MOD007698 Supply Chain Assignment Sample

Introduction

Supply chain management is referred as a significant area of the business environment which is related with the flow of goods and services in a market. The overall procurement of raw materials to the delivery of the final product or service each activity is related with the supply chain management of these aspects. This consultancy report is based on AbTech is a start-up which is based in the United States dealing in new thinner LCD touch glass that is recycled through mobile phones and tablets which have been discarded by the customers. An innovative solution has been developed by the organisation to recycle these electronic devices in order to produce high quality touch glasses which can be used for further use by other businesses in new devices. This report is focussing on the different supply chain strategies and frameworks, outsourcing and forecasting of the sales of the business. The different risk management practices and its advantage for the business are analysed in this report. The use of technology and useful supply chain strategies are analysed which can be recommended for better changes in the business environment.

Scenario Analysis

The CEO of AbTech is Jonathan Furness who has introduced this innovative technology by using his problem solving and critical thinking skills. A deep analysis and research has been made by Jonathan to find effective solutions in order to recycle the discarded electronic devices to generate better products out of it (Attaran, 2020, July). AbTech has built a team of experienced professionals which have proficiency in the field of engineering, science and research. 3 million dollars are invested by the US bank in this start-up in return of the 25% share of AbTech.

This deal has been made by the investors after getting impressed by the sustainable approach which is adopted by the organization to produce its products and reduce the overall wastage which is having a negative impact on the overall environment. Jonathan has taken this investment in order to undertake his expansion practices to different nations and places where the high quality LCD touch glass can be sold and better profit be made by the business. There are certain issues and challenges with generally arise among the business for the allocation of their raw material and overall management in the supply chain operations (Cole et. al. 2019). These issues generally have a negative impact on the overall success of the business as they reduce the productivity of the company to achieve better results and gain better quality of output. Changing policies and procedures of the government, lack of raw material, unfavourable suppliers etc. are major problems which arise among the business and increase the overall difficulty for them to grow in the industry.

The US bank has identified that the supply chain production and management activities of AbTech are not properly organised. This factor is having a negative influence on the overall relationship between the US bank and the organisation which is considered as a potential threat in the overall management of the organisation. It is crucial for the organisation to monitor their supply chain management and satisfy the investor’s in order to see their best interest in the organisational activities. The organisation and suppliers which generate e waste in large quantities are majorly targeted by AbTech for reducing the problem of raw material allocation which is needed by them in order to grow and attain butter success in the end. However, the US government has also put external pressure on the businesses to recycle at least 10% of their products in their production process and enhance their overall success.

The unavailability of appropriate resources is having a direct impact on the supply chain management of the business as it reduces its growth to effectively manage the interest of the different people which are associated with the process. Shipment costs have also experienced a rise in the prices due to inflation which is also creating difficulties for the management to have a control over their expenses properly (Cousins et. al. 2019). AbTech are facing the problem of large queues in front of their factory as Lorries get accumulated in large numbers due to miss management of the supply chain. It is necessary for the organisation to adopt suitable supply chain Strategies and use the models and frameworks which are developed by authors in order to improve their overall performance in the industry. These practices are considered as important for the organization to improve their management of the supply chain and experience better results in increasing their quality of output.

Supply chain strategies and frameworks

Supply chain models

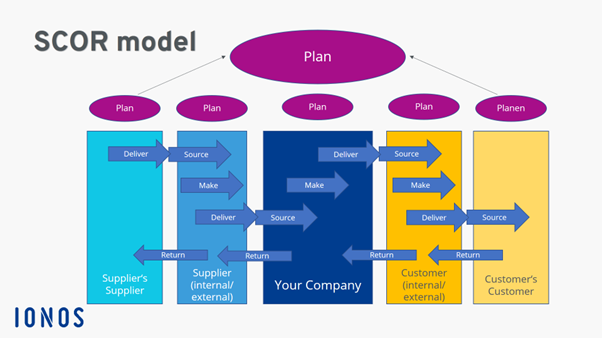

There are different models and frameworks which are introduced by authors in order to support the organisations which are facing issues in their supply chain management. The supply chain operations reference model (SCOR) is a unique model which is helpful in in identifying the issues with generally arise among the businesses and useful in developing effective mitigation strategies which are critical for organisational success. There are different areas which are included in this model which needs to be understood in order to improve the supply chain management of the AbTech are as follows:

Plan

Planning and strategy for raising the overall demand and supply of the products and services in the market is one of the most important stages which needs to be followed by the organisation. This can enhance the overall strategic development practices which can be helpful for preventing the company from getting infected through different risks and challenges (Craighead et. al. 2020). Establishing effective communication in the supply chain is important for AbTech to facilitate the overall management of different operations which take place on a daily basis in the business environment. A proper system can be established by the organisation with the help of these factors which are considered as an integral part of the business process.

Source

The procurement of the required resources and equipment for the production process comes in this practice which is considered as an integral part of the business management. It is crucial for AbTech to identify their needs and invest in the inventory, supplier network etc. activities which are essential for the establishment of a better supply chain management process. Sourcing the raw materials from the right suppliers can be useful for the company to generate better quality of output and increase their sustainability in the industry.

Make

The production process of the LCD screens requires proper consideration and monitoring by the AbTech in order to have better control over their supply chain management. It is crucial for them to identify the different elements which are required for them and the aspects which need to be neglected while conducting their supply chain management practices (Esmaeilian et. al. 2020). The use of the procured resources should be effectively made by the organisation in order to justify their expenditure and increase the profitability of the company.

Figure 1: SCOR Model

(Source: The SCOR model: definition and tasks explained, 2022)

Deliver

In this stage, transportation and storage activities of the prepared products are undertaken for supplying the goods to the customer. This is useful for increasing the satisfaction levels of the retailers and suppliers to which the products are transferred. Management of the products, packaging of inventory, overall calculation of the products etc. are different practices which are necessary for the company to regulate in order to grow and the business environment.

Return

The return of the Containers in which the rejected products are sent back to the organisation is also considered as an important factor to have a focus (Harini et. al. 2020). This tells about the effectiveness of the organisation to prepare complete products and the overall efforts which are made by them to gain better benefit from the process.

Outsourcing of the supply chain

The outsourcing of Business activities and practices has become excessively popular in the market recently. This service has been provided by organisation to other businesses in order to reduce the external burden which is faced by them in managing certain aspects which need proper consideration. The advantages and disadvantages of the process of outsourcing are discussed as follows:

Advantages

Outsourcing is considered as a better service which provides the organisation within option to manage their work with the help of external sources. This feature provides them with the option to focus on their other related areas which requires more consideration and time. It increases the overall productivity of the employees as they don’t have to look out for the area which has been already outsourced by the management to any other organisation (Holmström et. al. 2019). With the help of outsourcing practices, AbTech can reduce the overall expenses which are having a negative impact on their profitability. This can provide them with better benefits and increase their sustainability in the business environment.

Disadvantages

There are certain drawbacks of outsourcing as it is slightly Complex for the organization to manage and include a third party for doing their tasks which can often hit back on their overall productivity. There can be an increase in the mistakes in the work which is done by an Outsourcing company having a major influence on the sustainability of the business in the competitive industry. There are several hidden charges which are associated with the Outsourcing processes that can reduce the productivity of the company in ensuring better success in their business environment. The shipping cost and freight charges have significantly increased due to the inflation in the business environment which can directly impact the profitability of the organisation to outsource their work to other businesses.

Forecast and modelling of sales to downstream suppliers

Forecasting is an effective practice which provides a brief understanding of the metrics that are going around in the business environment. It is crucial for the AbTech to forecast their sales and adopt better strategies which can be helpful for them to enhance the overall supply chain management. This can help them to allocate the resources in a better manner and further assist their production teams to focus on the estimated sales and undertake their production activities accordingly. Delphi Method is considered as an effective business framework which is used for forecasting the sales and helping the business to identify their future sales in advance (Khan et. al. 2021). Different questionnaires and surveys are effectively used with the help of this method in order to predict the sales of companies and develop better strategies which are crucial for getting better advantage and growth in the business environment. These activities are helpful for the downstream suppliers to circulate the products in the market and increase the overall productivity of the business to generate better quality of output. This can provide them with better resistance to allocate and deliver the products in a sophisticated way that can provide the maximum benefit to the business management to achieve higher quality of results.

Sustainability across supply chain

Sustainability is one of the most important factors which needs to be addressed by the business organisations in order to provide a better future to the coming generations. The business environment in today’s time is generating the maximum level of wastage which is degrading the quality of the natural resources which are available to people and having an overall negative impact on their living standards (Koberg and Longoni, 2019) . It is the moral responsibility of AbTech to have better control and monitoring over their wastage which can hamper the sustainability of the. An environment better system should be created by the management of the company to identify their wastage practices and develop better Strategies for mitigating the possibility of such risks which can act as a threat to the sustainability of the environment. Better frameworks can be established by the business to reduce their current wastage practices and enhance the overall success which is achieved by them to create better practices for the people to live in a wastage free environment. Ensuring sustainable practices at each level of the supply chain can provide better assistance to the business to effectively achieve this position where the wastage levels are low.

Supply chain risk management

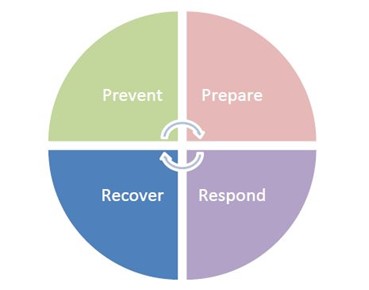

It is necessary for AbTech to adopt a suitable risk management strategy which can be helpful for them to mitigate the potential risks and threats which generally arise in their supply chain management. The PPRR risk management model is considered as an effective framework to analyse the performance of any Organisation in the business environment. It provides a brief idea to the company regarding the major changes which need to be made in their current practices in order to sustain in the business environment and ensure better effectiveness in the overall industry. The elements of the PPRR the model are as follows:

Prevention

Undertaking prevention is one of the best solutions to reduce the possibility of certain risks and challenges which usually arise among the businesses having a negative impact on their performance (Lahane et. al. 2020). Useful measures can be adopted by the AbTech to increase their productivity and identify the major risks which arise among their businesses.

Preparedness

The development of a contingency strategy is crucial for the business to effectively react in the time of emergency. Being prepared is considered as imported in the business environment as the supply chain management is generally dynamic in nature.

Figure 2: PPRR Model

(Source: PPRR Explained, 2022)

Response

The execution of the needed steps which are strategized by the business is considered as an important practice which must be effectively undertaken by the business. The proper management and execution of the reaction of AbTech can reduce the effect of the risks which arise among the business on a regular basis (McMaster et. al. 2020).

Recovery

Effective changes can be made by the organization in the decision making process which can improve the overall effectiveness of the business to protect them from such risks. These changes can provide them with a better approach towards conducting their supply chain activities which are an integral part of the business.

Using technology for enhancing the business

Technology plays a vital role in the management of supply chains as new business systems have been developed by IT firms which are critical for the overall management of the business operation. A significant change in the organisational productivity can be experienced by AbTech through the inclusion of such technological systems or software that can provide a better technological approach towards the management of their supply chain practices. This can provide the information of real time activities which are conducted by the people associated in the supply chain management process of the business (Nunes et. al. 2020). The record of inventory, accounts, people etc. can be effectively made through these high quality IT equipment which are considered as best suitable for the organisation to stabilize their supply chain management process. This provides innovative solutions for the business management to inculcate certain factors in their strategy which are useful for them to produce and circulate better quality LCD screens in the market.

Supply chain strategies

There are several supply chain strategies which are developed by authors in order to provide better assistance to the businesses and increase their management of the supply chain processes which are described as follows:

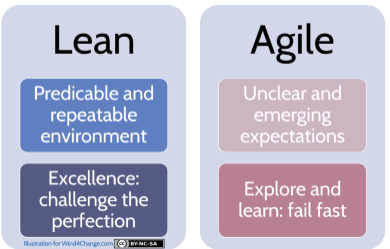

Lean supply chain strategy

This strategy is helpful for the businesses to have a control over their wastage in the supply chain management with the help of making certain changes in their level of inventory (Pettit et. al. 2019). It is effective for the business organisation to exclude external margins on their products which are reducing their overall profitability in the industry. However, a disadvantage of this strategy can be identified as the dependency of the businesses towards the forecast which is provided by this strategy to them. It is not suitable for a business which is working in a highly dynamic business environment.

Agile supply chain strategy

This strategy is different from the lean supply chain strategy as it considers making external expenses in order to achieve the overall goals of the business. Expenditure is made on the market analysis and Research which is critical for the business is to identify the demand and supply factors which are currently active in the market (Saberi et. al. 2019). This is helpful for them to prepare better Strategies and make effective changes in their supply chain management according to the market trends. Although, this strategy can become complex for some businesses to understand and make an effective use of the principles which are communicated by it. It can increase the risk of loss for the business which is not suitable for them to grow.

Figure 3: Supply chain management strategies

(Source: Agile vs Lean: what are differences between Aile and Lean?, 2022)

Hybrid supply chain strategy

The hybrid strategy is referred to as the effective use of both Agile and lean supply chain management strategies in order to produce better quality of output. It is generally a flexible approach which focuses on both the aspects of saving money and doing certain expenditures in the Research and Analysis of the market situation (Wieland, 2021). With the help of this strategy and effective use of the both supply chain management strategies can be made which is critical for the success of the AbTech in the difficult market conditions where they are finding issues in the management of their supply chain properly.

The hybrid strategy is considered as the best suitable for AbTech to adopt and enhance their supply chain management practices which are an integral part of the business process and have a better impact on their success in the industry (Zekhnini et. al. 2020). An effective use of both the strategies can be made by the organisation for finding better results and achieving higher quality of output that is necessary for them to grow in the business environment.

Conclusion and Recommendations

It has been concluded from the above report that AbTech has faced various difficulties in their supply chain management process which has a negative impact on the overall performance. The productivity of the company in the competitive business environment has reduced due to this factor which is considered to be having a major impact on its sustainability. The use of different supply chain Strategies and models has been effective for the organization to mitigate the impact of such risks and challenges on their organizational success (Xu et. al. 2020). Better results have been found by the organisation with the help of these strategies that are considered as important for them to sustain in the business environment.

It is recommended to the organisation to adopt Advanced Technological Solutions that can improve their supply chain management in a better Manor. The use of hybrid supply chain strategy is effective for the company to increase their overall success in the business environment. With the help of such changes the organisation has been able to grow and advance their overall business environment and achieve better quality of output.

References

Attaran, M., (2020, July). Digital technology enablers and their implications for supply chain management. In Supply Chain Forum: An International Journal (Vol. 21, No. 3, pp. 158-172). Taylor & Francis.

Cole, R., Stevenson, M. and Aitken, J., (2019). Blockchain technology: implications for operations and supply chain management. Supply Chain Management: An International Journal.

Cousins, P.D., Lawson, B., Petersen, K.J. and Fugate, B., (2019). Investigating green supply chain management practices and performance: The moderating roles of supply chain ecocentricity and traceability. International Journal of Operations & Production Management.

Craighead, C.W., Ketchen Jr, D.J. and Darby, J.L., (2020). Pandemics and supply chain management research: toward a theoretical toolbox. Decision Sciences, 51(4), pp.838-866.

Esmaeilian, B., Sarkis, J., Lewis, K. and Behdad, S., (2020). Blockchain for the future of sustainable supply chain management in Industry 4.0. Resources, Conservation and Recycling, 163, p.105064.

Harini, S., Hamidah, H., Luddin, M.R. and Ali, H., (2020). Analysis supply chain management factors of lecturer’s turnover phenomenon. International Journal of Supply Chain Management.

Holmström, J., Holweg, M., Lawson, B., Pil, F.K. and Wagner, S.M., (2019). The digitalization of operations and supply chain management: Theoretical and methodological implications. Journal of Operations Management, 65(8), pp.728-734.

Khan, S.A.R., Yu, Z., Golpira, H., Sharif, A. and Mardani, A., (2021). A state-of-the-art review and meta-analysis on sustainable supply chain management: Future research directions. Journal of Cleaner Production, 278, p.123357.

Koberg, E. and Longoni, A., (2019). A systematic review of sustainable supply chain management in global supply chains. Journal of cleaner production, 207, pp.1084-1098.

Lahane, S., Kant, R. and Shankar, R., (2020). Circular supply chain management: A state-of-art review and future opportunities. Journal of Cleaner Production, 258, p.120859.

McMaster, M., Nettleton, C., Tom, C., Xu, B., Cao, C. and Qiao, P., (2020). Risk management: Rethinking fashion supply chain management for multinational corporations in light of the COVID-19 outbreak. Journal of Risk and Financial Management, 13(8), p.173.

Nunes, L.J.R., Causer, T.P. and Ciolkosz, D., (2020). Biomass for energy: A review on supply chain management models. Renewable and Sustainable Energy Reviews, 120, p.109658.

Pettit, T.J., Croxton, K.L. and Fiksel, J., (2019). The evolution of resilience in supply chain management: a retrospective on ensuring supply chain resilience. Journal of Business Logistics, 40(1), pp.56-65.

Saberi, S., Kouhizadeh, M., Sarkis, J. and Shen, L., (2019). Blockchain technology and its relationships to sustainable supply chain management. International Journal of Production Research, 57(7), pp.2117-2135.

Wieland, A., (2021). Dancing the supply chain: Toward transformative supply chain management. Journal of Supply Chain Management, 57(1), pp.58-73.

Xu, S., Zhang, X., Feng, L. and Yang, W., (2020). Disruption risks in supply chain management: a literature review based on bibliometric analysis. International Journal of Production Research, 58(11), pp.3508-3526.

Zekhnini, K., Cherrafi, A., Bouhaddou, I., Benghabrit, Y. and Garza-Reyes, J.A., (2020). Supply chain management 4.0: a literature review and research framework. Benchmarking: An International Journal.

Agile vs Lean: what are differences between Aile and Lean?. (2022). [Online]. [Accessed through]: < https://wind4change.com/lean-agile-difference-same-vs-what/>

PPRR Explained. (2022). [Online]. [Accessed through]: < https://www.gawler.sa.gov.au/services/emergency-management/pppr-explained>

The SCOR model: definition and tasks explained. (2022). [Online]. [Accessed through]: <https://www.ionos.com/digitalguide/online-marketing/online-sales/scor-model/>

Know more about UniqueSubmission’s other writing services: