Simulation and Optimizing Technique for Supply chain Management

Get the best assignment Sample on Simulation and Otimizing Technique for Supply chain Management.

Section 1: Introduction

In this report, supply chain management will be discussed along with the mathematical approaches such as robust optimization, discrete simulation, objective criteria to solve the problems and the way of addressing uncertainty.

Quantitative approaches in supply chain management

Supply chain management refers to a specific chain through which manufacturing, processing, delivering and selling of the products complete successfully in order to improve the industrial organization. Quantitative supply chain management describes the important tools and methods that may help to manage the operational activities in manufacturing industries. Quantitative supply chain management is short, however, it is important to help the company to enhance quality of services and reduce excess stocks in order to improve productivity by low purchasing prices. Supply chain management is the process from the raw materials coming from the suppliers to the selling of that particular product to customers via different shops. Quantitative supply chain management also detects the effectiveness of supply chain through which an organization peacefully deals with the customers’ needs.

Section 2: Importance of Quantitative approaches in designing a resilient Supply Chain Network

Literature Review

Supply chain management is an effective process to deal with the manufacturing, processing and logistics of that product in order to develop a sustainable business. Robust optimization is one of the important factors for effectively handling supply chain management in an organization. Robust optimization is the ability to adjust the internal and external disturbances or disruptions that may affect the sustainability of this chain. Supply chain management is a large processing chain led by the management of an organization so that any disruption or disturbances may affect the entire industries as well as the employees. The main risks of supply chain management are fundamental risks that may be maintained properly. It is necessary to measure the operational and structural robustness of supply chain and disruptions may be easily solved to achieve the organizational motives (Safaei et al., 2017).

Stochastic programming is a framework of addressing the optimization problem that includes uncertainty, more specifically, all or some of the problem parameters is uncertain. Stochastic programming model is developed for supply chain management in which sales growth, supply chain costs and fixed assets are the main parameters of supply chain management. Sales growth depends on the activities done by the management regarding the organization and it improves the productivity of the organization. On the other hand, it may be stated that the problems arise during the work, it is necessary to prevent the operational activities from the uncertainty or disruption. The significance of the uncertainty described to detect the stochastic parameters in the supply chain management including the distribution of raw materials and products. Two stochastic models are designed in supply chain management for demand uncertainty. The first stage of the stochastic program includes deciding the configuration decisions and the second stage of this program involves processing of the raw material from the supplier to the customers based on uncertain scenarios and configurations.

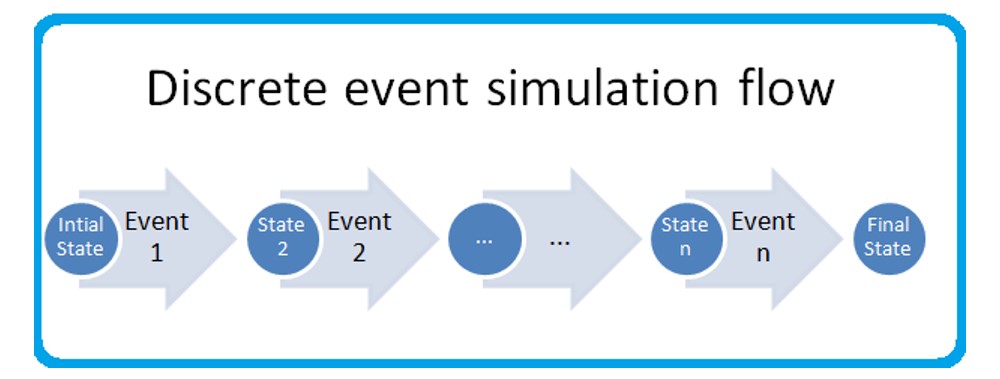

Discrete Event Simulation (DES) is equally important similar to others as it determines the effectiveness or appropriateness of the supply chain management in an organization. The Discrete Event Simulation or DES basically focuses on the material and order handling process through which the products effectively reach to customers. On a contradictory note, it may be stated that material handling is one of the essential processes to explore the business market. In an organization, raw materials are supplied from the suppliers and then that raw materials are used to manufacture a particular product which an organization sells to various markets, all over these processes are managed by handling gently. A raw material supplying, manufacturing and logistics function through gently handling is essential in order to maintain the sustainability of the supply chain management. Discrete Event Simulation is a flow chart which describes proper planning, analysing and presenting the supply chain management through various events for determining the appropriateness of this supply chain (Kogler et al., 2017).

Figure 1: Discrete Event Simulation

(Source: Zhiwen et al., 2020)

At first, it is essential to evaluate the risks or disturbances regarding the supply chain management and try to solve the problems by adopting the solving approaches such as metaheuristics and simulation. Metaheuristic has to be considered as a capable technique to solve the problems easily by providing a solution instantly (Zhiwen et al., 2020). On the contrary, it may be mentioned that supply chain management related problems such as logistics are solved with the help of this metaheuristic method. More specifically, this technique easily detects the disruptions, disturbances regarding operational activities and vehicle route related problems. The simulation model represents the logical rules regarding the logistics network. For maintaining the sustainability of this chain, logical rules and regulations need to be maintained by the organization to achieve the organizational objectives.

The objective criterion similar to income, cost or profit depends on the productivity of an organization, furthermore, if the productivity gradually increases then that particular business gains profit and effectively that business explores all over the market. Quantitative method of supply chain detects the risks and evaluates the risks related to the solution so that the objective criterion may be minimized or maximized easily and that has a great effect on the organizational success.

Customer demands improve the productivity of any industry and it also enhances capacity of that particular organization. On a contradictory note, it may be mentioned that if a particular organization fulfils all the customers’ demands that gain profits to manage the organizational success. At the time of designing the resilient supply chain, capacity is highly addressed as capacity determines the capability of production rate that enhances the profit. Moreover, designs of resilient supply chains are necessary to determine the effectiveness of supply chain so the addressing of the uncertainties such as costs, demands and capacity are highly necessary to remove the difficulties from the uncertainty if necessary (Kamble et al., 2020).

Conclusion

In order to effectively and efficiently handle the organization, resilient supply chain management designing is necessary through quantitative methods including stochastic programming and robust optimization for determination of the disturbances in the operational activities in supply chain management. To prevent this supply chain activities from the disruptions metaheuristics and simulations are necessary.

References

Kamble, S.S., Gunasekaran, A. and Gawankar, S.A., 2020. Achieving sustainable performance in a data-driven agriculture supply chain: A review for research and applications. International Journal of Production Economics, 219, pp.179-194.

Kogler, C. and Rauch, P., 2019. A discrete-event simulation model to test multimodal strategies for a greener and more resilient wood supply. Canadian Journal of Forest Research, 49(10), pp.1298-1310.

Safaei, A.S., Roozbeh, A. and Paydar, M.M., 2017. A robust optimization model for the design of a cardboard closed-loop supply chain. Journal of cleaner production, 166, pp.1154-1168.

Zhiwen, Z., Yujun, X., Junxing, L., Limin, G. and Long, W., 2020. Supply chain logistics information collaboration strategy based on evolutionary game theory. IEEE Access, 8, pp.46102-46120.

Know more about UniqueSubmission’s other writing services:

Your article gave me a lot of inspiration, I hope you can explain your point of view in more detail, because I have some doubts, thank you.