MMD4038-N-FJ1-2021 Supply Chain Management Assignment Sample

Supplier-customer co-development

The relationship between supplier and customers in terms of product quality, complaints, service, and deliveries is important to maintain better organisational growth. Suppliers provide sufficient resources required in a business and deliver finished goods to the customers (Oinonen et al. 2018). Customers are individuals or businesses that buy goods and services from other organisations. Streamlining supply and demand is a way to help organisations respond rapidly to market changes while enhancing operational efficiency. It is essential to identify different ways to streamline the operations of the supply chain. Business organisations are required to take surgical measures to further reduce operational costs. Supply chains are required to execute customisation strategies and also should be agile (Tarafdar and Qrunfleh, 2017). Mass customisation is one of the ways of becoming lean and it is a process of batch size production to address customer-specific demands. It is a combination of a mass production process of low unit cost with individual customisation flexibility. Hence it is important to maintain a positive relationship between suppliers and customers. Supplier-customer co-development means the involvement of customers and suppliers both in improving business processes (Oinonen et al. 2018). Co-development between suppliers and customers may help to deliver goods, and products as per the needs of customers. The customer-centric mindset of suppliers and business organisations provides better customer values and enhances organisational growth (Najafi-Tavani et al. 2020). Customer-supplier co-development strategies also help to minimise the risk in volatile business markets of retail industries. Management of retail industries must develop relationships with customers and suppliers by implementing supply chain management strategies to get better success in business. The supplier-customer co-development indicates the involvement of customers with suppliers in developing new products as well as services (Mitrega et al. 2018). It helps suppliers to commercialise new products as well as services for a competitive industrial market. The main objective of developing customer-supplier co-development is to improve customer satisfaction and promote the customer-centric mindset of suppliers as well as business brands. ( MMD4038-N-FJ1-2021 Supply Chain Management Assignment Sample)

Different types of supplier-customer co-development

Companies may fail to meet customer demands and have very slow reactions towards them and are highly prone to suffer consequences such as decreased sales, higher inventory and decreased profitability. Hence, companies are required to adapt to rapid changes in business conditions. Small businesses are prone to face additional pressures because of competing with other organisations as well as key rivals in the industry. Quality problems can take place for not having adequate products in stock and it can also lead to late delivery (Anderson, 2020). Companies which are slow towards adapting to changes have a lot of inefficiencies which results in uncompetitive pricing that leads to the failure in addressing customer requirements and the companies suffer through low sales. However, there are different types of customer-supplier co-development in an organisation that can improve organisational processes effectively (Lehtimäki et al. 2018). Process, design, relationship, and communication improvement are the important types of supplier-customer co-development.

The involvement of customers and suppliers in the product or service designing process is important to bring innovative products to a market (Oinonen et al. 2018). Suppliers can get enough information about the customer’s wants to develop products as well as services. However, the process creates immense pressure on the supply chain as it involves the responsibility of differentiating a product based on specific customer needs (Cooper and Slagmulder, 2017). Hence, supply chains should be both lean and agile. No business organisation can entirely depend on either the strategies of push or pull logistics but rather a combination of push-pull applications can help in generating the best result thereby optimising supply chains. The process of supplier-customer co-development increases relationships with customers in a business. An inefficient supply chain results in poor delivery performance due to which an increased number of customers get dissatisfied with the delivery issue and they tend to shift to other companies for a better experience (Fernie and Sparks, 2018). Therefore, Design of a product is important for an organisation in volatile market segments as there is a high risk of product failure (Appio and Lacoste, 2019). Therefore, the supplier-customer co-development process indicates the involvement of customers while designing a product. It helps to design products and design supply chain processes according to the customer’s needs. It is important for the retail industry to maintain a positive relationship with customers and suppliers by implementing effective supply chain strategies. Maintaining effective relationships with customers and suppliers is the main focus of customer-supplier co-development. The development of communication processes is important for customer-supplier co-development (Andreini et al. 2018). It helps suppliers to communicate with customers and increase their involvement in designing products as well as services.

Measures of supplier-customer co-development

A lean supply chain has potential benefits in terms of organisational success. However, the implementation gap in the context of lean tools interaction with SPM generates a lot of problems for organisations and acts as a barrier to achieving success in the long run. Sometimes companies have insufficient management time for supporting lean (Tezel et al. 2018). Employees of retail organisations often do not understand the importance of lean implementation. Therefore, it is necessary to maintain supplier-customer co-development strategies to minimise these supply chain issues.

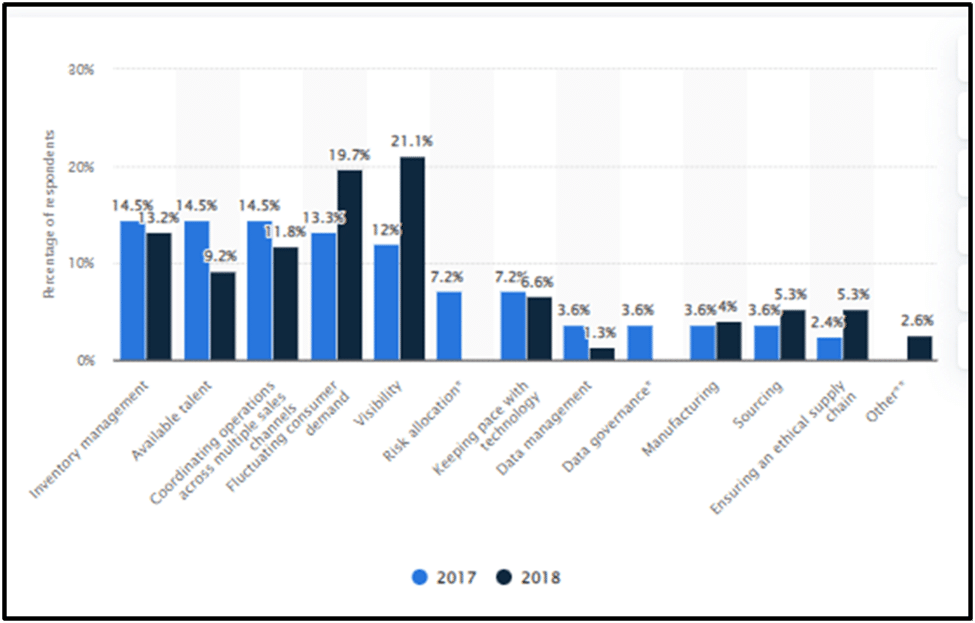

Figure 1: Challenges faced within the supply chain

(Source: Statista.com, 2022)

The above figure shows various supply chain challenges such as inventory management, valuable talents in the supply chain, risk allocation and so on (Statista.com, 2022). These challenges work as a barrier to implementation of lean tools and techniques within SCM. Supply chain members can face enough challenges in this context due to which they can show a high level of resistance towards the application of lean within the supply chain management. Company management can also face difficulties in understanding the attitudes of the members involved in SPM and the proper reasons for resisting changes therefore improvement of customer-supplier co-development is important. Insufficient workforce skills also become a major barrier to lean implementation because without proper knowledge it is not possible to make effective use of lean tools in the process of supply chain management (Abu et al. 2019). A collaborative approach must be followed by management to improve the strategies of customer-supplier co-development. The collaborative approach will help to increase the engagement of customers and suppliers in developing supply chain services, and products effectively (Oinonen et al. 2018). Management needs to measure cost, benefits, and risk in improving relationship co-development between customers and suppliers. Maintaining supplier-customer co-development plays a significant role in minimising the cost of product development in the retail industry (Adamik and Nowicki, 2019). There is a high risk of maintaining delay in organisational production by using supplier-customer co-development. The involvement of customers and suppliers in improving product design creates market delays and negatively impacts supply chain operations effectively. Management of retail organisations can develop supplier-customer co-development for achieving better benefits in customer relationship management (Cao et al. 2021). A customer-centric mindset of suppliers and brands helps to provide greater customer value and maintain positive relationships with customers. Supply chain optimization helps in the reduction of operational costs. The expense of supply chain infrastructure can be effectively controlled and managed by optimising the warehouse and the entire process of logistics. Lean supply chain leads to the improvement of the activities of this practice and this enables manufacturing companies to deliver products quickly without any delay with a minimum generation of waste (Nimeh et al. 2018). This helps in saving a significant amount of the company’s cost as the manufacturing business generates lots of waste and implementation of lean practices can save costs thereby improving operational efficiency. These organisations are now increasingly trying to become lean due to its additional advantages and to get competitive advantages in the market. The entire market scenario has changed after the hit of COVID-19 and the companies that already implemented lean tools were capable of dealing with the changes in the business process caused by the hit of the pandemic. It also helps to bring new ideas, products, and services as per the customer’s wants therefore the risk of product failure and supply chain disruption can be reduced. It has been seen that maintaining supplier-customer co-development strategies will provide better advantages for an organisation in maintaining their business cost and bringing good quality products. Supply chain management plays an important role in developing products and involving customers in the design process.

Future trend of supplier and customer development

Implementation of innovative technologies and communication platforms are the major trends in the supply chain process to collaborate with customers in managing customer-supplier co-development (Adamik and Nowicki, 2019). Many retail organisations implement advanced technologies to track their supply chain operation and engage customers in developing products as well as services effectively. It is the responsibility of suppliers to sell products to customers through retailers. The retailers make orders from suppliers and sell them to customers (Yang et al. 2018). This is the overall structure of the supply chain where the pull strategy is applied to generate a higher level of order quantity. It would allow companies to instantly adapt to changes arising in the work process, faster delivery of products, and reduction of resource waste, increased productivity and improvement in flow efficiency. Manufacturing facilities are effectively benefited while transforming push systems into pull systems (Frank et al. 2019). The main focus of organisations is to promote sustainable supply chain practices and reduce business operational costs in the future. Therefore, it is important to improve collaboration strategies in developing supplier-customer co-development strategies within the business.

Case study example

There are different retail organisations such as Tesco, and Asda in the UK that focus on developing a customer-centric mindset within the business to improve organisational performance effectively (Cao et al. 2021). Tesco uses innovative communication strategies through digital platforms to collaborate with customers and involve them in developing supply chain processes, products as well as services. Shipping companies such as Walmart conduct in-depth research regarding various factors for the determination of demands and incorporation of knowledge into the company’s supply chains. Push and pull supply chains are the most important part of managing inventory and this has led Amazon to become the world’s biggest online retailer. The management of Asda is also modifying its supply chain process and wants to maintain good relationships with suppliers to design products as per the customer wants. Good collaboration strategies with customers help retail organisations to get better success in relationship management and enhance business profitability effectively. It is important to improve a customer-centric mindset to minimise the market failure risk in an effective way. There is a risk regarding delays in the market that can be faced by organisations by developing customer-suppliers co-development (Lehtimäki et al. 2018). The Involvement of customers in developing products as well as services reduces organisational productivity and it may directly impact business growth in several market segments. Therefore, it is important to improve the customer-supplier co-development strategies for maintaining future trends in the supply chain process. Hence, it is evident that the development of customer-supplier co-development strategies helps in improving the overall efficiency of the process which further helps in sauvignon the cost of supply chain activities and overall time. This allows manufacturing companies to deliver products to potential customers within an estimated timeframe which further leads to the enhancement of customer satisfaction and they become more loyal to the company (Colicchia et al. 2017). Manufacturing and services companies can therefore gain the trust of their potential customers which increases the retention rate to a significant extent. This as a result helps in the improvement of brand reputation which becomes a powerful tool for these companies in the context of marketing to attract new customers. Companies become faster in delivering their services and more accurate which increases their profitability rates and business revenue. There are different supply chain optimization tools available in the market and the selection of the right one would enable companies to deliver the right kind of orders to the right consumer thereby satisfying customers’ needs.

References

Abu, F., Gholami, H., Saman, M.Z.M., Zakuan, N. and Streimikiene, D., 2019. The implementation of lean manufacturing in the furniture industry: A review and analysis on the motives, barriers, challenges, and the applications. Journal of Cleaner Production, 234, pp.660-680.

Adamik, A. and Nowicki, M., 2019. Pathologies and paradoxes of co-creation: a contribution to the discussion about corporate social responsibility in building a competitive advantage in the age of industry 4.0. Sustainability, 11(18), p.4954.

Anderson, D.M., 2020. Design for manufacturability: How to use concurrent engineering to rapidly develop low-cost, high-quality products for lean production. Productivity Press.

Andreini, D., Romano, E. and Pedeliento, G., 2018, June. How Can Marketing Enhance the Innovation Process in B2B Context?. In Practitioners Proceedings of the 2018 University-Industry Interaction Conference (p. 66).

Appio, F.P. and Lacoste, S., 2019. B2B relationship management in complex product systems (CoPS). Industrial Marketing Management, 79, pp.53-57.

Cao, Y., Dong, Y., Ma, D. and Sun, L., 2021. Customer concentration and corporate risk-taking. Journal of Financial Stability, 54, p.100890.

Colicchia, C., Creazza, A. and Dallari, F., 2017. Lean and green supply chain management through intermodal transport: insights from the fast moving consumer goods industry. Production Planning & Control, 28(4), pp.321-334.

Cooper, R. and Slagmulder, R., 2017. Supply chain development for the lean enterprise: interorganizational cost management. Routledge.

Dieste, M., Panizzolo, R., Garza-Reyes, J.A. and Anosike, A., 2019. The relationship between lean and environmental performance: Practices and measures. Journal of Cleaner Production, 224, pp.120-131.

dos Santos Hentschke, C., Torres Formoso, C. and Echeveste, M.E., 2020. A customer integration framework for the development of mass customised housing projects. Sustainability, 12(21), p.8901.

Fera, M., Fruggiero, F., Lambiase, A., Macchiaroli, R. and Miranda, S., 2017. The role of uncertainty in supply chains under dynamic modeling. International Journal of Industrial Engineering Computations, 8(1), pp.119-140.

Fernie, J. and Sparks, L. eds., 2018. Logistics and retail management: emerging issues and new challenges in the retail supply chain. Kogan page publishers.

Frank, A.G., Mendes, G.H., Ayala, N.F. and Ghezzi, A., 2019. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technological Forecasting and Social Change, 141, pp.341-351.

Jekiel, C.M., 2020. Lean human resources: redesigning HR processes for a culture of continuous improvement. Productivity Press.

Lehtimäki, T., Komulainen, H., Oinonen, M. and Salo, J., 2018. The value of long-term co-innovation relationships: experiential approach. International Journal of Business Innovation and Research, 16(1), pp.1-23.

Mitrega, M., Henneberg, S.C. and Forkmann, S., 2018. Capabilities in business relationships and networks: An introduction to the special issue. Industrial Marketing Management, 74(1), pp.1-3.

Najafi-Tavani, Z., Mousavi, S., Zaefarian, G. and Naudé, P., 2020. Relationship learning and international customer involvement in new product design: The moderating roles of customer dependence and cultural distance. Journal of Business Research, 120, pp.42-58.

Nimeh, H.A., Abdallah, A.B. and Sweis, R., 2018. Lean supply chain management practices and performance: empirical evidence from manufacturing companies. International Journal of Supply Chain Management, 7(1), pp.1-15.

Oinonen, M., Ritala, P., Jalkala, A. and Blomqvist, K., 2018. In search of paradox management capability in supplier–customer co-development. Industrial Marketing Management, 74, pp.102-114.

Statista.com, 2022. What is the biggest challenge you are facing in your supply chain?. Available at: https://www.statista.com/statistics/829634/biggest-challenges-supply-chain/ [Accessed on 5 May 2022]

Tarafdar, M. and Qrunfleh, S., 2017. Agile supply chain strategy and supply chain performance: complementary roles of supply chain practices and information systems capability for agility. International Journal of Production Research, 55(4), pp.925-938.

Tezel, A., Koskela, L. and Aziz, Z., 2018. Lean thinking in the highways construction sector: motivation, implementation and barriers. Production Planning & Control, 29(3), pp.247-269.

Yang, L., Cai, G. and Chen, J., 2018. Push, pull, and supply chain risk‐averse attitude. Production and Operations Management, 27(8), pp.1534-1552.