Global Supply Chain and Operations Management Assignment

Assignment Sample on Global Supply Chain and Operations Management Assignment.

Executive summary

This report is based on the impact of Industry 4.0 for improving the supply chain of an organisation and its impact on operation management. There are some specific technologies mentioned in case of understanding the impact of it. The possible ways are mentioned to utilise it to improve the business performance. Therefore, this also impacts the employees of the organisation and helps to maintain the working environment. There are some theories mentioned that help provides the information of using this faculty to its maximum usage. Rather this, there is some recommendation that an organisation have to keep in mind for their development process.

1. Introduction

Industry 4.0 is a revolutionary change for the organisation that implies advanced production processes and innovative operation techniques with the help of advanced technology. This helps the organisation to track the organisational performance, resource status and the performance of tier employees to maintain the workflow of the organisation. These revolutionary changes provide competitive advantages to the organisation to step ahead from their competitors in this competitive market. This report provides information about the effect of using industry 4.0 in various organisational departments and factors. The aim of this report is to know the impact of industry 4.0 in organisational operations and the supply chain management of an organisation.

2. Main Body

2.1 Impact of industry 4.0 on supply chain

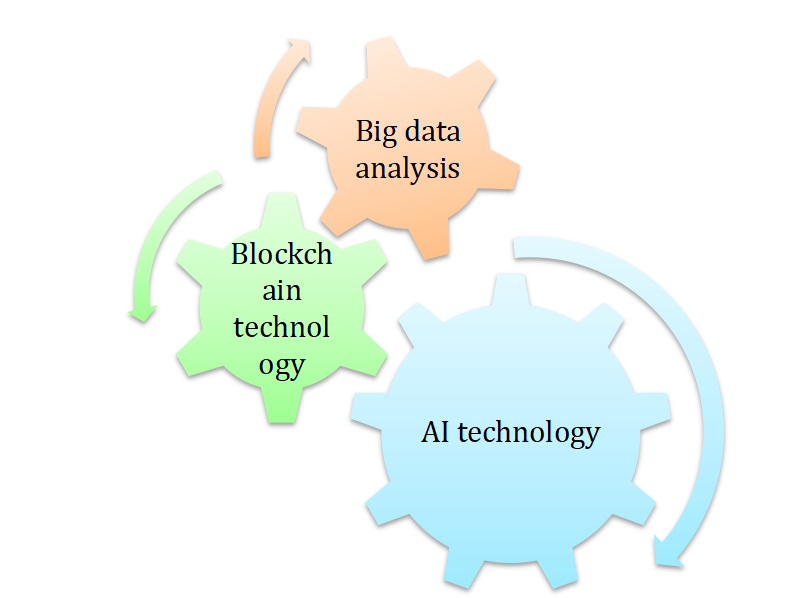

In the modern world, organisations are into using advanced features to improve the organisational performance and most of the organisations are depending on bringing revolution as an implementation of industry 4.0. Industry 4.0 helps to improve the production process and the organisational operation techniques. This process implements new advanced technologies such as AI technology, human robots, block chain technology, big data analysis and all. The Supply chain process is the key to maintaining the resources in time. Proper supply chain management help to provide raw materials and equipment to the project site and maintain the workflow of an organisation. Other than this, a proper supply chain management process helps maintain the relation with the resource provider that helps to maintain the quality of the raw materials and the supplier provide the raw materials in the problematic situation of the organisation (Luthra et al. 2020). This helps to mitigate the loss of the organisation and the employees are able to fulfil the project in the meantime.

Figure 1: Advanced technologies in Industry 4.0

(Source: Self-Made)

Impact of AI technology

The organisation is able to improve the production of the organisation and is able to develop their products that fulfil the demand of their customers. Improved product quality helps to attract more customers to organisation products the organisation can increase their loyal customer base. In this case, AI technology plays an important role. It is able to provide information about issues and risk factors of the organisation and it also helps the management team of an organisation to develop a competitive strategy that is able to maintain the supply chain management process (Torresen, 2018). AI technology helps the organisational team to get updates about the resources of the organisation as well as the information of the area management process of an organisation.

Impact of Block chain technology

Other than this, there is a block chain analysis process that is important to improve the supply chain management process of a company. Block chain analysis develops the supply chain process and helps to mitigate the issues of this process (Niranjanamurthy et al. 2019). The block chain process reduces the cost of the raw material that provides an advantage to the organisation in the long run. This analysis process improves the visibility and traceability of an organisation. However, the customers are able to track their order and this helps to gain customer trust towards the organisation and their service. An organisation implements human robots to boost the performance of the organisational employees. These human robots help to maintain the quality of the products by utilising those raw materials and it improves the production function of a company. Supply chain sustainability helps the organisation to maintain the workflow and continuously develop their products to the demands of their customers. Apart from this, Without having proper supply chain management the organisation are is unable to improve its business and the organisation maintain the annual income of the organisation (Saberi et al. 2019). The supply chain is the process that should be developed continuously as it provides the raw material to the employees and the organisation to produce the organisational products. The supply chain management process helps to analyse multiple suppliers and their resource percentage and the organisation can hire an affordable supplier who can provide quality raw material to the organisation in the meantime. In this case, the organisation has to look after the quality of the raw material, other than this, they are unable to maintain the quality of their products and satisfy their customers. Industry 4.0 implements these technologies to improve the supply chain management of an organisation that improves the over the performance of the organisation. A company can be able to expand their business in the meantime as well as great the competitive advantages of using this feature.

2.2 Impact of industry 4.0 on operation management of a company

The operation management process helps the department to maintain the workflow of the organisation and look over the individual performance of the organisation. This department is responsible for improving the performance of the employee. Other than this, the organisation is able to expand their business and improve their growth through hiring trained employees who are capable of performing in problematic scenarios, and they are able to motivate their teammates. The operation management has to hire proper employees that are able to improve the performance of the organisation and also maintain the working environment (Fathy and Abdelaziz, 2018). These departments track the performance of the individual employees and get the issues they are facing in case of performing a task. Then this hierarchy implies industry 4.0 and advanced technologies to improve the performance of the employees.

Training and development process

Training and development process is necessary for the employees to adopt new skills and make them able to take work pressure and perform in sudden problematic situations. This department uses advanced technologies to improve the decision-making process of the organisation. Fast and effective decisions help them to mitigate the issues and it reduces the time-consuming part for the working environment. On the other hand, the hierarchy uses advanced technology such as cognitive management processes, AI technologies and other technologies to get the information of the whole infrastructure of the organisation and the work efficiency of the employees (Rodriguez and Walters, 2017). AI technologies help the organisation to improve the strategies and the training procedure of those employees and the management team is able to analyse the possible outcomes of those strategies. Improving the skills of the organisational employees also impacts on managing various departments.

Goodwill development

The employees are able to maintain the supply chain management procedure and import quality raw materials and use them to develop high-quality products. Other than this, IR 4.0 also helps employees to manage the stakeholders of the organisations that maintain the relationship with their customers and other people and this creates the goodwill of the organisation (Vogne et al. 2018). The organisation can build trust among their customers and make a loyal customer base that helps them in the long run in this competitive market. Employees are the face of an organisation and are the key to recognising the demand of their customers. Apart from this, the customer engagement process is improved by one to one conversation and the organisation gets those data and information that helps them to develop innovative products according to the demands of their customers. This is the reason the operation management have to mitigate the issues of their employees by which they are able to get better customer interaction and handle any vast situation and maintain the company workflow. The operation team has to provide the opportunity to their employees to utilise the advantages of the advanced technology that makes them take effective decisions. IR 4.0 also improves the performance of the operation management team by which they are able to look over multiple departments and the work progress of their employees and able to take possible steps to improve the organisational performance as well as maintain organisational workflow.

2.3 Impact of Industry 4.0 on organisational performance

Industry 4.0 is able to improve the operational management of an organization and improve the performance of a company through implementing advanced technology to the organisational infrastructure. In case of improving organisational performance, this revolutionary method provides the facility to the employees and the management team of the organisation. Advanced technology helps the organisation to develop innovative strategies to improve its performance. Other than this, it provides the opportunity to the management to get the information of the issues and risk factors that are creating hurdles in the path of development. The hierarchy of management is able to track the individual performance of their employees. The employees are able to get information about their issues and the leaders provide training sessions to their employees to improve their skills (Dong et al. 2017). Therefore, this helps the employees to improve their individual skills to perform better in their task and it improves the organisational performance. Apart from this, industry 4.0 helps to maintain the relationship between managers and employees. The managers provide the necessary development process and motivate their employees to improve their performance. This improves the working environment and it improves the concentration of the employees by which they are able to improve their work efficiency. Industry 4.0 helps to improve the Manufacturing Execution Systems (MES) that help to improve the workflow of the organisation. Other than this, this IR 4.0 are able to improve the Industrial Internet of Things (IIoT) that help to provide information of with the company the issues that an organisation are facing and the management team are able to develop an effective strategy to improve the supply chain management process, operation management process and it improves all overgrowth of a company.

Therefore, the hierarchy should provide training sessions to the employees based on their issues. It may increase the cost and time duration of a company but it helps improve the performance of the organisation and they will look after multiple tasks and perform their best. In this scenario, an organisation can use motivation theory and leadership theory to improve employee performance (Shafiei and Maleksaeidi, 2020). IR 4.0 provides the advantage to a company to utilise the advanced technology and implement to improve the performance of their employees and motivate them to improve their skills. There are Herzberg’s motivation theory can be implemented in case of improving employee motivation. This motivational theory helps them to share their ideas and strategies with others. This helps the organisation to get new ideas that can be utilised to develop the strategies. Therefore, the leaders should implement the involvement of every employee in a particular project that helps them to overcome their doubts as well as improve their performance. In this case, the organisational manager may arrange meeting sessions with their employees and inform them of their performance on the weekly basis. Proper interaction with their employees helps to build a healthy relationship with their employees. Improvement of the skills of those employees improves the supply chain management process of the organisation. The employees are able to concentrate on their tasks and the organisational team get the update of their resources. If there are any sudden issues faced by the organisation, this IR 4.0 process finds a possible way to improve that citation to mitigate the financial loss of the company. The internal relation of a company plays an important role in case of improving the performance of the organisation. A healthy relation between manager and employee helps the organisation to mitigate the risk of having sudden issues between the employees and they perform and support each other to improve their performance and it develops the business growth in this competitive market.

2.4 Impact of industry 4.0 on people of the organisation

Organisational people are the most important person to run a business. This is the reason organisations have to take care of their employees. The employees are the people which use to collect data and information through several surveys or from web surfing. Then, they utilise it for the development of the organisation. The organisation is able to improve its whole infrastructure through the support of their employee performance. Apart from this, the hierarchy of an organisation has to develop organisational strategies based on the potentiality of their employees. Other than this, organisational people also maintain the working environment of a company and mitigate the issues of having internal issues between the employees (Riyanto et al. 2017). IR 4.0 help to boost the performance of the employees and help them to identify the faults they are having that are creating barriers to improve either performance. The employees are able to resolve those issues and improve their individual skills to improve their performance. Other than that, it helps the organisation to improve the performance of the management team as they can able to provide responsibilities to those employees and look after every department and resolve the issues. IR 4.0 provides the facility to the organisation to get the information of their competitors and it provides motivation to the employees to perform their best to get an advantage for their organisation.

Employees of an organisation interact with people and provide customer service and this creates a positive view for the company in the customer’s mindset. Most of the customers do not go for the organisational products, they go for the customer service they can have and technical support for the organisational product. This creates goodwill in their mind and they refer their relatives and friends to buy products from that particular organisation and get the opportunity to have their customers’ service. This helps to gain the trust of the organisation and using IR 4.0 helps them to improve the performance of their customer service. IR 4.0 helps the organisation to solve the queries of their timers through utilising their employee empowerment. IR 4.0 help to clear the vision of the employee and give them a particular organisational goal that has to be fulfilled for the development of their company and people of an organisation tries to achieve it together that improves the organisational performance.

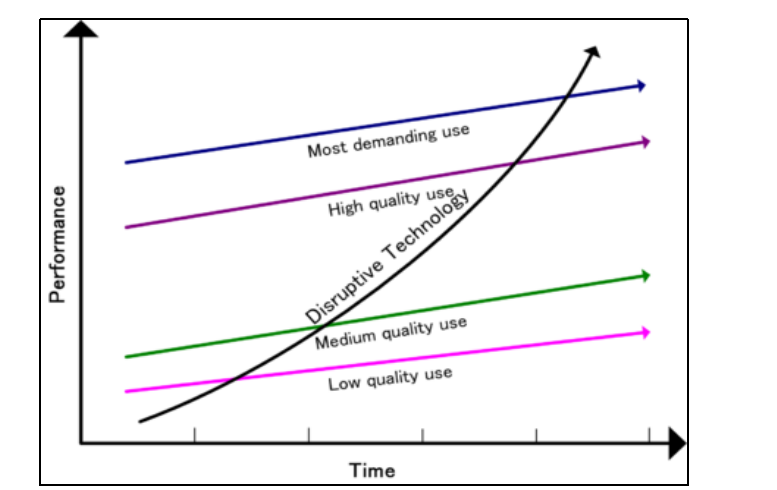

Disruptive innovation theory

Figure 2: Descriptive innovation model

(Source: Heikkilä and Bowman, 2018)

This theory helps an organisation to know about the information of their competitors that are currently emerging in the market. The organisation is able to make an effective strategy to maintain its organisational position. Other than this, this theory also helps the organisation to enhance its performance through utilising advanced technologies and production management processes. Advance technology helps the organisation to improve an innovative and sophisticated product to attract more people towards their organisation. Then, the customer sales for the customer develop goodwill for the organisation and the people get motivated to get those products from that company and it increases the sales percentage of the organisation (Vogne et al. 2018). In this case, IR 4.0 helps to improve the supply chain procedure that helps the organisation to improve its performance. Other than this, IR 4.0 helps the operation management team to provide training sessions to employees to improve the performance of their employees and the organisation is able to develop innovative products to increase the demand in the market (Dong et al. 2017). Disruptive theory helps the organisation to get competitive advantages and increase its loyal customer base.

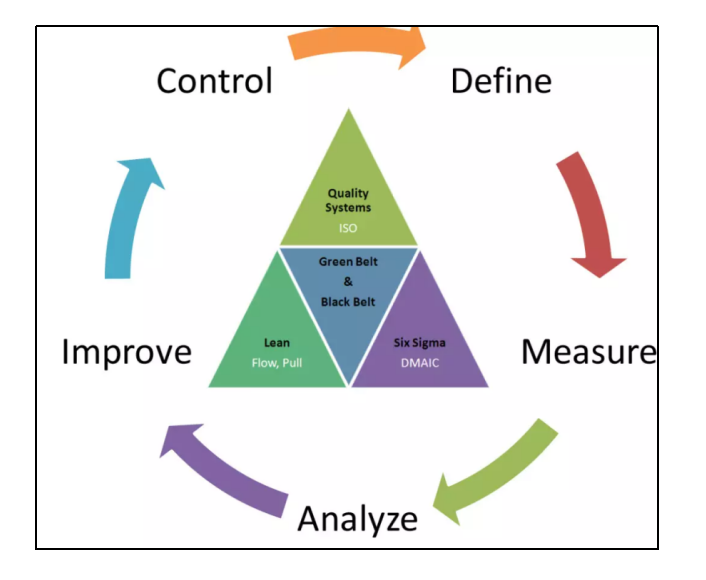

Six sigma theory

Figure 3: Six sigma theory model

(Source: Wang et al. 2019)

This theory helps the organisation by providing some tools that are able to improve the products and service quality of the organisation. It is a data-driven process and it provides information to the management team on the possible ways to improve the business procedure. Therefore, it helps to mitigate the manufacturing risks of a tan organisation that decrease the cost of the organisation and the company is able to utilise it in the other departments. In this scenario, the organisation is able to use IR 4.0 to analyse the organisational issues and to improve or control it that defines the workflow of the organisation. This theory focuses on the managerial approach of the organisation can able to decrease the rate of defective products and reduce the percentage of having waste materials (Trimarjoko et al. 2019). This theory provides the data and information of the project and the management can use this theory and utilise the advanced technology to improve the quality of the products that help to increase the annual income of the organisation and develop their business.

3. Recommendations

- The organisation should have proper financial backup to implement this IR 4.0 and utilise its facilities. Financial backup helps them to install those advanced technologies to improve the performance of the employees’ and the organisation are able to improve their workflow. As it has a high to maintain the technologies at their maximum potential.

- An organisation should have a proper source of power supply for operating those advanced technologies for the development of their company and their business growth. Proper power helps the employees and management team to operate the technologies 24*7 properly and an organisation can able to mitigate all of its risk factors and issues.

- An organisation should an experienced technical team to operate them properly and if there are any issues that have been found in those technologies. They can resolve it in the meantime. Rather than this, the technical tea is able to update the features and set them according to the project requirements.

- The organisation is able to maintain the procedure of those technologies and try to evolve the working process of the organisation and develop their strategies. The organisation has to make up strategies to utilise those technologies for the improvement of the company.

4. Conclusion

This report is based on the effect of IR 4.0 on the development process of operation management and an organisation’s supply chain management process. This assessment provides the utilisation of advanced technology and the impact of the technologies in case of improving the operations of an organisation and improving the skill set of the employees. Other than this, there is the process mentioned that improved the organisational performance and the employee performance. Therefore, there is a brief description of the theories that provide the information of the topic and have a better understanding. These theories can be applied to implement this IR 4.0 and other technologies. This report provides information on the importance of employee motivation and having good relationships with employees.

References

Dong, Y., Bartol, K.M., Zhang, Z.X. and Li, C., 2017. Enhancing employee creativity via individual skill development and team knowledge sharing: Influences of dual‐focused transformational leadership. Journal of Organizational Behavior, 38(3), pp.439-458. Available at: https://www.researchgate.net/profile/Chenwei-Li-4/publication/308293733_Enhancing_employee_creativity_via_individual_skill_development_and_team_knowledge_sharing_Influences_of_dual-focused_transformational_leadership/links/59dfea86aca272386b633f30/Enhancing-employee-creativity-via-individual-skill-development-and-team-knowledge-sharing-Influences-of-dual-focused-transformational-leadership.pdf

Fathy, A. and Abdelaziz, A.Y., 2018. Single and multi-objective operation management of micro-grid using krill herd optimization and ant lion optimizer algorithms. International Journal of Energy and Environmental Engineering, 9(3), pp.257-271. Available at: https://link.springer.com/article/10.1007/s40095-018-0266-8

Heikkilä, M. and Bowman, H., 2018, June. Business Model Innovation in European SMEs-Descriptive analysis of quantitative survey and case survey data. In Bled eConference (p. 4). Available at: https://www.researchgate.net/profile/Marikka-Heikkilae/publication/325768809_Business_Model_Innovation_in_European_SMEs_-_Descriptive_analysis_of_quantitative_survey_and_case_survey_data/links/5b3344fa4585150d23d5b45f/Business-Model-Innovation-in-European-SMEs-Descriptive-analysis-of-quantitative-survey-and-case-survey-data.pdf

Luthra, S., Kumar, A., Zavadskas, E.K., Mangla, S.K. and Garza-Reyes, J.A., 2020. Industry 4.0 as an enabler of sustainability diffusion in supply chain: an analysis of influential strength of drivers in an emerging economy. International Journal of Production Research, 58(5), pp.1505-1521. Available at: https://derby.openrepository.com/bitstream/handle/10545/624165/IJPR.pdf?sequence=1&isAllowed=n

Niranjanamurthy, M., Nithya, B.N. and Jagannatha, S., 2019. Analysis of Blockchain technology: pros, cons and SWOT. Cluster Computing, 22(6), pp.14743-14757. Available at: https://www.academia.edu/download/58091776/Analysis_of_Blockchain_technology__pros__cons_and_SWOT_new_document_treated.pdf

Peter, F., Adegbuyi, O., Olokundun, M., Peter, A.O., Amaihian, A.B. and Ibidunni, A.S., 2018. Government financial support and financial performance of SMEs. Academy of Strategic Management Journal, 17. Available at: http://eprints.lmu.edu.ng/2288/1/Government-financial-support-and-financial-performance-1939-6104-17-3-207.pdf

Riyanto, S., Sutrisno, A. and Ali, H., 2017. The impact of working motivation and working environment on employees performance in Indonesia stock exchange. International Review of Management and Marketing, 7(3), pp.342-348. Available at: https://dergipark.org.tr/en/download/article-file/367764

Rodriguez, J. and Walters, K., 2017. The importance of training and development in employee performance and evaluation. World Wide Journal of Multidisciplinary Research and Development, 3(10), pp.206-212. Available at: https://www.researchgate.net/profile/Kelley_Walters/publication/332537797_The_Importance_of_Training_and_Development_in_Employee_Performance_and_Evaluation/links/5cefe41092851c4dd01ba833/The-Importance-of-Training-and-Development-in-Employee-Performance-and-Evaluation.pdf

Saberi, S., Kouhizadeh, M., Sarkis, J. and Shen, L., 2019. Blockchain technology and its relationships to sustainable supply chain management. International Journal of Production Research, 57(7), pp.2117-2135. Available at: https://farapaper.com/wp-content/uploads/2019/04/Fardapaper-Blockchain-technology-and-its-relationships-to-sustainable-supply-chain-management.pdf

Shafiei, A. and Maleksaeidi, H., 2020. Pro-environmental behavior of university students: Application of protection motivation theory. Global Ecology and Conservation, 22, p.e00908. Available at: https://www.sciencedirect.com/science/article/pii/S2351989419305955

Torresen, J., 2018. A review of future and ethical perspectives of robotics and AI. Frontiers in Robotics and AI, 4, p.75. Available at: https://www.frontiersin.org/articles/10.3389/frobt.2017.00075/full

Trimarjoko, A., Saroso, D., Purba, H., Hasibuan, S., Jaqin, C. and Aisyah, S., 2019. Integration of nominal group technique, Shainin system and DMAIC methods to reduce defective products: A case study of tire manufacturing industry in Indonesia. Management Science Letters, 9(13), pp.2421-2432. Available at: http://m.growingscience.com/msl/Vol9/msl_2019_187.pdf

Vogne, T., van Zuylen, E. and IANIA, L., 2018. 9-year analysis of the impact of goodwill and other intangible assets on the EBITDA of FMCG companies listed on the Euronext: 2009-2017. Available at: https://dial.uclouvain.be/downloader/downloader.php?pid=thesis%3A15298&datastream=PDF_01&cover=cover-mem

Wang, X., Wen, D., Wang, W., Suo, M. and Hu, T., 2019. Application of biological variation and six sigma models to evaluate analytical quality of six HbA1c analyzers and design quality control strategy. Artificial cells, nanomedicine, and biotechnology, 47(1), pp.3598-3602. Available at: https://www.tandfonline.com/doi/pdf/10.1080/21691401.2019.1642207

Know more about UniqueSubmission’s other writing services: