MOD002406 Procurement and Supply Chain Management

Task A: Evaluation of procurement system

Introduction

Procurement planning is the process of collecting, recognizing, and integrating the various requirements of a certain project within a limited timeframe (Nielsen and Saha, 2018). In this study, the procurement system would be evaluated using the MEAL plan. This plan would suggest that the planning would not have any wastage of resources and be very cost-effective. It would also benefit the constrictors and guide them to complete a certain project more effectively.

Discussion

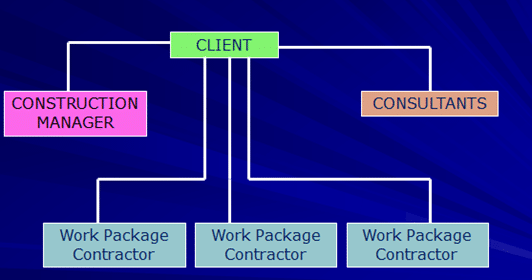

Figure 1: Construction management

As stated in Figure 1, the client is the most important factor in the management of construction projects. The vision and demand of the client is essential in developing the procurement planning (Palmer, 2017). The working of the managers and consultants depends totally on the client. In strategic procurement planning, the goals should be defined properly. The external and internal factors should be properly analyzed in order to develop excellent planning. Hence, it is very important to continuously monitor the changes in order to develop an excellent plan. According to Li et al. (2005), in the past, the planning was constructed only by analyzing the resources and frameworks provided by the contractors. The negative and positive factors effected the procurement planning in the UK. As a result, wasted resources took place which increased the cost of the project. Hence, it can be evaluated that excellent planning requires analyzing the external and internal factors properly. It increases the accuracy and relevance of the project. It is, therefore, necessary for the project manager to examine the internal and external factors properly. This would minimize the wastage of resources and increase the reliability of the constructors and customers.

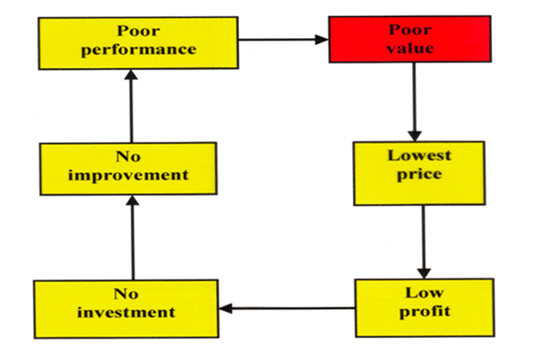

Figure 2: Constructor’s dilemma

As shown in figure 2, without proper collaboration the constructer faces several challenges. Improper planning results in poor value, which affects the price, profit, investment, pattern, performance of the project (Hamerski et al. 2018). Collaboration in procurement planning helps to reduce the complexity of the work. Otherwise it increases the complexity of the constructed as shown in figure 1. It helps to determine the working and the various arrangements required for the project. According to Smith et al. (2004), the past improper collaboration resulted in mismanagement of the project planning. Government of China faced many problems regarding procurement planning is the past. Collaboration not only increases the flow of the exchange of knowledge but also helps to improve the skills of the stakeholders. Hence, it is very beneficial to collaborate with procurement planning as it helps to increase the efficiency of work. It also helps to utilize resources more effectively, improves project quality, and helps to complete the project within time. It helps to resolve problems much faster, improves the safety of the project, and enhances customer satisfaction.

The JCT Framework agreement Act of (2016) helps to improve the efficiency of the project. The main aim of this agreement was to introduce certain principles for the benefit of the contractors. It is integrated teams and their alliances started to attract supply chain

Management started with the standard form of PPC 2000. This helped the organizations to increase the efficacy of the supply chain. This framework also provides policies in case of conflicts between the contractors. It is a very good attempt in order to unify the partnership agreements, delivering projects, managing contracts, and many more facilities. Therefore it is very important for the project managers to learn about the benefits of the JCT Framework Agreement in order to increase the productivity of the project.

The procurement strategy is very necessary in order to provide excellent management to the whole process. It also helps to address possible risks that can take place while the project is ongoing. As stated by Li et al. (2005), this strategy has helped to reduce the costs, time, performance, and many other factors of the project. In public sector procurement, the main aim should be focused on reducing the cost and increasing the efficiency of the project. In this case, procurement strategy is very beneficial as it would help to address the risks of the project and has the capacity to satisfy the customer demands. Hence, it is very essential for the managers to strategically plan the procurement process so that the productivity of the projects can improve in the future.

| Model name | Uses |

| User requirement model | Generation of documents, easy integration, development of tools for testing |

| System requirement model | Monitor work performance, developed frameworks, and many more |

| Architectural model | Visualize the project, improve efficiency, planning of the process and many more |

| Component design model | Increases efficiency and maintains consistency of the project |

| Unit design model | Realistic and accurate unit planning for the project. |

Table 1: Models for management

(Source: Created by author)

There are various new models as stated in table 1, which would help the managers increase the efficiency of construction projects. The main aim of these models is to engage the suppliers properly and become transparent with the cost of the projects to the stakeholders. According to Palmer (2017), the construction projects in the past were much more complex. There was not proper transparency with the costs required for the projects. This model helps to save the cost up to 20%, which benefits the clients immensely. Hence, it is very necessary to implement these models in the future to decrease the complexity of management. Furthermore, these models help to increase innovation and help to maintain better relationships with the customers, which would increase the sustainability of the organization in the future (Pagano and Liotine, 2019).

Conclusion

An excellent procurement plan would help to discuss properly the process of recognition and selecting the resources, contractors, suppliers, and consultants for the project. A procurement plan is very necessary in order to determine the accuracy and relevance of the project. It also benefits the project manager to increase the performance and mitigate risks in the project.

Reference list

Li, B., Akintoye, A., Edwards, P.J. and Hardcastle, C. (2005), “Perceptions of positive and negative factors influencing the attractiveness of PPP/PFI procurement for construction projects in the UK: Findings from a questionnaire survey”, Engineering, Construction and Architectural Management, Vol. 12 No. 2, pp. 125-148.

Palmer, G., 2017. A framework for incorporating EROI into electrical storage. BioPhysical Economics and Resource Quality, 2(2), p.6.

Pagano, A.M. and Liotine, M., 2019. Technology in Supply Chain Management and Logistics: Current Practice and Future Applications. Elsevier.

Smith, J., Zheng, B., Love, P.E.D. and Edwards, D.J. (2004), “Procurement of construction facilities in Guangdong Province, China: factors influencing the choice of procurement method”, Facilities, Vol. 22 No. 5/6, pp. 141-148.

Task B: Benefits of supply chain management

Introduction

Supply chain management can be defined as the management of the production flow of a product from the raw material to the customers. It is very essential to increase the efficiency of the supply chain so that the performance of the organization can improve. In this task, the management benefits would be discussed in detail.

Discussion

Integrated supply chain management can be defined as the management of resources, suppliers, managers, all distribution activities. Risks are associated with every organization regarding the development of products, utilization of resources, and many others. All these factors are managed with the help of a single chain in order to reduce the complexity of the organization. According to Al-Werikat (2017), previously the organizations have various networks for management which increased the complexity. This technology is very helpful to increase the efficacy of procurement planning and increasing customer satisfaction. Therefore it is very much necessary for the organizations to integrate their supply chain for increasing the productivity of the organizations and mitigating risks. The potential faults in the working process can be identified beforehand. This provides enough time for the managers of the company to find solutions. This helps the managers to increase the quality of products and thus satisfy the customers. The brand name and loyalty of the company increases with proper supply chain management. It also helps the managers to increase the customer base.

In the case of construction projects integrated supply chain management helps to utilize all resources properly on the site. Made-to-order supply chains are efficient to deliver a completely new product from the previous components. As stated by Schniederjans et al. 2020), improper management of the supply chain in the past restricted the innovation of the project. It also increases the cost of the management system. Construction projects are very essential for the development of society. Excellent integration of the supply chain would help the projects to work properly. In addition, it would also help in collaborating with the employees and mitigate risks. Hence, it is very essential for the managers to implement this latest technology in the system for better productivity. The quality of the product is also enhanced with the management of the supply chain. The customers are very concerned with the kind of products they receive. Excellent management helps to find out the risks associated with the product quality.

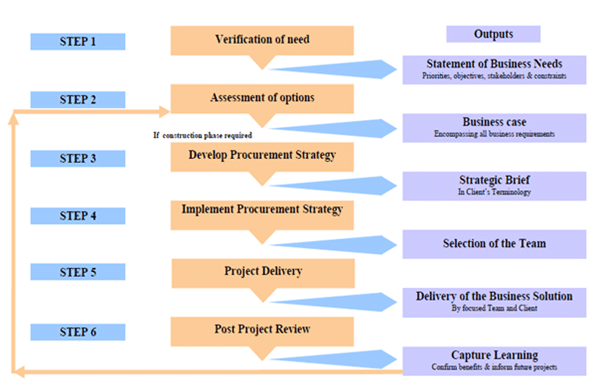

Figure 3: Procurement strategy

As stated in figure 3, the procurement strategy has a number of steps. The first is verification of resources, assisting options, developing strategy, implementation, and delivery of project and reviewing the project. Improper management of supply chain could hamper the entire process (Nguyen and Doan, 2019.).

In order to increase the efficiency of the supply chain, it is very essential to improve the performance. Improving the performance of the supply chain would help the organizations to improve their customer care services. As stated by Nguyen and Doan (2019), in the past the organizations were unaware of the demands of the customers. It restricted them to manufacture the products as per the demands of the customers. Hence, supply chain management is very essential in order to increase the efficiency of the project. It is therefore very essential for organizations to improve the efficiency of the supply chain. Customers are very important for increasing the profit margin and revenue of the company (Adam et al. 2020). With unsatisfied customers, the company can lose its brand value and loyalty. It is very important for the organization to increase the customer base by proper management of the supply chain.

Collaboration helps to increase the problem-solving capacities of the company. The quality of the products is also improved with excellent management of the supply chain. It also helps in reducing the costs of the organizations. Hence, it helps boost their productivity. According to et al. 2020), it is estimated that in the past companies faced huge amounts of overhead costs. 70% of the companies faced challenges regarding implementing innovation. It is therefore very necessary for organizations to understand the benefits of the supply chain. Every organization is required to improve its management in order to increase its competitive advantage in the market (Mehta et al. 2020). It also helps the firms to recognize their opportunities in the potential market. Identifying opportunities helps the company to develop products and mitigate weakness thus boosting productivity.

Conclusion

Excellent management of supply chains helps to improve the working of the organizations. It reduces the overhead costs and also helps in reducing the procurement cost of a company. It eases the process of identifying suppliers, better coordination, and control the departments in the company.

Reference

Adam, M., Wessel, M. and Benlian, A., 2020. AI-based chatbots in customer service and their effects on user compliance. Electronic Markets, pp.1-19.

Al-Werikat, D.G., 2017. Supply chain management in construction revealed. Int. J. Sci. Technol. Res, 6, pp.106-110.

Hamerski, P.C., Irving, P.W. and McPadden, D., 2018. Learning Assistants as constructors of feedback: How are they impacted?. In Physics Education Research Conference Proceedings.

Mehta, A.M., Ali, F.H., Farooq, S. and Tariq, M., 2020. Dynamic Managerial Capabilities, Competitive Advantage and Business Performance: An Integrative Model, Literature Review and Research Propositions. Academy of Strategic Management Journal, 19(4).

Nguyen, T.T.B. and Doan, T.T.T., 2019. Blockchain for Food Supply Chain Management: Major Benefits and Critical Challenges. Sustainable Business Development in the Connected Age, p.394.

Nielsen, I.E. and Saha, S., 2018. Procurement planning in a multi-period supply chain: An epiphany. Operations Research Perspectives, 5, pp.383-398.

Schniederjans, D.G., Curado, C. and Khalajhedayati, M., 2020. Supply chain digitisation trends: An integration of knowledge management. International Journal of Production Economics, 220, p.107439.

Know more about UniqueSubmission’s other writing services: