BE275 Global Supply Chain and Operations Management Sample

Introduction

The technological advancement is leading the world towards a new world which is more technologically advanced. With time technology is gaining a lot of important as they are working on the different areas and changing the way of living for the humans. It is making the entire world more advanced by making the rapid changes in technologies used, industries and the social patterns as well.

For the 21st century the internet had gained a lot of important as it is allowing us to connect with the people across the globe. Due to the increasing globalisation and better technologies the industries are going under major changes which are having a major positive impact on the businesses operating in diverse industries.

The technologies is making the work easier for all the businesses and helping them in managing their complex business operations in an effective manner (Oztemel & Gursev, 2020). All these technological changes in the business world had led the industries towards the Industry 4.0 which is a new transformation of the way the businesses are producing and managing their business operations and especially in the production area.

In this essay the author would be focusing on explaining the concept of Industry 4.0 and how it is affecting the different factors of the businesses and the industry especially in the way they operate and manage their business operations.

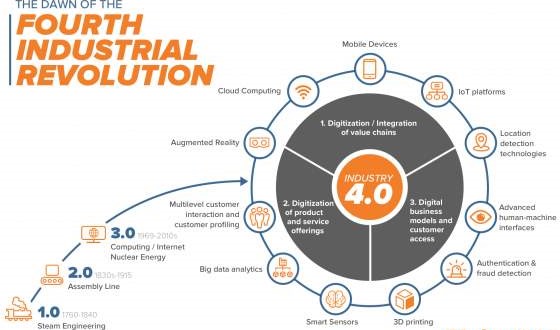

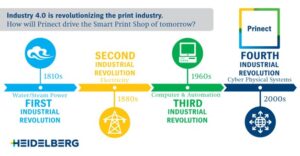

In general terms industry 4.0 is referred as the transformation or the industrial revolution which focuses on higher interconnectivity in the industries, automation, real time data and the machine learning. All these factors are having a major influence on the way the businesses are operating in diverse industry. This essay would focus on explaining that how the concept of Industry 4.0 is affecting the supply chain management, business operations management and employees working in the different industries.

Impact of Industry 4.0 on supply chain and operation management

With the increasing complexities related to manufacturing and the need for making the business operations there is a demand to make modifications in the industry 3.0 due to which the revolution of Industry 4.0 had come into existence. The main aim of the industry 4.0 is to make major changes in the production and operations of the businesses which can have a major positive impact on the industry performance.

If the latest or the emerging technologies are well applied to the manufacturing industry then it would be having a major positive impact on the production which would lead the firms towards success, development and higher revenues (Tjahjono et. al. 2017). The way the latest technologies of the industry 4.0 are applied by the industries or the manufacturing firms would be having a major role to play on th3 success of the firm in the new technologically advanced market and industries.

The technological needs for all the different businesses are quite different. For this the companies needs to identify that which technology would help them in solving their challenge related to production and other business operations. The industry 4.0 is having a major impact on the way the firm’s communication and connect with their stakeholders and manage the operations with them (Tortorella et. al. 2019). From this it can be said that Industry 4.0 would be having a crucial effect on the all the different business operations including supply chain management as well.

Industry 4.0 is having greater ability to change the way people are living their life’s. The significant impact on the Industry 4.0 is on the supply chains and the manufacturing systems of the firms. If the companies which are highly depending on the manufacturing. Industry 4.0 is bringing greater digital transformations which focus on merging the physical and the digital work of the company.

The different technologies which are included in the industry 4.0 include the artificial intelligence, 3-D printing, material science, biotechnologies, nanotechnology, energy storage and many more. Apart from this cloud computing, cyber security, robotics, additive manufacturing and augmented reality are also the important strategies which are used for digitalization of the industries in Industry 4.0 (Sony & Naik, 2019).

The major idea of Industry 4.0 is to make use of the latest technologies in the manufacturing which can help in making the manufacturing easier, agile and flexible. Let us consider that how Industry 4.0 is changing the food manufacturing industry.

Then this industry is complex to manage as with the shifting customer needs it is crucial to make the consumer satisfied by meeting their needs. Industry 4.0 is having major positive influence on the performance of the food and beverage industry. Thus it can be said that the Industry 4.0 is making major changes for the industries which rely on the manufacturing.

Managing the global supply chains is an most important and the challenging task for the businesses. Due to this reason the businesses always focuses on making use of the technologies which can help them in making their supply chains more efficient and improving the performance of their supply chains in an effective manner. Industry 4.0 is having greater potential to affect the supply chains in different areas which can offer several benefits to the company (Liao et. al. 2017).

The digitalisation and the automation are having greater ability to change the way the supply chains are working and are managed by the businesses. Automation can help the companies in meeting the customer demands in an effective manner and reducing the waste as well.

Also the digitalisation and the automation of the supply chains can help the companies in making major changes in the way they are managing the logistics and warehousing which can offer several cost effective benefits to the company (Pereira & Romero, 2017).

The increased complexities due to the global supply chain and the management of large number of suppliers and buyers at international level had become difficult but the technologies of Industry 4.0 are having greater ability to solve the different challenges which are being faced by the firms while managing the global supply chain.

Figure 1 Industry 4.0 revolution

(Source: UKEssays, 2018)

One of the important uses of the technologies of Industry 4.0 is in the demand forecasting which is a very important aspect for managing the supply chain and ensuring better supply of the products as per the customer demands.

In Industry 4.0 the businesses are making use of the machine learning algorithms for demand forecasting and this is helping the firms in making better decision related to the order as per the market trend and customers’ demands. Along with this it is helping in better or the detailed data analysis of the data which is helping in better demand forecasting.

This is helping the businesses operating in diverse industries to reduce the forecasting errors as more accurate methods are now being used in forecasting. Along with this it is also helping them in optimising their supply chain and inventory in an effective manner which is helping them in reducing the unnecessary cost and offering cost benefit to the company which is important for sustainable development of the firm.

Developing better cooperation and collaboration with the suppliers is always an important challenge for the firms while managing the supply chain and especially the global supply chain. But the latest technologies of Industry 4.0 are having great ability to solve this problem in an effective manner. In Industry 4.0 the businesses are now focusing on making use of the digital supply chain management software which can help in sharing the information in an effective manner.

This digital supply chain management software helps the company in better information sharing which helps in developing better cooperation and collaboration among the suppliers and it helps in developing trust and support among the suppliers and the company itself (Ivanov & Dolgui, 2020). This is very important for making the entire supply chain more efficient and this is also having a significant positive influence of the management of the supply chain.

These software are having an ability to reduce the lead time which in making all the raw material available before the stock out. Along with this it focuses on developing better communication and ensures that the firm should have proper availability of the goods and services.

Digitalisation of the supply chain is also having a greater positive influence on the warehouse management. Better technologies used in the supply chain can help in improving the warehouse management which is important for better logistic management and smooth functioning of the supply chains.

This is helping the company in real time tracking which helps in improving the customer satisfaction to a greater extent. Different businesses operating at the global level had used the better technologies for their warehouse and logistics management (Piccarozzi et. al. 2018). For instance Amazon one of the leading retailers had made their logistics operations digital.

This allows the customers to track their orders and helps them in having timely delivery of their goods and services which is adding value to the company performance in the international market. This is also helping the company in reducing the transportation cost and inventory through accurate demand prediction.

The use of the latest technologies of Industry 4.0 is helping the firms in making their supply chain more appropriate by helping the management to make better decisions with the help of the great data collected through the suppliers, customers, service providers and many more (Koh et. al. 2019).

The use of better technologies is making the supply chain more intelligent which are having an ability to estimate or predict the risk and taking better actions which can help the companies in managing the supply chain in an effective manner. During the covid-19 pandemic the businesses across the world are facing issues related to the supply chain disruptions.

But with the help of digital supply chain the companies are ensuring that the basic products should be made available to all the customers in an effective manner. Along with this in industry 4.0 the transparency and accuracy in the global supply chains had increased to greater extent.

Better use of the effective technologies are helping in ensuring end to end transparency which is improving the overall performance of the company in terms of supply chain management. This is also helping the management in better risk management which is helping them in keeping the companies away from the risks in an effective manner.

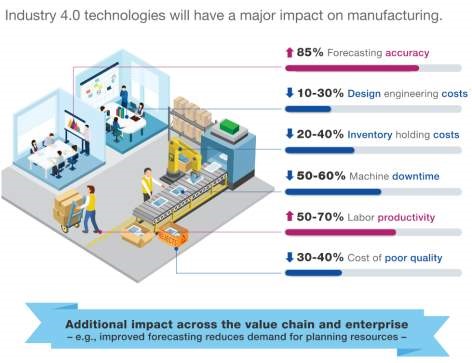

The changes in the technologies used by the company would make the changes in the way the firms are being operated and managed. If the businesses would be implemented the changes related to the industry 4.0 in an effective manner then it would add better value to the companies. One of the most significant benefits of the company in the context of the use of digital technologies of Industry 4.0 is the improvement of the productivity and profitability.

These technologies would be changing the business operations management to a greater extent (Núñez-Merino et. al. 2020). Along with this it would allow the firms to establish smart factories and intelligent workplaces which is important for the bright future of the firms. Different firms operating at the global level are using different strategies which can help them in making their firms smarter and improving their operations efficiency.

Industry 4.0 is such a wide concept that it is having an ability to bring several major changes in the operation management of the firm. Managing the business operations is quite challenging for the businesses due to the expansion of the businesses at the global level.

For managing the firms effectively at the global level it is essential for the firm to make use of advanced technologies which is quite possible under industry 4.0 (Müller & Voigt, 2018). The digitalisation of the businesses under industry 4.0 is having better ability to create both the opportunities and challenges in the context of operations management for the firms.

The better use of the information and communication technologies is helping the companies in developing positive influence of the operational efficiency. This is helping the firms in making the management of the business operations and processes more intelligent and smart with the integration of better technologies into it.

This is important for applying the major changes in the way they manage their operations and this also helps in better integration of the Industry 4.0 technologies in the industries. Manufacturing is one of the important operations for the business which can be improved to a greater extent under industry 4.0.

The businesses are making use of the machine monitoring or automation which is having a positive influence on the production.

Along with this the use of technology is having an ability to make use of the resources in more appropriate manner which is having an ability to improve the overall productivity of the firm in an effective manner. Improving the operational efficiency is always an matter of concern for the businesses which can now be achieved with the help of technologies (Fatorachian & Kazemi, 2021).

Figure 2 Impact of Industry 4.0 on manufacturing

(Source: UKEssay, 2018)

Different technologies related to industry 4.0 are making the business processes more efficient because of automation. For example, Apple is one of the leading brands and wants to have better flow of supply as per their demand. Due to this their manufacturing partner Foxconn is investing better capital in establishing automation across all the factories.

This is helping them in transformation their manufacturing units into the smart factories which are having better efficiency and the ability to improve the overall productivity of the firm which can offer different cost benefit to the company.

Different companies operating in diverse industries are making use of better technologies which is helping them in improving the productivity, flexibility and the profitability of the business. It can be said that the increasing operational efficiency under the technologies of Industry 4.0 is having greater positive impact on the customer experience, customer satisfaction and the company performance.

This is having an influence on the revenue of the company and helping the firms in managing the different operations management challenges effectively by developing better integration among all the stakeholders and ensuring better operational management in the firm (Ghadge et. al. 2020).

When the businesses undergo technological changes then it is having a major impact on the employees working in the firm. The employees need to make changes in their working styles and have to develop their skills in an effective way. While making use of the latest technologies related to the industry 4.0 then development of the skills is very important.

The companies have to focus on investing better capital for developing the skills and knowledge of the employees and making their workplaces more advance and smart (Fettermann et. al. 2018).

The use of automation and digital technologies in the businesses would increase the work of the employees. For making better use of the technologies it is essential to make sure that the company must have right employees who can make use of the technologies in an effective manner. Under the concept of Industry 4.0 remote working has increased to a greater extent.

This is offering better flexibility to the employees and helping the firms in satisfying them in an appropriate manner. Increasing use of automated machines in the manufacturing sector would be affecting the workers of manufacturing sector to a greater extent. Along with this the way the employees are working is different from industry 3.0.

There are a lot of positive influence of the latest and the advanced technologies of Industry 4.0 but it is also important to explore the disadvantages. There are always both the pros and cons associated with the change. The updating of the industry or the revolution of industry 3.0 to 4.0 would create a lot of opportunities and challenges for businesses.

In this context it is important to understand that how the industry 4.0 is affecting the businesses positively and negatively. The company structure and the management of the firms under industry 4.0 would be complex. If the company would not be having better management then it would affect the company negatively (Wichmann et. al. 2019). Along with this due to the increased use of the digital technologies and the software in the firm would increase the risk of cyber security.

It can be said that implementing and using the digital technologies of the industry 4.0 would not be an easy task for the businesses as they would have to create an appropriate digital infrastructure. The companies have to focus on investing better capital for the development of the skills and knowledge of the human resource. Along with this greater innovation and significant capital investment would be required from the companies for making use of the technologies.

It can be recommended that the companies needs to focus on better planning before using the advanced technologies in their company. Managing the digital supply chain and making the operational management more digital is quite challenging.

The companies need to ensure that they are having better availability of the resources which are important for managing the businesses effectively in the industry 4.0. If the companies would be making better use of automation, advanced technologies and digital technologies then it would help them in gaining the competitive advantage over others (Birkel & Müller, 2021).

Conclusion

On the basis of the above discussion it can be said that the advanced technologies of the industry 4.0 are having greater potential to make significant changes to the supply chain management and operations management. If the firms start using the digital technologies and making their supply chain digital then it will help them in increasing the operational efficiency and improving the performance of supply chain. There are different issues and challenges which are being faced by the international firms while managing the global supply chain effectively. But the use of technologies of Industry 4.0 can help the firm’s in solving majority of the challenges in an effective manner.

It can be concluded that due to the increasing technological advancement it is essential for themselves to make use of better technologies. This can help them in increasing the company performance and gaining competitive advantage over. In the highly competitive business world it is essential to make use of digital technologies and automation which can help the company in improving the overall operational performance and can led the firm towards success.

References

Birkel, H., & Müller, J. M. (2021). Potentials of industry 4.0 for supply chain management within the triple bottom line of sustainability–A systematic literature review. Journal of Cleaner Production, 289, 125612.

Fatorachian, H., & Kazemi, H. (2021). Impact of Industry 4.0 on supply chain performance. Production Planning & Control, 32(1), 63-81.

Fettermann, D. C., Cavalcante, C. G. S., Almeida, T. D. D., & Tortorella, G. L. (2018). How does Industry 4.0 contribute to operations management?. Journal of Industrial and Production Engineering, 35(4), 255-268.

Ghadge, A., Kara, M. E., Moradlou, H., & Goswami, M. (2020). The impact of Industry 4.0 implementation on supply chains. Journal of Manufacturing Technology Management.

Ivanov, D., & Dolgui, A. (2020). A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Production Planning & Control, 1-14.

Koh, L., Orzes, G., & Jia, F. J. (2019). The fourth industrial revolution (Industry 4.0): technologies disruption on operations and supply chain management. International Journal of Operations & Production Management.

Liao, Y., Deschamps, F., Loures, E. D. F. R., & Ramos, L. F. P. (2017). Past, present and future of Industry 4.0-a systematic literature review and research agenda proposal. International journal of production research, 55(12), 3609-3629.

Müller, J. M., & Voigt, K. I. (2018). The impact of industry 4.0 on supply chains in engineer-to-order industries-an exploratory case study. IFAC-PapersOnLine, 51(11), 122-127.

Núñez-Merino, M., Maqueira-Marín, J. M., Moyano-Fuentes, J., & Martínez-Jurado, P. J. (2020). Information and digital technologies of Industry 4.0 and Lean supply chain management: a systematic literature review. International Journal of Production Research, 58(16), 5034-5061.

Oztemel, E., & Gursev, S. (2020). Literature review of Industry 4.0 and related technologies. Journal of Intelligent Manufacturing, 31(1), 127-182.

Pereira, A. C., & Romero, F. (2017). A review of the meanings and the implications of the Industry 4.0 concept. Procedia Manufacturing, 13, 1206-1214.

Piccarozzi, M., Aquilani, B., & Gatti, C. (2018). Industry 4.0 in management studies: A systematic literature review. Sustainability, 10(10), 3821.

Sony, M., & Naik, S. (2019). Key ingredients for evaluating Industry 4.0 readiness for organizations: a literature review. Benchmarking: An International Journal.

Tjahjono, B., Esplugues, C., Ares, E., & Pelaez, G. (2017). What does industry 4.0 mean to supply chain?. Procedia manufacturing, 13, 1175-1182.

Tortorella, G. L., Giglio, R., & Van Dun, D. H. (2019). Industry 4.0 adoption as a moderator of the impact of lean production practices on operational performance improvement. International journal of operations & production management.

UKEssays. (November 2018). Implications of Industry 4.0 for Business Operations and Personal Career. Available on :< https://www.ukessays.com/essays/technology/implications-of-industry-4-0-for-business-operations-and-personal-career.php?vref=1>.

Wichmann, R. L., Eisenbart, B., & Gericke, K. (2019, July). The direction of industry: a literature review on Industry 4.0. In Proceedings of the Design Society: International Conference on Engineering Design (Vol. 1, No. 1, pp. 2129-2138). Cambridge University Press.

Appendix

Know more about UniqueSubmission’s other writing services: