BSS054-6 Risk and Procurement Management Assignment Sample

Introduction

The process of procurement for any organization plays a major role in determining the effectiveness of the supply chain. Therefore, the following study would evaluate the case of Toyota. The findings of this study would help in the development of a bespoke procurement process for the organization. The report aims to identify three stages and methods of the procurement management process for the organization that would help Toyota to minimize the existing issues linked with its supply chain management and procurement. In this regard, the risk management process applied in the procurement process would also be discussed along with the different types of contractors and their importance in terms of collaboration. Furthermore, procurement processes are subject to contract breaches and thus, four types of contract breaches, as well as the ways through which they can be resolved, would also be discussed in the following report

Q1. Three stages and methods of a bespoke procurement process

In order to develop a bespoke procurement management process, it would be essential to identify the importance of the three stages involved in the procurement process that are planning negotiation and clearance. Hence, at present it has been seen that due to the existence of covid-19 pandemic organizations supply chain and production facilities have been greatly affected (Business today, 2021). As a result, it has also been identified that the organization is unable to achieve its annual target which requires the company to manufacture a minimum of 9 million vehicles. Due to the onset of the covid-19 pandemic, the organization had to shut down 5 major manufacturing plants and has led to the disruption in the production of at least 20,000 vehicles (Business today, 2021).

To ensure that the procurement process organization does not get affected by such disruptions it would be essential to hire two contractors for the company. A logistics contractor needs to be hired by the organization that would single-handedly operate all the logistics operations of the company as well as a raw material contract that would supply the raw materials to the organization (Rane et al. 2019).

Planning

The planning is the first stage of the procurement process; hence, the organization would identify the number of raw materials and items they need for the assembly of the vehicles. Thus, the organization can set out tenders to various suppliers and this would allow the organization to identify a range of different potential suppliers that the company can utilise. The planning stage would also require the organization to set a tender for a logistic partner that would help the organisation with all the logistics and transportation (Bag et al. 2020).

Negotiation

The negotiation is the second phase of the recruitment process and therefore, the company needs to effectively negotiate with the various suppliers that they have identified in the previous stage of the procurement management process (Duica et al. 2018). In this stage, the organisation would also negotiate with potential logistics contractors to identify a logistics and contract that can help the organisation to minimise the risk linked with all the logistics. It is essential to hire logistics contractors to ensure that their raw materials are delivered to the organisation at the right time as well as to ensure that the finished products are received by the dealers within the given time period. The effectiveness of the logistics contractor would determine the company’s ability to meet the demands in the market and would also help in achieving its annual goal of manufacturing 9 million vehicles (Heinis et al. 2021).

Clearance

The clearance stage is the final step of the procurement management process and in this regard, the organisation would need to carefully evaluate and quality checks the difference from materials sent by the suppliers. Toyota already utilizes a total quality management process in their manufacturing process and this would support their organisation’s clearance process effectively (Ershadi et al. 2021). Furthermore, Toyota is also known for utilising just-in-time (JIT) inventory system where collaboration of the raw material contract and the logistic contractor plays a major role.

Risk management by best for the procurement process

| Risk | Risk | Threat | Mitigation |

| Quality issues | 5 | High | The procurement process can be facing the risk of quality issues and in this regard, the organisation can meet quality issues by ordering a surplus of raw materials. Ordering surplus raw materials can help in minimising the risk of quality issues as the company would not need to return the entire stock that they have procured rather the damaged items (Harb et al. 2019). |

| Late deliveries | 3 | Medium | Late deliveries are another risk that the organisation can face as a part of its new bespoke procurement process; thus, it would be essential for the company to ensure that their assembly plants are aware of the extra time that the logistical deliveries are taking. This would keep the rest of the workforce prepared to achieve the deadlines. |

| Equipment breakdown | 3 | Medium | Equipment breakdown during the procurement process is another risk that attack and face and to mitigate such risks the organisation needs to have a technical team ready to fix any kind of equipment breakdown and technical issues (Tripathi and Gupta, 2020). |

| Injuries | 5 | High | To minimise the risk of injuries it would be essential for the organisation to ensure that health and safety measures are adopted throughout the production and requirement process |

Q2. Contractors and form of collaboration for the work package involved the procurement process

Logistics contractor

Logistics contractors play an extensively crucial role for Toyota as the company needs to procure the materials or parts to assemble the product into one whole part. It is the responsibility of the logistics contractor to deliver the items or parts to the company within the stipulated time (Winkelhaus and Grosse, 2020). However, it needs to be said that if the company delays the process, every related process of the company would be hampered and it can create issues in various departments. In addition to that, procurement is done to avoid the time and high costs of manufacturing the products. However, the inefficiency of the logistics contractor can put the company at the risk of not being able to assemble the products in time and thus the reputation and goodwill could be hampered (He et al. 2018).

The prime objective of Toyota is to satisfy the needs of the customers by fulfilling their desires of procuring a product within an affordable price range. However, to attain that it can be seen several times that the cost of making the products by the company themselves is becoming critical and along with that the time that is being consumed is extensive (Tang and Veelenturf, 2019). Therefore, certain parts are procured from other sources which give the company enough time to focus on other aspects and in addition to that saves the high cost of manufacturing. However, this process created a dependency on the contractors of the logistics. A high portion of the operations in the company becomes dependent upon the functioning and efficient management of the logistics. Without the support or cooperative nature of the logistics contractor, the whole vision or mission of the company can get affected extensively and the delivery of the products in time can get hampered. These significant inefficiencies can create issues with the branding of the company from the perspectives of the customers.

Furthermore, it needs to be said that to spread the presence of the company in the market positively, it needs to be efficient in all aspects of its operations and planning (Chua et al. 2018). Any delay or issue in any process, be it logistics or other, can hamper its operation which can directly affect the company’s reputation and functioning as a whole. In addition to that, the materials which are being supplied by the logistics need to be handled appropriately, otherwise even if the logistics arrive in time, any damage while they are in transit can create issues in both the company and the source from where the parts are arriving from.

Raw material contractor

Raw material contractors are referred to as those contractors, which supply raw materials to the company for producing the final product. Apart from outsourcing certain products, there are various parts of vehicles that are produced by Toyota themselves and used in assembling for manufacturing a whole product. Therefore, the contractors of the raw materials play a significantly crucial role in the functioning of the company. Raw materials are the essential parts while making the final product (Tisza and Czinege, 2018). However, the delay caused by the contractor in delivering the raw materials can delay the overall process of manufacturing a whole product. Even the company puts an extensive reliance on the raw materials contractors for providing them with the necessary raw material in time. The quantity ordered by the company needs to be provided by the raw materials contractor within the stipulated time otherwise several consequences and issues can emerge.

Consumers are the ultimate focus of the companies. Without attracting consumers into making purchases of products in the company would direct the company into excessive losses and risks of sustaining in the competitive marketplace (Kolotzek et al. 2018). Therefore, new and trendy products need to be manufactured which can ignite the desire of the customers into making the purchases; however, to do that, with the changing of times, appropriate production of the products becomes necessary which needs the utilisation of raw materials without which the whole process would be ineffective (Lundesjö, 2018). Therefore, the cooperation and the collaboration of the raw material contractor is essential as it is the base source from which the company would plan for its other related processes in the production processes.

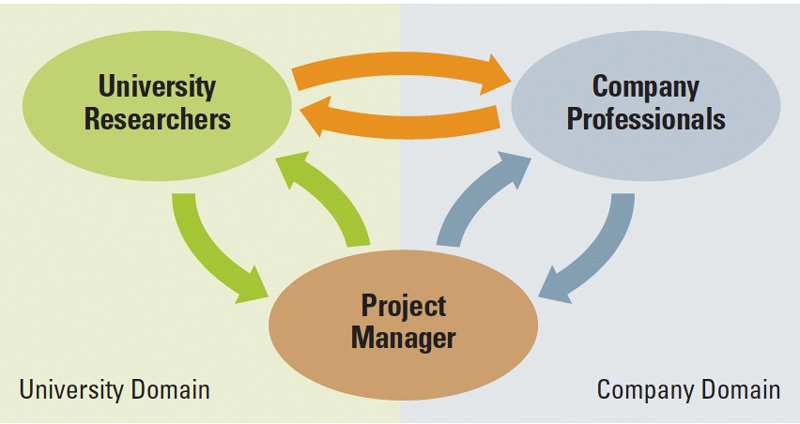

Collaboration between both the contractors

The collaboration between logistics and raw material contractors can be said as extensively crucial for Toyota. It can be said that both the contractors need to be efficient to rely on them for the procedures to be completed by the company. For instance, it needs to be stated that if the raw material contractor is efficient and provides the company with the necessary items on time but the logistics contractor because of certain reasons could not deliver the items produced by the raw materials on time to the company. On the other hand, if the logistics contractor of the company is efficient but the raw materials which were ordered from the contractors have been readied due to whatever reason the company can also encounter several challenges. Therefore, it needs to be stated that a healthy collaboration between both the logistics and the raw material contractor is necessary to operate the company efficiently and effectively without any interruption in the meanwhile processes (Heirati and Siahtiri, 2019).

In addition to that, it can be said that while forming a company, the organisations are said to be dependent on several factors. However, several companies are known to be operating all by themselves without having to outsource or depend on external sources. They are said to be completely independent and able to proceed with their work without depending on or relying on anybody. However, during the times, when the company has gotten bigger and needs to handle large scale operations also by maintaining the cheap rate of products to satisfy the customers, outsourcing certain elements becomes necessary for companies like Toyota. Therefore, a sound collaboration between both the contractors can positively impact the company on a huge scale for making new and existing products efficiently (Le Dain et al. 2020).

Q3. Potential contract breaches and methods of resolution

Agreements can be difficult to negotiate, primarily, whenever the externally or internally circumstances force a shift in engagement. In this context, the report will further proceed in identifying contract breaches along with their resolution effectively.

Minor breach

A minor breach is commonly known as a “Partial Breach of Contract” or an “Immaterial Breach of Contract”, occurs when the agreement’s deliverables are eventually received by another party, but the defaulting party fails to fulfil a certain element of the commitment (Gillani et al. 2021). In these types of situations, the person who has been affected may only be able to seek legal remedies if they can show that the infringement resulted in financial losses. If the breaching party lacks demonstrate that the delay manifested in financial consequences. For example, Toyota who makes sure and promotes safety concerns has been found to be accused of dealing with complaints against the company due to safety issues. The Prius vehicle has allegedly been noted as a risk for the drivers (FenderBender, 2019). Therefore, this sort of breach can be resolved by the rescission of the contract between both parties.

Material breach

Whenever one party accepts considerably less advantage or a markedly different consequence than what has been promised in the agreement, it is considered a major breach. Difficulties in completing the responsibilities set forth in a commitment, or inability to fulfil commitments made on time, are examples of material breaches (Dazzi et al. 2019). For example, there is an organisation or a manufacturing company has stated in their contract that they are about to provide certain signified parts for the products and in the end, they are unable to do so could be termed as a material breach. Furthermore, when a material breach develops, the opposite party might sue for damages for both internal and external consequences of the action to resolve the problems.

Actual breach

An actual breach happens when a party declines to accomplish their share of the arrangement by the given deadline or executes their tasks in an unsatisfactory manner. For example, a late delivery can be referred to as an actual breach. In this context, when this kind of incident happens, another party has numerous options for resolving the situation (Dubey and Dimri, 2021). This would include monetary damages to compensate for immediate financial losses arising from the breach, as well as a major setback, which seem to be indirect losses, which exceed the previous contract value but still are caused by the infringement.

Anticipatory breach

An anticipatory breach occurs whenever the other person or the party anticipates that perhaps the contract’s opposite party will fail spectacularly their terms of the deal later. This can be directly interlinked with the data security breach scenario of Toyota and Lexus dealers and thus, which has already formed an assumption about the possibility of foreseeable breaches in the company (Matthews, 2019). Moreover, in this instance, the non-breaching participant has the option of breaking the agreement and filing a lawsuit for penalties even before a breach has occurred.

Conclusion

The findings of the above study have helped in the identification of a base for the procurement management process that can be utilised by Toyota as a part of its supply chain management. The procurement management process has been distinguished into three different stages that involve different methods of procurement from suppliers and well as with the use of a logistical contractor. The study has also identified the importance of collaboration among the different contracts as the company is willing to hire as a part of its bespoke procurement management process. Furthermore, the risks linked with the contract breach as well as the ways through which these breaches can be addressed have also been discussed which can help Toyota in strengthening its entire bespoke procurement management process.

Reference

Bag, S., Wood, L.C., Mangla, S.K. and Luthra, S., 2020. Procurement 4.0 and its implications on business process performance in a circular economy. Resources, conservation and recycling, 152, p.104502.

Business today, 2021. Toyota to halt production at 5 factories in January due to supply chain issues. [Online]. Available at: <https://www.businesstoday.in/latest/story/toyota-to-halt-production-at-5-factories-in-january-due-to-supply-chain-issues-316198-2021-12-20#:~:text=The%20stoppage%20at%20the%20factories,to%20manufacture%20nine%20million%20vehicles.&text=Toyota%20Motor%20Corp%20said%20on,and%20the%20COVID%2D19%20pandemic.> [Accessed on 8 January 2021]

Dazzi, S., Vacondio, R. and Mignosa, P., 2019. Integration of a levee breach erosion model in a GPU‐accelerated 2D shallow water equations code. Water Resources Research, 55(1), pp.682-702.

Dubey, M. and Dimri, S., 2021. Effect of pandemic on performance of contracts and remedies to the cases of breach: Looking into legal responses. Linguistics and Culture Review, 5(S3), pp.1231-1240.

Duica, M.C., Florea, N.V. and Duica, A., 2018. Selecting the right suppliers in procurement process along supply chain-a mathematical modeling approach. Valahian Journal of Economic Studies, 9(1), pp.47-58.

Ershadi, M., Jefferies, M., Davis, P. and Mojtahedi, M., 2021. Achieving sustainable procurement in construction projects: The pivotal role of a project management office. Construction Economics and Building, 21(1), pp.45-64.

FenderBender, 2019. Jury Finds Toyota Liable for Breach of Contract. [Online] Available at: <https://www.fenderbender.com/articles/13140-jury-finds-toyota-liable-for-breach-of-contract> [Accessed on 8 January 2022]

Gillani, A., Kutaula, S. and Budhwar, P.S., 2021. Psychological contract breach: Unraveling the dark side of business-to-business relationships. Journal of Business Research, 134, pp.631-641.

Harb, A., Antoun, R.A., Kassem, A. and Baena, C., 2019. Empirical classification and effect of procurement process on organisational performance outcomes. International Journal of Procurement Management, 12(1), pp.88-111.

He, M., Shen, J., Wu, X. and Luo, J., 2018. Logistics space: A literature review from the sustainability perspective. Sustainability, 10(8), p.2815.

Heinis, S., Bamford, D., Papalexi, M. and Vafadarnikjoo, A., 2021. Services procurement: A systematic literature review of practices and challenges. International Journal of Management Reviews.

Heirati, N. and Siahtiri, V., 2019. Driving service innovativeness via collaboration with customers and suppliers: Evidence from business-to-business services. Industrial Marketing Management, 78, pp.6-16.

Kolotzek, C., Helbig, C., Thorenz, A., Reller, A. and Tuma, A., 2018. A company-oriented model for the assessment of raw material supply risks, environmental impact, and social implications. Journal of Cleaner Production, 176, pp.566-580.

Le Dain, M.A., Merminod, V. and Yager, M., 2020. Collaborative practices in new product development projects involving suppliers. Production Planning & Control, 31(4), pp.308-321.

Lundesjö, G., 2018. Consolidation centres construction logistics. Urban Logistics: Management, Policy and Innovation in a Rapidly Changing Environment, p.210.

Matthews, K., 2019. Incident Of The Week: Toyota’s Second Data Breach Affects Millions Of Drivers. [Online] Available at: <https://www.cshub.com/attacks/articles/incident-of-the-week-toyotas-second-data-breach-affects-millions-of-drivers> [Accessed on 8 January 2022]

Rane, S.B., Narvel, Y.A.M. and Bhandarkar, B.M., 2019. Developing strategies to improve agility in the project procurement management (PPM) process: Perspective of business intelligence (BI). Business Process Management Journal.

Tang, C.S. and Veelenturf, L.P., 2019. The strategic role of logistics in the industry 4.0 era. Transportation Research Part E: Logistics and Transportation Review, 129, pp.1-11.

Tisza, M. and Czinege, I., 2018. Comparative study of the application of steels and aluminium in lightweight production of automotive parts. International Journal of Lightweight Materials and Manufacture, 1(4), pp.229-238.

Tripathi, S. and Gupta, M., 2020. A framework for procurement process re-engineering in Industry 4.0. Business Process Management Journal.

Winkelhaus, S. and Grosse, E.H., 2020. Logistics 4.0: a systematic review towards a new logistics system. International Journal of Production Research, 58(1), pp.18-43.

………………………………………………………………………………………………………………………..

Know more about Unique Submission’s other writing services: