PROCUREMENT RISK AND CONTRACT MANAGEMENT ASSESSMENT

Introduction

Procurement is concerned with the act of obtaining goods and services for business purposes. The act of procurement involves finding goods and services required for business and creating an agreement with the vendor, and acquiring goods and services. Mangan and Lalwani, (2016) defined procurement as something that involves sourcing and purchasing and covers all the activities that are part of product or service sourcing, purchasing, and delivery from the seller to the buyer. Procurement is done as a part of input in the organisation from which organisations create final products that they sell to their customers. Procurement involves several risks for the business and they can be minimised by appropriate and strong risk management strategies. Risk management involves identifying risks and taking actions accordingly to reduce the impact and possibility for the occurrence of the risk (Nyokabi, 2021). This study will discuss procurement processes and sourcing method and procurement risks in Unilever in the sector of raw material.

Unilever is a multination company based in the UK and operates in the consumer goods industry. The company was founded in 1929 and is headquartered in London, UK. Products of Unilever include food, minerals and supplements, tea, coffee, breakfast, cleaning agents, pet food, beauty products, and personal care products (Buica et. al. 2021). Unilever completes procurement in large quantities.

Procurement function and sourcing methods

Procurement is a very important activity in Unilever because the company operates on a large scale and produces a huge quantity of goods. Procurement affects the quality of goods being produced, and along with this, procurement also affects how well a company can negotiate to ensure the cost-efficiency of procurement. There are two approaches in procurement reactive and proactive, and Unilever adopts the proactive approach of procurement. A proactive procurement approach involves, seeking opportunities for improvement in the procurement process and throughout the supply chain of the organisation (Rejeb et. al. 2018). Proactive procurement involves minimizing, mitigating, and sidestepping the risk involved in procurement. Proactive procurement also involves automating the procurement process in the right way and using data for strengthening relationships with suppliers of Unilever. In proactive procurement in Unilever data plays a very important role by improving decision-making and also improving the efficiency of the complete procurement process.

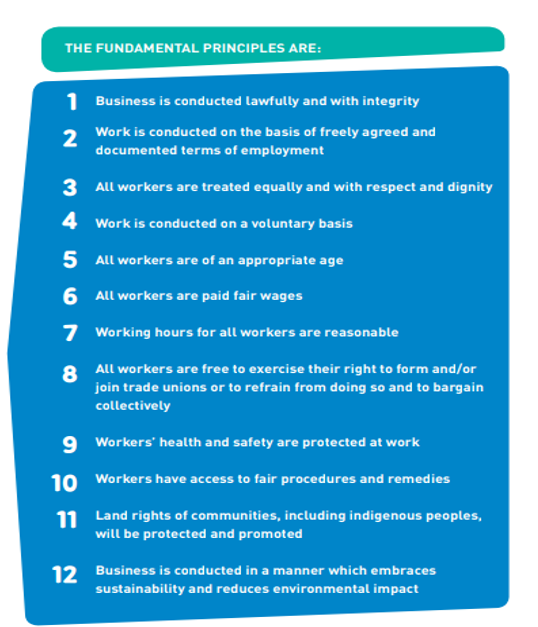

Sourcing is concerned with the process in which business organisations or buyer businesses locate and select businesses or individuals based on certain criteria. Sourcing decision is one of the very important parts of procurement management in the organisation. Sourcing decision involves considering the variety of factors like product quality, location, communication, and logistics (Kakwezi and Nyeko, 2019). Sourcing decisions in Unilever are taken on the basis of the responsible sourcing policy of Unilever. This policy is based on 12 fundamental principles that are outlined in the following figure.

Figure 1 Sourcing Decisions at Unilever

(Source: Responsible Sourcing Policy, 2021)

In order to be a supplier for Unilever, it is a must that organisations or businesses follow these principles. There are three sections that guide suppliers of Unilever about the requirements of the company. Section 1 states that all mandatory requirements are being met by the suppliers, section 2 states that suppliers contain the benchmark of continuous improvement and section 3 states that supplier contains the disclosure and reporting.

Many organisations outsource their procuring activities in which procurement is completed by a firm outside the organisation. However, in Unilever the activities are carried out within company and by employees of the company (Nyokabi, 2021). Procurement team at Unilever purchase from worldwide network of partners that spans to 190 countries in which products of the company are sold.

Supplier relationship is a primary area of focus in Unilever procurement activities. Unilever believes that for the purpose of growing and for receiving purpose late growth organisations need strong partnership. The belief is the importance of relations and suppliers as they are crucial to creating the value capacity and capability that organisations need to deliver brand and product. Unilever has a strong emphasis on supply relationships, and this is why a new program named ‘Partner with Purpose’ was launched in 2020. A part of this program a virtual event was organised where 300 suppliers of Unilever got the opportunity to hear from top leaders about the importance of partners or suppliers (Wahu et. al. 2017). It is a very important step to build strong relations with suppliers and not just the virtual event the program consists of several other subparts. Unilever is creating opportunities and an ecosystem of opportunities for everyone to collaborate with the company on a one-to-one basis and become part of the multi-partner partnership.

Unilever sells its product in around 190 countries across the world and also sources from these countries. Global Sourcing in Unilever involves Sourcing products and materials from several countries. However, there are certain standards that suppliers of Unilever have to follow in order to become a supplier of the company.

Unilever is a large organisation having a presence in 190 countries across the world with 400 brands and works with 149000 people. Unilever is working on making sustainable living commonplace, and this is why there is decentralised procurement in Unilever. Decentralized sourcing includes that every activity related to sourcing is not carried out at its headquarter and sourcing decisions are taken as per the requirement of different business places (Bag et. al. 2020). In addition to this, sourcing decisions can also be taken by brands that are owned by Unilever. Hence, it can be said that for Unilever decentralized sourcing is appropriate because of its size and nature of work.

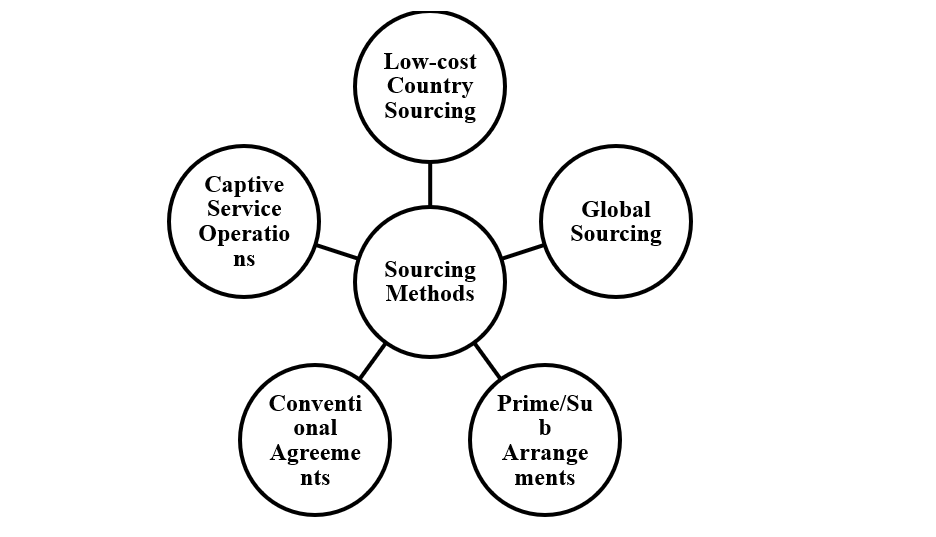

SOURCING METHODS

Low-cost Country Sourcing: It is a method of processing in which Unilever can benefit from a country that offers goods and services at a lower cost. This method provides a competitive advantage to the organisation in which they can reduce the overall cost and expenses of the company and allow them better financial performance through their procurement or Sourcing strategy. In this regard, company focuses mostly on laws and regulations of country which drives towards sustainable and responsible country sourcing.

Global Sourcing: Global Sourcing is similar to low-cost country sourcing however; this method of Sourcing does not get benefited from cheap materials and resources. In this method, the company is to taste international market and getting more options in Sourcing. The operational department identifies the significant growth opportunities in countries.

Prime/Sub Arrangements: It is a method of Sourcing in which Unilever can work with established Outsourcing providers for the purpose of procurement (Ghimire et. al. 2020). Outsourcing providers contract the work to a small company and this way the complete process of procurement is completed. Prime sub arrangement arrangements reduce the burden of the organisation to deal with import and export restrictions and carry out the process.

Captive Service Operations: It is a method of routing in which outsourced services are provided to customers on the company. This method of rooting provides a high level of control and confidentiality and security along with infringement rights that can be well addressed. Therefore, in regards to Unilever, offshore captive centres help in gaining momentum only as multinationals seek to reap the value of their initial investment in an offshore operation effectively.

Conventional Agreements: It is a conventional or traditional way to source in which buyer and seller companies create agreements that are beneficial for both companies (Sthapit et. al. 2019). The control that buyers can have is mainly dependent on the agreement created for sourcing. Unilever contracts related to agreement provides the application of the 1980 Vienna Convention on the International.

Procurement Functions

Figure 2 Procurement Functions

Source: Top 12 Most Important Job Functions for a Procurement Department

Along with the functions of procurement discussed above that are carried out in Unilever, there are some basic functions regarding procurement. The functions must be adequately and appropriately carried out to ensure the effectiveness of the overall procurement process in Unilever. These are core functions of procurement department in the organisation and these are as follows-

Sourcing: It is the first and most important function of procurement. In this an organisation has to identify and select suppliers who will be able to supply required material and resources to the organisation (Sun et. al. 2021). Concerned with this Unilever have a certain set of requirements that suppliers must meet to supply goods and services for Unilever.

In this regard, transaction cost theory by Williamson described the best structure for a company to focus on minimising the cost of operations and exchange to achieve economic efficiency. Hence, Unilever is focused on managing the transaction costs by monitoring, managing and controlling per transaction cost.

Negotiating and contracting: Procurement is a very important function for a business organisation in which Unilever is required to negotiate and develop a contract with the selected suppliers. This involves negotiating quality and price as well as terms of the transaction with suppliers. Contracting involves agreeing on the terms of the transaction and developing a contract that becomes the basis for buyer and seller to ensure how certain activities are carried out by them. The contract also provides a form of reference that binds business organisations to do or not do certain activities when they are involved in a contract.

Monitoring suppliers’ performance: Monitoring of suppliers’ performance is an important function for the procurement department. Procurement at Unilever is a very important activity and the company has a strong emphasis on quality and certain practices by its suppliers. Hence, the procurement department at Unilever needs to monitor suppliers’ performance. There are certain principles outlined and Responsible Sourcing Policy at Unilever. Suppliers of the company are required to ensure that they meet the requirements of the policy.

In order to maintain the balance of supplier power, it is important for the company to understand the supply risks and profit contribution. In this regard, Kraljic portfolio purchasing model helps a buyer in understanding the risk and profit he or she gets from the product. Thus, it is crucial for the company to provided value for money products for the customers as compared to any other brand.

Compliance with business protocol: In this function of procurement at the company, Unilever is required to ensure compliance with its business protocol (Knofius et. al. 2021). Compliance with business protocol and might include compliance with quality requirement compliance with requirements of suppliers and all other aspects of procurement.

Leveraging technology for the procurement function: This function includes leveraging technology that is used by Unilever for its procurement function. Unilever is continuously improving its technology so that it can improve its procurement and supply practices. Unilever is also working on connecting its suppliers through technological platforms.

Key risks that the selected organisation faces in procuring goods and services

Inaccurate analysis of internal need

It is the first and most probable risk that Unilever can face in procuring goods and services. For an organisation of the size of Unilever needs for goods and services are huge and also may vary at times. It can lead to inaccurate analysis of internal needs in simple words, if the organisation cannot adequately analyse needs for the number of goods and services it can lead to risk in procurement (Stevenson, 2018). Overestimation of quantity required can lead to procurement of goods and services that are not required which is a waste of resources. Underestimation of quantity required can lead to a shortage of goods and services in the organisation.

Wrong selection of suppliers

Wrong selection of suppliers is another important risk that Unilever faces. Unilever has a strong standard for the selection of suppliers however as many suppliers are selected on a regular basis possibility of selecting the wrong supplier is also there. Selecting from a supplier can affect the overall procurement process including quality of goods and services as well as compliance with the contract by the supplier.

Non-compliance with contract

Non-compliance with the contract is a risk in which company might experience that supplier it has selected for procurement are not complying with contracts. Contract compliance is very important to ensure that Unilever is receiving high-quality goods on terms that were finalised in the contract (Lyu et. al. 2019). In a situation, when suppliers do not comply with the contract, they can create difficulty for Unilever and negatively affect the quality of its procurement.

Delays in sourcing

Sourcing is the first step of the procurement process in which potential supplies are located and selected. Delay in Sourcing or delay in locating and selecting suppliers can lead to risk for Unilever in procuring goods and services. This means that if suppliers are not selected on time then it will delay the complete procurement process which might cause an unfavourable situation in the organisation.

Possibility of fraud or corruption

The possibility of fraud or corruption is another risk that Unilever can face regarding procurement. Unilever deals with many suppliers, and there is a high possibility that suppliers can do fraud and corruption with Unilever (Hegde and Rokseth, 2020). Fraud and corruption are unethical activities and are not fit for Unilever as per its responsible Sourcing policy. Fraud and corruption can also lead to a negative impact on the quality of goods and services procured by Unilever.

Price instability

Price instability can lead to an increase in the price of goods and services that Unilever procures. It is very important that the price remains stable so that adequate planning can be done according to the price of goods. An increase in the price of procured goods and services impacts the overall financial performance of Unilever by an increase in the cost of the final product. It is a very important and big risk for Unilever regarding procurement.

Supply chain disruption

The supply chain plays a very important role in procurement for Unilever. Procurement is a part of the internal supply chain through which inputs are obtained in the organisation. Disruption or delays in the supply chain can make a significant impact on procurement as it can delay goods and services arrival in a manufacturing facility. Delay in good arrival of goods and services can affect manufacturing practices of the company (Buzdoğan-Lindenmayr et. al. 2019). It means that if goods and services do not arrive on time at the manufacturing facility it may cause disruption in manufacturing that can lead to significant financial losses.

Poor performance of suppliers

The performance of suppliers is another risk for Unilever regarding procurement. Suppliers are an important element of our procurement process in an organisation. Performance of suppliers is concerned with their ability to provide required material at the required time. The incapability of suppliers to do so can lead to risk for procurement. It is very important that suppliers are aware of the product needed by Unilever and the time at which the products need to be supplied.

Unethical sourcing by the supplier

Unilever is highly concerned about responsible and ethical Sourcing and procurement of goods and services. It is a big risk for procurement in Unilever that it is unethically sourced by its suppliers (JI et. al. 2020). There are standards that suppliers need to meet in order to supply goods and services to Unilever however, their unethical practices can make a negative impact on Unilever’s procurement practices.

Inaccurate forecast of supply chain

An inaccurate forecast of the supply chain is a risk for procurement in Unilever. It is very important that the supply chain is adequately and accurately forecasted about its functioning in relation to procurement. In case the supply chain is not accurately forecasted it can lead to delay in obtaining goods and services that the organisation needs to procure from the buyer.

Risk Assessment

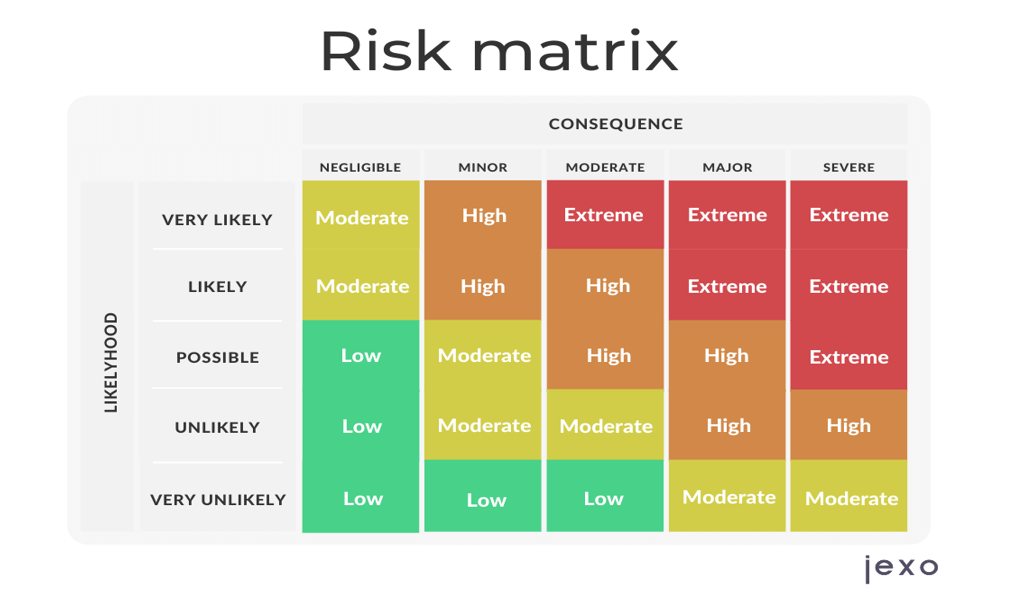

Figure 3 Matrix for risk assessment

(Source: Risk Management, 2020)

Risk assessment is a practice to identify the possibility or likelihood of occurrence of a risk. It also involves determining and consequences that can make if it occurs. Risk assessment helps in identifying risk and their impact through which a risk management plan can be developed. In the identification of the likelihood of risk, there are 5 possibilities for the likelihood of risk. These possibilities are very unlikely, unlikely, possible, likely, and very likely. Based on their possibilities they are scored and very unlikely is scored one unlikely is scored two, possible is scored three, likely scored four, and very likely scored five. In the determination of consequences of risk, there are five consequences that can happen. 5 possibilities are negligible minor moderate major, and severe. The risk that is very likely to happen and can make severe impacts are given the highest priority in risk management. In order to determine priorities to be given to risk score calculation can be helpful. The score given to likelihood is multiplied by the score given to consequences, and the overall score can be calculated.

Risk score scheme for Unilever

| Consequences | ||||||

| Negligible

(1) |

Minor

(2) |

Moderate

(3) |

Major

(4) |

Severe

(5) |

||

| Likelihood | Very likely

(5) |

Price instability | Unethical sourcing by the supplier | |||

| Likely

(4) |

Possibility of fraud or corruption | |||||

| Possible

(3) |

Supply chain disruption | Poor performance of suppliers | Delays in sourcing | |||

| Unlikely

(2) |

Non-compliance with contract | Inaccurate forecast of supply chain | ||||

| Very unlikely

(1) |

Wrong selection of suppliers | Inaccurate analysis of internal need | ||||

Risk matrixes were applied for risk that has been identified for procurement in Unilever. On the basis of likelihood and consequences unethical Sourcing by suppliers’ important risk that needs to be given high priority. Along with this, price instability and the possibility of fraud and corruption are also the risks that need to be considered. These are certain risks that can make a significant impact on the organization and can affect the image of the organization. However, there are other risks that need to be given priority and insured that they are addressed well in order to avoid any possible impact on the organization.

Risk management assessment

| Risk | Probability | Impact | Risk score | Risk control | Residual risk | Secondary risk |

| Inaccurate analysis of internal need | 1 | 4 | 4 | Mitigate | 0 | Affect manufacturing process |

| Wrong selection of suppliers | 1 | 3 | 3 | Mitigate | 3 | can lead to low quality goods and services |

| Non-compliance with contract | 2 | 4 | 8 | Transfer | 4 | Can make negative impact on other suppliers |

| Delays in sourcing | 3 | 4 | 12 | Accept | 6 | Delay in followed activities |

| Possibility of fraud or corruption | 4 | 4 | 16 | Transfer | 8 | Can affect organizational image |

| Price instability | 5 | 3 | 15 | Accept | 10 | Can increase cost |

| Supply chain disruption | 3 | 2 | 6 | Mitigate | 0 | Can affect follow activities |

| Poor performance of suppliers | 3 | 3 | 9 | Transfer | 6 | Impact on quality of final goods |

| Unethical sourcing by the supplier | 5 | 4 | 20 | Reduce | 10 | Affect standards |

| Inaccurate forecast of supply chain | 2 | 5 | 10 | Mitigate | 5 | Can affect followed activities |

Risk management assessment is carried out to determine how risk can be managed by the organisation. This provides possible solutions for identified risks and what are secondary risks associated with them and also residual risk. Residue risk is concerned that it remains after it has been addressed. However, it can be said that these may be the possible ways in which Unilever can mitigate their associated risk within the procurement sector.

Conclusion

Based on the above discussion it can be concluded that requirement is a very important activity of an organisation. Recruitment activity or function in the organisation has several functions associated with it. The success of procurement significantly depends on how well all the functions have been carried out. It is analysed from Unilever perspective that procurement is very important for the overall success of an organisation when it provides goods and services to its customers. Hence procurement must be free of all the risks. In a situation that old bricks cannot be mitigated or avoided they should be managed well to avoid the significant impact of the risks on the organisation’s procurement function. Although, it is recommended to the company to make underestimation of quantity required in a timely manner as it can lead to a shortage of goods and services in the organisation. Unilever must ensure that it is receiving high-quality goods on terms that were finalised in the contract in order to maintain the customer satisfaction and sourcing balance.

References

Books and Journals

Bag, S., Wood, L.C., Mangla, S.K. and Luthra, S., (2020). Procurement 4.0 and its implications on business process performance in a circular economy. Resources, conservation and recycling, 152, p.104502.

Buica, N.A., Avram, M. and Mihai, M., (2021). Financial Audit Procedures Employed in Sustainability Assurance. Ovidius University Annals, Economic Sciences Series, 21(1), pp.703-709.

BUZDOĞAN-LINDENMAYR, E., Güray, K.A.R.A. and SELCUK, A.S., (2019). Assessment of supplier risk for copper procurement. Communications Faculty of Sciences University of Ankara Series A1 Mathematics and Statistics, 68(1), pp.1045-1060.

Ghimire, K.H., Joshi, B.K., Gurung, R., Pudasaini, N., Gauchan, D., Sthapit, S. and Jarvis, D., (2020). Diversifying the sourcing and deploying methods to enhance the crop diversity. NAGRC; LI-BIRD; Alliance of Bioversity International and CIAT.

Hegde, J. and Rokseth, B., (2020). Applications of machine learning methods for engineering risk assessment–A review. Safety science, 122, p.104492.

Hong, Z., Lee, C.K. and Zhang, L., (2018). Procurement risk management under uncertainty: a review. Industrial Management & Data Systems.

JI, R., HUO, F., CHEN, J., WANG, S., LIU, J., ZHENG, Y. and CAI, Q., (2020). Risk assessments of organ donation and procurement during COVID-19 pandemic. Chinese Journal of Organ Transplantation, pp.212-216.

Kakwezi, P. and Nyeko, S., (2019). Procurement processes and performance: Efficiency and effectiveness of the procurement function. International Journal of Social Sciences Management and Entrepreneurship (IJSSME), 3(1).

Knofius, N., van der Heijden, M.C., Sleptchenko, A. and Zijm, W.H., (2021). Improving effectiveness of spare parts supply by additive manufacturing as dual sourcing option. OR Spectrum, 43(1), pp.189-221.

Lyu, H.M., Shen, S.L., Zhou, A. and Yang, J., (2019). Perspectives for flood risk assessment and management for mega-city metro system. Tunnelling and Underground Space Technology, 84, pp.31-44.

Mangan, J. and Lalwani, C., (2016). Global logistics and supply chain management. John Wiley & Sons.

Nyokabi, P., (2021). Effect of the Procurement Function on the Utilisation of Medical Devices in Public Level Five Hospitals in Kenya (Doctoral dissertation, United States International University-Africa).

Rejeb, A., Sűle, E. and G Keogh, J., (2018). Exploring new technologies in procurement.

Stevenson, M., (2018). Assessing risk assessment in action. Minn. L. Rev., 103, p.303.

Sthapit, B., Gauchan, D., Sthapit, S., Ghimire, K.H., Joshi, B.K., De Santis, P. and Jarvis, D.I., (2019). Sourcing and deploying new crop varieties in mountain production systems. Farmers and Plant Breeding, pp.196-216.

Sun, Z., Di, L., Fang, H., Guo, L., Tan, X., Jiang, L. and Chen, Z., (2021). Agro-geoinformatics Data Sources and Sourcing. Agro-geoinformatics: Theory and Practice, p.41.

Wahu, K.E., Namusonge, G.S., Mungai, C. and Chilion, O., (2017). Factors Affecting Performance of the Procurement Function in Kenyan Public Secondary Schools: A Case Study of Gatundu District.

Online

Responsible Sourcing Policy. 2021. [Online]. Available Through: <https://www.unilever.com/Images/slp-unilever-responsible-sourcing-policy-2014_tcm244-409819_en.pdf>.

Sean Cummins. 2020. Risk Management. [Online]. Available Through: <https://jexo.io/blog/ppm-glossary-risk-management/>.

Suppliers. 2021. [Online]. Available Through: <https://www.unilever.com/suppliers/>.

Top 12 Most Important Job Functions for a Procurement Department. 2021. [Online]. Available Through: <https://docucollab.com/most-important-job-functions-for-a-procurement-department/>.

We are Unilever. 2021. [Online]. Available Through: <https://www.unilever.com/our-company/>.

Appendix

………………………………………………………………………………………………………………………..

Know more about Unique Submission’s other writing services: