KB7030 Department of Mechanical and Construction Engineering Sample Assignment

Introduction

The improvement of the economy, construction speed, and environmental performance are key variables that challenge the modern construction industry to balance. The use of innovative prefabricated construction techniques is one of the strategies used to achieve this goal. Therefore, there is a growing demand for detailed scientific research that addresses the potential environmental benefits of pre-production, especially in the use of materials accumulated through waste reduction and better efficiency. Prefabricated module structures that have great likely to change conventional construction techniques at a rapid rate due to the fast delivery and convenience of the site (Li et al. 2014).http://KB7030 Department of Mechanical and Construction Engineering Sample Assignment Pre-synthesized building modules (for example office space, apartments, stairs case, etc.) can be built with architectural finish and services in a perfectly controlled factory environment, ready for distribution and integrated on-site to form supporting structures. Nowadays, most manufacturers fill any architectural design with innovative modular units accordingly.

This study provides an overview of the pre-fabricated construction techniques and intended to highlight the sustainable features of this method compared to conventional construction methods. It was found that a predetermined system with a steel structure reduces the use of materials by 80% compared to conventional concrete construction. Yet, the prefabricated steel building increases the resistance of concrete compared to the concrete building which has essential characteristics of the steel-making process. This form has the potential to make a significant contribution to improving the sustainability of the environment in the construction industry while providing faster production with investment value (Zabihiet al. 2013).http://KB7030 Department of Mechanical and Construction Engineering Sample Assignment

Literature Review

Prefabrication is becoming increasingly used universally as another construction method. The main reasons are affordable and efficient construction methods that save materials and time in building a strong, robust building shell. At present, in Japan, the prefabrication industry is a skilled and sophisticated industry of its own in the world. In addition to highly restrictive building codes for energy efficiency and human comfort, the building structures must prevent catastrophe. In 2011, modular temporary buildings were used to help prevent a catastrophic tsunami. Presently, the new project called “New Temporary House” was created to set up a manufacturing production line in emerging Asian countries that could efficiently build housing units before the disaster strikes. In 2009, the government of China also announced the distribution of nearly one large area. Million pre-modified housing units for Sichuan Province after the earthquake struck. Along with that, the prototype of the sustainable pre-fabricated Zero Energy House was created, which combines sustainable practices to promote the use of regional materials for pre-fabrication (Alwanet al. 2017).http://KB7030 Department of Mechanical and Construction Engineering Sample Assignment

Features of prefabricated modular structures

Buildings will not be based on a particular module as modern architecture brings innovative design. Building designers can design a building in a traditional way to meet the wishes and market demands of a client. The building was then adjusted and divided into units suitable for transport in width and length and adjusted to the height of the site by a crane at the site. Building remodeling has been shown to reduce construction waste by up to 52%, mainly through a small number of spin-offs (Musa et al. 2014).http://KB7030 Department of Mechanical and Construction Engineering Sample Assignment

As a result, there are significant improvements in energy, construction costs, and time savings. The features (modules) of this construction unit are as follows:

- Every component of a building, together with stairs, elevator shafts, corridors, facades, and services, can be included in these modules.

- The modules produce a manufacturing facility whose quality is controlled in addition to better quality control as well as more economics.

- The size and shape of the module may differ for any anticipated architectural plan, in which dimensions can be limited depending on the layout of the transport (for example traffic level, the highest restriction on road, which required to be traveled on during the module transport).

- Future modules are easily detached from the mainframe for future relocation or recycling. At present, numerous developed economies have a market for used modular units.

- There is negligible work to do to complete the buildings as facades and interiors are a part of the modules themselves.

- Currently, modular constructions reduce construction time by more than 50% the site-intensive buildings.

- Reducing construction time means that modular homes become comfortable for end users only after conventional construction.

A review of the prefabricated building

While prefabrication has become a viable option for the reconstruction of cities with a relatively small workforce available, prefabrication in the construction industry has its roots in the years after World War I. Along with that, factory-built homes in the United States were built to support major economies during the Great Depression (1929-39) developed. After World War II, Europe and Japan used housing built to meet the needs for extensive rebuilding. Although the manufactured buildings were originally designed for low-income end-users, the method of construction is now becoming attractive to a wider market (Chiu and Chu, 2012).http://KB7030 Department of Mechanical and Construction Engineering Sample Assignment

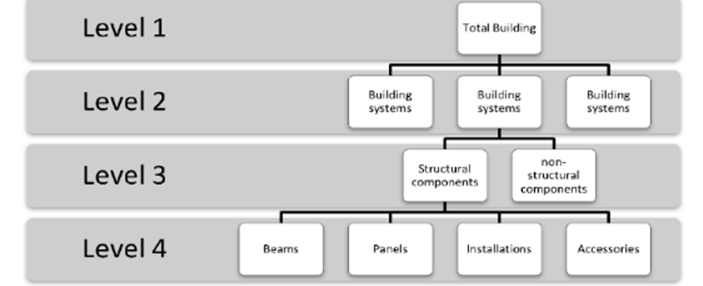

Prefabrication is defined as “the practice of manufacturing the components of a structure in a factory and transporting complete or semi-complete assemblies to the construction site where the structure is to be located”. Moreover, the scope of pre-fabrication ranges from the construction of individual components to the construction of the entire building. Harris and McCaffer (2013) proposed four basic levels, together with system prefabrication, total building prefabrication, element prefabrication, and component prefabrication illustrated in Figure 1.

Figure 1: Four basic levels of prefabrication in construction

Prefabrication can also be classified as volumetric or non-volumetric. In this way, Non-volumetric prefabrication includes single sections or components that are moved to the project site for installation and assembly, for example, cold-steel panels/structures, precast concrete, structured insulated panels (SIPs), prefabricated trusses, and panelized walls. In addition, non-volumetric prefabrication methods eliminate the assembly of various components in the factory and prevent wastage of transportation space, however, the process of connecting components to the construction site increases the complexity of the construction. Besides, volumetric prefabrication involves the production and assembly of free-standing building units in a secure factory environment. In the residential sector, volumetric prefabrication is modular, produced, and classified as a park home (Lovell and Smith, 2010).http://KB7030 Department of Mechanical and Construction Engineering Sample Assignment

Modular construction has been used interchangeably in the industry over the past decades. The Modular Building Institute defines modular construction as the process of transporting all large volumetric units to the site for the constitution as a design and monolithic process of building modules under defined off-site conditions. The module should be a self-sustaining and structured unit that may or may not be finished in the factory. Modular construction is mostly used for housing and small commercial buildings, but high-rise buildings have some recent applications. Modular homes are different from manufactured homes because they do not have a fixed axis (Tykkäet al. 2010). http://KB7030 Department of Mechanical and Construction Engineering Sample AssignmentAlso, they must comply with all local building codes for their proposed use, just like any conventional building.

Manufactured housing is the process of producing building units in a permanent chassis and transporting one or more sections to a construction site. Houses manufactured must meet both the US Housing and Urban Development (HUD) requirements in both the construction and manufacturing process. Along with that, Manufactured Housing Industry (MHI) is one of the most affordable housing providers in the United States. Moreover, MHI shows that 14% of all new single-family homes sold in the United States, including 14% of manufactured homes and shipped homes, increased by 15% in 2016 (Monahan and Powell, 2011).http://KB7030 Department of Mechanical and Construction Engineering Sample Assignment Along with that, the park models are one of the kind manufactured homes built on trailers that are much smaller than ordinary homes and designed for short-term use. Besides, park models are commonly used for recreational purposes, and must be below 400 square feet (Kamali and Hewage, 2017).http://KB7030 Department of Mechanical and Construction Engineering Sample Assignment

On the other hand, prefabrication can be used to construct a resilient building potentially. The most significant benefits for coastal areas are as follows:

- Rapid Replacement of Damaged Buildings:

The controlled factory environment enables the construction and assembly of components. If the project’s design is already completed, the factory can begin the construction of the material either before or after a natural disaster. However, since the building industry generally responds to a project-by-project claim, the possibility of up-front investment for pre-production projects should be debated (Pan et al. 2012).http://KB7030 Department of Mechanical and Construction Engineering Sample Assignment

- Affordability:

Prefabricated projects are generally cheaper than conventional projects. Financing is also available for manufactured housing and can be extended to modular construction.

- Environmental Benefits:

A system that combines Prefabrication strategies with sustainable policies has the potential to be efficient and responsive. Prefabrication materials and sites have the potential to reduce the difficulty. A significant benefit is the ability to isolate and reuse components at the end of the project life. For example, modules or components can also be returned to the factory where materials for new projects can be recycled and reused.

- Resistance and durability:

Prefabricated construction has explicit building codes and requirements for at-risk areas such as storm-risk zones and floodplains. The building materials used for modular building are not different from the conventional building, but the technique of assembly of components in the prefabrication can increase the resistance of the entire building. Building codes have been updated for manufactured homes, but there should be continuous studies of methods to improve these buildings (Kamali and Hewage, 2016).http://KB7030 Department of Mechanical and Construction Engineering Sample Assignment

- Community resilience:

Incentives for regional production can also encourage the establishment of community-based resilience and provide a tool to increase participation.

- Innovation:

Conventional construction methods create a building that must be stable enough to withstand any external energy. But this approach is not always effective, especially when referring to natural disasters when faced with constantly changing conditions, buildings should be equipped with a method that allows for flexibility and reconstruction (Mao et al. 2013).http://KB7030 Department of Mechanical and Construction Engineering Sample Assignment Recent concepts, such as immovable buildings and floating architecture, allow buildings to interact with the environment and adapt to different situations. The same principles govern sustainable development and resilience.

Methodology

Research question

How can the key to providing sustainable housing demand for a developing country be to have modular prefabricated systems produced?

The need for environmentally sustainable housing is essential with the integration of advanced building services. The need for growing squatters in developing countries, as well as those who have benefited from recent economic progress, should be kept both.

Purpose

This study will aim to understand modern prefabricated construction techniques and how they can improve and influence environmental sustainability in specific countries. In order to achieve this objective, this study will do the following;

- To understand the diverse types of prefabricated modular buildings.

- To analyze the several case study methods to evaluate the applicability of the principles in modern Prefabricated Construction Techniques.

- To highlight the sustainability characteristics of Prefabricated Construction Techniques compared to conventional construction methods

The researcher will apply the qualitative research design in this research, where there are several case study techniques assisted by the semi-structured interview method for collecting data. A literature review will examine an empirical case study in the context of environmental sustainability with modern prefabricated construction techniques. Along with that, the research will look at the constraints and limitations imposed on prefabricated construction techniques, as well as the alternatives and development that can be applied to environmental sustainability improvement in construction projects.

Research Type

This study will be the exploratory study aimed at developing an understanding and knowledge of environmental sustainability with modern prefabricated construction techniques. Following open questions, the authors searched for similar findings. Using descriptive research, this study will improve knowledge management on the subject, but explanatory research will analyze the cause and effect of interrelationships among modern prefabricated construction techniques and environmental sustainability (Kumar, 2019).http://KB7030 Department of Mechanical and Construction Engineering Sample Assignment

Epistemology

It is the philosophical branch that regulates what should be considered acceptable knowledge in a field of study and explores different ways of understanding the nature of the social and physical worlds. In this way, there are four cognitive approaches, such as pragmatism, positivism, interpretivism, and realism. The methodology of managing each company and its projects is different, especially when construction management has not measured a profession and the role that more and more professionals play. The prefabricated construction techniques can be interpreted separately by a science and an individual, where project management should be viewed as a temporary venture and should be established and led by the construction project with processes and procedures.

Considerations of environmental sustainability are at the top of the project, and four cognitive approaches will ensure that modern prefabrication building strategies are essential to ensure that they understand decisions and actions. The construction industry expresses itself through understanding barriers as well as understanding environmental sustainability decisions, an aspect that further supports the choice of explanatory knowledge.

Research Methodology

The research methodology is the methodological process or method that leads to the identification of the problem, the collection of data or information, the analysis of this information as well as the process of problem-solving, to reach a specific decision or to a specific problem, or a specific generalization for any theoretical construction. In addition to this, the research methodology is used to collect relevant data, as well as analyze the research design, sampling techniques, and data collection and analysis according to the measurements and materials. Furthermore, it offers a number of alternative approaches as well as interdependent methods and practices that often overlap. Since there are numerous aspects of the research methodology, activity should be prioritized among different options. The choice of the appropriate approach can be achieved by evaluating the objectives and comparing different options (Russell, 2013).http://KB7030 Department of Mechanical and Construction Engineering Sample Assignment

The method adopted during the course of the study will be evolutionary, it will build an inference using current research, and the study will be designed to test my hypothesis with supposed observation. The most appropriate approach to this study is to determine the relationship between social studies and theory in the process of knowledge production (Savin-Baden and Major, C.H., 2013).http://KB7030 Department of Mechanical and Construction Engineering Sample Assignment

In this case, the tendency of the study is to determine how environmental sustainability can be applied through construction activities that test research and theory. The deductive approach has been further strengthened by the presence of existing literature on environmental sustainability and prefabricated construction technique. The data collected for the answer to this research question will quantify the interaction among them and how modern prefabricated construction techniques can impact environmental sustainability. In addition to modern prefabricated construction techniques, as well as theoretical studies on sustainability, it is possible to analyze the results obtained in the previous report and provide some information about how they are available for them (Savin-Baden and Major, C.H., 2013).http://KB7030 Department of Mechanical and Construction Engineering Sample Assignment

The method chosen for the research question is appropriate because it represents data through qualitative research interviews and processes that use numerical data, including the classification of data that it produces or produces.

The goal of qualitative research is to gain a deep understanding of the decisions, activities, and considerations made by the project manager in prefabricated construction techniques when applying environmental sustainability to modern prefabricated construction strategies; the selection of the qualitative research approach is a consistent and prior cognitive selection. A qualitative research method makes it possible to study the principles of environmental sustainability proposed in the literature, as shown by the different ways people engage in the practice. Along with that, potential weaknesses in the selected methodology include data collection through interviews and the factors that may be involved (Russell, 2013).http://KB7030 Department of Mechanical and Construction Engineering Sample Assignment

In this way, environmental sustainability and modern prefabricated construction combined with geographical, cultural, and environmental differences have a lot of meaning, especially in how they are perceived by staff. There are previous studies using this qualitative method based on literature review, this method also eliminates thematic and quantitative research as well as experiment. The method of collecting case studies in the art of difference allows researchers to better understand the topic of research (Kumar, 2019).http://KB7030 Department of Mechanical and Construction Engineering Sample Assignment

The principles of environmental sustainability are revised based on the culture, budget, and location of both organization and customers, in that way creating the study of the content of policy enforcement, and pursuing the goal of using the case study

Because of a qualitative study, this study will guarantee a close relationship between the research team and the participants, it will enable the interview method which allows to combine in-depth and targeted listening with a useful questionnaire. Every case study will be exclusive with different processes, challenges, and methods. The management team will all qualitative views of environmentally sustainable responsibilities. Through a number of case studies, this study will focus on standardizing the results to allow severe investigation and to allow robust research.

Ethics

The respondents will be informed of what is involved in the structure, time, and manner. Participation in this study will be on a volunteer basis and will be invited with the consent form. Before participating in the survey, every respondent will be introduced to academic research questions as well as the purpose, aims, and benefits of the structured interview technique. Every participant will be invited to be informed of the confidentiality and ethical agreement in which all personal information will not be disclosed if the participant agrees to comply with the terms and conditions of this Agreement.

Reflection

I have learned the process of prefabrication, which is included in the reconstruction of cities, by using a small workforce. For completing this part of the study, I collected different information from different reliable sources that were presented in the course. This research taught me to collect the useful information that was needed for conducting the research work. To begin with the task, I choose the research question and worked on collecting the needed information which was an important aspect that was needed for properly and effectively conducting the research task. I ensured to choose the right methodology that would help me to collect the required information needed for concluding the research work.

The research work was planned to find how modular construction has changed in the last few years and for this indulged in the primary and the secondary research task where the needed information was accurately collected and used for completing the research task. This was not an easy task, as I had to spend quality time in their collection and evaluation of the information. I planned the information collection and its analysis process, which assisted in evaluating the facts and using them for the conclusion of the research facts.

Alwan, Z., Jones, P. and Holgate, P., 2017. Strategic sustainable development in the UK construction industry, through the framework for strategic sustainable development, using Building Information Modelling. Journal of Cleaner Production, 140, pp.349-358.

Chiu, M.C. and Chu, C.H., 2012. Review of sustainable product design from life cycle perspectives. International Journal of Precision Engineering and Manufacturing, 13(7), pp.1259-1272.

Harris, F. and McCaffery, R., 2013. Modern construction management. John Wiley & Sons.

Kamali, M. and Hewage, K., 2016. Life cycle performance of modular buildings: A critical review. Renewable and sustainable energy reviews, 62, pp.1171-1183.

Kamali, M. and Hewage, K., 2017. Development of performance criteria for sustainability evaluation of modular versus conventional construction methods. Journal of cleaner production, 142, pp.3592-3606.

Kumar, R., 2019. Research methodology: A step-by-step guide for beginners. Sage Publications Limited.

Li, Z., Shen, G.Q. and Xue, X., 2014. A critical review of the research on the management of prefabricated construction. Habitat international, 43, pp.240-249.

Lovell, H. and Smith, S.J., 2010. Agencement in housing markets: The case of the UK construction industry. Geoforum, 41(3), pp.457-468.

Mao, C., Shen, Q., Shen, L. and Tang, L., 2013. Comparative study of greenhouse gas emissions between off-site prefabrication and conventional construction methods: Two case studies of residential projects. Energy and Buildings, 66, pp.165-176.

Monahan, J. and Powell, J.C., 2011. An embodied carbon and energy analysis of modern methods of construction in housing: A case study using a lifecycle assessment framework. Energy and Buildings, 43(1), pp.179-188.

Musa, M.F., Mohammad, M.F., Mahbub, R. and Yusof, M.R., 2014. Enhancing the quality of life by adopting sustainable modular industrialized building systems (IBS) in the Malaysian construction industry. Procedia-Social and Behavioral Sciences, 153, pp.79-89.

Pan, W., Dainty, A.R. and Gibb, A.G., 2012. Establishing and weighting decision criteria for building system selection in housing construction. Journal of Construction Engineering and Management, 138(11), pp.1239-1250.

Russell, R.M., 2013. Research methods. Final Report on the 2013 Season of The Mayapán Taboo Cenote Project, p.23.

Savin-Baden, M. and Major, C.H., 2013. Qualitative Research: The Essential Guide to Theory and Practice. Qualitative Research: The Essential Guide to Theory and Practice. Routledge.

Tykkä, S., McCluskey, D., Nord, T., Ollonqvist, P., Hugosson, M., Roos, A., Ukrainski, K., Nyrud, A.Q. and Bajric, F., 2010. Development of timber framed firms in the construction sector—Is EU policy one source of their innovation?. Forest Policy and Economics, 12(3), pp.199-206.

Zabihi, H., Habib, F. and Mirsaeedie, L., 2013. Definitions, concepts, and new directions in Industrialized Building Systems (IBS). KSCE Journal of Civil Engineering, 17(6), pp.1199-1205.