality service performance, Dell. Available at: https://i.dell.com/sites/doccontent/shared-content/data-sheets/en/Documents/dell-enterprise-service-management-services-datasheet.pdf [Accessed on 25 November 2022]

Dell, 2022. Who are we, Dell. Available at: https://www.dell.com/en-us/dt/corporate/about-us/who-we-are.htm#:~:text=We%20are%20among%20the%20world%27s,we%20do%20impacts%20everyone%2C%20everywhere [Accessed on 25 November 2022]

Ferrari, B., 2019. Added Visibility To Apple’s Hardware Supply And Product Demand Risk Mitigation Efforts, Supply Chain. Available at: https://theferrarigroup.com/added-visibility-to-apples-hardware-supply-and-product-demand-risk-mitigation-efforts/ [Accessed on 25 November 2022]

Hansen, S. T., and Podolny, J. M., 2020. How Apple Is Organized for Innovation, HBR. Available at: https://hbr.org/2020/11/how-apple-is-organized-for-innovation [Accessed on 25 November 2022]

Liu, W., Wei, W., Choi, T.M. and Yan, X., 2022. Impacts of leadership on corporate social responsibility management in multi-tier supply chains. European Journal of Operational Research, 299(2), pp.483-496.

Macrotrends, 2022. Apple Inventory 2010-2022 | AAPL, Macrotrends. Available at: https://www.macrotrends.net/stocks/charts/AAPL/apple/inventory [Accessed on 25 November 2022]

Macrotrends, 2022. Apple Revenue 2010-2022 | AAPL, Macrotrends. Available at: https://www.macrotrends.net/stocks/charts/AAPL/apple/revenue [Accessed on 25 November 2022]

Martins, D., 2020. Apple: Kings Of Inventory Management, The Street. Available at: https://www.thestreet.com/apple/news/apple-kings-of-inventory-management [Accessed on 25 November 2022]

Mint, 2020. Apple iPhones are in demand again, here’s why, Mint. Available at: https://www.livemint.com/technology/tech-news/apple-iphones-are-in-demand-again-here-s-why-11571051236477.html [Accessed on 25 November 2022]

Neowin, 2022. Apple Inventory Value FIFO/LIFO?, Neowim. Available at: https://www.neowin.net/forum/topic/314193-apple-inventory-value-fifolifo/ [Accessed on 25 November 2022]

Ovide, S., 2021. Apple’s Strategy Bends the World, NY Times. Available at: https://www.nytimes.com/2021/06/29/technology/apple-business-strategy.html [Accessed on 25 November 2022]

Parvez, M., Ullah, N., Sabuj, M.A. and Islam, S., 2018. Profit Maximization of DELL Inc. through Build-to-Order Supply Chain for Laptop Manufacturing. American Journal of Industrial and Business Management, 8(06), p.1657.

Rostamkhani, R. and Ramayah, T., 2022. A Quality Engineering Techniques Approach to Supply Chain Management. Springer Nature.

Shrum, A., 2021. A Look at Apple’s Supply Chain Management, Dynamic Management. Available at: https://www.dynamicinventory.net/apple-best-supply-chain-management-company/ [Accessed on 25 November 2022]

Surya, B., Menne, F., Sabhan, H., Suriani, S., Abubakar, H. and Idris, M., 2021. Economic growth, increasing productivity of SMEs, and open innovation. Journal of Open Innovation: Technology, Market, and Complexity, 7(1), p.20.

Utami, M.C., Sabarkhah, D.R., Fetrina, E. and Huda, M.Q., 2018, August. The use of FIFO method for analysing and designing the inventory information system. In 2018 6th International Conference on Cyber and IT Service Management (CITSM) (pp. 1-4). IEEE.

Villalba-Diez, J., Schmidt, D., Gevers, R., Ordieres-Meré, J., Buchwitz, M. and Wellbrock, W., 2019. Deep learning for industrial computer vision quality control in the printing industry 4.0. Sensors, 19(18), p.3987.

Younas, W., Farooq, M., Khalil-Ur-Rehman, F. and Zreen, A., 2018. The impact of training and development on employee performance. IOSR Journal of Business and Management (IOSR-JBM), 20(7), pp.20-23.

Know more about UniqueSubmission’s other writing services: