BO7668 Operational Management Assignment Sample

Here’s the best sample of BO7668 Operational Management Assignment, written by our expert.

Executive Summary

McDonald’s is an industry that provides fast food products. In this report, our focus is on McDonald’s operation management. Around 68 million McDonald’s customers are present in all its outlets in the world’s 100 most significant countries. This report analyzes the issue of operational management of McDonald’s through its theory of supply chain management and total quality management, and lean production and report also explain three dimensions of operational strategy. Consequently, this helps to maintain the safety and quality standards of the company’s products and services, increasing profitability due to building trust among customers.

Introduction

Operation management is the area that deals explicitly with the business practices to achieve the highest level of outcomes with the help of optimum utilization of organizations available resources (Choi et. al. 2018). Operation management is formerly known as production management, but it is called operation management due to its modern approaches and continuous support in the organization’s growth. The present report focuses on the operational issue faced by McDonald and analyses those challenges. Further, the report provides the appropriate recommendations for overcoming those challenges.

Overview of organization and challenges faced by McDonald’s

Overview of organization and challenges faced by McDonald’s

McDonald’s is a world-famous fast-food chain business that was founded in the year 1940 by Richard and Maurice McDonald’s (Nagarajan et. al. 2019). The headquarter of the company is situated in Oak Brook, and the company’s first store was opened in San Bernardino, California (McDonald’s, 2015). Currently, the company is operating in 168 countries around the globe with more than 37000 outlets. It is estimated that this prominent fast-food chain serves 69 million people daily in the world. The main principle products of the company include the hamburger fast food varieties that serve its clients. This company also has various soft drinks, milkshakes, French fries, coffee, and desserts. According to the recent analysis, the company has extended its menu with 100 new dishes and also provides a facility to the customers to customize their burgers according to their choice. Developing marketing strategies and branding approaches that can consistently grow a consumer base are challenging to develop a consumer base. The company also faced certain operations management challenges related to its supply chain management. Poor level of transportation and low level of infrastructure in storage, and low level of quality of products of agricultural products are the company’s main issues recently.

McDonald’s Operational Analysis

The evaluation of the company’s operations reveals that the enterprise’s products have lost their appeal to its clients. It is the approach taken to market McDonald’s products that is causing the company’s products to lack appeal to millennials, who are the future client base. Retrospectively, McDonald’s branding efforts necessitate them enlisting the services of agencies that manage its brand image (Lagorio and Pinto, 2021).

Therefore, organizations have provided a distinct and clear message about their brand by reaching out to their client base by creating marketing campaigns. As part of the process of improving the McDonald’s brand experience, the company has to address a number of operational issues. The company’s primary objective lies in the areas of operation in order to keep the products produced as efficiently as possible. In other words, they produce the highest quality results possible with the same assets. McDonald’s faced several operational problems in the areas of supply chain management, competitor analysis, product innovation, and quality management.

McDonald’s Operations Management

OM (operations management) at McDonald’s Corporation is responsible for ensuring that the chain is the largest in the world. Management of operations is the process of organizing and coordinating multiple strategic areas of a business to ensure optimum performance and productivity (Tarigan et. al. 2021). As a global corporation, McDonald’s operations management demands a variety of strategic capabilities, including human resources and supply chain management.

- Goods and Services Design – McDonald’s is focused on providing affordable products in this area of strategic decisions in operation management. As a result, the company has set its prices and serving sizes in line with changing consumer expectations.

- Quality Management – McDonald’s focuses upon methods related to the line of production in order to maintain its quality of product and consistency within levelled constraints, such as price limits and cost factors. Thereby, the said company strives to enhance its product quality by observing its market constraints.

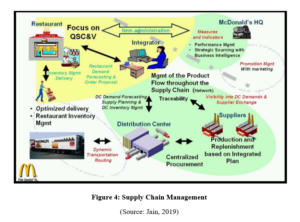

- Supply Chain Management – McDonald’s global supply chain allows the firm to support its many branches all over the globe. McDonald’s follows a strategy of diversification in their supply chain, which is an important part of the company’s operations management. For McDonald’s supply chain to reduce risks, the company seeks suppliers from different regions.

- Inventory Management – For McDonald’s, minimizing inventory costs and supporting restaurant operations is the aim of this strategic decision area within operations management (Demir, 2019). Products and ingredients are not directly sold to the restaurants by the company. McDonald’s restaurant managers coordinate inventory management with regional and local intermediaries and distributors.

Theories of Operational Management and McDonald’s

Supply Chain Management

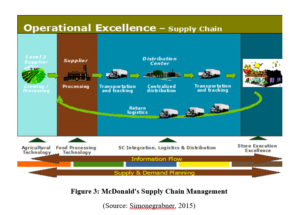

The supply chain management discipline is concerned with managing the connections between organizations that create value through the movement of goods and services upstream and downstream as a result of the changes that occur in the processes.

A company with 35.000 McDonald’s restaurants has to be able to provide supply chain management that can meet the requirements of around 70 million daily customers (Rajawat et. al. 2020). A strict authority on responsibility for planning each task and following through on the plans are necessary to prevent that products run out. Therefore, it is important to calculate the daily orders well in order to prevent running out of products.

- Management of supply chains is concerned with the flow of information and materials between the units, which constitute the strands of a supply chain; in order to control the supply chain, McDonald’s places a great deal of emphasis on tracing the products’ ingredients.

- McDonald’s tries to use UK-based suppliers whenever it is possible. However, they must still meet all of McDonald’s specifications, including product quality and hygiene.

- In Europe, they provide all of their beef, and in the UK, they largely source their beef from Britain. According to this ‘supplier quality index, all McDonald’s suppliers are measured (SQI). In addition to monitoring the performance of agricultural and non-agricultural suppliers, it gives the company valuable insight into their performance (Zain al. 2020).

- Restaurant managers are contacted regularly by this team to learn about upcoming events in the area.

- Material such as beef patties, buns, salad ingredients, packaging, and paper cups is delivered to restaurants 3 to 5 times each week. There is always something for sale in a restaurant, such as side salads, Big Macs, and fish.

- First In, First Out policies govern the handling of raw materials, work-in-progress, and finished products at McDonald’s. As raw materials are used in order of receipt, they are used in the order they are received. Due to the fact that products are sold in the order of manufacture, the stock is never old.

In order to manage stock more effectively, the central restaurant supply planning team communicates continuously with individual restaurants. Team members communicate on a regular basis via email and telephone with each of the nearby restaurants they work with. The team needs to record any factors that could influence customer visits to a specific restaurant. Supply Planners are responsible for predicting raw material consumption using stock control systems. They ensure McDonald’s distribution centres are able to leave with the right amount of raw materials. Thus, restaurants are able to prepare the meals necessary for the level of demand forecasted. In order to determine future demands for each McDonald’s restaurant based on past performance, McDonald’s Supply Planners consider a range of causal factors (Dekkers, 2020). In order to make McDonald’s Restaurants as successful as possible, managers need to use accurate data when entering data into the system.

McDonald’s has been practising a backwards vertical integration (upstream) by replacing the majority of its suppliers, which is done for two reasons:

1) To mitigate costs, and

2) To ensure that their goods are made to the highest possible quality.

This example illustrates how vertical integration reduces the risk of delayed deliveries (reliability) by providing one of the company’s coffee suppliers owned by Distant Lands. The McDonald’s operational management of the supply chain will allow McDonald’s operators and suppliers to handle supplier demands for supplies more efficiently, track inventory more accurately, and maintain quality control more precisely. As a result, both operators and suppliers will have less food wasted in the end.

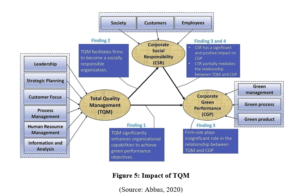

Total Quality Management

In this McDonald’s article, there is a discussion of relevant Operations theory and the use of Total Quality Management (TQM) to improve management. McDonald has developed a structured root system to improve its performance that improves its operational performance.

- Speed – McDonald’s drive-through aim is to complete the drive-through in 90 seconds, but does it always achieve this? No, not all of the time. There are lots of people who complain about drive-through mishaps, waiting for food when it is busy, organisms stuck in lines, etc. This problem is overcome through proper drive-thru management. The basic principle of queuing is that first-in, first-out, later customers often don’t get service until all previous customers have been treated. In this case, only one complicated order can slow down an entire line of people among fast orders.

- Cost – McDonald’s uses the cost food plans that make it possible for customers to buy sandwiches, French fries, and beverages at a lower rate when they buy them together (Bak, 2020). McDonald’s’ middle cost will decrease because of the increased number of people participating in this offer. The cost of energy constitutes a major part of restaurant operating costs. Lighting for parking lots, heating and cooling systems, and further utility costs contribute to restaurant operating costs.

- Quality – As a matter of fact, each McDonald’s restaurant undergoes periodic quality examinations. However, the company can conduct shock tests if a store does not outdo the review the second time around, meaning the company can take over the store and employ additional personnel to ensure that the correct processes and equipment are being used (Zain al. 2020)

- McDonald’s restaurant workers may have access to e-learning tools online. Further, McDonald should make sure that all the requirements of its workers are met and that the employees get recognized for their outstanding performance. Once this is accomplished, employees will be motivated to perform their tasks mechanically & of course, happy employees lead to improved service & ultimately satisfied customers.

- Dependability – In the event McDonald’s chooses double-line layouts along with a reliable system such as Delphi order verification, customers can be sure that its operations can be trusted. By utilizing the double-line format, the food will always be ready at a certain time without any mistakes & they will be able to exit quickly between lines.

- Flexibility – There are times when McDonald’s can have a number of skilled employees (Byrne al. 2019). Yet another time, this will cost money but be beneficial in the long run. McDonald’s provides their customers with all resources and provides them with a single order number so that when they come to pick up the food, they will already have it all ready. The disadvantage is that a worker would have to be specifically tasked with obtaining all orders when customers call.

In order to put the customer first, McDonald’s strives to anticipate and exceed the needs of its customers by using market research to determine what they want and ensuring that on-time service standards are met. By putting the customer first, they guarantee complete customer satisfaction and make sure that all service standards are met. Every member of the team must be involved, from the CEO to the crewmembers of McDonald’s. McDonald’s goal is simple: to deliver world-class products to customers anywhere in the world while maintaining high standards of service. An organization of quality improvement will employ Total Quality Management as a philosophy.

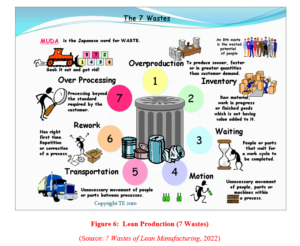

Lean Production

Manufacturing and production are being approached in a new way that has led to lower costs and the ability to achieve the shifting demands of consumers immediately (Gladysz et. al. 2020). By using technology to manage delivery systems efficiently, it is able to reduce costs. The fast-food industry has been dominated by McDonald’s since the mid 20th century. Since then, the company has been facing stiff competition, which has impacted every aspect of its operations. Despite all of the competition, McDonald’s has been able to maintain its position on the market by implementing a lean strategy. The following are some of McDonald’s key ‘lean’ practices. To be lean means to be able to meet demand while simultaneously maintaining quality and eliminating waste immediately. In order to deal with the sources of McDonald’s waste, the following strategies were adopted:

- Overproduction – Early McDonald’s sandwiches were prepared in batches and kept warm in warming bins. The reduction in serving time would benefit them, but it would also cause the wastage to increase, which would damage their reputation (Lemaire al. 2019). Rather than dealing with this problem, McDonald’s has started keeping patties, salads, and other sides prepared so they can be combined into sandwiches only upon a customer’s order. A few minutes are taken during this procedure, enabling a quick reaction to any changes in demand. There is, therefore, no risk of overproduction.

- Waiting Time – As the order is placed, the production staffs receive the information directly from the computer system. This has drastically reduced the waiting time. At McDonald’s, modern equipment and highly skilled workers prepare orders in less than one minute. As a result, the whole order is completed in three minutes.

- Processing Wastage – During the assembly process at McDonald’s, the order is assembled using a system known as the “Speedy System.” This process generates a lot of waste due to excessive handling. The McDonald brothers created this system, which has been in use ever since. Having the assembly line synchronizes the different operations reduces the handling of the items, resulting in reduced waste.

- Inventory – Lean manufacturing principles state that holding inventory incurs an opportunity cost, so the organization should get rid of it (Edward, 2020). McDonald’s, however, must be able to meet customer demands at all times; therefore, it uses a sophisticated stock control system that enables management of the process and eliminates wastage.

- Defects – The McDonald’s process is simplified to eliminate delays caused by defects. As a result, they achieve high-quality standards with highly trained and motivated staff. That results in fewer defects, which in turn reduces waste.

The involvement of all employees at McDonald’s is very important to the company. The lean culture emphasizes teamwork and involving everyone in the process. From suppliers to staff serving customers, all team members are involved in the overall process.

Three strategic dimensions of the operational strategy for McDonald’s

- Value – Almost one million McDonald’s burgers are sold daily. Everyday processes are repetitive and systematic. The employees must ensure that the taste and quality of all the burgers are the same each time in order to manufacture such a large number of burgers.

- Varieties – In addition to breakfast items, fruits, vegetables, and salads, McDonald’s offers a variety of kid’s meals to meet the needs of their customers (Chia al. 2020). The McDonald’s menu consists primarily of chicken, beef, bread, milk, and potatoes. There are also local specials and new products on the menu that consumers are interested in. The Big Mac and French fries are on the menu, which is popular items. In Europe, it’s McWraps, in Australia, it’s Angus Burgers, and in the US, it’s McCafé that offers coffee and smoothies to attract customers new to the company.

- Variations – It is so well organized that McDonald’s can anticipate customer demands; meet changing capacity needs, and ensure flexibility. The demand for products is estimated by analyzing the historical mix of products available at individual stores over the last two years, as well as store-specific and national causal factors, such as events that happened on a given date.

Recommendations

As McDonald’s does have direct participation in the global market, and through controlled subsidiaries, has ample control over strategic marketing and its success to think deeply about how the business will develop over a period of many years, it should not adhere to some mismatch between expectations and situational requirements that arises from a breakdown to apply the marketing strategy procedure that is implemented in the core business.

- For McDonald’s to be successful with its operations and financial success, it is crucial that the company pays attention to its employees and their performances as well as adopting new ideas that could improve their efficiencies.

- Employees need to be made aware of the dangers related to food safety and hygiene.

- The implementation of McDonald’s operation management in the highly competitive fast-food industry of today requires the adoption of solutions such as blockchain technology to streamline its processes and to meet the required quality standards.

- Other services that the company can offer its customers who visit its stores must also be taken into consideration. A variety of facilities may be provided, such as comfortable seating arrangements whereby employees can meet with colleagues in a friendly and relaxed atmosphere while having access to easy Wi-Fi.

- Also, McDonald’s believes in multi-skilling, meaning each employee should have knowledge of all stages of the operation. Besides fostering a sense of ownership, the assembly line system also promotes a sense of responsibility in all the team members.

Conclusion

After discussing the issue above, it has now been concluded that while McDonald’s is among one of the famous and largest fast-food chains across the globe. Thus, it must improve the management of its operations, especially when considering the fierce competition in its industry. The organization must make use of all the opportunities that present themselves, including rapid technological development providing enormous benefits to the organizations, and must take advantage of such modern concepts in order to combat its competitors. A just-in-time strategy is incorporated by McDonald’s into its strategy. This allows the restaurant to serve fresh food quickly by working with the engaged suppliers who meet the requisite standards of product quality pre-determined by the said company. McDonald’s supply chain management has a lack of transparency that has led to various foods related scandals, so embracing the use of blockchain technology would be beneficial for the company. The enhanced performance quality will lead to higher profitability for the business due to a higher customer base created by the use of blockchain technology.

References

7 Wastes of Lean Manufacturing, (2022) [Online]. Accessed Through <https://leanmanufacturingtools.org/77/the-seven-wastes-7-mudas/>. Accessed on 11th January, 2022.

Abbas J., (2020) Impact of total quality management on corporate green performance through the mediating role of corporate social responsibility [Online]. Accessed Through <https://www.sciencedirect.com/science/article/abs/pii/S0959652619333281>. Accessed on 10th January, 2022.

Bak, S., (2020). 4. McDonald’s in Seoul: Food Choices, Identity, and Nationalism. In Golden arches east (pp. 136-160). Stanford University Press.

Byrne, J. and Pecchenino, R.A., (2019). Heigh Ho, Heigh Ho: flexible labor contracts with real option characteristics. Business Economics, 54(1), pp.25-34.

Chia, X.R., Kee, D.M.H., Khor, S.T., Chin, K.Y., Lok, T.X., Almutairi, H.A., Quttainah, M.A., Balakrishnan, H. and Kulkarni, S., (2020). Contributing Factors to Organizational Success: A Case Study of McDonald’s. International journal of Tourism and hospitality in Asia Pasific (IJTHAP), 3(2), pp.38-47.

Choi, T.M., Wallace, S.W. and Wang, Y., (2018). Big data analytics in operations management. Production and Operations Management, 27(10), pp.1868-1883.

Dekkers, J., (2020). From servant to driving force: Transforming the role of the supply chain in McDonald’s The Netherlands. Journal of Supply Chain Management, Logistics and Procurement, 3(1), pp.6-17.

Demir, A., (2019). THE IMPACT OF STRATEGIC OPERATIONS MANAGEMENT DECISIONS ON SHOPPERS’WELLBEING. Asian Academy of Management Journal, 24(1).

Edward, W.P., (2020). LEAN PRINCIPLES. European Journal of Academic Research-Volume, 1(1). Sage.

Gładysz, B., Buczacki, A. and Haskins, C., (2020). Lean Management Approach to Reduce Waste in HoReCa Food Services. Resources, 9(12), p.144.

Jain A., (2019) Supply Chain Management of McDonalds India [Online]. Accessed Through <https://medium.com/@jainaditya017/supply-chain-management-of-mcdonalds-india-58e1064274b5>. Accessed on 10th January, 2022.

Lagorio, A. and Pinto, R., (2021). Food and grocery retail logistics issues: A systematic literature review. Research in Transportation Economics, 87, p.100841.

Lemaire, A. and Limbourg, S., (2019). How can food loss and waste management achieve sustainable development goals?. Journal of cleaner production, 234, pp.1221-1234.

McDonald’s Logo and Its History, (2022) [Online]. Accessed Through <https://blog.logomyway.com/mcdonalds-logo-history/>. Accessed on 10th January, 2022.

Nagarajan, K., Kee, D.M.H., Thevarajan, R., Kumaran, S., Letchumanan, M. and Aziz, A., (2019). Efforts of McDonald’s Towards Green Environment: Case Study on McDonald’s. International journal of Tourism and hospitality in Asia Pasific (IJTHAP), 2(2).

Operations Management McDonald’s Paper Editing Services, (2022) [Online]. Accessed Through <https://www.ozassignments.com/solution/operations-management-paper-editing-services>. Accessed on 10th January, 2022.

Rajawat, A., Kee, D.M.H., Malik, M.Z.B.A., Yassin, M.A.Q.B.M., Shaffie, M.S.I.B.A., Fuaat, M.H.B., AlDosari, N. and Santoso, M.E.J., (2020). Factors: responsible for McDonald’s performance. Journal of the Community Development in Asia (JCDA), 3(2), pp.11-17.

Simonegrabner, (2015) SUPPLY CHAIN MANAGEMENT OF MCDONALD’S [Online]. Accessed Through <https://logisticsmgepsupv.wordpress.com/2015/05/13/supply-chain-management-of-mcdonalds/>. Accessed on 10th January, 2022.

Tarigan, Z., Mochtar, J., Basana, S. and Siagian, H., (2021). The effect of competency management on organizational performance through supply chain integration and quality. Uncertain Supply Chain Management, 9(2), pp.283-294.

Zain, M., Saadat, Z., Ali Khan, M. and A Arbi, K., (2020). Analytical Review of Bullwhip Effect in Manufacturing and Services Supply Chain: Analyzing How Workload Creates Bullwhip in Service Sector. International Journal of Management, 11(9).

________________________________________________________________________________

Know more about UniqueSubmission’s other writing services: