Individual Assignment on Construction Company

Introduction

This individual report is based on the planning, organizing, and managing of the construction processes by the International Construction Company called “B&W” using the standard software and effective coordination of information modeling using the ASTA Powerproject BIM (Sharon, 2017). Being the planning manager, I will have to produce an effective construction program of the project within Merseyside in the UK and will include a Gantt chart and Critical Path Method networks, Work Breakdown Structure (WBS), resource analysis diagram, progress tracking and delay analysis. Further will report the risk analysis involved in the project program and produce an evaluative report of the tasks involved in the project.

Gantt chart and CPM

Planning a construction project consists of defined activities and relationship precedence. While planning a construction program, two important components that are inter-dependent need to be maintained. The first one involves the construction time planning and scheduling and the second one is the resources and cost planning and scheduling. For planning the construction time planning and scheduling, the effort has been given to facilitate the working time-table of the project activities for the completion of the project within a specific time using the Gantt chart (Ismail et al., 2017). Scheduling the tasks involved in the project involves the process of determining the duration of each activity and the resources required and then applying the Critical Path Method (CPM) so that calculations can be done on the late and early activity at the beginning and the end time of the project and also in the floating time as well. As earlier critics have mentioned, the traditional form of methods that were utilized in planning projects was developed in the 1950s (Lin et al., 2017). These methods slowly showed a large development in them and thus included program evaluation, work breakdown structure, and also the methods of Gantt chart, CPM, and review technique. The CPM has always played a key role in the process of project management.

Work Breakdown Structure

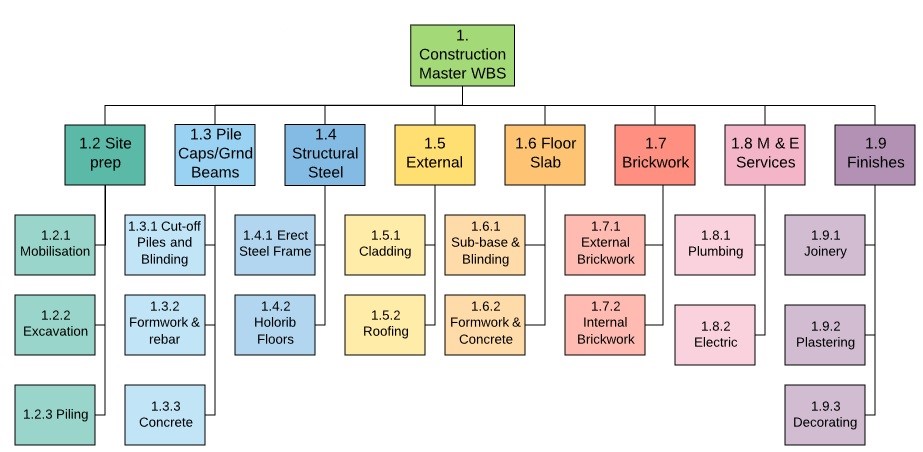

The Work breakdown Structure involved in construction planning can be understood as a logical and systematic breakdown involved in a project regarding its components and sub-elements put into hierarchical order. The process continues until the whole work is breakdown into a unit of works that is manageable against which responsibility can be properly defined. This process is considered to be the first step involved in the planning process in the execution of the project (Lin et al., 2019). This structure has a lot of benefits as it helps to organize deliverables and tasks, lists the dependencies and subtasks, visualizes the project schedule, sets the baselines for schedule, estimates the task duration, and identifies the phases involved in the project.

Figure 1 Work breakdown Structure of Construction Project

As Late As Possible

By using the method of As Late as Possible task constraint instead of CPM certain changes need to be made in the project planning. Using this constraint the dependent tasks that are present in the project planning are rescheduled (Vignesh, 2018). The ALAP method helps in scheduling the tasks in such a way in which if an order is placed for material then it would be delivered just before its implementation time which may be an effective process in the construction project sometimes but also may not as if by any chance, a certain issue arises during the delivery process of the product then that may incur loss and management problems during the project initials.

Resource optimization

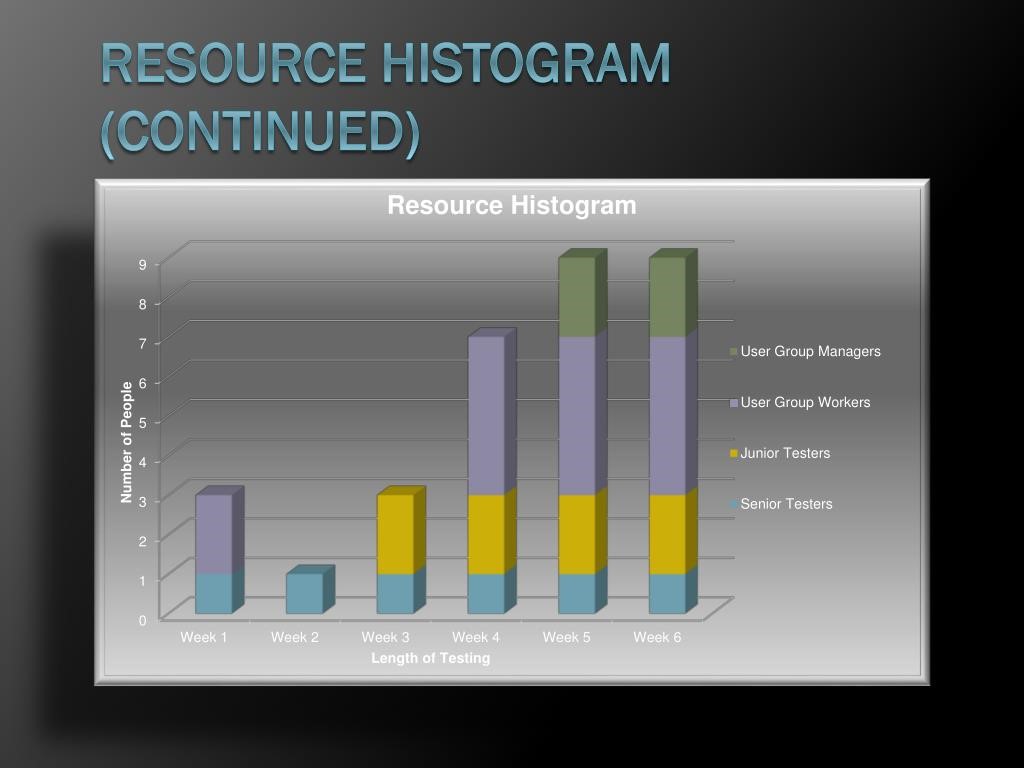

Resource histogram

This tool is used by the planning team in the project process and is considered as a means to provide a visual representation to the team. Its main purpose is to display the specific time allotted for a particular scheduled resource on which the work has to be done over some time and a predetermined period (Abdel-Basset et al., 2020). It involves a feature that is comparative for the available resource used for comparison. The resource optimization is produced through the resource histogram which states the resources that are occurred before and after the level of smoothing.

Figure 2: Resource Histogram before and after smoothing

Resource smoothing and Leveling

The process of resource smoothing and leveling is used to reduce the allocation of resources done on the tasks. For instance, a task that has been allocated previously was 90% but afterward was reallocated to 70% after the process of resource smoothing. While scheduling the construction project, the key challenge that comes up for maintaining the process project schedule is to maintain that scheduling (Turkan et al., 2019). Resource leveling is considered to be an approach in a scheduling project whereby the beginning date and end date of the task are determined wholly upon the availability of external and internal resources. The process of resource smoothing and leveling is followed because the demand for the resources often varies depending on the life of the project and may necessarily delay the activities that are non-critical to even out the resources.

Resource Management

While carrying out the resource leveling and produced a leveled histogram for the equipment of the resources, only those resources which can be used for 10 units per day are considered.

Resource management is known as a project management facet that deals mainly with humans, distribution, financial, and project resources demand. If the management of human resources is carefully done then it will lead to the success of the project. However, resource mismanagement may also lead to overtime, overages of budget, unfortunate events, and other failures. Being the project manager of this construction program, certain expectations, roles, and responsibilities are considered (Omar, 2016). It is the responsibility of the project manager to plan, allocate resources, execute, and report and timesheet the work progress and ending. Being a good project manager, it becomes mandatory to have the mastery levels of the process of “business within the business. For successful delivery of the project, the project manager has to have great communication skills, must excel in the management expectation, and also have the utilization and resourcing skills (REDDY et al., 2016). The project managers also must know how to implement project tools or methodologies in the project process for its successful completion.

Tracking Progress

A project program that is related to construction is linked inextricably to the matter of visibility. The project manager can effectively monitor the site progress in real-time and has full control over the project and then offers the data which is required to align every employee, reduce the downtime and improve the processes in the future (Khosiin et al., 2020). After tracking the project progress at the end of week 25 it could be evaluated that the work progress is going on in the second level of the activities measured and due this time certain exceptional events have occurred in the project (Pehlivan, 2018). The first occurrence stated that the steelworker contractor was suffering from labor resource problems and started the work progress of the structural steel frame after 4 weeks which delayed the work progress.

The second occurrence which happened was that the client that is the international construction company “B&W” changed their specification for service duct due to which commencement of the service duct got delayed by 3 weeks and took 2 more weeks to complete it as per its scheduled time (Sutrisna et al., 2018). Another problem that arose was due to the adverse weather due to which the duration of the work increased as the sub-structure of brick walls increased by 4 weeks though the task had started on its pre-stated schedule (Hasan, 2018). Due to all these sudden occurrences that came up within the work progress of 25 weeks, it delayed the work progress of the construction project and it could be determined that it won’t be finished within the stipulated time.

Delay in Project

Different types of delays occur during the process of a construction project. Some can be determined as delays that are excusable with compensation, some do not have compensation, non-excusable delays, and concurrent delays. All the occurrences that took place in the project and delayed the work progress can be categorized as concurrent delay as here both the client and the contractor had the issues which led to the delayed process of work. The impacts which are faced due to these effects are time overrun, cost overrun, and many more (Amandin, 2016). The effect of the delays in the construction work progress carries a tremendous rippling effect on both the parties as well as on the citizens in the particular surrounding. Cost overrun leads to cost in an excess amount over the estimated cost for the project. The excess cost becomes an inconvenience for both the parties involved in the project. Another effect that can be measured is the total abandonment of the project.

Impact of Project

A project manager can apply certain defenses to the damages caused by the delayed issues which can either be by stating the option of no damages will be claimed for delay or can impose a notice requirement before which id the owner wants to abandon the project or take another kind of action then the project manager can forfeit and claim for a time extension or assume liability (Rachid et al., 2019). To defend from the situation, acceleration can be a way out for the extra expenses incurred to complete the project.

Risk Simulation and Analysis

Any construction project is always expected to be completed within a certified period and if it gets delayed for some reason then the cost incurred gets increased due to which the penalty is faced by the contractor or the project manager. But while working on project management of construction, various uncertainties may occur due to which a risk development process needs to be performed so that it can deal with the risks that occur suddenly during the project execution period. The risk management in construction project needs to identify the factors that cause delay during the completion of the project activity. Different types of risks are determined which can either be dynamic risks, static risks (Durdyev, 2019). Certain parameters always remain associated with evaluating the risk involved in the construction project and these parameters are higher costs, an extension of the project, failure in satisfying the specified requirements, and many more.

| Risk Type | Estimation Duration | |

| Optimistic | Pessimistic | |

| Low Risk | 20% | 20% |

| High Risk | 20% | 20% |

Scheduled analysis of risk can be performed using the Monte Carlo simulation. All the durations were put into the software and then the distribution probability was assessed. Normally the triangle distribution is preferred while submitting the data and can be determined in a judgmental manner (Zareei, 2018).

Due to all the delays that occurred and the extra time is taken to complete the project, the minimum time which could be taken was 288 days and the maximum time was 294 days. The above-mentioned figure represents the cumulative graph of frequency.

Probability and Sensitivity Risk Factors

Identifying the probability and sensitive risk factors is the main task which is involved in a project. The sensitivity analysis is implemented to analyze the various kinds of risks that are involved in a project while looking into the various aspects that are involved in a project and their impacts on the delivery of the project. The sensitivity analysis is considered as a technique of qualitative type and can help in determining the different variables that are present in the construction project and can put a great effect on the project as a risk (Sha et al., 2017). Risk probability or likelihood is known as the possibility of risk involved in an event that is occurring. The likelihood can be also be expressed in both quantitative as well as in a qualitative manner.

Few steps which the project manager needs to take for delivering the construction project on time to the client is by creating a flow of communication properly, making a habit of the following planning continuously, performing a budget for the project with an appropriate platform of execution, embracing the automated system of reporting and following certain strategies that can help to bring in a successful project (Kassem et al., 2019). The most important aspect to be kept in mind by the project manager in handling a construction project is to take care of the time management and resource allocation, only then the project will be completed on time.

References

Abdel-Basset, M., Ali, M. and Atef, A., 2020. Resource levelling problem in construction projects under neutrosophic environment. The Journal of Supercomputing, 76(2), pp.964-988.

Amandin, M.M. and Kule, J.W., 2016. Project delays on cost overrun risks: A study of Gasabo district construction projects Kigali, Rwanda. ABC Journal of Advanced Research, 5(1), pp.21-34.

Durdyev, S. and Hosseini, M.R., 2019. Causes of delays on construction projects: a comprehensive list. International Journal of Managing Projects in Business.

Hasan, M.F. and Mohammed, M.S., 2018. Time overrun model for construction projects in Iraq by using fuzzy logic. Int. J. Civ. Eng. Technol, 9, pp.2593-2607.

Ismail, A., Srewil, Y. and Scherer, R.J., 2017. Integrated and collaborative process-based simulation framework for construction project planning. International Journal of Simulation and Process Modelling, 12(1), pp.42-53.

Kassem, M.A., Khoiry, M.A. and Hamzah, N., 2019. Using probability impact matrix (PIM) in analyzing risk factors affecting the success of oil and gas construction projects in Yemen. International Journal of Energy Sector Management.

Khosiin, M.W., Wang, W.C. and Wijatmiko, I., 2020. Integrating CBS and WBS in Construction Projects by Using Data Analytics. Nusantara Science and Technology Proceedings, pp.91-95.

Lin, X., Ho, C.M. and Shen, G.Q., 2017. Who should take the responsibility? Stakeholders’ power over social responsibility issues in construction projects. Journal of cleaner production, 154, pp.318-329.

Lin, X., McKenna, B., Ho, C.M. and Shen, G.Q., 2019. Stakeholders’ influence strategies on social responsibility implementation in construction projects. Journal of Cleaner Production, 235, pp.348-358.

Omar, T. and Nehdi, M.L., 2016. Data acquisition technologies for construction progress tracking. Automation in Construction, 70, pp.143-155.

Pehlivan, S. and Öztemir, A.E., 2018. Integrated risk of progress-based costs and schedule delays in construction projects. Engineering Management Journal, 30(2), pp.108-116.

Rachid, Z., Toufik, B. and Mohammed, B., 2019. Causes of schedule delays in construction projects in Algeria. International Journal of Construction Management, 19(5), pp.371-381.

REDDY, T.P., SAFIUDDIN, M. and KHATOON, S., 2016. EVALUATION OF WAYS TO RECOVER LATE CONSTRUCTION PROJECTS. EVALUATION, 2(16), pp.49-57.

Sha, M.K., Shahi, P.B., Pandit, R. and Pandey, A., 2017. Causes and Effects of Delays in Construction Projects. Journal of Mechanical and Civil Engineering, 14(2), pp.52-58.

Sharon, A. and Dori, D., 2017. Model‐Based Project‐Product Lifecycle Management and Gantt Chart Models: A Comparative Study. Systems engineering, 20(5), pp.447-466.

Sutrisna, M., Ramanayaka, C.D. and Goulding, J.S., 2018. Developing work breakdown structure matrix for managing offsite construction projects. Architectural engineering and design management, 14(5), pp.381-397.

Turkan, Y., Olsen, M.J., Gambatese, J. and Puri, N., 2019. Project Progress Tracking Using Lidar and 4D Design Models (No. FHWA-OR-RD-19-12).

Vignesh, V., 2018. Resource Optimization of Construction Project Using Primavera P6. IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE) e-ISSN, pp.2278-1684.

Zareei, S., 2018. Project scheduling for constructing biogas plant using critical path method. Renewable and Sustainable Energy Reviews, 81, pp.756-759.

Know more about UniqueSubmission’s other writing services:

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?