VACUUM BRAKING SYSTEM FOR INCREASED SAFETY AND RELIABILITY OF AUTOMOBILES 2020

PART 1

A braking system is the safety mechanism of a vehicle that slows down or halts the vehicle when needed. In order to halt automobiles, the brakes convert the kinetic motion of the vehicle into heat, and it is termed as friction. Vacuum braking is an advanced mechanism that relies on a vacuum pressure to halt a vehicle from further movement. Pressing the brake pedal will open a valve present between the power cylinder and the intake manifold. Applying the brakes results in air exhaustion from the piston head, thus, the vacuum created applies an atmospheric pressure on the rods and creates a pulling force on the rod attached to the piston. On pulling the rod the brake shoes get inflated and apply pressure on the tires. The friction generated will stop the tires from moving further. Therefore, in this research, the advanced braking system of using a vacuum will be studied to ensure more safety and reliability in automobiles.

The vacuum braking system is an advanced braking system that holds the potential of ensuring better safety and reliability of automobiles. The principle of this braking system involves a loss of vacuum in the brake pipe, resulting in the brake shoes to apply pressure on the tires and halt the vehicle. Therefore, as per Mao and Liu, (2018), the braking system consists of many complex parts, coupling and decoupling of hoses and valves. In this research, the main problems associated with the vacuum braking system will be discussed.

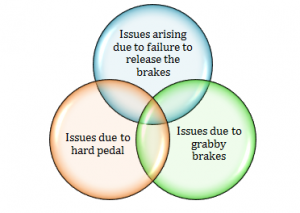

Figure 1: Issues in Vacuum braking system

(Source: Mao and Liu, 2018)

- Issues due to hard pedal–

- Hydraulic brake lines are damaged

- Failure in the generation of vacuum

- Diaphragm is damaged

- The air filter element is restricted

- Misalignment in piston positioning

- Brake discs are worn out

- Issues due to grabby brakes–

- Broken brake lines

- Master cylinder has insufficient fuel

- The seals in the master cylinder are defective

- The casting and casing of the master cylinder is showing signs of cracking

- The bleed system that transmits the air in the hydraulic pipes needs to be replaced

- Issues arising due to failure to release the brakes–

- The air passage in the power piston is blocked

- Problems in the operation of air valves

- Malfunction in the return spring of the piston

- Linkage in the pedals are too tight

- The air valve spring is damaged

3. Benefits to industry and society

A vacuum braking system holds an advantage over the air brakes and thus there are many applications of using vacuum brakes in the vehicles. The research will be carried out with the objective to promote the greater use of vacuum brakes over the standard air brakes in order to enhance the safety of the drivers. The vacuum braking system is fail-safe braking in which the vacuum created removes the atmospheric pressure and this air pressure pushes the piston and applies the brakes. The industry is highly benefited due to the low incurred cost of making the brakes and its simple design. The exhauster in this braking system has two operating functions, one for high speed and the other one is for low-speed operations. Thus, the brakes can function accordingly with changes in the speed of the vehicle.

As stated by Yin et al, (2016), the main advantages of using vacuum brakes can be described as:

- Simple in design

- The ability of partial release, this holds an advantage over pneumatic and air brakes as these other brakes need additional equipment to perform a partial release operation.

- Vacuum lossage results in a more efficient braking system and ensures greater reliability and safety.

- The driver can control freely as the system possesses an automatic application of the vacuum brakes towards the entire length of heavy vehicles.

- Vacuum brakes are considered as fail-safe since the loss of vacuum is the main feature of this braking system.

4. Aim, objective and scope of the project

Aim

The aim of the proposal will be to enlist and outline the use of a vacuum braking system in order to improve the safety and reliability of the automobiles. The proposal will present clear-cut information on the operating principle of vacuum braking and how the system will be beneficial to the automobile industry.

Objectives

The main objectives of the research proposal will be to:

- To identify the usefulness of a vacuum braking system over the air and pneumatic brakes

- To underpin the advantages and benefits of vacuum braking system

- To recognize the necessary tools and techniques used in the braking system

- To promote the use of vacuum braking as the fail-safe braking system

Scope

The scope of the vacuum braking system will be quite high as in the present day most of the heavy vehicles are functioning with the aid of vacuum brakes. Thus, as stated by Deepa et al, (2018), with the rising innovation and technology, the introduction of sensors will be able to create a much better application of the vacuum braking system.

5. Deliverables and potential risks

Deliverables

A huge spurt is expected in the innovation process of the vacuum braking system in the coming years as the automobile industry will encounter new technologies and concepts. Brakes are the fundamentals of an automobile and innovation has been incorporated to improve its functions for ages. Through the help of the research work, the vacuum system operations and benefits will be properly addressed with the help of tools and techniques. As stated by Tamaldinet al, (2017), the industrial requirements and the milestones will be captured by the researcher to develop a general knowledge of the topic. This will not only drive the mechanics but also drive company management to recognize the potential of vacuum brakes in heavy vehicles and spark creative approaches to improve its operations.

Potential risks

Risks and limitations in a project cannot be completely eliminated, and in this research also there will be major risks that can affect the study. The potential risks for the project will be the budget constraint that will narrow down the data collection to a smaller scale. As mentioned by Lee et al, (2017), identifying, organizing, Time constraints will be another major problem in completing the research work. In the industrial application of brakes, there are also few limitations that will be taken into consideration while preparing the work.

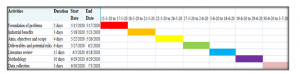

Phase 1: The expected problems of the vacuum braking system are stipulated. The phase will take 2 days to complete from 15-5-20 to 17-5-20.

Phase 2: Enlisting the industrial requirements. The phase will take 3 days to complete from 18-5-20 to 21-5-20.

Phase 3: Capturing the pieces of knowledge to understand the aim, objectives and scope of the project. This phase will take 4 days from 22-5-20 to 26-5-20.

Phase 4: Developing and redesigning generic comprehension in completing the risk framework. In order to properly identify the potential milestones and deliverables, this phase will require 6 days from 27-5-20 to 2-6-20.

Phase 5: Academic journals are used to grasp the literature review of the research and will take 15 days from 3-6-20 to 18-6-20.

Phase 6: Finalizing the relative solutions and proper analysis of the methodologies in the research work. The phase will need 10 days from 19-6-20 to 29-6-20.

Phase 7: Submission of the compiled results by collecting the data and presenting it in the final reports. The phase will need an additional 3 days from 30-6-20 to 3-7-20, to present the collected data in the final report.

Figure 2: Gantt chart

(Source: Created by Learner)

Article 1: Implementation of Automated Vacuum elevator system

Main contribution

The idea to incorporate new technologies such as vacuum in place of air in the pneumatic elevator system is presented in the article. According to Mohammed et al, (2018), the main usefulness of the pneumatic vacuum elevator is to transport the people from one place to another without the aid of cable wires, pulleys, and counterweights. Thus, the article’s main contribution is to spread the use of PVE in the lower residential buildings to enhance the safety of the workers.

Shortcomings

The article does not have any major shortcomings due to its easy installation, zero energy consumption, less incurred cost and flexible operations. The only shortcomings are expected to be its limitation in the usage of short storied buildings.

Article 2: High-Speed Vacuum Air Vehicle

Main contribution

The major contribution of this article is to outline the impact of a vacuum air vehicle and its high rate of acceleration according to the load requirement. As stated by Mishra et al, (2018), the high pressurized air coming out from the vehicle is effective in reaching supersonic speed from zero states within a fraction of seconds.

Shortcomings

The main shortcomings in the vacuum air vehicle are its indirect usage of energy. As argued by Mao and Liu, (2018), due to the low energy density of the compressed air it is difficult to enhance the efficiency factor of the vehicle. Moreover, even if the efficiency is increased, refuelling the container with compressed air is a hectic job.

Article 3: A hole in the vacuum hose of a vehicle provides lower differences in brake measurements by the Ministry of Transport Brake Testers rather than the characteristics of the tester used

Main contribution

The main contribution of the article is to portray the functional importance of maintenance so that there are no holes in the vacuum hose of the vehicle. As stated by Senabreet al, (2018), a leak in the hose pipe of the booster means that the pedal is difficult to press thus there is a definite time lag in operation. The brake function that has the potential to operate smoothly may get delayed by a few seconds due to the issue. Such small issues are critical in heavy traffic and lead to accidents.

Shortcomings

There are no shortcomings for this article as the article guides through the impact that a hole in the hose pipe of the booster creates under operation.

Article 4: EMI noise reduction with zero state PWM for Integrated Dynamic Brake System

Main contribution

The article proposes the use of zero state PWM in the integrated dynamic braking system in order to improve the stability factor of the brakes. As commented by Baiket al, (2018), the zero state PWM can effectively suppress the noise emission of EMI while operating under loaded conditions.

Shortcomings

The main shortcomings of this article are that the article only took EMI noise cancellation as the main objective and did not consider the problems arising due to electromagnetic interference in the operations.

Article 5: Development of a cooperative braking system for front-wheel drive electric vehicles

Main contribution

The article highlights the regenerative braking system that can control the electrical stability of the system. The cooperative braking system can whisk the frictional torque of the system and achieve higher efficiency in the electric drive wheels. Thus, as per Zhao et al, (2018), the implementation of cooperative brakes holds a greater potential of enhancing energy recovery performance under different torque loads.

Shortcomings

The main shortcoming is that the article did not present the effects of the cooperative braking system with increasing speeds. Energy loss cannot be fully stopped or recovered as friction will be required when stopping the vehicle.

Article 6: Real-life safety benefits of using brake deceleration in car-to-pedestrian accidents: Stimulation of vacuum emergency braking

Main contribution

The article provides useful information for precise braking operations that can be achieved in the future under the application of a wide sensor field. Through the study, it can be observed that with the help of Automated emergency braking features the performance of vacuum emergency brakes can be drastically improved (Jeppssonet al, 2018).

Shortcomings

The main shortcoming is that automated emergency braking can be only implemented on the frontal side. Another main shortcoming of the article is that the feature is focused on the usage of a widescreen sensor, which is still in motion of installation.

Article 7: Power assisted braking control based on a novel mechatronic booster

Main contribution

The article highlights the use of a novel mechatronic booster in the braking system to enhance the braking efficiency. According to Liu et al, (2016), the experiment was performed in order to achieve a power boost in the system and through the report a timely braking behaviour module was obtained for a different boost ratio.

Shortcomings

The assisted braking control over pedal-force fitted the depression process of the brake and required new strategic improvements to progress in strategic control over the system.

Article 8: Development of an integrated electro-hydraulic braking system and its ABS application

Main contribution

The article highlights a new type of electro-hydraulic braking system with improved functional operations of the ABS system in the loop. As mentioned by Tan et al, (2016), there are three proposed modes by the new EHB that result in proposing its usefulness in diverse fields.

Shortcomings

The article fails to underpin the problem of the cost of EHB in relation to other mechanical braking systems. Moreover, the fluids also must be compatible with the braking material to avoid any issue or failure.

Article 9: Development and analysis of a driving cycle to identify the effectiveness of the vacuum brake booster

Main contribution

The article was aimed to outline the importance of electric vacuum pumps with respect to traditional vacuum pumps. As per Berjozaet al, (2016), the electric vacuum pump has the advantage of instilling smooth braking activation without any kind of interruptions.

Shortcomings

The main shortcoming of the article is that it did not propose any countermeasure to prevent injury from fluid slugs.

Article 10: Rapid optimal design of a light vehicle hydraulic brake system

Main contribution

The article presents a rapid designing method of a light vehicle hydraulic system. As mentioned by Anselmaet al, (2019), the design pool is deemed as a safe method to carry out and evaluates the maximum efficiency function by minimizing the cost of design.

Shortcomings

The design requires the initial setup to be perfect and out of flaws. Moreover, a large space is required to comprehend the design parameters in a faster way.

The main research gaps observed in the studies is that the utilization of vacuum brakes may require a little innovation to spark improvements. The vacuum brakes can suck in debris and therefore result in a malfunction of systems, which is not mentioned in the articles. The size of the cylinder and piston is also a major problem that is left behind in the dust and therefore, can be treated as a research gap.

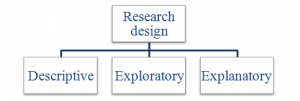

In order to understand and grasp the knowledge of the research, it will be of paramount importance to understand the research design. Therefore, a research design is helpful in meeting the goals and completing the project in the schedule. According to Atmowardoyo, (2018), the main segments of the research design are the descriptive, explanatory and exploratory. However, in this work, the descriptive research design will be chosen due to its unfathomable advantages. The descriptive research work will help to underpin the research problems associated with the research by proper data collection techniques. Therefore, the descriptive design will be able to link the present ideas with the research and validate the results.

Figure 3: Research Design

(Source: Atmowardoyo, 2018)

3 novel points of the research

The main novel points of the research will be to highlight the following clauses:

- To shed light on the usefulness of vacuum braking system over the air and pneumatic braking system

- To identify the potential use of the features and concepts regarding vacuum brakes

- To provide insights into the benefits and limitations of the vacuum braking system and thereby develop innovative ideas to solve the problems (Curtis and Allen, 2018)

A research approach is defined as the vision of the researcher to map the path that the research is going to take. As mentioned by Woiceshyn and Daellenbach, (2018), There are two types of approaches that can be followed while performing a research study and these two types are inductive approach and deductive approach. In order to study the thematic work, the research will follow the deductive approach. The deductive approach will be useful in the formulation of questionnaires and scrolling down the obtained data with precision.

Figure 4: Research approach

(Source: Woiceshyn and Daellenbach, 2018)

Data collection method and technique

The research will follow the qualitative data collection technique with the aid of the secondary data collection method. Secondary data will be collected from academic journals and websites related to the topic. The functional operations of vacuum brakes will be properly discussed through the channels of secondary data collection. As stated by Umanailoet al, (2019), a thematic analysis will be useful to support the evidence collected from the secondary data collection method. Thus it will be necessary to adopt qualitative data collection techniques in this research.

The impact of vacuum brakes will be properly conveyed with the help of this research proposal. The mechanics and the industrialists will be able to improve the features of the vacuum braking system through innovation. Moreover, with the wide application of computer-aided technology and BIM approaches, it will become easier to design the vacuum brakes and increase its potential. As observed by Kniekeet al, (2017), vacuum brakes have the upper hand over pneumatic and air brakes in the application of heavy vehicles, thus the research will be helpful to promote its significance to the readers.

Anselma, P.G., Patil, S.P. and Belingardi, G., 2019. Rapid Optimal Design of a Light Vehicle Hydraulic Brake System (No. 2019-01-0831). SAE Technical Paper.

Atmowardoyo, H., 2018. Research methods in TEFL studies: Descriptive research, case study, error analysis, and R & D. Journal of Language Teaching and Research, 9(1), pp.197-204.

Baik, J.H., Yun, S.W., Kim, D.S., Kwon, C.K. and Yoo, J.Y., 2018. EMI noise reduction with new active zero state PWM for integrated dynamic brake systems. Journal of Power Electronics, 18(3), pp.923-930.

Berjoza, D., Pirs, V., Dukulis, I. and Jurgena, I., 2016. Development and analysis of a driving cycle to identify the effectiveness of the vacuum brake booster. Agronomy Research, 14(3), pp.672-682.

Curtis, K.R. and Allen, S., 2018. Target Market Identification and Data Collection Methods.

Deepa, N., Dasmunshi, S., Verma, S., Shukla, A. and Nanda, S., 2018. Brake failure detection and electronic auxiliary braking system. International Journal of Engineering & Technology, 7(2.8), pp.350-352.

Jeppsson, H., Östling, M. and Lubbe, N., 2018. Real life safety benefits of increasing brake deceleration in car-to-pedestrian accidents: Simulation of Vacuum Emergency Braking. Accident Analysis & Prevention, 111, pp.311-320.

Knieke, C., Körner, M., Rausch, A., Schindler, M., Strasser, A. and Vogel, M., 2017. A Holistic Approach for Managed Evolution of Automotive Software Product Line Architectures. Special Track: Managed Adaptive Automotive Product Line Development (MAAPL), along with ADAPTIVE, pp.43-52.

Lee, J., Kim, M., Ha, J., Lee, C., Yun, S., Kim, Y., Nam, K. and Nah, W., 2017, September. Modeling of conducted EMI with current probe method for a motor-drive braking system. In 2017 International Symposium on Electromagnetic Compatibility-EMC EUROPE (pp. 1-5). IEEE.

Liu, H., Deng, W., He, R., Qian, L., Yang, S. and Wu, J., 2016. Power assisted braking control based on a novel mechatronic booster. SAE International Journal of Passenger Cars-Mechanical Systems, 9(2016-01-1644), pp.885-891.

Mao, K. and Liu, G., 2018. An improved braking control method for the magnetically levitated TMP with a fast transient response. Vacuum, 148, pp.312-318.

Mishra, R., Rajat, M., Sharma, H., Himanshu, S., Mishra, H. and Harshit, M., 2018. High-speed vacuum air vehicle. Transportation Systems and Technology, 4(3 suppl. 1), pp.328-339.

Mohammed, F.M., Mohammed, J.A.K. and Naji, M.A., 2018. Implementation of an Automated Vacuum Elevator System. Journal of University of Babylon for Engineering Sciences, 26(10), pp.150-165.

Senabre, C., Valero, S. and Velasco, E., 2018. A hole in the Vacuum Hose of a Vehicle Provides Lower Differences in Brake Measurements by the Ministry of Transport Brake Testers Rather Than the Characteristics of the Tester Used. Mechanics, 24(2), pp.284-288.

Tamaldin, N., Saifuddin, M., Yamin, A.M. and Omar, G., 2017. New approach of designing braking system for electric vehicle using artificial intelligence. Proceedings of Mechanical Engineering Research Day 2017, 2017, pp.53-54.

Tan, Z.H., Chen, Z.F., Pei, X.F., Guo, X.X. and Pei, S.H., 2016. Development of integrated electro-hydraulic braking system and its ABS application. international journal of precision engineering and manufacturing, 17(3), pp.337-346.

Umanailo, M.C.B., Hamid, I., Hamiru, H., Assagaf, S.S.F., Bula, M., Nawawi, M., Pulhehe, S., Yusuf, S. and Bon, A.T., 2019. Utilization of Qualitative Methods in Research Universities. Education science, 21(36), p.20.

Woiceshyn, J. and Daellenbach, U., 2018. Evaluating inductive vs deductive research in management studies. Qualitative Research in Organizations and Management: An International Journal.

Yin, Y., Xiao, L., Feng, Y., Zhang, X. and Zeng, L., 2016. Analysis on Defect Accident States of Automobile Braking System. DEStech Transactions on Materials Science and Engineering, (icmeat).

Zhao, D., Chu, L., Xu, N., Sun, C. and Xu, Y., 2018. Development of a cooperative braking system for front-wheel drive electric vehicles. Energies, 11(2), p.378.