Procurement Risk and contract management

Introduction

Procurement risk is the process of anticipating the risk associated while sourcing the goods and services required to produce the final goods for timely delivery of the products or services by organisations. Procurement risk management is the process of analysing the risk associated while sourcing and safeguarding the business from the unwanted risk that can cause a problem during the procurement of the goods (Hong et. al. 2018). The procurement of goods brings the factor of quality of the product, the vendor reliability upon the contract, the quality and brand image with customer satisfaction. So, each aspect is needed to be analysed before the procurement of the goods or services. On the other hand, contract management is the process of a legal contract with the sourcing partners, vendors, customers for efficient execution of the business activities. Contract management is a process of managing the risk of execution of the contract among vendors, partners, customers that can form a barrier during the execution of the business activities efficiently. In this report, the Coca-Cola company will be considered for analysing the procurement function and sourcing methods implemented during the procurement process. The company will also be analysed to identify the risk associated with the procurement for understanding the importance of procurement risk management in managing projects. The process of risk management will be implemented to analysing the effectiveness of the sourcing of raw materials. And the risk assessment test will be implemented to identify the risk associated with procurement.

Procurement function

The main role of the procurement function is to ensure that the material required for producing the finished goods is available on time for minimisation of wastage and saving time. A company’s ability to sustain and grow in the global field is to implement a successful procurement strategy for supply chain management (Schuhmann and Eichhorn, 2017). The supply chain execution is the main part of procurement and if the process achieves excellence in procurement effectively the company’s objective can be fulfilled with optimisation of cost alongside timely delivery to the target market destinations. Here the Cola-Cola global procurement function will be shown for understanding the procurement process for successful growth in the business internationally.

Quality, cost, and delivery control: The Coca-Cola quality and supply chain is one of the best functions for procurement of the goods required sourcing of local areas rather than importing from different regions. The suppliers need to stay innovative and environment-free for delivering the raw materials. The bottling partner contract is a franchise partner who has also the responsibility of retaining the supplier eco-friendly certificate for forming a contract to execute the finished beverage to the market within 48 hours (Rahimian, 2020). The sourcing of suppliers has been a procurement process to low the cost and manage the quality with certification and declaration of quality by suppliers. The procurement function is to check the legal compliances protocol for better quality and social responsibility towards the target market for brand recognition.

Managing the process of bottling: The managing procedure during the execution of the sourcing is a very important function of procurement. The management of the internal processes helps build a good image in the external environment with control of the suppliers. Coca-Cola has an expert corporation working as regional headquarters near the bottling partners for ensuring and monitoring the standard followed by each group of partners (Haapio and Siedel, 2017). The bottler’s office works directly with Coca Cola export corporation for direct production and distribution in the region forming a strong supply chain process for quick delivery. The collaboration and the guidelines set between bottlers and the company is a procurement contract function conducted for managing the distribution of the goods at the regional end effectively.

Supplier relationship: A key aspect to procurement and management of the supply chain is its supplier. Coca-Cola follows the procurement strategy of forming a program of the supplier to enhance innovation among suppliers (Dosumu, 2018). The company’s procurement teams try to form a good relationship with yearly meetings for innovativeness in bringing changes for better quality products. The raw materials required are managed and reviewed yearly with good incentives for better performances.

Policy management: The procurement process function is to analyse and form changes in policy for better execution of production in Coca-Cola. Health and safety are the main concerns for people and with the set of new guidelines, the bottling partners need to form relations with suppliers who follow the guidelines of supplying syrups that are hygienic and safe for people. The policy change is also during the formation of supplier innovative programs (Suhonen et. al. 2019). And while controlling the employee’s movement with more than 100 employees of logistic in manufacturing regions for ensuring safe distribution of goods from factories to retail partners on time.

The key Process of procurement contract management in Coca Cola

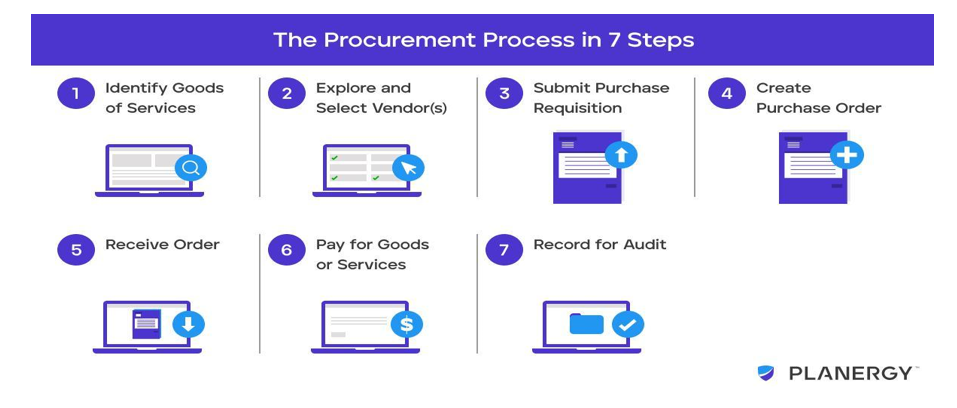

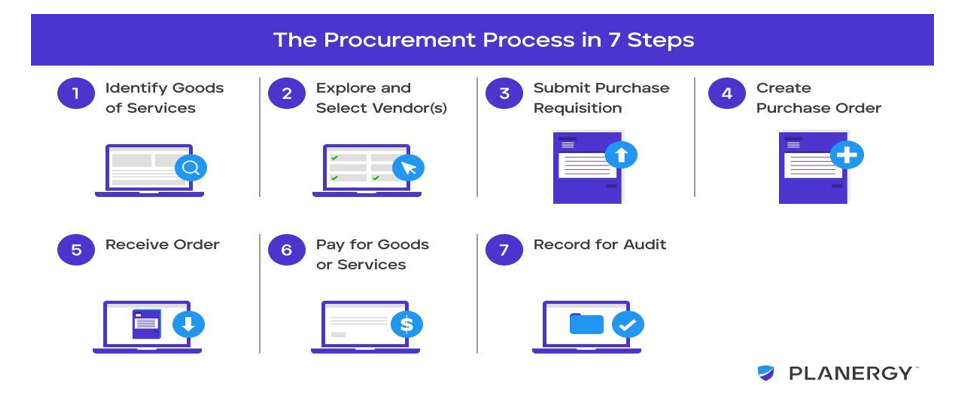

The identification of goods and service needs: Procurement and outsourcing begin with the requirement of the need for goods and services to manufacturing the final product. In Coca-Cola Company the requirement of need for raw materials is analysed and form a contract legally with suppliers and partners for manufacturing the final goods (Handayani, 2018). The bottling partner HCCBPL is the bottling franchise partner that is forming an agreement with the parent company for providing bottles with low environmental effects. The company forms ties with local partners that fulfil the requirement of the company for quality products.

Exploring and selecting vendors: The second stage is to explore and hire the vendors from the global sourcing method as per the requirement of the company. The cost-efficiency, quality, reliability, speed of the service delivery, and contacts will be analysed while selecting the vendors by Coca-Cola Company.

Submit purchase requisition: The purchase requisition is the process of internally varying with the finance department before the final purchase order. The purchaser branch, availability of transportation, service time, the price will be submitted to the internal financial department by procurement managers in the Coca-Cola company (Rendon, 2019). If the procurement guidelines match the next process is issued.

Create purchase order: The purchase order is created by the finance department in Coca-Cola after the final approval and the issue order of purchase is electronically formed for enabling the purchase legally with evidence.

Figure 1procurement stages in Coca Cola

(Sources: Murphy, 2017)

Receive invoice and order: The invoices are created after the delivery of the goods from vendors and the invoice of the order delivered, received invoices are aligned by Coca-Cola to checking the discrepancies for accurate payments after receiving the delivery of goods.

Final audit: After the order is received the invoices are compared by Coca Cola finance department and paid out to the vendors (Murphy, 2017). Now the final audit of the procurement of the goods is monitored for better growth in the business.

Sourcing methods of Coca Cola (Procurement and contract management types)

Sourcing is the process of finding and agreeing with external sources for forming a relationship with a contract for acquiring goods and services. Sourcing is procurement that is involved in forming the decision of buying to produce finish goods under resource scarcity (Myerson, 2018). The two types of procurement are used to source the goods for the final product in Coca Cola factory. They are:

Direct procurement: The sourcing of Coca-Cola company usage the direct procurement method for acquiring the raw materials required for end products. The factory of Coca-Cola procures the raw materials of syrup, agricultural products to make the drink, and bottling is direct sourcing where the bottle is assembled for final delivery of the goods.

Goods procurement: The goods procurement method is used by the company to source the raw material that is physical in nature and relies mostly on supply chain management for assembling the raw materials together for the final delivery of the goods.

Global sourcing: The Coca-Cola company implements the method of sourcing from the global market. The low-cost sourcing from the country includes only low-cost products but in global sourcing, the focus is on retaining quality products for manufacturing final goods (Yoon et. al. 2020). The main focus is to carry on the business in the local international market where the raw materials are mostly available with good distribution reach. The main focus of the company is to retain new resources as skills to improve the quality of the products.

Fixed firm price: The contract management of the Coca-Cola company follows the rule of providing only fixed price for a time frame with quality process checking at every access to the raw materials. The quarterly meetings are mandatory and the contract with the suppliers is to provide fixed prices for the goods and the variances in quality will be taken responsibility by suppliers (Wondimu et. al. 2018). These methods are very easy to form the budget for the expenses to incur during a year for raw materials helping in managing the cost of the production.

Fixed-price incentive fee: This is the same way of forming contract with the vendors by the company but the change is the incentives provided while souring the suppliers as this will help to increase the performance in production and distribution of the raw materials on time.

The procurement and contract management methods of sourcing help to source the suppliers that can form a contract relevantly with legal compliances in documents including a special clause to fulfil the quality of the goods. The methods of sourcing used in Coca-Cola helps to form contracts that eliminated the frauds among suppliers as the payment is fixed and breach the contract in terms of frauds and degradation in quality.

Key procurement risk associated with the procurement of goods and services with the help of risk assessment

Risk is part of procurement and the sourcing of the raw materials from external factors can be very unpredictable and unreliable. Risk assessment is the process of overall risk identification, risk analysis, and evaluation of the risk. The risk assessment will probably provide an understanding of the risk caused, the consequences of the risk, and the possible outcomes in the future (Yuan et. al. 2021). Therefore, to minimise the risk the identification of the risk is important to determine. With the help of risk assessment techniques, the risk procurement of the goods and services in Coca-Cola Company will be determined for future changes in procuring to acquire quality raw materials during production. The process of risk management will be implemented to identify the risk associated with Coca-Cola company procurement through the production of risk assessment.

Risk identification: The hazard risk that can be caused by the Coca Cola company during procurement are:

Vendor selection: The selection of the vendor is one of the toughest choices made by Coca-Cola. The vendors are selected as per the legal compliances and policy standards set by the company. The contracts are signed before the purchase orders are made. The vendor selection from across the globe is a difficult choice to make at remote areas distribution channels.

Contract management process: The contract management process is very organised in Coca-Cola company in terms of the agreement between vendors and company. But the risk is with the manipulation of the contract in between the internal management process. The quality of the contract decreases with the non-explanation of the contract towards the suppliers causing risk in the quality of the supply in the company (McNamara and Sepasgozar, 2018). The direct face-to-face interaction with the CEO is not available with widespread of the manufacturing units in Coca Cola. And this is a barrier for contract management procurement.

Talent shortage: The risk is the shortage of talent in local areas. As the shifting in local regions for manufacturing the products can be very unlikely for employees. The people who don’t want to transfer to local areas need local talents. The risk can increase in terms of quality check if the local talents are not skilled as per the requirement in procuring and checking the quality of the raw materials provided.

Variation in supplier relationship: The supplier relationship is very good in the Coca-Cola company. However, the supplier who does not attend meetings are rated low and review can be biased in terms of low participation in Coca Cola supplier programs (Amankwah and Ayarkwa, 2021). The supplier is not provided incentive who does not innovate and participate in new areas. Therefore, the insecurity among suppliers can be cause for low-quality products supply in certain remote areas due to offensiveness.

Risk assessment

Probability technique: Another way is to use the probability technique of risk assessment. The probability of the risk in procurement can be evaluated with high impact and low impact aspects with the occurrence of the factors.

Here the likelihood of occurrence will be multiplied with impact to get the risk.

Table for risk assessment for Coca Cola

| Risk | Probability | Impact | Risk score | Risk control | Residual risk | Secondary risk |

| Planning time | 4 | 4 | 16 | Mitigate | 8 | Overworking of the staff or mismanagement among the staff |

| Complexity | 4 | 3 | 12 | accept | 4 | Due to delay in time and workload for international reach |

| Supplier relationship | 2 | 1 | 2 | accept | 2 | Due to change in contracts |

| Talent shortage | 4 | 5 | 20 | mitigate | 18 | Due to local preferences |

| Vendor selection | 2 | 5 | 10 | accept | 8 | Shortage of vendor |

| Contract management process | 2 | 1 | 2 | accept | 1 | Legal intervention |

| Technical issue | 2 | 1 | 2 | accept | 2 | Increase of the cost and technical errors |

| Demand of customer | 1 | 4 | 4 | accept | 3 | none |

| Financial risk | 5 | 5 | 25 | mitigate | 22 | Delay in project |

| Management control | 2 | 5 | 10 | mitigate | 8 | Delay in making decisions |

1= Rare/insignificant

2=unlikely/Minor

3=Possible/Moderate

4=Likely/major

5=almost certain/catastrophic

Risk matrix model

| Probability | RARE

1 |

Demand of customer | ||||

| UNLIKELY

2 |

Supplier relationship

Contract management Technical issue |

Vendor selection

Management control |

||||

| POSSIBLE

3 |

||||||

| LIKELY

4 |

Complexity | Planning time | TALENT SHORTAGE | |||

| ALMOST CERTAIN

5 |

Financial risk | |||||

| INSIGNIFICANT

1 |

MINOR

2 |

MODERATE

3 |

MAJOR

4 |

CATASTROPHIC

5 |

||

| IMPACT | ||||||

Figure 2: Chart of risk-ranking

This chart represents the risk that is associated with the areas of risk in Coca Cola company

Supplier relationship: The Low impact and likely to occur will be the variation in a supplier relationship. The supplier with bad relations can be made off the contract by the Coca-Cola company with many other reliable vendors across the globe.

Talent shortage: However, the High impact with likely occurs is the Talent shortage that can affect the procurement of goods and services with bad quality control causing more damage to the company’s reputation.

Vendor selection: The high impact and unlikely occur is the Vendor selection as the selection of vendors in Coca-Cola has a policy set for quality products available and this process will not be compromised at any level (Domfeh and Fugar, 2021). Therefore, the occurrence of this risk is low however, if it occurs the impact is the damage of product quality and low customer loyalty towards the brand.

Contract management process: It is low impact and is unlikely to occur in the contract management process. The contract management is mostly been signed by legal consultants. However, the chances are very likely when a supplier does not understand the terms. But the occurrence will have a very low impact as the company has already signed the contract.

Planning time: Likely to occur and has a major impact on the planning of the project may vary due to delay in scheduling causing major impact in the manufacturing of the units.

Technical issues: very unlikely to occur as coca coal has significant technical support to protect the IT system and very rare to occur.

The demand of customers: The competition is high but demand is very rare to diminish as the brand recognition is high but a major impact will occur with this risk.

Financial risk: The financial risk is very certain due to changes in the economical situation across the globe which will have a high impact on the company.

Complexity: The complexity can be likely with the various competition and running of the business across the globe. And it will have a moderate impact on the company.

Management control: The management discrepancy is unlikely to occur but if it does, it will have a catastrophic high impact on the business ruining the stakeholder’s trust over the company.

Risk analysis/ consequences: The scenario analysis will be used to identify the problems of each scenario identified as a risk and with the risk associated with each skill. The highest affected risk will be the one that will harm the Coca-Cola company the most.

The problems are related to the contract management legal compliances misunderstanding during the miscommunication between vendors and purchasers (Mena et. al. 2018). The other is related to the shortage of talent that can harm the quality of the products. The next is variation in supplier relationships due to lack of insecurity. However, from the three key procurement issues, the possibility of causing a high impact on the company during procurement is the sourcing of the right talents. The lack of talents can cause variation in retaining the quality products and managing the supply chain distribution on time for quick delivery causing low customer satisfaction.

The consequence that will be highly affected by the scenario analysis is the shortage of talent. The other two can be changed with good legal advisor availability and proper incentives to every supplier through training.

Recording of the findings: The scenario analysis and probability risk assessment showed that the consequences of the procurement of risk are related to quality team absence in procuring the raw materials. The raw materials are required with quality and the procurement of the products can be declined when the quality of the products is not been able to analyse due to the local sourcing of the talents (Gupta and Ivanov, 2020). Global procurement can cause issues if the talents are not available due to human resources preferences. The unskilled local hiring can cause more damage to the procurement of goods and services. Therefore, with the controlling risk management planning, the consequences of the management risk in procurement must be checked for identifying the risk associated with every aspect.

Control planning of procurement risk: The risk assessment process must be initiated every few days for acquiring the possibility of risk associated with procurement management. The risk management process in weeks will help to alternate the procurement risk and choose the best one for controlling the risk factor in procuring goods and services with high quality.

Risk management is important in the development of sustainable procurement

The risk management process that has been implemented for identifying the risk associated with the procurement of products and services is important for sustainable development and maintenance of procurement. Risk management helps the company to ensure that the dependence on the supplier is not reliable which is the core reason for the disruption of the company’s supply chain management (Mäntylä, 2021). Risk management is helpful in identifying the risk associated with the procurement and supply chain during the sourcing of raw materials. The Coca-Cola company is with risk assessment techniques and risk management process can build a sustainable procurement sourcing with quality goods acquisition on time for better customer value. The controlling and monitoring process can be helpful in analysing the internal need of the company identifying the budget available, the quality required, vendors availability, and requirement so far for better risk management planning from time to time. The delay due to the shortage of talent will be minimised with a timely assessment of the risk for a quick waste control procedure for managing the procurement in supply chain management. The controlling of the unwanted waste pollution for sustainable procurement is only possible with the risk management process.

The Coca-Cola company with a risk management process can identify the sourcing method like low-cost country sourcing for budget control and access more vendors for agricultural products supply at ease. This type of requirement of procurement methods can be determined by risk analysis. The next is helping the company apply the techniques of hazard operability analysis for identifying the hazardous chemical and quality low products for better eco-friendly production of the beverages (Manners-Bell, 2020). And reforming the agreement of the contract with vendors with incentives after the identification of the performances with risk assessment of the sourcing of the vendor’s quality products. Also, identify transportation facility excellence to identify the risk associated to manage the sustainability of procurement with quality growth.

Conclusion

Thus, it can be concluded after the analysis of the report that the Coca-Cola Company needs to analyse the risk associated with procurement for implementing new sourcing methods and risk assessment techniques. The procurement of the risk can be easily identified with the risk management process through production risk assessment for controlling the variances while procuring the raw materials from vendors. The risk management and the procurement in quality goods distribution on time can be efficient with risk assessment. And also, with the effective process of procurement for controlling the risk associated with contract management.

References

Books and Journals

Amankwah, L. and Ayarkwa, J., (2021). Assessing the practice of green procurement in Coca-Cola Company limited (Doctoral dissertation).

Domfeh, S.N. and Fugar, F., (2021). A study on the impact of project management on the profitability of beverage producing companies: A focus of coca cola company (Doctoral dissertation).

Dosumu, O., (2018). Assessment of the Likelihood of Risk Occurrence on Tendering and Procurement of Construction Projects. Journal of Construction Business and Management, 2(1), pp.20-32.

Gupta, V. and Ivanov, D., (2020). Dual sourcing under supply disruption with risk-averse suppliers in the sharing economy. International Journal of Production Research, 58(1), pp.291-307.

Haapio, H. and Siedel, G.J., (2017). A short guide to contract risk. Routledge.

Handayani, D.I., (2018). Risk Management Of Supplier-Buyer In Procurement Of Raw Materials For Improving Supply Chain Performance. Jurnal Manajemen, 22(3), pp.293-309.

Hong, Z., Lee, C.K. and Zhang, L., (2018). Procurement risk management under uncertainty: a review. Industrial Management & Data Systems.

Manners-Bell, J., (2020). Supply Chain Risk Management: How to Design and Manage Resilient Supply Chains. Kogan Page Publishers.

Mäntylä, J., (2021). Best practices of supplier relationship management in value creation.

McNamara, A. and Sepasgozar, S.M., (2018). Barriers and drivers of Intelligent Contract implementation in construction. Management, 143, p.02517006.

Mena, C., Van Hoek, R. and Christopher, M., (2018). Leading procurement strategy: driving value through the supply chain. Kogan Page Publishers.

Myerson, P., (2018). Lean demand-driven procurement: how to apply lean thinking to your supply management processes. Productivity Press.

Rahimian, R., (2020). Providing Risk Management Strategies in Procurement and Supply Processes. Advanced Journal of Chemistry-Section B, 2(4), pp.247-253.\

Rendon, R.G., (2019). Enhancing professional and technical excellence: Analysis of contract management competency models. Acquisition Research Program.

Suhonen, N., Tammi, T., Saastamoinen, J., Pesu, J., Turtiainen, M. and Okkonen, L., (2019). Incentives and risk-sharing in public procurement of innovations: Towards contracting strategy framework. Journal of Public Procurement.

Wondimu, P.A., Klakegg, O.J., Lædre, O. and Ballard, G., (2018), July. A comparison of competitive dialogue and best value procurement. In Proc. 26th Annual Conference of the International Group for Lean Construction (IGLC) (pp. 13-22).

Yoon, J., Talluri, S. and Rosales, C., (2020). Procurement decisions and information sharing under multi-tier disruption risk in a supply chain. International Journal of Production Research, 58(5), pp.1362-1383.

Yuan, M., Peng, X. and Li, X., (2021). Research on Equipment Procurement Contract Performance Evaluation. In Journal of Physics: Conference Series (Vol. 1757, No. 1, p. 012188). IOP Publishing.

Online

Murphy, 2017. Procurement stages of Coca Cola. [online]. [accessed through]:

https://planergy.com/blog/procurement-process-cycle/

………………………………………………………………………………………………………………………..

Know more about UniqueSubmission’s other writing services:

Fantastic Product

Feel free tο visit my web blog: smart contract use cases