Assignment Sample on Comparative Life Cycle Analysis of Paper Towel and Cloth

Introduction

The rising population and demand for new products are continuously increasing, which has impacted businesses in the long run (Suszyński, 2020). At the same time, global economics and politics have played a significant role in altering global GDP growth where initially, GDP growth was calculated at up to 2% in 2018; however, the same decreased considerably by the end of 2022 due to growing contemporary business issues (Gourinchas, 2022). Even if issues like global economic slowdown, environmental, social, governance, CSR, and digital transformation are not extensive, worldwide entrepreneurs are constantly being affected, causing sustainability problems. According to the World Health Organization (WHO) reports, the use of paper towels is known to be convenient and useful; nevertheless, in recent years, the impact of paper towels has considerably caused global warming, deforestation, and ever-increasing waste problems (Drašković, 2020). Therefore, reusable cloth towel is an alternative to paper towels which will effectively contribute towards sustainability and environmental protection.

The present analysis of contemporary global challenges will investigate the life cycle assessment (LCA) of two products such as paper towels and cloth towels which have a respective environmental impact (Shah et. al. 2023). Moreover, the essay will highlight the need for sustainable innovation in hygiene practices by considering provided facts and figures, which will enhance sustainability and environmental balance.

- Paper Towel: As described by Kim (2022), a paper towel is a product made with paper that is generally used for drying hands, dusting, and wiping windows. The product is used as a conventional towel, and the majority of the population uses paper towels as they are easily disposable and avoid contamination. However, the environmental damage due to paper towels has significantly increased recently (Issa and Issa, 2020). According to U.S. EPA figures, around 3500 thousand tons of paper towels were used in 2020 which accounted for over 15 grams of carbon dioxide emissions. For the same, an equivalent of 270 million trees were destroyed, causing excessive deforestation.

| Composition of paper towel | Percentage (%) |

| Cellulose fibres | 30-45% |

| Water | 3-7% |

| Fillers | 12-25% |

| Chemical additives | 20-22% |

- Cloth Towels: Paper towels are made with simpler methods and ingredients. However, as per Kenters al. (2018), the negative impact on the environment has provoked a sense of emergence among entrepreneurs to think of other alternatives like microfibre cloth towels which is not only a sustainable product but rather provides higher absorbance and quality compared to a paper towel (Batabyal and Das, 2019). Today’s industries have replaced paper towels with cotton napkins and microfibre cloth towels as they are eco-friendly and fairly inexpensive.

| Fibres used in Microfibre cloth towels | Microns |

| Polyester filament | 22.7 |

| Acrylic dtex staple | 12 |

| Polyester fine | 11.1 |

| Polyester ultrafine | 3 |

| Polyester superfine | 2.1 |

| Silk | 12 |

Figure 1: Global paper towel market expectations till 2028

(Source: Data Bridge, 2022)

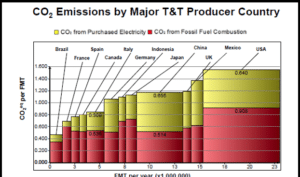

Figure 2: CO2 Emissions by Tissue Manufacturing Company

(Source: Informa, 2023)

Thus, the above-mentioned picture highlights Carbon emissions by major tissue manufacturing companies, where the USA accounted for the highest CO2 emission per FMT, where CO2 from chemical combustion was recorded at 0.6, and CO2 from purchased electricity for manufacturing tissues was calculated to be 0.90.

Lifecycle Analysis of two products: Paper Towel and Cloth Towel

Lifecycle assessment is a defined way of analyzing the potential environmental impacts of different products and services. Thus, for two products, paper towels and cloth towels, analyzing life cycle stages is important.

Raw Material Acquisition and Production

The material produced from synthetic fibers is composed of ultra-fine fibers that measure less than ten micrometers and weighs under 0.7 D. As the popularity of microfibre is increasing, people have started replacing paper towel with microfibre cloth towels due to higher sustainability and less environmental impact (Sergeenko et. al. 2022). On the other hand, paper towel is made up of ingredients like water, wood, pulp adhesives, and printing ink that has accounts for considerable environmental pollution. Moreover, according to Ahr et. al. (2023), paper towel production has significantly caused wildlife endangerment, greenhouse gas emissions, and rising global temperatures, which means there is an urgent need to replace the product with greater sustainability items.

Processing and Manufacturing

Compared to other products, the manufacturing of microfibre cloth towels is easy and requires less hydrolytic power, which signifies sustainability (Gurtu et. al. 2022). On the other hand, the use of two non-compatible fibers results in less heat generation, which again is an environmental advantage. However, the first step in paper towel manufacturing is preparing the pulp from wood fibers which requires excessive water and chemical additives that cause environmental pollution (Abd El-Sayed et. al. 2020). On the other hand, the bleach raisins used as a white coloring agent require cooling rollers which consumes a lot of energy.

Packaging

According to Ratnakumar et. al. (2021), Unlike packaging of paper towels where plastic films or poly wrap are used, microfibre packaging comes with eco-green packaging with reduced plastic content. Moreover, the towels are so finely packed that the pores of eco-green packaging restrict the entry of even the smallest dirt and bacteria, providing greater safety and cleansing (Deshwal et. al. 2019). Paper towel packaging is made of polyester and polyethylene, which has a high chance of combustion when exposed to heat.

Distribution and Supply

Since 2010, the use of tissue paper and paper towels has significantly increased. Almost every industrial sector, like hospitality, health and care, automotive, construction, Education, and manufacturing sector uses paper towels, which have increased global business challenges and carbon emissions (Jayasekara and Ratnayake, 2019). On the other hand, microfibres made of synthetic materials are less popular in today’s era. However, environmental reports suggest that soon the effective features of paper towels will be replaced by cloth towels in every industry, which will certainly impact the distribution and supply of both products.

Disposal

While both products cause waste after the usage, they need to be disposed of in an effective manner. Unfortunately, paper towels cannot be recycled because mixtures of wood, cardboard and pulp used for manufacturing paper towels weaken in later stages (Ahmed et. al. 2021). Thus, transforming and recycling paper towels is not possible. On the other hand, microfibre is technically recyclable and accounts for less environmental pollution. Moreover, the disposal of cleansing cloth towels also causes less contamination (FMI, 2021).

From the above comparison, it is noticed that microfibre made of synthetic fibers causes less damage to the environment and is easily recyclable. At the same time, paper towel is reported to contribute greatly to carbon emissions and deforestation, which has resulted in environmental damage (Gowthaman et. al. 2021). Moreover, production, packaging, and manufacturing practices also play a significant role in sustainability because when techniques are not efficient, it causes significant damage. In any case, the use of products should limit waste and enhance sustainability so that society and people are benefitted (Yan et. al. 2020). Among products like paper towels and cloth towels, the report will focus on recyclable cloth towels whose usage can be increased in the future by implementing sustainable innovations.

Sustainable Innovation of cloth towel

The unique cleansing product called microfibre is a lighter and thinner product that is created with a net-like woven structure that provides easy cleaning. The biggest benefit of microfibre over other cleansing products is that it is highly sustainable and causes lesser environmental damage (Javaid et. al. 2021). Since 1920, the use of tissue paper increased every year, and most industries neglected pollution caused by paper products. However, the consumption of paper towels increased significantly by the end of the 20th century which marked high environmental damage (Vijayaraghavan, 2021). Therefore, an alternative to paper towels was introduced in the market, which is not only environmentally friendly, rather it also emits fewer greenhouse gases resulting in nature protection and ecological balance.

Also, as per Pantaleon, (2023), the usability and popularity of microfibre cloth towels can be increased in upcoming years by focusing on carbon hotspots and focal actors. Earlier, the manufacturing industries neglected strategies and interventions to popularise products which resulted in compromised customer satisfaction (Tkaczyk et. al. 2020). Today, it is possible to focus on interventions that advance sustainability and decrease carbon emissions.

Absorbance

Before implementing innovative solutions to enhance microfibre quality, it is necessary to understand the factors of high-quality microfibre (Choi et. al. 2017). No doubt, the cloth towels used for drying, cleaning, and other purpose serves the purpose of cleaning; however, they are not of very good quality. Therefore, the company’s manufacturing cloth towels initially need to check for absorbance (Gowthaman et. al. 2021). The content of cellulose and microfibre should be enhanced in cleaning cloth towels. The reason being when microfibre is used in good amounts, it tends to dry and clean up the spills easily. Moreover, the interaction of water with the cloth towels increases when a high-quality microfibre is used.

Thickness and durability

Thickness and durability play a significant role in providing high-quality microfibre. Thickness and durability today are compromised because less than 250 microns of microfibre is used in 250 gms of a towel (Thomson, 2021). When the amount of microfibre is increased, it not only protects the towel from reducing its quality, but allows easy washing and recyclability. At the same time, sunlight and stretch tests should also be conducted to look for the quality of products. Manufacturing companies in Europe, America, and Africa have initiated sunlight stretch tests to ensure the cloth towels is of the highest durability and thickness (Javaid et. al. 2021). When thickness is good, it may last up to hundred washings.

Reduction in fabric softener

When excessive fabric softener is used, cloth towels cannot be reused and recycled. Therefore, the use of softener should be reduced. At the same time, when fabric softener is used in large quantities, it considerably reduces quality which ultimately results in a negative environmental impact (Tkaczyk et. al. 2020). Moreover, the drying capacity of microfibre cloth towels also decreases when more softener is added because when the product is directly exposed to heat and other chemicals, its drying capacity reduces. In addition, the microfibre becomes unfit for use when the cloth towel is bleached. Therefore, the use of softeners should be reduced.

Innovative solutions

From the above discussion, it can be said that advancing microfibre cloth towels proves to be advantageous for every industry as it improves ecological sustainability by consuming fewer resources. Almost every resource today is limited as human needs are growing. Furthermore, it is expected that, with the growing population, products and demands will eventually rise (Deshwal et. al. 2019). Thus, industries like the hospitality sector, healthcare, agriculture, construction, and miscellaneous industries should implement technologies that not only enhance ecological sustainability but also benefit the population by increasing the availability of reusable and recyclable products.

Factors like absorbency, durability, thickness, and quality must be focused on replacing paper towels with cloth towels in the future because, conceptually, cloth towels provide greater benefits in terms of environmental sustainability (Henry et. al. 2019). No doubt, manufacturing companies of cloth towels may face coordination and collaboration issues. However, in the future, the use of cloth towels will considerably increase, replacing paper towel and other drying materials.

Conclusion

The individual essay report summarises that microfibre cloth towels is 100% recyclable and reusable, so the environment suffers less. The reason is, its manufacturing involves products that use less water, less energy, and chemicals than paper towels. Moreover, processing, packaging, distribution, supply, and disposal of cloth towels is easy. Thus, most of the worldwide population is switching towards microfibre. Of the all the products introduced in the market, sustainability remains the main concern in modern world business. According to environmental statistics, global emissions due to unsustainable products have increased in past decades, which has not only affected the environment but has also resulted in ethical issues.

The lifecycle assessment of both products shows significant variation in raw materials, manufacturing, production, packaging, distribution, and disposal. Choosing a highly sustainable product that uses fewer resources benefits organizations and people in the society. Today citizens are aware of growing environmental destruction due to unsustainable manufacturing practices. Thus, switching to more advanced practices is necessary for balancing nature in the coming years. Even when adopting sustainable practices may cause several challenges where stakeholders may restrict collaborations due to different reasons. However, improving biological systems is necessary. Therefore, government and industrial officials should focus on collaboration between customers, legal bodies, manufacturers, suppliers, and traders for harmony and sustainability.

References

Ahmed, I., Zia, M.A., Afzal, H., Ahmed, S., Ahmad, M., Akram, Z., Sher, F. and Iqbal, H.M., (2021). Socio-economic and environmental impacts of biomass valorisation: A strategic drive for sustainable bioeconomy. Sustainability, 13(8), p.4200.

Ahr, E., Potvin, P., Charland, P., Chastenay, P., Brault Foisy, L.M., Bruyère, M.H., Boissard, B. and Cyr, G., (2023). The Paper Towels Challenge: an open-ended scientific inquiry activity to promote science understanding, scientific skills and 21st century skills. Science Activities, pp.1-10.

Batabyal, D. and Das, D.K. eds., (2019). Global Trends, Practices, and Challenges in Contemporary Tourism and Hospitality Management. IGI Global.

Choi, H.J., Kumita, M., Hayashi, S., Yuasa, H., Kamiyama, M., Seto, T., Tsai, C.J. and Otani, Y., (2017). Filtration properties of nanofiber/microfiber mixed filter and prediction of its performance. Aerosol and Air Quality Research, 17(4), pp.1052-1062.

Data Bridge, (2022). Global Facial Tissue Paper Market – Industry Trends and Forecast to 2028. [Online]. Accessed through: https://www.databridgemarketresearch.com/reports/global-facial-tissue-paper-market

Deshwal, G.K., Panjagari, N.R. and Alam, T., (2019). An overview of paper and paper based food packaging materials: health safety and environmental concerns. Journal of food science and technology, 56, pp.4391-4403.

Drašković, L., (2020). After washing one’s hands, they should be dried with a paper towel, and towels should be washed more. [Online]. Accessed through: https://www.unicef.org/montenegro/en/stories/after-washing-ones-hands-they-should-be-dried-paper-towel-and-towels-should-be-washed-more

Ecosystems United, (2021). What is a life cycle assessment? what the different parts of a life cycle assessment? [Online]. Accessed through: https://ecosystemsunited.com/(2020)/06/22/what-is-a-life-cycle-assessment-what-the-different-parts-of-a-life-cycle-assessment/.

FMI, (2021). Microfibre Cleaning Cloth Market. [Online]. Accessed through: https://www.futuremarketinsights.com/reports/microfiber-cleaning-cloth-market

Gourinchas, P.O., (2022). Global Economic Growth Slows Amid Gloomy and More Uncertain Outlook. [Online]. Accessed through: https://www.imf.org/en/Blogs/Articles/2022/07/26/blog-weo-update-july-2022

Gowthaman, N.S.K., Lim, H.N., Sreeraj, T.R., Amalraj, A. and Gopi, S., (2021). Advantages of biopolymers over synthetic polymers: Social, economic, and environmental aspects. In Biopolymers and Their Industrial Applications (pp. 351-372). Elsevier.

Gurtu, A., Johny, J. and Buechse, O., (2022). Paper and packaging industry dynamics during COVID-19 and their strategies for the future. Strategic Management-International Journal of Strategic Management and Decision Support Systems in Strategic Management, 27(4).

Henry, B., Laitala, K. and Klepp, I.G., (2019). Microfibres from apparel and home textiles: Prospects for including microplastics in environmental sustainability assessment. Science of the total environment, 652, pp.483-494.

Informa, (2023). Carbon benchmarking for tissue manufacturing. [Online]. Accessed through: https://www.tissueworldmagazine.com/technical-theme/carbon-benchmarking-for-tissue-manufacturing/

Issa, T. and Issa, T.B., (2020). Contemporary global challenges and ethical mindsets. Journal of Information, Communication and Ethics in Society, 18(2), pp.183-196.

Javaid, M., Haleem, A., Singh, R.P., Suman, R. and Rab, S., (2021). Role of additive manufacturing applications towards environmental sustainability. Advanced Industrial and Engineering Polymer Research, 4(4), pp.312-322.

Jayasekara, S. and Ratnayake, R., (2019). Microbial cellulases: an overview and applications. Cellulose, 22, p.92.

Kenters, N., Gottlieb, T., Hopman, J., Mehtar, S., Schweizer, M.L., Tartari, E., Huijskens, E.G.W. and Voss, A., (2018). An international survey of cleaning and disinfection practices in the healthcare environment. Journal of Hospital Infection, 100(2), pp.236-241.

Kim, R.C., (2022). Rethinking corporate social responsibility under contemporary capitalism: Five ways to reinvent CSR. Business Ethics, the Environment & Responsibility, 31(2), pp.346-362.

Omni calculator, (2022). Hand Drying Footprint Calculator. [Online]. Accessed through: https://www.omnicalculator.com/ecology/hand-dryers-vs-paper-towels.

Pantaleon, L., (2023). Environmental Cleaning and Disinfection. In Infection Control in Small Animal Clinical Practice (pp. 112-127). GB: CABI.

Ratnakumar, A., Samarasekara, A.M.P.B., Amarasinghe, D.A.S. and Karunanayake, L., (2021). Cellulose microfibres from traditional rice straw: Physicochemical properties and analytical characterization. Materials Today: Proceedings, 45, pp.5714-5719.

Sergeenko, Y.S., Erokhina, T.V., Galkina, O.V., Devyatov, O.V., Yakushenko, S.M. and Utalieva, M.A., (2022). Contemporary Challenges Vs. Legal Protection Of Workers. European Proceedings of Social and Behavioural Sciences.

Shah, S.H.A., Aman, N., Al Azhari, S., Alvi, B., Amjad, R., Ishaque, F.I., Kiani, O.I. and Sheikh, M.Z.A., (2023). How Frugal Innovation, Social Transition, and Business Sustainability Are Related: Insights on the Contemporary Transition Towards Sustainability. In Frugal Innovation and Social Transitions in the Digital Era (pp. 167-176). IGI Global.

Suszyński, C., (2020). Revolutionary context of the evolution of a business enterprise. In Contemporary Challenges in Cooperation and Coopetition in the Age of Industry 4.0: 10th Conference on Management of Organizations’ Development (MOD) (pp. 345-358). Springer International Publishing.

Thomson, K., (2021). Microfibres. Renew: Technology for a Sustainable Future, (155), pp.57-64.

Tkaczyk, A., Mitrowska, K. and Posyniak, A., (2020). Synthetic organic dyes as contaminants of the aquatic environment and their implications for ecosystems: A review. Science of the total environment, 717, p.137222.

Vijayaraghavan, V., (2021). Are Paper Towels Bad for the Environment? [Online]. Accessed through: https://www.nomomente.org/post/are-paper-towels-bad-for-the-environment#:~:text=That’s%20an%20average%20of%2040,by%20a%20whopping%20200%25

Yan, S., Henninger, C.E., Jones, C. and McCormick, H., (2020). Sustainable knowledge from consumer perspective addressing microfibre pollution. Journal of Fashion Marketing and Management: An International Jour

Know more about UniqueSubmission’s other writing services: