ACC539 Platinum Case Study Assignment Sample

Here’s the best sample of ACC539 Platinum Case Study Assignment, written by the expert.

Executive summary

The report emphasizes on the internal control measures that will be used to make the management system effective as well as stronger. This information has been given in the context of platinum manufacturing group, as the company does not have the controlling measures in the firm. They face the issues of not carrying any perpetual inventory system at the workplace. Other than that, the issue regarding the precision or the accuracy is the issue that is majorly arising. In this context, the practical control measure SAP has been introduced in order to manage the compliances process more effectively. Moreover, the study also includes the recommendation in which suggestion regarding individual performance check has been given in order to check the individual performance over the SAP process.

Introduction

The study aims to carry out the need of the automatic or electronic forms in the platinum manufacturing case. The Electronic platforms are the most valuable tools that serve the ranges of benefits to the organization working and their efficiency. In this emerging world, the electronic forms are making the working easier and transparent. However, the case has shown that company is more on the paperwork and also they are not having the proper records on the inventory. Thus, in this case, the weakness and their impact have been highlighted. Alongside, the practical approach has shown in order to overcome the issues.

A Summarized overview of the expenditure process

Platinum manufacturing group is the manufacturer of the electrical equipment. The company has shown the tremendous growth from raising their profits in the last two years. The organization has hired the sufficient staff to manage their inventory. The staff manages the ordered raw material and delivered into the storeroom, where the storekeeper checks on all the order by making the count. All the delivered, undelivered, outstanding orders are recorded by the purchasing team on the register that will be checked at the end of the month. It does not have any specified inventory management system that can manage day to day stocks of the equipment. Moreover, the further needs of the orders are placed on the supplier through emails. Hence this is the way the company manages their inventory (Platinum case).

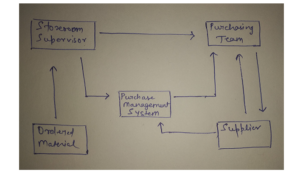

Level 0 Data Flow Diagram

Data flow diagrams (DFD) are most commonly used by organizations to represent the business information in graphical manner highlighting about the processes and flow of data. Whether it is any information processing or material processing, DFD can be used as a tool to describe processes and their flow to transfer information or material from one end to other. It is divided into logical and physical where logical DFD includes data flow system upon which certain functions of a business are performed. On the other hand, physical DFD is focused on describing how to implement the logical data flow. All the functions or processes through with material or data is flowed from one user to another or from one organization to other are visually represented that acts as a sound communication between user and system designer.

Level 0 diagram, also known as context level diagram is considered as a highest level DFD that mainly focus on single process used in the entire system. It includes all the external entities or users involved to process material to and from. In level 0 diagram, there is no storage process.

For platinum, a Level 0 DFD for raw material purchasing process can be represented as below.

From the diagram presented above, it can be seen that there is a single purchase management system through which all the information regarding raw material requirement and purchase order flows. It can be seen that the company has a storeroom supervisor to whom ordered materials are directly supplied by supplier keeping purchasing team informed about the supply. Storeroom supervisor when finds there is any mismatch in the physical count of the material, material purchase requisition is filled with the number of inventory required and sent to purchasing team. Once this is received, purchasing team reviews it and prepares purchase order that is sent to supplier putting the information into the system.

Identification of Internal Control system

| Internal Control Weakness | Impact of the weakness

|

Control To mitigate the weakness | Latest development |

| n The company does not carry any perpetual inventory system at the workplace in order to manage the remaining as well as the outstanding stock of the equipment (Platinum case).

n The organization has mainly majorly emphasized on loads of paperwork. The entire task, weather related to the delivery of the equipment or to the receipt is noted down on the papers only (Platinum case). n The issue regarding the precision or the accuracy is high because all the checks over the raw material are made physically. n The processing of keeping the emails regarding the packaging slips has been cleaned daily. Thus with this, data will be cleared in the system hence it can make trouble later. n One of the major issues in the case of the platinum group is regarding keeping records. They don’t record for the goods received or issued (Platinum case). |

The organization is having the strong base for the small and medium-sized customer which is considered as the good sign of growing. However, the negative impact on the internal management affecting the overall working of the organization. It is essential to have the transparency at the workplace because with this the ratio of fault could be raised and the company started declining (Platinum case).

In the case of Platinum manufacturing group, the impact of these weaknesses could be so converse because the day to day working can get affected at the workplace. The use of paperwork may irritate the workers as the world is using the digital technology to manage those things. Other than that, accuracy in the records of the order may affect the profitability of the organization. It is very important to keep the effective relations with the suppliers, as they are the sources who serve the raw material for the product. However, the inaccuracy can lead to impact towards their relations. Moreover, the working pressure can rose among the workers (Platinum case). On another side, the company is giving the responsibility to the manager who manages the storeroom, purchasing team and other. Thus if any drawback or misconduct occurred, the organization will only call him the victim as he is keeping an eye over each inventory management system. |

The organization is facing the internal mismanagement issue because of the lacking in the controlling measures. In this context, platinum manufacturing should use SAP process control system as it can be used to manage the compliances process more effectively (Mandal, & Gunasekaran, 2002).

The process is majorly effective because it served the documentation for the controls catalogs. In addition to this, the process can make the control of the performed task by allowing the audit trail (Sadiq, et. al., 2007). SAP can gives continues check over all the processing like inventory checking, purchasing process, delivering process and others. This is used in the form of the software thus the past records can be recorded easily in this. It can also make the checks for the segregation of the duties (Giesen and Kimball 2017). One of the major issues of this case is that the workflow is majorly high on the workers. the SAP can control the workplace by implementing the online channels of checking the inventories as well as records. In next to this the channel gives the automated controls so that the platinum working can become flawless.

|

According to the automated generation, the concept of SAP controls system can be achieved with automated controls. As the working of this system will be conducted through the software that can automated controls, master the data control as well as the transactional controls over the working that has been taking place. The software’s keep the past records through comparison along the past years can be made easily through this system. In addition to this, the automation can save the time of an individual, and the needs of workers become lesser in the company.

Other than the aim of having perpetual inventory system can also be achieved effectively through SAP system (Giesen and Kimball 2017). |

Conclusion and recommendation

The Platinum case analysis shows the traditional way of doing the work. This has issue to the management systems or the inventory has not been controlling through this. Thus in this context, the above analysis shows the internal control measure, SAP that can make the working effectual and translucent. However, the company should also add to the individual performance system so that they can keep the eye on the individual. With this, the company can track the fair records and leads to earn huge profits from the market.

References

Mandal, P., & Gunasekaran, A. (2002). Application of SAP R/3 in on-line inventory control. International Journal of Production Economics, 75(1-2), 47-55.

Sadiq, S., Governatori, G., & Namiri, K. (2007, September). Modeling control objectives for business process compliance. In International conference on business process management (pp. 149-164). Springer, Berlin, Heidelberg.

Giesen S. and Kimball D. A. (2017). A Practical view on SAP process control Retrieved from: https://www.compact.nl/pdf/C-2017-3-Giesen.pdf?x33882

________________________________________________________________________________

Know more about UniqueSubmission’s other writing services: