EBSC7190 Global Logistics and Supply Chain Management Assignment Sample

Module code and Title: EBSC7190 Global Logistics and Supply Chain Management Assignment Sample

Introduction

Global logistics and supply chain management is described as the process of managing the flow of resources (products) between consumers and businesses. Global logistics is the process of acquisition of products, the way goods are stored, and the methods of transporting the products in the supply chain (Zijm et. al. 2019).

The portfolio is focused on describing the concept of global logistics and supply chain management concerning the case of fast fashion T-shirts. It will initiate the supply chain design of fast fashion T-shirts with the help of diverse supply chain tools and models. Along with that, the risks associated with the supply chain are described adequately and mitigation strategies are also proposed.

Global Logistics and supply chain management

Global logistics is a small segment of supply chain management combining the flow of goods, services, capital, and information right from raw material to end customer. On the other hand, supply chain management is a broader term concerned with the sourcing of raw material, procurement of consumer requirements, transforming raw material into final goods, and distributing it to end customers (Sweeney et. al. 2018).

The primary difference between logistics and supply chain management is that supply chain management is the movement and coordination of supply chains of an organisation; whereas, logistics management is the procedure of maintenance and integration. The five primary components of logistics involve storage, warehousing, materials handling, packaging and unitisation, inventory, transport, information, and control.

Due to increased globalisation, global logistics have achieved significant importance. It is necessary to have improved global logistics services along with better transportation for the movement of products and services from one region to another. Logistics plays a crucial role in achieving business success in a globalised world (Khan and Yu, 2019).

Global logistics is being supported by improved trade logistics like infrastructure development including roads & highways, railways, airports, ports, and more. Development in warehousing infrastructure is also helpful in supporting global logistics. The economic development and success of any business organisation primarily depend on the trade logistics in the global market nowadays.

Supply chain design

Supply chain design is defined as the process by which a company manages and structures the supply chain so it can have the right balance between manufacturing cost, inventory, and transportation (Sabouhi et. al. 2021). The supply chain design is majorly used for establishing a balance between supply and demand during various unpredictable situations by managing inventory efficiently. In today’s fast fashion era, consumer demands are changing frequently which increases the supply chain complexity to a great extent.

Fast fashion is highly responsible for changing the market dynamics and apparel categories items are now kept half as long as they were kept a decade ago. With the changes in consumer demands and fluctuations in fashion trends and clothing, the organisation has to expand their wardrobes affordably so they can keep up with the latest trends. It has changed the way consumers are purchasing and currently the fast fashion industry is around $2.5 trillion and it is expected to grow by 43% in 2029.

Supply chain design of Fast Fashion T-shirt

Due to continuous changes in consumer demands and market trends the concept of fast fashion has evolved. Organisation operating using a fast fashion business model has to change their clothing design every one-two month on average so they can stay competitive (Camargo et. al. 2020). The fast fashion industry and competitors operating in the sector change their T-shirt designs every two-three months so they can follow the market trends and current fashion.

It demands a highly responsive supply chain as it is core to the organisation’s success. It is necessary to operate and monitor supply chain operations effectively to manage global business operations. While designing a supply chain for fast fashion T-shirts some elements need to be kept into concern. These elements are described below:

Shortest lead times: Fast fashion means taking fashion trends from the runway or social media and producing them to bring a purchasable garment in less possible time. While designing a supply chain for fast fashion t-shirts it is necessary to have the shortest possible lead time from designing to distributing or delivering to the end customer (Li et. al. 2018). For instance, the fast fashion company Boohoo takes 2 weeks for designing, manufacture, and dispatch the design. Therefore, having the shortest lead time is necessary for being responsive to customer demands and trends.

Test and repeat: Fast fashion primarily depends on changing trends continuously and it is necessary to avoid brands from having high amounts of inventory the companies can’t sell (Arrigo, 2020). For this purpose, the organisation needs to use a test and repeat model suggesting that the organisation must try out styles and ranges before producing them in bulk.

Outsourcing: This approach helps in keeping the price as low as possible. As per Pal et. al. (2019) through this approach, the organisation aims at choosing countries that have low labour and manufacturing costs and utilise the low-cost transportation method so the garments can be transported to the place they are being sold.

Sustainability: Fast fashion is highly responsible for environmental pollution and the fashion sector accounts for around 10% of carbon emissions and 20% of freshwater pollution (Niinimäki et. al. 2020). Diverse initiatives are adopted for reducing the environmental impact like sustainable cotton communiqué. Therefore, the fast-fashion t-shirt supply chain should also be designed to keep sustainable initiatives into concern.

Supply chain management

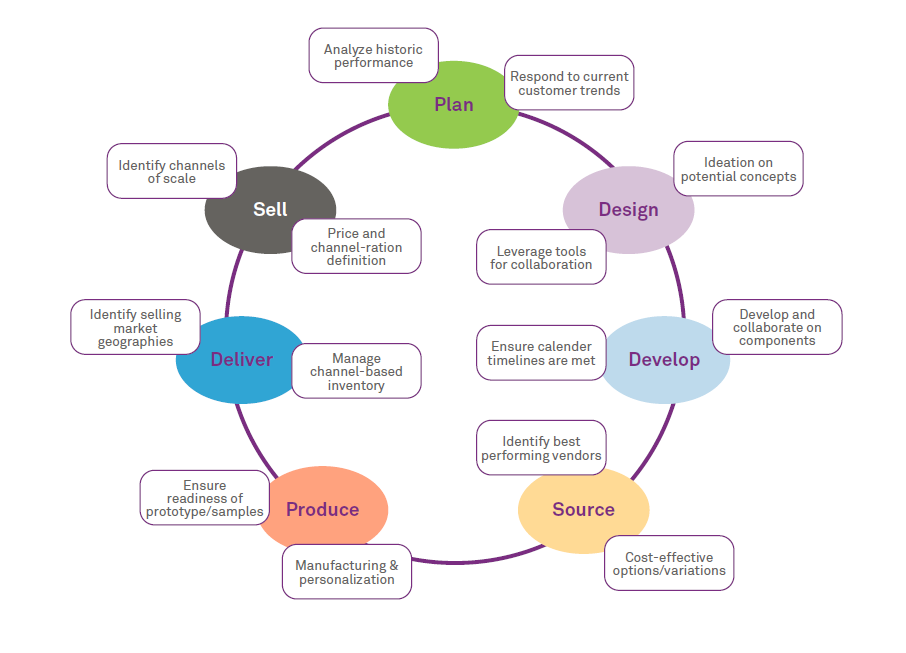

Supply planning is described as the entire planning procedure that plans for distribution, manufacturing, procurement, and more to implement a successful supply chain. During their supply planning, the designing of t-shirts is done to select raw materials and manufacture them effectively.

While planning, the place from where raw materials are sourced, the place where the manufacturing process will be done and more will be planned in this stage (Buzzo and Abreu, 2019). After the supply planning is done sourcing of raw materials is done that will further transform into finished goods for distribution.

Figure 1: Supply chain design of fast fashion. (Source: A Breakdown of the fashion supply chain, 2019)

Figure 1: Supply chain design of fast fashion. (Source: A Breakdown of the fashion supply chain, 2019)

The supply chain of fast-fashion t-shirts should focus on supplying raw materials in bulk so they can be transformed into final products as per demands. While sourcing raw materials, the organisation needs to form a strong relationship with its suppliers and negotiate with them effectively so the raw material can be supplied cost-efficiently.

After sourcing raw materials, the raw materials are then sent to factories and production plants for the manufacturing process. Once the manufacturing process is done, the finished goods are then loaded into transports for delivery to the warehouse (Backs et. al. 2021). Once they reach the warehouse, the goods are then delivered to different stores and outlets for their journey to end customers.

The fast model of supply chain

It is the model most primarily used by the organisation that produces products having a short market lifecycle making it most efficient and common for distributing products that are considered trendy. The model applies to the companies that change their products frequently and deliver the finished product to market till it loses its trend (Guercini and Runfola, 2020).

The fast model is primarily used by fast fashion brands so they can set up a delivery system for new supplies to deliver them into the market before it loses their trend. Fast fashion has achieved significant importance nowadays and it is necessary to have effective supply chain design for fast fashion t-shirts so they can reach to end customer before the trend goes out and a new trend comes in.

Furthermore, with the help of this model, the organisation would be able to work as per customer perspectives. Customer’s opinion suggests that company should be capable of updating their product portfolio and bringing in the latest market trends to achieve success in the fast fashion business (Nguyen et. al. 2020).

Further, the company needs to have an informed and effective logistics system that supports the concept of a fast model and delivers the product before the trend goes out. Hence, the fast model will help in implementing supply chain design for fast fashion t-shirts effectively.

Agile and lean supply chain

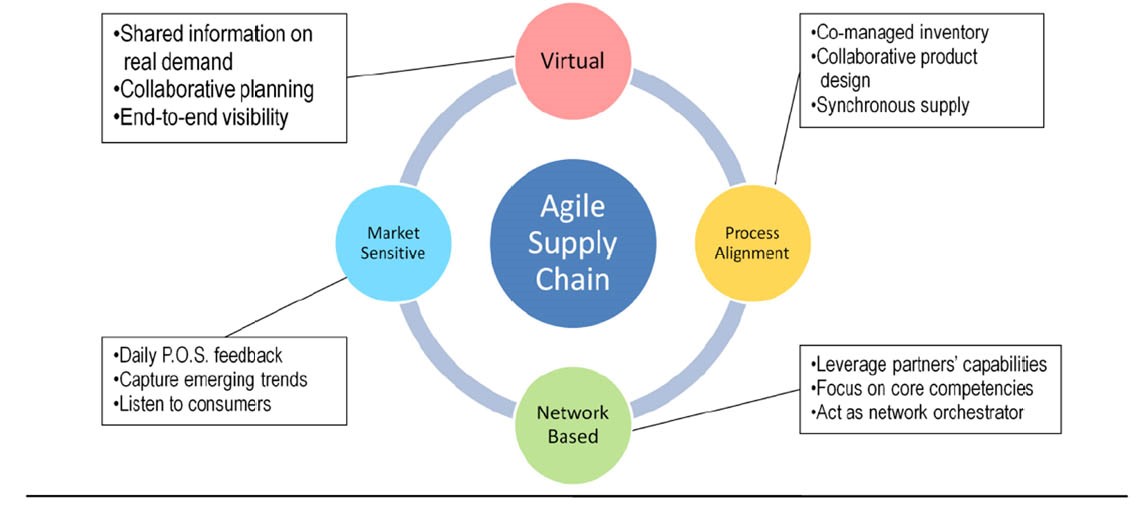

The agile supply chain is described as the system of product distribution concerning doing things quickly, cost savings, maintaining flexibility, keeping productivity high, and being responsive to market demands. Agility in the supply chain is necessary for today’s era of fast fashion. Four primary components need to be considered in the agile supply chain model (Sabegh et. al. 2019). It includes process alignment, virtual integration, network base, and market sensitivity.

Virtual integration is described as the process of tracking changes in market demand in real-time. Fast fashion is all about being responsive and adapting to market-changing demands effectively. With the help of virtual integration, the organisation would be able to identify the fashion trends in real-time. Process alignment is the concept of sharing supply chain responsibilities across the business effectively (Agile supply chain management, 2020).

This helps in segmenting all the activities so all the business operations can be completed successfully. It can be managed if the organisation has co-managed inventory, all parts of the supply chain should run in sync, effective product designing, and many more.

Figure 2: Agile supply chain. (Source: Agile supply chain management, 2020)

Figure 2: Agile supply chain. (Source: Agile supply chain management, 2020)

Network-based is that every member involved in the supply chain should contribute equally to supply chain success and growth. At last, market sensitive element helps in changing the production rate by monitoring the demand changes (Gupta and Gentry, 2018).

With the help of virtual integration and market-sensitive element, the organisation would be able to bring changes in production as per changes in demands or changes in market trends. This model is best suitable for companies that operate in a market having a high degree of demand variation.

Supply chain risks and mitigation strategies

Political and government changes: Political instability is the major concern of the supply chain as the changes in the exchange rate, import and export taxes, and more can affect the price of final products. The pandemic was responsible for inflation, recession, and changes in tax rates in many regions that affect the cost of products and transportation (Pandey et. al. 2021).

In the UK Brexit has impacted the supply chain and trade to a huge extent. An organisation must be aware of one or more suppliers so they can connect with them during such events or they should be aware of some shippers that operate outside of the affected government to stay unaffected by these risks.

Economic instability: Economic instability is another major threat to global logistics. For example, the decline in the economic growth of one country has the potential to a reduction in global supply chain shipping capacity (Lahane and Kant, 2021). Other than that, economic instability affects diverse supply chain operations as well which can affect business growth. It is necessary to focus on the economic conditions of the country along with its future forecasts to plan strategically.

Covid-19 and Brexit: Unpredictable events like Brexit and Covid-19 have brought diverse supply chain risks that affected the business finances and economic growth due to great extent. Many fast fashion companies have faced troubles either while sourcing raw materials or distributing products because of transportation bans (Ozdemir et. al. 2022). The economic downturn has affected the spending power of consumers as well. Hence, it is necessary to have flexibility and agility in the supply chain so the organisation’s supply chain can deal with such unpredictable events.

Conclusion

The trend of fast fashion in the fashion industry is increasing rapidly and to operate efficiently it is must that the company has an agile and flexible supply chain. Supply chain management is the process of sourcing raw materials and transforming them into finished goods till delivering them to final customers. On the other hand, global logistics is the concept of handling inventory, warehousing, and distribution and it is a part of SCM.

The report has described the fast model and agile model of the supply chain as would help the organisation in managing the supply chain effectively and cope with the changing trends in the fashion industry. At last, supply chain risks associated with the political environment, economic instability and unpredictable events like Covid-19 and Brexit have been analysed.

References

Arrigo, E., (2020). Global sourcing in fast fashion retailers: Sourcing locations and sustainability considerations. Sustainability, 12(2), p.508.

Backs, S., Jahnke, H., Lüpke, L., Stücken, M. and Stummer, C., (2021). Traditional versus fast fashion supply chains in the apparel industry: an agent-based simulation approach. Annals of Operations Research, 305(1), pp.487-512.

Buzzo, A. and Abreu, M.J., (2019). Fast fashion, fashion brands & sustainable consumption. In Fast fashion, fashion brands and sustainable consumption (pp. 1-17). Springer, Singapore.

Camargo, L.R., Pereira, S.C.F. and Scarpin, M.R.S., (2020). Fast and ultra-fast fashion supply chain management: an exploratory research. International Journal of Retail & Distribution Management, 48(6), pp.537-553.

Guercini, S. and Runfola, A., (2020). Adapting business models in buyer-seller relationships: paradoxes in the fast fashion supply chain. Journal of Business & Industrial Marketing.

Gupta, S. and Gentry, J.W., (2018). Evaluating fast fashion: Examining its micro and the macro perspective. In Eco-friendly and Fair (pp. 15-23). Routledge.

Khan, S.A.R. and Yu, Z., (2019). Strategic supply chain management. AG: Springer International Publishing.

Lahane, S. and Kant, R., (2021). Evaluation and ranking of solutions to mitigate circular supply chain risks. Sustainable Production and Consumption, 27, pp.753-773.

Li, J., Liu, C., Zeng, X. and Zhang, N., (2018). Optimization and coordination of crowdsourcing supply chain in fast fashion industry. Mathematical Problems in Engineering, 2018.

Nguyen, H.T., Le, D.M.D., Ho, T.T.M. and Nguyen, P.M., (2020). Enhancing sustainability in the contemporary model of CSR: A case of fast fashion industry in developing countries. Social Responsibility Journal.

Niinimäki, K., Peters, G., Dahlbo, H., Perry, P., Rissanen, T. and Gwilt, A., (2020). The environmental price of fast fashion. Nature Reviews Earth & Environment, 1(4), pp.189-200.

Ozdemir, D., Sharma, M., Dhir, A. and Daim, T., (2022). Supply chain resilience during the COVID-19 pandemic. Technology in Society, 68, p.101847.

Pal, R., Shen, B. and Sandberg, E., (2019). Circular fashion supply chain management: Exploring impediments and prescribing future research agenda. Journal of Fashion Marketing and Management: An International Journal.

Pandey, S., Singh, R.K. and Gunasekaran, A., (2021). Supply chain risks in Industry 4.0 environment: review and analysis framework. Production Planning & Control, pp.1-28.

Sabegh, M.H.Z., Caliskan, A., Ozturkoglu, Y. and Cetiner, B., (2019). Testing the effects of agile and flexible supply chain on the firm performance through SEM. In System Performance and Management Analytics (pp. 35-46). Springer, Singapore.

Sabouhi, F., Jabalameli, M.S. and Jabbarzadeh, A., (2021). An optimization approach for sustainable and resilient supply chain design with regional considerations. Computers & Industrial Engineering, 159, p.107510.

Sweeney, E., Grant, D.B. and Mangan, D.J., (2018). Strategic adoption of logistics and supply chain management. International Journal of Operations & Production Management.

Zijm, H., Klumpp, M., Regattieri, A. and Heragu, S. eds., (2019). Operations, logistics and supply chain management (pp. 978-3). Cham: Springer.

Online

A Breakdown of the fashion supply chain. (2019). [Online]. Accessed through: <https://www.wipro.com/engineering/a-breakdown-of-the-fashion-supply-chain/>

Agile supply chain management. (2020). [Online]. Accessed through: <https://conspecte.com/en/supply-chain-management/agile-supply-chain-management.html>

Learning Log

Week-1

The primary topic of discussion in Week-1 is logistics and supply chain management. As per the lectures, we have learned that the supply chain is described as a network of diverse processes that helps in transforming raw materials into final products for the end consumer. It has been learned in the lecture that nowadays competition is between organisation’s supply chain and not between companies. Unlike traditional purchasing, SCM primarily focuses on the total cost of ownership.

On the other hand, I have understood that logistics is the process of integrating the maintenance and movements of products in an out of the organisation and its primary aim is to enhance customer satisfaction. The two primary business models have been discussed as well including the push-based and pull-based models. The agile supply chain has been chosen in the business report concerning the case.

Week-2

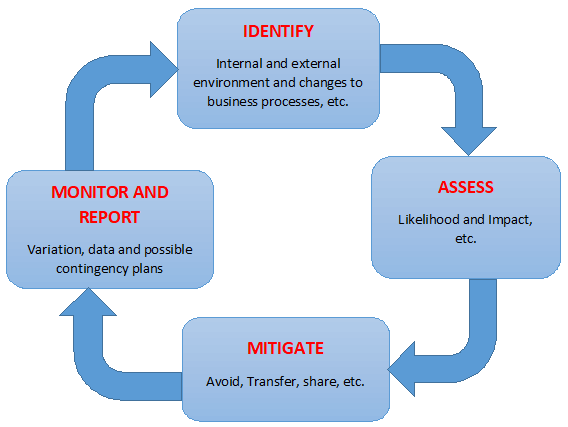

In Week-2, the primary discussion was on supply chain risk management and resilience. The current focus is on the risk management framework. It is necessary to manage risk in the supply chain to achieve agility and flexibility in the supply chain. I have understood that it is necessary to identify that risk exists, its impact, things to avoid, and ways to mitigate it. The risk management framework discussed in the lecture has four primary stages including identifying, assessing, mitigating, monitoring, and reporting.

The first stage is to identify the internal and external market environment, current changes in business processes, and many more. I have understood that identifying the risk associated with these changes is must to address those changes. The second stage is assessing focusing on evaluating the probability of risk occurrence and its impact on the supply chain. The third stage focuses on planning for mitigating strategies and the last stage is to monitor and report the risk.

Week-3

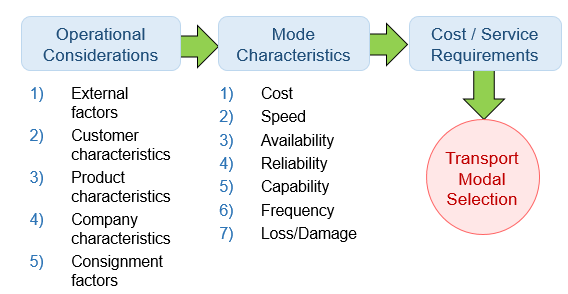

In this lecture, various modes of transportation in logistics operations have been discussed. The primary topic selected is the criteria for modal selection. The factors considered before choosing the transportation mode include operational considerations, mode characteristics, and cost/service requirements. It helps in choosing the best transportation mode as per the factors analysed.

It includes an analysis of external factors, customer characteristics, product characteristics, company characteristics, and consignment factors. Based on this analysis, cost, speed, availability, reliability, capability, frequency, and loss/damage are analysed. I have understood that comparing all the factors and choosing the transport modal selection that will be cost-effective.

Week-4

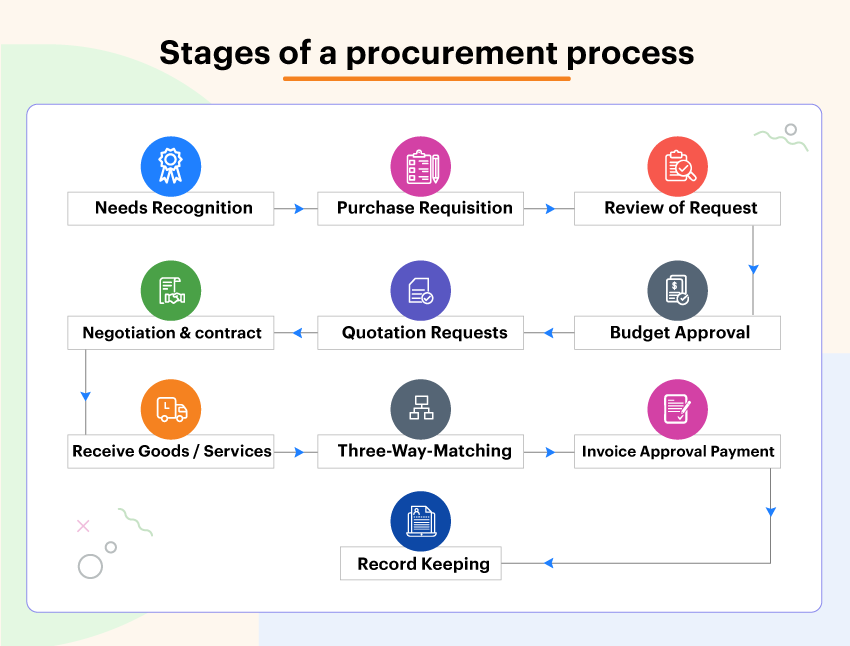

The week-4, has discussed the concept of purchasing, sourcing and procurement. The importance of understanding the procurement cycle is essential to have efficient supply chain. The procurement cycle includes 10 essential steps as per the lecture.

It includes recognition of need, specification, make or buy decision, source identification, source selection, contracting, contract management, receipt and inspection, payment, and fulfilment of need. The utilisation of procurement cycle helps in identifying the need and focuses on selecting the source that best meets the need of the customer and finally meet the need.

Week-5

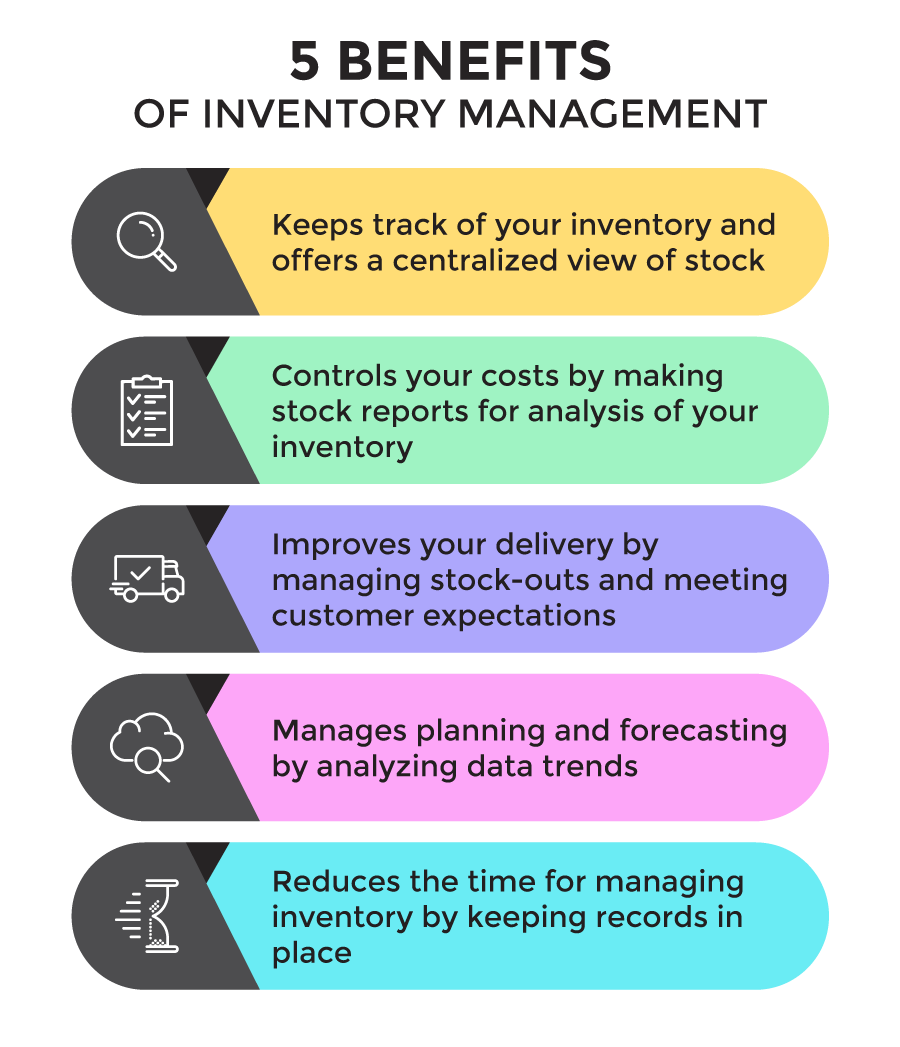

The focus of the Week-5 lecture is on inventory management in supply chain management. Inventory is described as the product that makes operations efficient in the manufacturing process by decoupling individual segments. Inventories have been classified into four primary segments including production inventory, MRO inventory, and finished goods inventories. Two types of inventory levels have been discussed which include high-level inventories and low-level inventories. Managing inventory is also necessary as both excess and low level of inventory can disrupt the delivery process.

Know more about UniqueSubmission’s other writing services: