Manufacturing Systems Assignment Sample

Introduction

As a manufacturer of pressure transducers, High-Tec provides a wide range of products for a variety of industries. Weight or force can be converted into an electrical signal in another variation of the gadget. A typical order from a customer is between three and ten units. L-shape building: office, engineering, machine shop, and assembly area occupy 12,000 square feet of space rented from a landlord. Machinists, engineers, assembly-line workers, secretaries, and salesmen make up the company’s 80-strong workforce. However, whereas Moore initially focused on the company’s finances and marketing, he is now more concerned with its manufacturing costs, inventories, and capacity. A 30 percent annual increase in sales is projected to continue shortly (Berekbussunova et al., 2019). Due to space constraints, we were unable to acquire a numerical control machine and more efficient testing equipment at the time. Both offers increased capacity and productivity, and their prices can be justified. A lack of space in the machine shop necessitated the relocation of equipment that was not in continual use. The second and third shifts are working with far more machines than they should. Quality and productivity are deteriorating at the same time.

Recommend expansion option

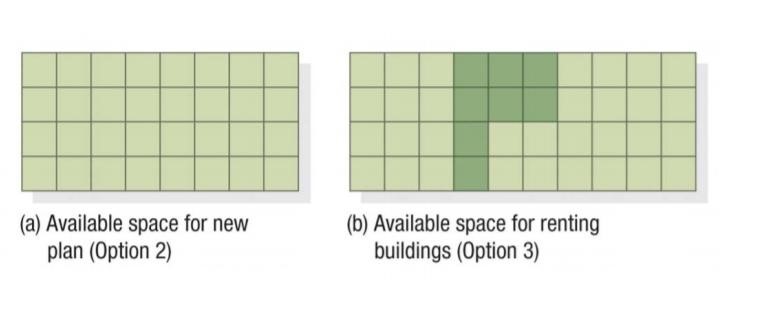

Hightec’s capacity may be increased in one of three ways, according to Glenn Moore. Renting movable units will alleviate crowded conditions while the lease on the present building is renewed for another five years. He ruled it out as being insufficient to deal with the rising issue. The second alternative is to buy a property and construct a new building with a total square footage of 19,000 square feet. It would cost $100,000 for land and $40 per square foot to build the most desirable location (Feng et al., 2020). He has a cost of capital of 15%. In a third alternative, a 7,000-square-foot structure just 30 feet away from the existing one may be rented for another five years. The monthly rent for both buildings is $2,800. There is a $15,000 price tag attached to this third option, which Moore has chosen. Moore, on the other hand, calculates that transferring the machines and losing regular-time capacity will save $20,000 in relocation expenses.

Option 1– Renew the rental contract on the current facility for another 5 years and rent portable units to ease the cramped conditions.

If an initial agreement is to be renewed or extended, the details of the renewal option are laid forth in the financial agreement. An agreement’s renewal clause specifies how long the original terms can be renewed or extended and specifies the conditions under which it can be done. Rental lease agreements are the most commonplace to find renewal choices. But they may be incorporated in any financial arrangement when a longer period is desirable for an organization (Götz and Anzt, 2018). When a lease is renewed, the lessee has the choice but not the responsibility to extend or renew the arrangement beyond its initial term. For both residential and commercial properties, lease agreements can be used. Three-year leases are common for start-up businesses. A renewal option would allow the company to extend or renew the lease beyond the three-year duration of the contract. As long as the firm is doing well at the location, this might be a benefit to the company. The firm might be evicted if it does not have the option of renewing its contract. Renewing the lease permits a failing company to shut down at the end of its first term without defaulting on the contract or feeling obligated to do so.

Moving items to and from the inventory storage room, where inventory is held at all phases of production, takes up around 10% of the time of the workers. Finding desired components is tough in the supply room due to the chaos, and a lot of time is wasted seeking. There will be a need for about 1,000 square feet of storage space outside of the manufacturing facility. Due to a lack of resources, Moore was unable to participate in numerous interesting projects. This has angered one specific salesperson, who stands to lose a sizable portion of her compensation (Kang and Lee, 2018). There have been several complaints from office workers about the crowded space and lack of privacy. Prospective clients who visit the company are put off by the poor quality of their workspace. The office has recently added more staff. A cutting from Moore’s favorite tropical plant, which had sentimental importance as a cutting when Hightec was created, had to be thrown out to make way for their workstations.

For the most part, the same rules apply to a person who is a residential leaseholder. The length of their contracts is typically one year. A residential lessee who has the option of renewing their lease might make that decision depending on their particular needs. It is critical for both residential and commercial leaseholders to understand the parameters of a renewal option and to advocate for one if it is not originally included in a lease agreement. Depending on the renewal selection, various conditions may apply (Helo and Shamsuzzoha, 2020). If the lease is renewed, the lessor may run another credit check to make sure the tenant is still in good financial standing. A lot of leases require the tenant to notify the landlord in writing of their intention to extend the original contract by a certain date.

Effective block plan

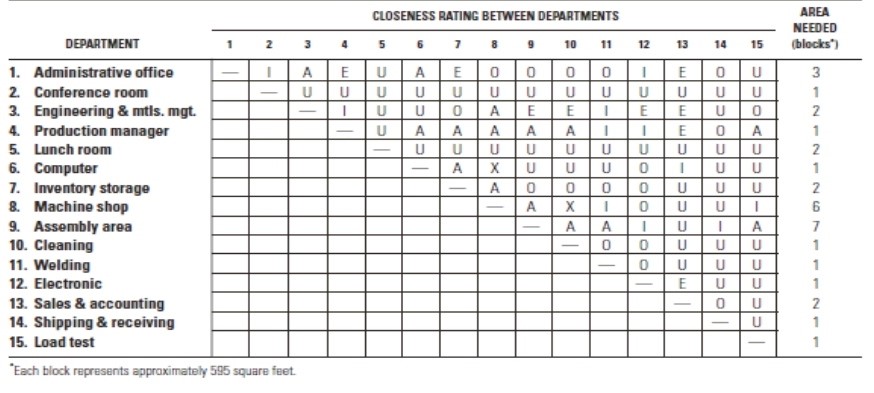

Whatever Moore decides to do, he will have to make improvements to the current arrangement. Waste management and cross-departmental communication are both hampered. When Moore first drew up the current structure, he put the office in the center and then arranged the rest of the departments around it. Other departments were concerned about the proximity of the machine shop to the cleaning area (Babu and Pamula, 2020). Exhibit 1 and Exhibit 2 demonstrate the information that Moore gathered to develop the new layout. For the next five years, the predicted area requirements should be enough. Both plans offer 19,000 square feet of space. Material handling and communication patterns are highlighted in the proximity matrix. A cup of coffee in Glenn Moore’s hand, he made his way inside the office. To make matters worse, it was far too early in the day for soup. Asked himself what to do next, he couldn’t decide.

Exhibit 1- REL Chart

Exhibit 2- Available Space for Options 2 and Option 3

Source-(Kim et al., 2021)

Creating a production site layout relies heavily on the arrangement of individual blocks. If you want to improve the production structure, this is especially true. This is because a block diagram of a factory or facility’s functional regions gives crucial information on the ideal arrangement of operational resources and space in the early planning stages of a project (Lu et al., 2018). This does not need a thorough understanding of the machine, system, or assembly station geometry. Existing structures and industrial facilities can make use of blocks, as can undeveloped land with a predetermined footprint. That first preliminary plant layout with equipment summarised and depicted as blocks will be the result.

The block layout abstracts logistics as well. A Sankey diagram is created by calculating the intensity of the material flow. Block layout objects are the diagram’s sources and sink. Consequently, a plan’s material flow linkages are an excellent way to depict the interdependencies of the blocks. The factory’s layout may now be planned methodically. As a result, any bottlenecks in the manufacturing or facility architecture can be identified at an early stage (Semeraro et al., 2021).

One of the aims of factory planning is to develop at an early stage assessable production or factory design concepts. In layouts, the progression from rough to fine is always evident. Rough planning may be accomplished using the block layout. There are seven basic parts in the VDI Guideline 5200 on industrial planning, and this guideline states that the rough layout is the product of concept planning. Variations of block layouts are constructed, for example, to aid in the early design of manufacturing structures. Using this example, we’ll demonstrate the process in the following video (Tirabeni et al., 2019). As a result, desired states are frequently represented by block or crude layouts in layout planning. On the other hand, existing productions are more typically built as detailed layouts with physical models of the functioning equipment in the actual scenario (e.g. as an equipment layout plan). Even so, it makes sense to keep track of the present state of a factory using a block structure instead of just a table. Resources such as machine groups and assembly lines are divided into blocks for this purpose so that they may be more easily tracked and accounted for, as well as logistical units (e.g. warehouses and storage facilities). Material flows from and to each other are combined. A hierarchical industrial layout is the end consequence of this approach. The block layout of the production, warehousing, social, and administrative sections is the most senior hierarchical level (plant layout structure).

It is the goal of this modeling to provide a “playground” for layout planning at the plant layout structure level, even for existing industrial facilities or structures. It is required when the operational factory business requires action in the direction of factory planning. Getting the knowledge of the block layout at the time of such a planning impulse is difficult and time-consuming, and it is often important to do so (Walther and Weigold, 2021). As a result, it is preferable if this step has previously been completed. Maintaining an eye on the block layout is essential, even if only minor adjustments have been made in terms of where working equipment is located. A master layout design is also created that is constantly current. This is also the foundation for any strategic examination of change stages and transformation perspectives.

Hightec should begin by ensuring that their company has the capabilities necessary to deliver the road map, and business capability maps give a framework for concentrating on the BT organization’s capacity to plan, implement, and manage the aspects of a BT technology road map. Business capability, according to Forrester Research, is the ability of a company to successfully carry out a certain business activity to accomplish a specific result. To carry out its goal or to maintain its market position, an organization’s business capabilities reflect a broad picture of what it must do. When two things happen, a collection of capabilities transforms into a capability map (Zhang et al., 2019). All of an organization’s operational model and value chain are brought together in the collection. For one thing, if each capability’s desired outcomes are included in the listing for each capability’s procedures and activities. The most successful capability maps are the simplest ones. Capability maps themselves aren’t difficult to create (Zietsch et al., 2020). The granularity required by most BT businesses utilizing capability maps for strategy and governance is between 20 and 40 capabilities at the top level. Additionally, within the same industry sector, BT capability maps don’t differ significantly from one company to the next. Therefore, the simplest method to construct a capacity map is to start with a straw man framework and then enhance it and concentrate it to meet an individual BT business progressively. There should be an evaluation of the BT organization’s capabilities map to ensure that it is compatible with the BT strategic technology plan. In particular, Hightecshould assesses the maturity of their organization’s ability to deal with the unique issues of the technological road plan. Updates may include adding new capabilities or removing older ones that are no longer required.

Conclusion

There is a lot to learn from the block layout when it comes to designing industrial facilities. It’s not only that the manufacturing structure may be shown in a rudimentary plan. In addition, the application of industrial design methodologies allows for efficient space use (e.g. Sankey diagram, logistics evaluation, especially transportation effort, area balance). In a project, it abstracts using blocks so that several versions may be swiftly developed and analyzed. In factories, the use of block layouts is a standard practice because of this same reason.

References

Babu, S.D. and Pamula, R., 2020, April. An Effective Block-Chain Based Authentication Technique for Cloud-Based IoT. In International Conference on Advances in Computing and Data Sciences (pp. 305-319). Springer, Singapore.

Berekbussunova, G.M., Almukhambetov, B.A. and Ala, P., 2019. The program of formation of the pedagogical orientation of future physical education teachers in the course of vocational training. Теория и методика физической культуры, (2), pp.26-30.

Feng, X., Ren, D., He, X. and Ouyang, M., 2020. Mitigating thermal runaway of lithium-ion batteries. Joule, 4(4), pp.743-770.

Götz, M. and Anzt, H., 2018, November. Machine learning-aided numerical linear algebra: Convolutional neural networks for the efficient preconditioner generation. In 2018 IEEE/ACM 9th Workshop on Latest Advances in Scalable Algorithms for Large-Scale Systems (scalA) (pp. 49-56). IEEE.

Helo, P. and Shamsuzzoha, A.H.M., 2020. Real-time supply chain—A blockchain architecture for project deliveries. Robotics and Computer-Integrated Manufacturing, 63, p.909.

Jiao, K., Xuan, J., Du, Q., Bao, Z., Xie, B., Wang, B., Zhao, Y., Fan, L., Wang, H., Hou, Z., and Huo, S., 2021. Designing the next generation of proton-exchange membrane fuel cells. Nature, 595(7867), pp.361-369.

Kang, H.S. and Lee, J.Y., 2018. A real-time cyber modeling approach in an MTConnect-based cyber-physical production environment. Procedia CIRP, 72, pp.462-467.

Kikolski, M. and Ko, C.H., 2018. Facility layout design–review of current research directions. Engineering Management in Production and Services, 10(3).

Kim, J., Ku, B.W., Yoon, J. and Lim, S.K., 2021. An Effective Block Pin Assignment Approach for Block-Level Monolithic 3-D ICs. IEEE Journal on Exploratory Solid-State Computational Devices and Circuits, 7(1), pp.26-34.

Lu, L., Deller, D. and Hviid, M., 2018. Price and Behavioural Signals to Encourage Household Water Conservation. Centre for Competition Policy Research Bulletin, 35, pp.2-4.

Moghaddam, M., Cadavid, M.N., Kenley, C.R. and Deshmukh, A.V., 2018. Reference architectures for smart manufacturing: A critical review. Journal of manufacturing systems, 49, pp.215-225.

Semeraro, C., Lezoche, M., Panetto, H. and Dassisti, M., 2021. Digital twin paradigm: A systematic literature review. Computers in Industry, 130, p.103469.

Shanks, W., Dunant, C.F., Drewniok, M.P., Lupton, R.C., Serrenho, A. and Allwood, J.M., 2019. How much cement can we do without? Lessons from cement material flow in the UK. Resources, Conservation and Recycling, 141, pp.441-454.

Tirabeni, L., De Bernardi, P., Forliano, C. and Franco, M., 2019. How can organizations and business models lead to a more sustainable society? A framework from a systematic review of the industry 4.0. Sustainability, 11(22), p.6363.

Walther, J. and Weigold, M., 2021. A systematic review on predicting and forecasting the electrical energy consumption in the manufacturing industry. Energies, 14(4), p.968.

Zhang, Z., Guo, Q., Chen, J., and Yuan, P., 2018. Collision-free route planning for multiple AGVs in an automated warehouse based on collision classification. IEEE Access, 6, pp.22-35.

Zietsch, J., Vogt, M., Lee, B.D., Herrmann, C. and Thiede, S., 2020. Enabling smart manufacturing through a systematic planning framework for edge computing. CIRP Journal of manufacturing science and technology, 31, pp.351-369.

………………………………………………………………………………………………………………………..

Know more about UniqueSubmission’s other writing services: