SG7001 Managing Strategy Operations and Partnerships.

Activity 2

Introduction

This assignment focuses on the business operations of the Sothema Company along with its relationships with the suppliers, customers, distributors, and even other organizations in the global market. The study further discusses various techniques used by the company to gain a competitive advantage.

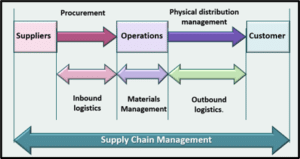

1. Supply Chain

The Sothema company has an extensive range of suppliers in their business; those are “A M Collection”, “Prismaroc”, “Linachimie”, “So Framar”, and “Lear Corporation”. Thus, operation processes in the sothema company refer to the organizational technique for getting a job performed. It includes four preliminary activities such as “planning, preparing, executing, and assessing” (Tüzemen and Yapraklı, 2022). The company has grabbed a large market share due to its effective business operations, and also from the support of customers. Every business gets 5 types of customers, which are patients, medical suppliers, physicians, payers, and distributors. Those customers still purchase the medicines and other equipment from the company, as it is the most trusted brand in the market.

Figure 1: Supply Chain Management

(Source: Tüzemen and Yapraklı, 2022)

The company’s appropriate sources are the suppliers, through which the company can easily carry forward its operations to deliver the goods. In addition to this, the company has a large network of distributors in the global market. Thus, this helps the company to manage inbound and outbound logistics to provide satisfaction service to the customers. Therefore, inbound brings materials into the business, and outbound deals with the distribution of goods and services to the customers.

2. Kraljic Matrix

The company used the Kraljic matrix whose author was “Dr. Peter Kraljic” to leverage the products in the market in regard to raising the competition level.

- The aim of the Kraljic matrix maximizes competition among the suppliers of the company.

The company has capable suppliers that bring higher revenue generation for business growth. Therefore, they have the strong bargaining ability to specify the attractiveness of the business in the market to lead the competition (Kiers et al. 2022). The company has an effective manufacturing process related to lean manufacturing procedure, which helps the company utilize the raw materials to their fullest to gain a higher profit margin in the competitive market. Thus, the Krajilic matrix helps to analyze the precise supplier segmentation to deliver products.

3. Lean Manufacturing

It is the process that aims to minimize waste in the production system of the sothema company, which simultaneously increases productivity and also gives less harm to nature. It takes less time to manufacture any good through this process, which can benefit the company with the “ever-changing” global market (Aucasime-Gonzales et al. 2020). Various giant companies such as Toyota, Nike, and many more to foster innovation in the “volatile” market also use this process.

4. Agile Manufacturing

Agile is the manufacturing process that deals with employee training, and supply chain collaboration with external and internal factors (Khalfallah and Lakhal, 2021). This is a mainly “customer-oriented” process that provides a quick response to the demand of the market. Thus, it provides a competitive advantage to grow rapidly in the global market.

5. Decoupling

Decoupling is the process to eliminate some assets from the business that seem to be of no use to the company (Horner, 2022). In the medical field, the company can reduce the use of technologies, or eliminate some staff that is not required further, even though they can eliminate some distributors as well.

Conclusion

The company has the risk in its quality of products, along with its lifecycle. Further, the risk of natural disasters and price increment can disrupt the supply chain in the company. Therefore, it can provide a huge loss to the company along with a bad reputation in the market. However, the company has control over internal risks such as technological issues, or employee shortage. On the other hand, external risks are out of the control of the company, such as natural disasters, changes in the economy, and many more.

Reference List

Aucasime-Gonzales, P., Tremolada-Cruz, S., Chavez-Soriano, P., Dominguez, F. & Raymundo, C. 2020, “Waste Elimination Model Based on Lean Manufacturing and Lean Maintenance to Increase Efficiency in the Manufacturing Industry”, IOP Conference Series.Materials Science and Engineering, vol. 999, no. 1.

Horner, R. 2022, “Global value chains, import orientation, and the state: South Africa’s pharmaceutical industry”, Journal of International Business Policy, vol. 5, no. 1, pp. 68-87.

Khalfallah, M. & Lakhal, L. 2021, “The impact of lean manufacturing practices on operational and financial performance: the mediating role of agile manufacturing”, The International Journal of Quality & Reliability Management, vol. 38, no. 1, pp. 147-168.

Kiers, J., Seinhorst, J., Zwanenburg, M. & Stek, K. 2022, “Which Strategies and Corresponding Competences Are Needed to Improve Supply Chain Resilience: A COVID-19 Based Review”, Logistics, vol. 6, no. 1, pp. 12.

Tüzemen, A. & Yapraklı, T.Ş. 2022, “The effect of supply chain orientation on supply chain risk and uncertainty: An application on members of dairy products supply chain in erzurum city in Turkey”, Emirates Journal of Food and Agriculture, vol. 34, no. 4, pp. 304-315.

Know more about UniqueSubmission’s other writing services: