OPS 928 – Logistics Systems

This paper discusses the approach adopted by Dell for planning and implementation of logistics / supply chain activities. It is because in the success of the Dell, there is a vital role of the Dell supply chain process. Along with this, this paper also discusses the issues impacting the implementation the decision of the supply chain and logistics management. This paper also elaborates the benefits and the limitation of using the all approaches and the techniques in the supply chain. Additionally, the future trends and recommendation of the all logistics process and supply chain management of Dell are also discussed in this paper.

Dell was established by Michael Dell in the year 1984 and the company operates its managerial functions in the field of computer hardware and software. The company satisfies the needs of international customers by offering personal computers, servers, peripherals, smart-phones, televisions, storage devices, cameras, printers and other electronic devices. Dell is one of the major leading players in the market, which offers technical services to the customers (Dell, 2017). In addition, the company is known for its innovative strategies used in supply chain management and e-commerce activities for gaining competitive edge over the competitors. The direct business model is followed by the company for eliminating the extra participation of retailers in the process. It is because the direct business model assists the company to develop strong relationship with the customers by evaluating their needs and requirements in the ever changing business environment (Cao, & Zhang, 2011).

The company was enabled in making its medium sized organization into fast growing enterprise by providing superior quality products and services to the target audience (Christopher, & Holweg, 2011). It is a leading technological company, which keeps its competitive pricing strategy for attracting more customers and making them loyal towards the brand. The size of company is huge and produces multiple ranges of products in the competitive business environment. The logistics and supply chain is managed by the company in an effective manner by procuring the raw material from specialized suppliers or vendors. The mechanical parts, devices and components are purchased from different wholesalers and are assembled in its production area. The production house of Dell is spread at different geographical areas such as China, Malaysia, Limerick, Ireland, Tennessee, Brazil, Nashville etc (Diabat, and Govindan, 2011).

Dell operates its managerial activities in the highly competitive environment and faces direct competition from Hewlett-Packard Company and Lenovo. At the same time, due to increase in the demand of technical products and services there are tough competitor in the market such as IBM Corporation, Apple Inc, HP, Acer, Asus etc (Cordeau et al., 2010). On the other hand, Dell is enabled to maximize its profit margin by providing the products to the customers as per there requirements. The customized services are also offered to the potential users to compete with the other technical companies in the computer hardware and software (Diabat, A. and Govindan et al., 2013). The market share of Dell in the competitive business environment is 16% because of its high quality products and services as compared with the competitors.

Approach adopted for planning and implementation of logistics / supply chain activities

Due to continue change in the need of the customers and the technology innovation, mange the entire work and to develop a good customer base is one of the major challenges for the firm. In addition, Dell is also one of the leading multinational leading computer technology firms and operates the business in different countries. But at the same time due to have the proper supply of the products firm the customers and to manage operational process as well as logistics/supply chain activities, there are different ways and the approaches that are used by Dell (Formentini, and Taticchi, 2016). However, there are different approaches that can be used by Dell to manage the business and the logistics/supply chain activity but at the same time firm uses the business process modelling approach in its business practices. This approach is quite popular among the firms because of providing the better control on the supply chain activities of the firm.

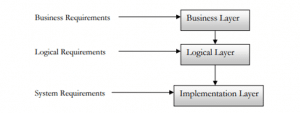

This approach is developed by artificial intelligence applications institute of the in Edinburgh University. In this approach, basically, three layers are considered such as logical layer and implementation requirement and the business requirements (Green et al., 2012).

(Source: Inf.ed, 2017)

With the use of all three layers, it is easy for the firm to get the idea about the exact demand of the products and the business requirement as well as it also helps the firm to gather the relevant information related to supply chain and the business that are mandatory in the successful process implementation. The used business process model of Dell is influenced by the supply chain strategies that are used to make the better flow of the supply chain. In the concern of Dell, it is clarified that the approach is used by Dell is totally supported by the handbook of the MIT process (Hsu et al., 2013). It is because all computers are created by Dell on orders. The major use of the MIT process is to identify the potential customers by using the customized channel that is directly connected with the users directly. It helps the firm to provide the better and effective products for the customers on their demand that directly increase the business excellence and to develop the customer base.

In order to achieve the sustainability, it is needed for Dell to formulate the effective business strategies that can be helpful for the firm to have the better use of the existing resources and to make a long term customer relationship. There is also a vital role of the business process modelling for the firm in terms of better implementation of the strategy that is quite useful for the firm in the better management of the supply chain (Hu, and Hsu, 2010). The all approach used by Dell also helps the firm to manage the supply chain part of the all computer system that also help the firm by building the long term relationship with the suppliers. At the same time, from the study of the Dell report of supply chain, it is determined that the direct model of the supply chain is used by Dell. In this, Dell direct get the order from the client though retail channels and on the basis of their need and want, Dell deliver the products for the customers. At present due to continues change in the need of the customer and increasing level of the completion, there is increasing demand of the personal computers. So, in order to get the competitive advantage and to develop a good customer base, there are different computers that are directly sold by the firm at directly and indirectly (Laguna, and Marklund, 2013).

At the same time, by concerning Dell supply chain activities, it is observed that the all strategies related to the supply chain that are used by Dell has uniqueness as compared to other firms supply chain marketing strategy that provide the competitive advantage for the firm and helps to develop its brand image in the market. In the research of Liao, and Kao (2014), it is determined that in order to sustain in the competitive market, the brand image of the firm and the market value are the major important aspects that are considered by the customers at high level. Because of this, there is an important role of the brand image of the firm in the market and among the customers to sustain in the competitive market. In like manner, the other reason behind to be the popular in the market of the Dell is the use of some unique and effective strategies and build-to-order strategy is also one the major strategies that is used by the firm. This strategy helps the firm to have the better use of the supply chain activities and develop a good public relation. Along with this, there are also some other strategies such as Just-In-Time (JIT) approach, etc that support the inventory management system of the firm (Ninlawan et al., 2010). In this, six day checking of the inventory and manage the all inventory through different approaches assist the firm to get the high profit and to develop the large customer base.

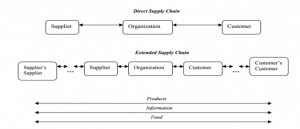

Dell Supply chain process

(Source: Inf.ed, 2017)

In addition to this, Dell also uses the collaborative strategy in order to manage the relationship with the customers and the suppliers. It is because along with a good customer base, the relation with the suppliers also plays a major role in the success of the firm. The all required materials to make the better products for the customers are provided by the customers. Because of this, if the firm has the better relationship with the suppliers then it helps the firm to have the better supply of the products and to better manage the all operational process of the firm as well (Govindan et al., 2015). In the supply chain activities of the firm, there are different steps like customers order, involve supplier, merging activity, customer, manufacturing and storing that are followed by the firm to successful managing the business. Due to this concern, it is also mandatory for Dell to follow the all activities but giving major focus on the all logistics activities. For this, the use of the internet is one of the major solutions that are used by the firm for better managing of the supply chain. It is because by using the Dell website, it is easy for the customers to identify the best suitable products according to their convenience and through website; they can easily place the order. Because of this, it can be determined that the use of website is the better solution for the firm to manage the supply chain and to develop the customer base as well (Qrunfleh, & Tarafdar, 2013). At the same time, from the study of Dell, it is also indentified that there are three managerial levels of the logistics activities such as strategic, tactical and operational that are used by Dell. These all logistics activities are managed by the managerial department of the firm for managing the all process effectively and to overcome the possibilities of arising any issues.

Dell SCM System

(Source: Inf.ed, 2017)

Additionally, in the supply chain activities of the firm, there is a vital role direct model and the information that are used and the shared with the different stakeholders of the firm. It assists the firms to have the better supply chain process and the inventory management control. In addition, the use of process modelling approach assists the firm to enhance the alternative computer solutions and to target the new market and to develop a good customer base in the new base (Rahman, and Subramanian, 2012). Along with using the different strategy, firm also uses the new model Configure-to-order (CTO model) from where, it is also easy the customers to configure their PC’s on the basis of their needs and the wants. It helps the firm to build a long term relationship and to develop a large customer base. So, from the supply chain strategy, it can be stated that configure-to-order (CTO) model and build-to-order (BTO) model are the best management model that are used by the firm that enhance the growth of the firm and to helps to manage the all activity related to the supply chain.

At the same time, along with using the different approaches and the model, there are also different techniques that are used by Dell. In this, the use of statistical process control (SPC) and benchmarking technique are the best techniques that are used by the firm. These all techniques help the firm for better managing of the supply chain and to understand and communicate the performance of the firm. But at the same time, the major use of these techniques to measure and monitor the all activities that are performed in the supply chain logistics and help Dell to reconnect its customers directly (Ranganathan et al., 2011). In addition, though networking system, it is easy for Dell to target the customers at worldwide as well as sometime as per the market demand and the customers need, firm also has some change in the approaches and technology that help the firm to sustain in the market for a long time and to develop a good customer base.

Issues impacting the implementation decision

In order to successful manage the business; there are different issues that are faced by the firm in the business. It is because in order to expand the business and to develop a good customer base, there are different things related to supply chain, demand of the products, market size, etc that are faced by the firms and create the business issue. Because of this, it can be determined that for successful managing the business, there are different issues that every firm face in the business process. In the concern of Dell firm, there are different issues related to the supply chain but the shortage of the supply of resources to the unit is the major issue that is faced by the firm in the supply chain logistic (Roh et al., 2014). In this, the shortage of the supply of resources creates the issue for the customers to get the desired products and also affect the performance of the firm as well. In like manner, the shortage of the supply of resources also creates a negative image of the firm in the customers mind that affect the customer buying behaviour.

At the same time, from the business study of Dell, it is identified that the all business of Dell is totally deepened on the supply chain activities of the firm. It helps the firm to get the competitive advantage and to meet out the demand of the products effectively. In addition to this, the trust is also one of the major issues that are also faced by the firm in its business practices. It is because from starting of this firm, there were some issues related to the quality of the products that is why firm faced some issues and lost its customer base as well as the competitive advantage. So, build the trust among the customers is became the big issues that also affect the business of the firm and create the operational and marketing issue of the firm (Rushton et al., 2014). In like manner, the products differentiation is also one of the major issues that are faced by the firm. It is because the all products of the firms are available at high price with innovation but there are also different competitive price products in the market that influence the customer buying behaviour and the market value. Because of this, it is also a big issue. There is also no differentiation in the products of the firm like Dell deals in the computer majorly that creates the business issue for the firm and also affect the customer base as well. This issue also affects the product supply and also affect the relationship between company and supplier. Additionally, all approaches used by Dell are quite helpful in the supply chain process of the firm but the use of Just-in-time model is not quite appropriate for the firm. It is because the use of Just-in-time model is only for the short time period that directly negatively affects the supply chain process of the firm (Sarkis et al., 2011). So, for managing the supply chain issue and to develop a good base of the business, there is a need for the firm to have its major concern on developing the supply chain management instead of other business aspects. It will help the firm to develop the customer base and to increase the performance of the firm.

Furthermore, according to the Sodhi, & Tang (2012), the lack of selling and the low revenue are also the major issues that Dell also faces in the business. This issue also affects the supply chain activities of the firm that makes the cause of low revenue and the business performance. In like manner, due to limited production unit in some specific locations, complete the demand of the people on time and meet the customer needs with fulfilling their expectation affect the customer base of the firm and the all process of the supply chain management. At the same time, successfully implement the decision is also the major issue that is faced by the firm and creates the business issue for the firm as well. It affects the marketing condition of the firm and also affects the employee’s morale of the firm as well. Because of this, it is one of the major issues for the firm in its business process and the supply chain process of the firm (Stadtler, 2015).

In like manner, from the study of Dell, it is defined that although Dell produces the customized products for the convenience of the customers but there are also different challenges that are also faced by the firm to produce the products and to meet the need of the customers. It has it’s directly impact on the customers buying behaviour (Stavrulaki, & Davis, 2010). So, it can be determined that there are different issues that have direct impact on the supply chain management activities of Dell as well as the above discussion, it can also assist in the successful decision implementation.

Benefits of Logistics and Supply Chain Management

There are various opportunities for the firm in the use better supply chain management activities as well as there are also different benefits for the firm that firms can have through better implementation of the supply chain. It can increase the profit of the firm and the sales of the firm as well. It is because due to increasing level of the competition and the changing need of the customers, there are different issues related to the profit and the sales that firm is facing, so, the better use of the logistics and supply chain management will be helpful for the firm to get the competitive advantages and to have a good customer base in the competitive market. In the research of Tang, and Musa (2011), in order to get the benefits in the logistics activities, the approaches used by the firm will be helpful. It is because these all approaches will make easy the firm to handle the all business operations and to better management of the supply chain activities.

At the same time, the mobilization of resources by managing the workforce of the firm and the business process will also be helpful for the firm. It is because it will help to increase the technical ability of the firm and will provide the maximum advantage in the minimum return. In like manner, from the research of Tayur et al., (2012), it is determined that the better use of the supply chain management also provides advantage for the firm for providing the quality of the products. It is because follow the supply chain process make easy the employees to resolve the any issue in the products and to provide the better products for the customers on time and effectively. It also increases the customer base of the firm and increase thee brand image of the firm in the market (O’Dell, & Hubert, 2011).

Along with this, by using the logistics and supply management, it is also easy for the firm to effectively manage the entire process of the firm products process such as from the raw material and to the end customers that helps Dell to be ensure the all products of the firm is supplied for the right customers that increase the productivity of the firma and also increase the loyalty of the customers towards Dell. In the views of Yang, & Yang (2010), due to changing market need and the scenario, target the right customers on the right time is one of the big issue for the firm. Because of this, Dell uses the ply chain and logistics management effectively that helps the firm to target the right customers and to meet the demand of the customers on time and effectively. At the same time, from the report of Dell, it is also determined that Dell also has the new innovation and the change in the supply chain management (Rushton et al., 2014). It helps the firm to get the idea about the changing need of the customers and the market and accordingly provide the products for the customers and to develop a good market value. So, from the overall discussion and the analysing the use of logistics and supply management, it can be stated that there are various opportunities for Dell in the market and firm is continuously performing well.

The one of the main limitation of using the logistics or supply chain activities is the use of Just in time approach. It is because in order to produce the products, Dell takes the time of six days that affect the product by reducing the efficiency of the products and directly affect the quality of the products as well. Because of this, the use of Just in time approach is one of the big limitations for Dell. Additionally, cost and the time are also the major approaches that are also create the business limitation for the firm in its business process. It is because the supply chain management process of the firm is quite lengthy that takes so much time and makes the cause of occurrence high cost for Dell. Because of this, cost and the time are considered as a high business limitation for the firm (Ninlawan et al., 2010). At the same time, there is also a need for Dell to have the skilled workforce for better management of the supply chain process. It is because if there is not skilled workforce in the firm then it will affect the working process and the operational process of the firm that will make the cause of business loss for the firm. Because of this, it is needed for the firm to have the skilled workforce for better handling and managing the work.

Future trends and recommendations

There is continuous change in the market fur to continuous change in the need of the customers and the increasing level of the competition in the market. So, in order to manage the future trends issue, Dell decided to use the core principles effectively and have some transformation in the existing business and marketing strategy. It is because it will help the firm to get the competitive advantage and to develop a good customer base as well (Liao, and Kao, 2014).

Furthermore, it can be recommended that although firm is continuously performing well but at the same time, it is also determined that there is a need for the fir to have its major focus on to make the string relationship with the suppliers. It is because having a string relationship with the suppliers is only the way which can be helpful for the fir to sustain in the competitive market for a long time (und Torney et al., 2012). At the same time, Dell should also make a long term and direct relationship with the customers. It is because it will be helpful for dell to make a good public relation and to control the risk related to the cost. Moreover, it can also be recommended that Dell should also use the other approaches instead of Just in time. It is because it will help the firm to control the cost and time related issues and to develop a good customer base (Roh et al., 2014). In like manner, there is also a need for Dell to develop its own manufacturing plant for all products rather than import and the export the products. It is because it will help the firm to keep safe the extra cost and to have a good and strong relationship with the customers. In addition, for managing the issues related to the decision implementation, there is also a need for the firm to use some innovative techniques of benchmarking and metrics that will assist the firm by improving the supply chain process of the firm and to provide the better and effective products for the customers as well.

From the above discussion, it can be concluded that there are different supply chain and business approaches like business process modelling approach that are used by Dell for better management of the supply chain and the business process. Additionally, it can also be stated that there are different issues related to the supply chain that is affecting the business of the firm and creating the business challenges. But at the same time, it can also be stated that the use own manufacturing, use core principles and the new approaches, direct relationship with the customers, etc are the major ways that can be used by the firm to manage the issues and to have a good control on the supply chain process.

Cao, M., & Zhang, Q. (2011) Supply chain collaboration: Impact on collaborative advantage and firm performance. Journal of operations management, 29(3), pp. 163-180.

Christopher, M., & Holweg, M. (2011) “Supply Chain 2.0”: managing supply chains in the era of turbulence. International Journal of Physical Distribution & Logistics Management, 41(1), pp. 63-82.

Cordeau, J. F., Dell’Amico, M., & Iori, M. (2010) Branch-and-cut for the pickup and delivery traveling salesman problem with FIFO loading. Computers & Operations Research, 37(5), pp. 970-980.

Dell (2016) Annual Report [Online] Available at: http://annualreport.dell.com/ (Accessed: 08 July, 2017).

Diabat, A. and Govindan, K. (2011) An analysis of the drivers affecting the implementation of green supply chain management. Resources, Conservation and Recycling, 55(6), pp. 659-667.

Ellram, L. M., Tate, W. L. and Feitzinger, E. G. (2013) Factor‐market rivalry and competition for supply chain resources. Journal of Supply Chain Management, 49(1), pp. 29-46.

Formentini, M. and Taticchi, P. (2016) Corporate sustainability approaches and governance mechanisms in sustainable supply chain management. Journal of Cleaner Production, 112, pp. 1920-1933.

Govindan, K., Soleimani, H., & Kannan, D. (2015) Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. European Journal of Operational Research, 240(3), pp. 603-626.

Green Jr, K. W., Zelbst, P. J., Meacham, J. and Bhadauria, V. S. (2012) Green supply chain management practices: impact on performance. Supply Chain Management: An International Journal, 17(3), pp. 290-305.

Hsu, C. W., Kuo, T. C., Chen, S. H., & Hu, A. H. (2013) Using DEMATEL to develop a carbon management model of supplier selection in green supply chain management. Journal of cleaner production, 56, pp. 164-172.

Hu, A. H. and Hsu, C. W. (2010) Critical factors for implementing green supply chain management practice: an empirical study of electrical and electronics industries in Taiwan. Management research review, 33(6), pp. 586-608.

Inf.ed. (2017) [Online] available at: https://www.inf.ed.ac.uk/publications/thesis/online/IM070456.pdf (Accessed: 08 July 2017).

Laguna, M. and Marklund, J. (2013) Business process modeling, simulation and design. USA: CRC Press.

Liao, C. N. and Kao, H. P. (2014) An evaluation approach to logistics service using fuzzy theory, quality function development and goal programming. Computers & Industrial Engineering, 68, pp. 54-64.

Ninlawan, C., Seksan, P., Tossapol, K. and Pilada, W. (2010) The implementation of green supply chain management practices in electronics industry. In Proceedings of the international multiconference of engineers and computer scientists Vol. 3, pp. 17-19.

O’Dell, C., & Hubert, C. (2011) Building a knowledge-sharing culture. The Journal for Quality and Participation, 34(2), pp. 22.

Qrunfleh, S., & Tarafdar, M. (2013) Lean and agile supply chain strategies and supply chain responsiveness: the role of strategic supplier partnership and postponement. Supply Chain Management: An International Journal, 18(6), pp. 571-582.

Rahman, S. and Subramanian, N. (2012) Factors for implementing end-of-life computer recycling operations in reverse supply chains. International Journal of Production Economics, 140(1), pp. 239-248.

Ranganathan, C., Teo, T. S. and Dhaliwal, J. (2011) Web-enabled supply chain management: Key antecedents and performance impacts. International Journal of Information Management, 31(6), pp. 533-545.

Roh, J., Hong, P. and Min, H. (2014) Implementation of a responsive supply chain strategy in global complexity: The case of manufacturing firms. International Journal of Production Economics, 147, pp. 198-210.

Rushton, A., Croucher, P. and Baker, P. (2014) The handbook of logistics and distribution management: Understanding the supply chain. UK: Kogan Page Publishers.

Sarkis, J., Zhu, Q. and Lai, K. H. (2011) An organizational theoretic review of green supply chain management literature. International Journal of Production Economics, 130(1), pp. 1-15.

Sodhi, M. S., & Tang, C. S. (2012) Strategic approaches for mitigating supply chain risks. Managing Supply Chain Risk, pp. 95-108.

Stadtler, H. (2015) Supply chain management: An overview. In Supply chain management and advanced planning (pp. 3-28). UK: Springer Berlin Heidelberg.

Stavrulaki, E., & Davis, M. (2010). Aligning products with supply chain processes and strategy. The International Journal of Logistics Management, 21(1), pp. 127-151.

Tang, O. and Musa, S. N. (2011) Identifying risk issues and research advancements in supply chain risk management. International journal of production economics, 133(1), pp. 25-34.

Tayur, S., Ganeshan, R. and Magazine, M. (2012) Quantitative models for supply chain management (Vol. 17). USA: Springer Science & Business Media.

und Torney, M. V. S., Dell-Kuster, S., Mechera, R., Rosenthal, R., & Langer, I. (2012) The cost of surgical training: analysis of operative time for laparoscopic cholecystectomy. Surgical endoscopy, 26(9), pp. 2579.

Yang, B., & Yang, Y. (2010) Postponement in supply chain risk management: a complexity perspective. International Journal of Production Research, 48(7), pp. 1901-1912.