Operations and Supply Chain Management ASSIGNMENT SAMPLE

1. Lean application

Lean is mainly developed to stay competitive in the globalized world of this current situation. It is evaluated that ignoring continuous changes, as well as continuously improved innovation technology, is dangerous to the future of any business (Djapic et al., 2019).

Thus, every business organization has to adapt, embrace, and change management and creativity as well. In order to improve operational management through the lean business plan, organizations need to define and gather all required information regarding work in silos, upfront and quality checks so that no longer waste can be found in the business.

Lean business analysis refers to the increasing efficiency in making incremental improvements through capturing and improving customer feedback and software development early and often (Djapic et al., 2019). On the other hand, it also helps in minimising waste during the product development cycle. Most importantly, lean business analysis refers to the prioritised system that would elaborate experimental planning as well as incremental benefits, continuous development, celebrating purposes and many more (Gamad, 2019).

Many organisations have utilised lean techniques in their operational, financial, and manufacturing divisions. It was repeatedly examined and established that the sole goal of the lean analysis is to eliminate waste (Čečević and Antić, 2018). A strategy called Kanban helps organisations get rid of excessive stockpiles that might be inefficient. Kaizen is a philosophy that aims to make every aspect of everyday work better while involving the staff.

The staff believed that maintaining and controlling these systems was extremely important to them. In order to easily improve job quality, the system must be updated. Motorola created the Six Sigma methodology, which consists of the Six Sigma DMAIC and Six Sigma DMADV procedures (Čečević and Antić, 2018).

2. Combined lean analysis

The consultants who were trained on lean analysis and the Six sigma approach understood the importance of Six Sigma tools. They have realised the connection between Six sigma and the Lean tools since 1980. The combination can improve the quality of work removing wastage. The combined approach of lean six sigma strengthens improves the quality and minimises the weaknesses of both approaches.

Most organisations that aim for greater quality of work took the initiative of this combined approach. The lean tools have been used by several organisations in their manufacturing, operational and financial departments. It was reviewed several times and it was proved that lean analysis only aims to remove waste (PURDUE UNIVERSITY, 2021). Kanban is a system to remove large inventories which could be wasteful for the organisation.

Kaizen is the concept that improves all the daily operations and involves the employees in the process. The employees felt that the maintenance and control of these systems were very critical for them. Therefore, the system needs to be modified to increase the quality of work easily. The Six Sigma philosophy was developed by Motorola which has two processes such as Six Sigma DMAIC and Six Sigma DMADV.

This management philosophy emphasizes the collection and analysing of data which results in reducing the defects in services and products. The philosophy states that the measurement of defects in the daily process will help to remove the defects systematically and get as much perfection as possible. Six Sigma DMAIC is a process that is used to measure, analyse, control and improve the existing processes that were used before Six Sigma. Similarly, Six Sigma DMADV measures, designs, analyses and verifies the new processes that are used for getting quality products.

All the processes of Six Sigma are done by the Six Sigma Green Belt or Black Belt holders. Then finally the process is checked by the Six Sigma Master Black Belts (SSMBB). This approach claims to reduce cost and waste materials by up to 50% and provides a better understanding of customer requirements and satisfaction. The process aims to provide more reliable and high-quality services and products to the customers.

The Six Sigma and Lean processes both aim to get an efficient system that will eliminate waste. Both the processes when combined result in a higher scope of identifying the wastes and defects and help in process improvements. The conceptual framework of Lean Six Sigma gives several benefits to the organisation and therefore these processes are used together by most organisations.

These processes reduce the operational cost eliminating the use of unnecessary labour and resources (Muhoro, 2019). It also helps in increasing the productivity of the organisation by reducing the volume of defective goods. The Lean Six Sigma process uses standardising processes to remove defective materials from daily operations which results in a higher quality product (Silva, 2022).

The combined approach relies on the improvements of the employees through proper training; therefore, it results in higher motivation. Simultaneously, the motivation of the employees boosts the total productivity (Silva, 2022).

3. Consolidated Lean Applied plan

Planning a fitting arrangement for the development of lean management by the thought of a hypothetical structure and proper model is profoundly essential for the accomplishment of progress with the early arrangement and thought of advancement.

Identification of likely difficulties and boundaries related to hierarchical activity and the board exercises contribute to planning successfully in administration approaches of controlling authoritative promoting exhibitions and business activity by lessening waste and deciding possible gamble in the underlying stage.

The organization has taken on the lean-worth stream as the underlying standards and waste end as second standards of lean management for hierarchical tasks in a methodical way.

Authoritative activities and exercises contributed to making significant items in view of the objective market. Numerous unmistakable practical gatherings participate in business exercises including creation and stepping for persistent authoritative activities (Ribeiro et al., 2019).

The organization centers around the board of waste in a likely methodology for a decrease of carbon impression. The third significant guideline of Caldertech is to request control of the board by the arrangement of genuine worth stages for matching up client interest and authoritative cycle.

For the development of business tasks and supply networks, the board of Caldertech thought of hypothetical components as exceptionally vital for progressing process planning strategies. The association centers around keeping up with corporate social obligation by taking on an eco-accommodating strategy for pipeline administrations however much as could be expected to keep up with maintainability and shrewd use of regular assets.

Transformation of fitting examination strategies for distinguishing every one of the potential choices for further developing resource management and showcasing exhibitions of the organization will help in further developing brand personality in the serious climate for expanding client channels and open doors for a business extension by getting chances of entering another commercial center. In this way, turnaround strategic and eco-accommodating methodologies are suggestions for the development of lean management arranging of Caldertech.

Rebuilding the authoritative stock organization by recognizing savvy courses and high-level programming is important for the board of time and assets of finishing undertakings and exercises in the serious commercial center. Transformation of time usage technique by fostering the briefest course for acquisition and strategies can contribute to further development by showcasing exhibitions from various aspects and expanding consumer loyalty levels altogether.

Traffic updates and area updates of supply vehicles will help in contributing to accomplishing business objectives and goals through the ordinary improvement of business commitment (Yadav et al., 2018). Improvement of a high-level lean management plan by considering proper market suggestions in light of late patterns and hypothetical perspectives can further develop business execution from numerous aspects and increment the benefit age process.

Transformation of clean wellsprings of energy and eco-accommodating stockpile network is significant in the contemporary promoting climate for keeping up with lawful and political systems because of rising worry on carbon decrease methodologies universally.

4. Performance Contextual performance Dimensions Analysis (polar diagram)

In the business context, supply chain management and logistic support are becoming crucially influential. Although an operations and supply chain management have many participants such as resellers, producers, and purchasers, relevant data and resource movement via these relationships from resource to client must be integrated for good implementation. A practical plan for handling issues with creation and processing in supply chains is important for perfect operations.

Their conceptualization relates to the three main collaboration systems. Many businesses have examined their production processes in relation to the participants, events, and processes used as a result of the distribution network and logistical concerns associated with them (Maditati, et al. 2018). Today, internationalization has taken over as the dominant force.

Purchasers have a wide range of options, which are generally comparable in relation to the competition, yet their requirements are now more volatile, active, and noticeable. When an enterprise views the entire globe as its industry, speed, sustainability, ingenuity, and economics determine its competitiveness. The idea that businesses are nodes in a connected logistics system has arisen as a result of rising worldwide rivalry, and institutional concentration on internal capabilities.

Since the war for profitability is gradually being contested against distribution networks and not organizations, the commercial climate gets more intense. The operation of an organization’s short- and long-term goals is strongly affected by the appropriate consumers, the procurement strategy, and developing relationships with potential partners.

It has become essential for any company all around the country to use supply chain management concepts in order to achieve these targets. In this situation, more enterprises are seeing the supply chain management strategy as a chance to accomplish these objectives (Brinch, et al. 2018). Corporations address challenges cantered on working with key stakeholders and making extensive use of software platforms to secure efficiency and preservation.

Over the last decades, several tactics for adaptable supply chains have been established. Structured supply chains with fixed provider hierarchies and commercial agendas transform into a visible range of supply chain organization in several disciplines. Flexible businesses with diverse organizational hierarchies, and expertise, with divisions that are customer-focused are being implemented in practice these days. Supply chain management developed and became a shared application of information that included all the processes that companies engaged in to add value to their businesses because of better structural, and economical benefits.

Productive supply chain management operations are dependent on interrelated operations between organizations, using efficient logistics to generate a lasting and significant advantage. Supply chain management operations are the primary critical element for boosting leadership efficiency and for properly implementing change including order fulfilment, higher margins, and competitive pressures. An important company function for the implementation of accounting policy is the production chain procedure.

Supply chain is evolving into a service strategic sourcing that acknowledges the significance of public needs and makes an effort to embrace the intricacies of product attributes as a foundation of difference in the supply network, to achieve productivity gains (Zavala-Alcívar, et al. 2020). The idea of a logistics system has really been established as well as the structure’s complexity, there isn’t a definite cause of SCM that applies to all situations.

The concept of supply chain management is often used to describe supply chain systems amongst organizations and corporations to prepare and regulate supplies, communication channels, and materials management. Production process refers to every process associated with acquiring merchandise from the point of origin to delivering it to the purchaser.

Those certain processes include obtaining factors of production, components, and inventory surveillance, order fulfilment and management, and distribution of the goods. Most of these tasks are coordinated and combined by supply chain management operations into a batch product. The benefits of mobility, and scalability are found in customer connections and dynamic supply chain systems elevated by an expansion of options to find potential for a cooperative effort made possible by efficient scheduling solutions.

Polar Diagram

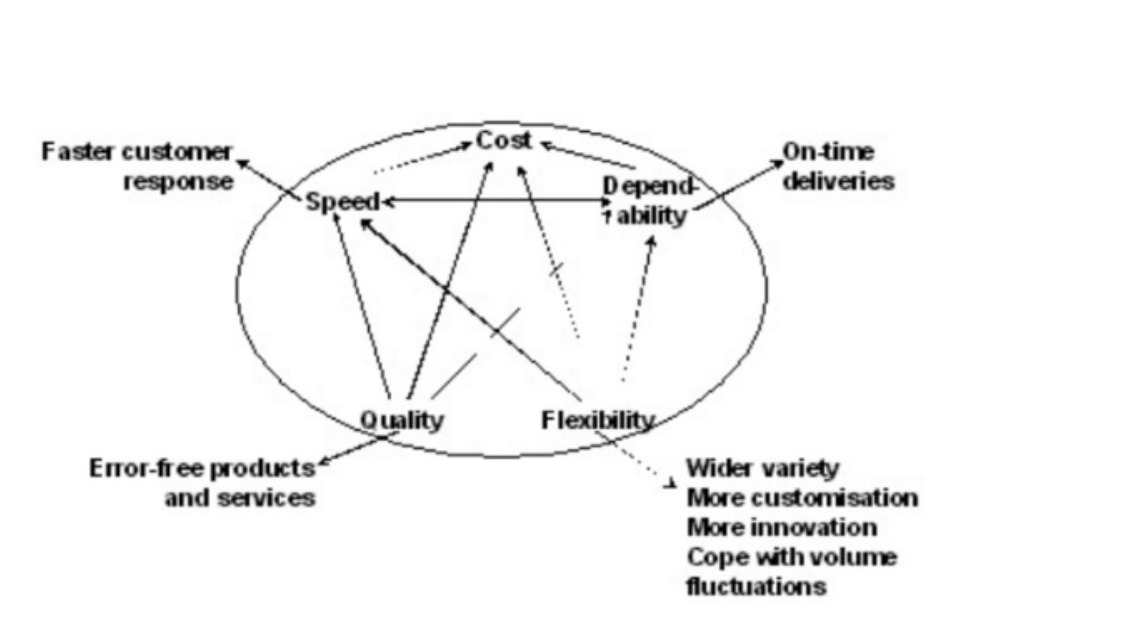

Figure 1: Contextual Framework of Supply Chain Management and Polar Diagram

In this polar diagram, we see the relationship between cost, dependability, flexibility, and quality speed. These aspects in turn affect delivery time, customization, innovation, volume fluctuations, error-free service and customer response.

When we analyse the data of this polar diagram, we see that an agency’s business model would become a crucial factor in its industry’s development and for creating a durable comparative benefit for the commodities. Analysts stress that having a flexible supply chain is a fundamental strategic criterion in the sector and that incorporating adaptability into activities necessitates an ongoing performance management with clients (Singh, et al. 2019).

Organizations must consistently present the concept, manufacture, and delivery operation of their product offerings to buyers in order to gain competitive advantage in today’s environment.

Lean Business Framework Improvement

Lean process improvement seeks to empower companies to discover methods to provide consumers with greater satisfaction and reduced time to send the product to the market. It accomplishes this by offering a methodical approach, and securely experimental method for incorporating sustainable growth into normal activities.

Productive lean process performance improvements require that any aspect of the organization be open to and prepared to compromise set routines for the betterment of the company. Beginning with the client, lean process optimization seeks to establish benefit before designing procedures that adequately suit that need of the company when using few resources and limited time (Almutairi, et al. 2019). Lean systems integration views all related company functions as developing variables instead of already accepted procedures since customer requests and expectations are ever-changing in today’s world.

Lean total quality management methods watch the entire business model as a controlled system and the segments are viewed as channels that merge into a single entity that finally contributes to the industry. The goal here is to get rid of as many obstacles as possible during the production and transport periods. Every activity in a genuine production system must benefit the finished project. A business that is devoted to lean operations needs to make an effort to cut corners across energy, and assets to name a few.

Wasteful shipping practices can result in high fuel usage, long production time, and substandard logistics providers. By locating connections that can be simplified or by relocating enterprises to advantageous positions, value chain analysis can assist in reducing shipping inefficiencies (Vanichchinchai, et al. 2019). It is necessary to keep enough items in stock to complete initial shipment and prepare for anticipated purchases but keeping merchandise in store requires a separate set of expenses.

While determining what material is required at what quantities without wasting resources, it is necessary to take into account everything from hiring warehouses to power cost, transit systems, and invested capital. Delaying in the production process can eventually become expensive for the company. For optimum use of labour, energy and money, correcting these situations to improve the lean business framework can be extremely beneficial for a company.

5. Impact of applied plan

Improvement of the lean management cycle of an organization helps in expanding capacities of giving high-level customer administrations and hierarchical capacity of keeping up with the lawful structure. Expanding capacities of giving high-level client administrations help in the maintenance of likely clients and make client channels for expanding authoritative deals.

This action has the capacity to further develop the benefit of age interaction generally. It likewise results in a positive commitment toward setting out business open doors of entering new commercial centers and producing the most extreme conceivable income (Koseoglu et al., 2018).

Acknowledgment of brand picture, improvement of representative abilities, mechanical variation, administration advancement, and cost-saving cycle are major upper hands that can be accomplished by Caldertech. These techniques are helpful for accomplishing authoritative objectives and targets from different aspects and accessing business potential open doors.

Planning of Advanced turnaround coordinated factors systems and the briefest course of finishing obtainment and stock exercises can help in creating abilities of hierarchical representatives. This technique can likewise emphatically contribute to working on the capacity of team management and connecting with various functional cycles by representatives through conceptualizing thoughts and dynamic cooperation in growing new systems.

Emphatically engaged towards the transformation of current innovation with the assistance of cutting-edge lean management techniques can likewise assume a huge part in expanding abilities and expert improvement of related representatives for expanding hierarchical capacities of offering progressed types of assistance to their client (Yadav et al., 2020). Upper hands utilizing trend-setting innovations help decrease hierarchical difficulties related to dispersion of items and management to the advertising region by affirming contingency plans and customary updates.

For instance, the establishment of live update administrations in the stock organization can help in following areas of management groups for different places and give nitty gritty data to the client for maintenance purposes and foundation of positive connections.

This technique can help in expanding reconciliation and devotion among clients by keeping up with cutting-edge authoritative worth by coordinated correspondence methodologies and mechanical ramifications (Neubert, 2018). Involving current devices and procedures for keeping a record of stock and acquisition exercises can likewise exceptionally contribute to the foundation of positive associations with related partners by returning higher in speculation and quality management.

Improvement of Advanced initiative abilities can be considered as a potential upper hand that can be accomplished by Caldertech through the execution of a created supply Network and cycle map for the development of lean management process in the organization. Usage of opposite planned operations methodology can help in setting out open doors of taking the quick choice of advancement of unrefined substances for giving pipeline administrations and increment exercise of hierarchical authority in the area of direction.

This cycle can help the situational dynamic course of authoritative pioneers in light of hierarchical interest to guarantee non-stop progression of benefit and effectively hold interior and outer partners for the longer term. Improvement of Creative methodology for acting in a serious promoting climate can set out open doors for practice in visionary and imagination abilities of hierarchical innovators to distinguish possible vital choices for improvement of cutting edge showcasing and functional exercises.

work on the inner and outer practical region of the organization (Neves et al., 2018). Accordingly, it may very well be expressed that Caldertech can build the proficiency of their stock organization and showcase exhibitions by centering towards expanding eco-accommodating methodologies and high-level waste administration methodology with new lean administration.

6. Conclusion

This paper concludes with the Six Sigma Master Black Belts checking the procedure at the end (SSMBB). This strategy promises to cut costs and waste resources by up to 50% while improving comprehension of client needs and satisfaction (Kumareswaran, 2019).

The procedure strives to give clients more dependable and high-quality services and goods. Lean and Six Sigma procedures both strive to create an effective system that will get rid of waste. Combining the two processes increases the potential for finding wastes and flaws and aids in process improvements. Since the Lean Six Sigma conceptual framework offers the organisation a number of advantages, most organisations combine these procedures.

These procedures cut operating expenses by avoiding the utilisation of extra labour and resources. Lowering the number of faulty items, also aids in boosting the organization’s production (Kumareswaran, 2019). By eliminating faulty materials from routine procedures, the Lean Six Sigma process produces a higher-quality end product.

The combined strategy depends on the employees’ growth through appropriate training, which raises motivation. Additionally, staff motivation increases overall productivity. Thus, the paper has evaluated the performance contextual framework with the help of polar diagrams.

Reference List

Journals

Almutairi, A.M., Salonitis, K. and Al-Ashaab, A., 2019. A framework for implementing lean principles in the supply chain management at health-care organizations: Saudi’s perspective. International Journal of Lean Six Sigma.

Balocco, R., Cavallo, A., Ghezzi, A. and Berbegal-Mirabent, J., 2019. Lean business models change the process of digital entrepreneurship. Business Process Management Journal.

Brinch, M., 2018. Understanding the value of big data in supply chain management and its business processes: Towards a conceptual framework. International Journal of Operations & Production Management.

Čečević, B.N. and Antić, L., 2018. SUITABILITY OF ACTIVITY–BASED COSTING FOR LEAN BUSINESS CONCEPT. Facta Universitatis. Series: Economics and Organization, pp.307-319.

Chassiakos, A., Karatzas, S. and Farmakis, P., 2019. BIM and Lean-Business Process Reengineering for Energy Management Optimization of Existing Building Stock. In Advances in Informatics and Computing in Civil and Construction Engineering (pp. 711-718). Springer, Cham.

Djapic, M., Popovic, P. and Lukic, L., 2019, November. Lean business practice as support to QMS implementation in according to ISO 9001: 2015. In IOP Conference Series: Materials Science and Engineering (Vol. 682, No. 1, p. 012017). IOP Publishing.

Gamad, L.C., 2019. Governing company performance agility through strategic quality management principles and lean business practices: evidences and challenges for the business industry in the Philippines. Review of Integrative Business and Economics Research, 8(4), p.17.

Koseoglu, O., Sakin, M. and Arayici, Y., 2018. Exploring the BIM and lean synergies in the Istanbul Grand Airport construction project. Engineering, construction and architectural management, 25(10), pp.1339-1354.

Kumareswaran, S., 2019. Factors Affect Effective Implementation of Lean System in the Glove Manufacturing Industry in Sri Lanka (Doctoral dissertation, University of Wolverhampton).

Maditati, D.R., Munim, Z.H., Schramm, H.J. and Kummer, S., 2018. A review of green supply chain management: From bibliometric analysis to a conceptual framework and future research directions. Resources, Conservation and Recycling, 139, pp.150-162.

Muhoro. N., (2019). Advantages & Disadvantages of Six Sigma. Available at: https://smallbusiness.chron.com/advantages-amp-disadvantages-six-sigma-43963.html [Accessed on 5.07.2022]

Neubert, M., 2018. The impact of digitalization on the speed of internationalization of lean global startups. Technology Innovation Management Review, 8(5).

Neves, P., Silva, F.J.G., Ferreira, L.P., Pereira, T., Gouveia, A. and Pimentel, C., 2018. Implementing lean tools in the manufacturing process of trimmings products. Procedia Manufacturing, 17, pp.696-704.

PURDUE UNIVERSITY, (2021). Lean Tools and Principles and Their Applications. Available at: https://www.purdue.edu/leansixsigmaonline/blog/lean-tools/ [Accessed on 5.07.2022]

Ribeiro, P., Sá, J.C., Ferreira, L.P., Silva, F.J.G., Pereira, M.T. and Santos, G., 2019. The Impact of the Application of Lean Tools for Improvement of Process in a Plastic Company: a case study. Procedia Manufacturing, 38, pp.765-775.

Silva. S., (2022). The Benefits of Lean Six Sigma. Available at: https://www.reliableplant.com/Read/29726/lean-six-sigma [Accessed on 5.07.2022]

Singh, C.S., Soni, G. and Badhotiya, G.K., 2019. Performance indicators for supply chain resilience: review and conceptual framework. Journal of Industrial Engineering International, 15(1), pp.105-117.

Yadav, G., Luthra, S., Huisingh, D., Mangla, S.K., Narkhede, B.E. and Liu, Y., 2020. Development of a lean manufacturing framework to enhance its adoption within manufacturing companies in developing economies. Journal of Cleaner Production, 245, p.118726.

Yadav, V., Jain, R., Mittal, M.L., Panwar, A. and Lyons, A., 2018. The impact of lean practices on the operational performance of SMEs in India. Industrial Management & Data Systems.

Zavala-Alcívar, A., Verdecho, M.J. and Alfaro-Saiz, J.J., 2020. A conceptual framework to manage resilience and increase sustainability in the supply chain. Sustainability, 12(16), p.6300.

Know more about UniqueSubmission’s other writing services: