Advance Manufacturing Technology Adoption in Developing Countries

Purpose: This study was based on the advanced manufacturing technology adaption. The main purpose of the research study was to find out the adaptation of the advanced manufacturing technologies in the manufacturing firms with focus on IBM. This research study explored factors that determined the advanced manufacturing procedure adaptation. This study focused on the impact of advanced manufacturing procedures in the organisational context, technological context, and environmental context. This study also evaluated the advanced manufacturing; the factors determine the advanced manufacturing, the process of advanced manufacturing, advantage and disadvantage of advanced manufacturing, advanced manufacturing technologies, and trends.

Design/ Methodology/ Approach: The quantitative research method was adopted for this research study. The information in the quantitative research was collected by using a close-ended questionnaire. The information was collected through the online survey in this study. In this study, the SPSS software was used to analyse the quantitative research. The result of the quantitative research was more reliable because the information was collected from a large number of populations. The exploratory research design was the appropriate research design for this research. The positivism research philosophy was the suitable research philosophy for this research study. In this research study, employees of production department from IBM were chosen to collect the information.

Findings: The advanced manufacturing is adapted to improve the performance of the industries. The factors that determine the technological context of the advanced manufacturing are perceived value and technological-in-use. Some external factors that influence the implementation of advanced manufacturing technologies are a technological trend, customer, government, and suppliers. The sue fo advanced manufacturing technologies enables the firms to reduce the cost of production and improve the efficiency to achieve higher competitive advantage

Originality/ Value: This research study fulfils to advance manufacturing technology adaption. This research study is significantly focused on the ongoing adoption of the advanced manufacturing technology in the manufacturing industry. This study provides the information about the importance of technology adoption for long-term competitiveness in the manufacturing industry which increases the productivity and output. This research study also provides the recommendation for the adoption of advanced technology in the manufacturing industry.

In this competitive business environment, it is required for the firms to adopt better technology and approaches to achieve the competitive advantage and grow their business significantly. For this, the firms focus on the advanced technologies to reduce their costs and improve efficiency level that enables them to enhance competitiveness and increase market share significantly (Dangayach & Deshmukh, 2003). In current time, the competition is dynamic, complex and uncertain that raises the need for the organizations to integrate the emerging and advanced technologies in their operations and increase their efficiency to handle the increasing competition properly. The increasing competition has raised also production of multi-products by a firm that has made the market diversified. At the same time, it has also raised the need for adopting the advanced manufacturing procedures based on modern technology. In relation to this, the manufacturing industry faces high competition in the market due to regular changes in needs of customers and product requirements. It has also made mandatory for the manufacturing companies to adopt better and advanced technologies to develop competitiveness and meet the market requirements. The manufacturing firms need to assess their strategies and manufacturing process by adopting the advanced technology (Chung & Swink, 2009). In order to lower the cost and improve the workers’ efficiency, it can be effective for the manufacturing firms to adopt the advanced manufacturing technologies.

The focus on the advanced manufacturing process can be effective for the manufacturing firms to make changes in the production and design process for responding emerging technologies and needs of the new customers. It is mandatory for the companies in manufacturing industry to handle the tense competition and attract both the international and domestic customers. At the same time, it is also expected from the seller to provide the quality products and services to the customers. To meet this expectation of the customers and also to attract global as well as domestic customers the industries in developing countries are adopting the advanced manufacturing procedures (Jabar, Soosay & Santa, 2010). A perfect interaction between the manufacturing challenges and technological potential is set up by the advanced manufacturing procedure.

The use of advanced manufacturing technologies enables the firms to improve quality of the product, greater flexibility, saving labour hour, greater reliability, reduce inventory and faster machine cycle. Along with the computer technologies, the use of advanced technologies in the manufacturing process helps to integrate the full range of manufacturing processes and production functions (S.E.G. & Lima, 2009). By adopting advanced manufacturing process, the firms can store the information by using computer technology. In this procedure, with a cheaper cost, the organisations can distribute and change data electronically.

This research is based on the significance of the advanced manufacturing technologies with the focus on different technologies like six sigma, SMDE, value chain and ABC analysis. The better understanding of these technologies can be useful for the manufacturing companies to improve their efficiency and achieve the market share. This research also discusses the different dimensions from which the factors of the advanced manufacturing technology affect the production process and raise the need for adopting advanced technologies in manufacturing operations. The outcomes of this research are also crucial for the management of the companies to operate the manufacturing operations effectively and achieve the competitive advantage in the market. In addition, this study is also important for other companies from different industries to adopt these technologies and operate their business with greater efficiency. It can help to reduce the time of entire operation of an organisation and as a result of this; the productivity of the organisation can be increased.

The key aim of this research is to determine the importance of the advanced manufacturing technologies in operations of the manufacturing companies. In this research, factors determining the need of adopting the advanced manufacturing technologies and significance of the advanced manufacturing procedures in the organizational performance are discussed.

The following objectives are accomplished on completion of this research:

- To assess factors determining the advanced manufacturing procedure adaptation

- To critically analyze the benefits and limitations of advanced manufacturing technologies

- To determine impact of advanced manufacturing technologies on organizational performance

This research is focused on the significance of the advanced manufacturing technologies in the organizational performance. In literature review, different factors that determine the adoption of advanced manufacturing processes and technologies in the manufacturing firms are discussed. At the same time, different technologies that are effective to improve organizational performance are also critically discussed with the consideration of benefits and challenges. In addition, the significance of these technologies is also assessed. In the methodology section, the chosen methods are discussed and the gathered information is analysed in the analysis and discussion section. Some recommendations are provided in this study to improve the process of adaptation of advanced manufacturing processes in the future.

It is significant chapter of this dissertation and research study that is helpful to increases theoretical knowledge on the research issue and problem. This chapter is related to analysed the presented literature and journal prepared by the previous authors and researchers. It is helpful to collect the wide information on the research issue and problem. In this chapter, the data regarding the research issue is collected from the different academics secondary sources such as the books, journal, articles etc. These collected data and information is critically analysed in order to develop the depth understanding on the research issue. With the help of this, the researcher will be able to minimise the gap between the available information and data and required data and information. In the context of this research study, this literate review will provide the knowledge of theories and concept related to advanced manufacturing procedure adaptation and advanced manufacturing technologies on organizational performance.

2.2 To assess factors determining the advanced manufacturing procedure adaptation

In the views of Alcaraz et al. (2016) the advance manufacturing process is associated with the use of the technology in order to make the manufacturing process of more effective and efficient. In this, the main aim of the firms to produce the maximum at the minimum cost. At the same time, the objective of the adoption of the advance manufacturing procedure or adoption is to increase to make the effective utilisation of the organisational resources. In the advanced manufacturing procedure, the products are produced with a high level of the design. It means that while adopting the concept of the advance manufacturing procedure, a company focuses on each area production where company can improvement. In the same concern of this, by the research study of Ford (2014) it is found that advance manufacturing is new concept of the manufacturing in which companies focus on the innovation in during the production. It is also defined that during the adoption of the advance manufacturing process, companies produce the innovative product that are able to solve the variety of the common problem of the producers and users of the company.

does not have a home in

According to Khanchanapong et al., (2016) human resource is one of the main and vital factors that determine the procedure of the advance manufacturing process. In this, it is found that the ability and skills are considered during the adoption of advance level technology at the workplace. It is because any process and technique that will be used in the workplace with be operated by the man power of the company. In this, it has also been seen that a company can adopt the advance manufacturing procedure in the ability of its employees’ ability and skills. If the company has not effective man power and labour then it is difficult for the company to get the advantage of the advance manufacturing procedure.

In the views of Maiga et al. (2014), several factors in relation to organisational context, technological context, and environmental context have a significant influence on the adoption of advanced manufacturing procedure. Organizational factors have a considerable impact on the adoption of the advanced manufacturing procedure because of the organisational adjustment. In addition, the manufacturing organizations can get competitive advantages by focusing on the advanced manufacturing technologies to make the current organizational design. In relation to this, Mellor et al. (2014) also state that organizational factors like top management, manufacturing strategy, organisational structure, HR practices and organisational culture play an important role in the adoption of the advanced manufacturing procedure and technologies. If the advanced manufacturing technology fits with the structure and employees and the organisation, then it is easy for the management to adopt this technology and achieve high performance. At the same time, Khanchanapong et al. (2014) argue that firms can handle the HR practices easily by adopting the advanced technologies. The use of new computerised technology enables the firms to keep all records relating to employees and production and make better decisions. But at the same time, Wu et al. (2015) argue that the focus on these new technologies raises the need for the companies to create better opportunities for employee involvement that also increases the job satisfaction of the employees and contribute to the organizational performance.

Meanwhile, the study of Vaezi et al. (2013) reflects the role of the technological factors in adopting advanced manufacturing technologies. The factors that determine the technological context of the advanced manufacturing are perceived value and technological-in-use. The current system and practices of an organisation can be influenced by adapted advanced technology. So, transformational changes need to be considered by adapting the advanced manufacturing. Therefore, the adapted technology can help in manufacturing the product efficiently.

On the other hand, it can be revealed from the research of Maiga et al. (2014) that environmental concerns are the major factors that influence the adoption of the advanced manufacturing technologies. In relation to this context, several factors like financial resources, supplier support, and external pressures play major role in adopting the advanced manufacturing technologies. The sufficient availability of the fund also encourages the firms to adopt the new technologies in manufacturing operations. It is because all these technologies including software and hardware are costly that raises the financial burden on the company. The firms which have good financial strength can spend money on this as financial aspects of the firm play an important role in adoption of new manufacturing technologies. Meanwhile, Mellor et al. (2014) depict that external pressures of the firm including competitive pressure and consumer pressure are crucial for the firms while adopting the advanced manufacturing process and technologies. The manufacturing industry is highly competitive and changing customer needs also cause high requirements for the firms to make changes in their products consistently. This can be possible by adopting newly advanced technologies that enable the firms to produce the varieties of products as per the changing demand of the customers and make the differentiation in their products to compete with the competitors. Supporting to this, Vaezi et al. (2013) also affirm that the use of advanced technologies enable the firms to compete with the competitors and handle the consumer pressure by meeting their requirements on time and increasing their satisfaction level. With the adaptation of the new technology in the manufacturing sector, the industry can fulfil the demand of the customers. The technological advancement in the manufacturing sector can also help the companies by offering a cheaper price to the customers by reducing the cost of production and competing with the competitors. At the same time, Laplume et al. (2016) also state in the environmental context by focusing on the supplier support. It is mandatory for the firms to get support of the suppliers while implementing the advanced manufacturing technologies. If the suppliers provide better support to the firms to access the required information, then it becomes easy for the firms to adopt new technologies.

2.3 To critically analyze the benefits and limitations of advanced manufacturing technologies

The research study of Laplume et al. (2016) is based on the effectiveness of the advance manufacturing technology. In this, it is found that the main advantage of using the advance manufacturing technologies is that it provides the competitive advantage to company. The researcher also discussed that most of the times; the main aim of the companies is to achieve the competitive advantage. The current business environment has become the very competitive. Due to this, it is difficult for the companies to achieve the sustainable advantage. Hence, the consideration of adopting the advance manufacturing technology provides the competitive advantage to the companies because it reduces the cost and improves the efficiency of the company.

Moreover, in the research study of Maiga et al. (2014), it is determined that the use of the advance manufacturing technologies helps the companies to increase the production quantity. In this, it is determined that in the current time, the science has developed the various advanced technologies that the used by the companies to increases the production quantity. The adoption of the advance manufacturing companies allows the companies to minimise the human being effort and reduce the cost of the product that lead to increase in the profit. In the support of this, Mandahawi et al. (2012) also stated that the use of the advance manufacturing technology is also helpful for the companies to increases the productivity and performance of the company. In the manufacturing process, companies adopt the new technology to improve the performance of their products so those customers more like their product as compared to other companies. It also increases the sales of the company and help to make the more profit.

But in contrary, Mellor et al. (2014) posited that the adoption of the advance manufacturing technology at the workplace increases the cost of the company and increase the cost of the product. It becomes the cause of decline in the profitability of the company. Due to increase in the cost of the production, sometime, it can be seen that companies financial activities also distracted because company has to divert its cost in the purchasing the technology.

In the same concern of this, it is also analysed in the research findings of Mueller (2012), the adoption of the advance manufacturing causes the distraction at the workplace. In this, it is analysed that when company adopt or implement the new technology then employees have to distract with the current or existing process in the manufacturing. But, due to some complex process, employees cannot become familiar with the new technology and it causes distraction at the work. The main negative impact of this can be seen on the performance of company and employees.

On the other hand, Mandahawi et al. (2012) condemn by stating that however, the use of advanced manufacturing technologies raises the need for high skilful employees that increases the financial burden on the company. In addition, it is also required for the firms to provide training to the employees how to run the new technologies that raises also costs for the company. In the support of this, Singhose (2009) exhibited that the higher maintenance cost is also a negative point of the adoption of the advance manufacturing technology. At the workplace, it can be seen that most of the time, it is expensive for the companies to buy the new technologies.

According to García Alcara et al (2012), advanced manufacturing technology is the social technical system in which regular revisions, changes as well as re-adjustments are needed in order to fulfill the needs of the world which is full of competition. In addition, advanced manufacturing technology has several advantages. With the help of advanced manufacturing technology competition can be affected positively for the organizations. It also include various other benefits such as reduction in cost as by adopting advanced manufacturing technology in the organization the business can overcome the expenses and the cost can be minimized which is incurred in handling overall business. Norall (2013), examines other benefits i.e. improvement in the quality by adopting advanced manufacturing technology in the businesses. The high quality is due to the process-related technologies enable for stability in the manufacturing process on the basis of product conformance. It has been determined that using advanced manufacturing technology shows evidence that corporate goals such as market share increment as well as gaining earlier entrance to the market can be taken into consideration. Advanced manufacturing technology is also helpful in minimizing the time in handling the customers as with the help of these technology customers can be satisfied easily in minimum time.

In the support of above author HYNEK and JANEČEK (2017), said that the adoption of this technology in the organization would be helpful in attracting more and more customers for the particular business. This technology helps the business in getting new products to the market more quickly. It provides flexibility for the organization to adapt changes in the market. In terms of increase in the flexibility enables the organizations to produce the lot of products at low volumes with no penalty or additional costs. There is increase in providing good service to the customers as normally it is the issue in all the organizations. In the views of Norall (2013), AMT also increases the productivity by minimizing the labour cost of the organization as well as minimizing the re-work costs. Advanced manufacturing technology also benefits in improving the better work relations with the workforce. This technology adoption helps in improving work relation among the employees in the organization. The main motivation to invest in AMT is stable. It also improves the working environment of the company as adopting this technology is helpful in handling easily all the work and there is no confusion in terms of accomplishing any work.

Cook (2017) argues that this technology helps in overcoming existing skills deficiencies. The major advantage of this technology is in gaining the competitive advantage to the great extent. It also widens the range of the products. It also helps in having better management relationship among the employers and employees. It can be concluded from the above discussed benefits that the manufacturing companies should adopt AMT in order to avoid certain issues the companies are facing. Changes are necessary in the organization for reaching to the success in the business. So AMT is one of the technologies that provide the success factor for the manufacturing companies.

2.4 To determine impact of advanced manufacturing technologies on organizational performance

According to Vaezi et al. (2013), the use of advance manufacturing technologies impacted the manufacturing firms in the terms of cost aspects in the manufacturing processes. However, as stated in the study of Khanchanapong et al. (2014) the advanced manufacturing technologies have impacted firms positively in contributing to development of new products as well as product and process innovation. It can be said that such technologies are influencing the organisation performance by innovative products and processes and reducing the cost of manufacturing process. It is also pointed in the study of Ford (2014) advanced manufacturing technologies puts an emphasis on improving the research and development capabilities towards providing the state of the art equipment and processes to enhance the firm manufacturing performance. The software as a service (SaaS) manufacturing software has increase the firm access to information at real time to make an effective decision for production of different products, decisions for batch production and pricing models for different production. Wu et al. (2015) mention the adoption and use of SaaS technology in manufacturing firms to improve flexibility in production process and achieve production functionality. At the same time, the solution of quality management in a firm using the six sigma software has gained much relevance in managing the quality aspects of the production processes. According to Timans, et al. (2012), six sigma has led to technological innovations to improve a firm operational performance and market competitiveness. It is also stated that six sigma technologies has affected manufacturing firms in reducing the cycle times by identifying and eliminating errors and defects and reduce cost of operations which has improved organisational productivity. However, Mandahawi et al. (2012) argue that the lean six sigma tools and technology to achieve outcome on organisational performance are impacted by the implementation dimension which needs to be adequate to achieve positive effect form this process improvement technology. On the different side, in the words of Maiga et al. (2014), the Activity Based Costing (ABC) implementation impact an organisation performance by control of costs and assistive in decision making on strategic issues where the information technology play a role in the success of ABC to archive the positive impact on a firm performance.

The advance manufacturing technology of additive engineering is helping the organisation to develop innovative products by having a 3 dimensional view of potential product, material layers and engineering aspects for better transformation of existing products or development of new innovative products. It is stated by Mellor et al. (2014) additive engineering technology is transforming the analog process to digital one to improve organisation performance in relation to achieving manufacturing efficiency and flexibility in the production operations. The study of Mueller (2012) describes 3-D printing as an advanced manufacturing technology that facilitate defining complex products accurately to aid in designing of products and process and enhance information technology collaboration among technical and operational staff for improving firm manufacturing performance. Similarly, according to Vaezi et al. (2013), the additive manufacturing technologies scan the object of complex geometrics in three dimensional to take decision on adding material layers to products to make them stronger and lighter to optimise performance during the manufacturing operations. It can be said that 3-D printing is impacting organisational performance by revolutionizing the process and operation in manufacturing. Differently, Vaezi et al. (2013) stated that 3-D printing has influenced organisation performance in customising the expertise of the customers by innovative and efficient products and marketing services. Thus, it can also be said that organizational performance is affected by the additive engineering technologies in relation to flexibility, efficiency and development of efficient products. Also, the study of Laplume et al. (2016) linked the additive manufacturing technologies with the value chain analysis. It is stated that these technologies allow changes in the value chain configuration for better organisational performance by the development of smarter value chain. The manufacturing technologies for smart value chain have given strategic planning in the production process with limited resource and to deal with growing competitive pressure. However, such technologies are more intensive in use in developed countries like the United States, Japan as compared to developing countries (Ford, 2014). However, Timmer et al. (2014) argue that smart value chain advanced technologies has also visible in its use in value chain analysis in high tech manufacturing firms in China. Thus, the smart value chain advanced technologies is impacting the firm performance in production of innovative products with scare resources thus, improving the operational performance of manufacturing process.

The advance manufacturing technology concerning precision engineering technology is known for design of machines, equipments and manufacturing structures that has greater load tolerances and improves machine times. In the views of Singhose (2009), precision engineering technology provides stable system and machine design for complex product geometries to enhance the manufacturing operations performance. It can be added by Singhose (2009) that advance manufacturing technologies has affected the manufacturing firm’s production planning capabilities and the potential of the firm towards innovation of products, processes and system.

On the other hand, Thomas (2016) provided views of the influence of AMT on organisation performance with regards to supply chain performance in planning and managing the supply chain operations/ activities and management of suppliers for flexible distribution of products.

By the advanced manufacturing technology, the manufacturing organisation can be planning and manage large and distributed suppliers and networks in the multi-echelon supply chain which is allowed to the strong, flexible and increasingly regionalized distribution of products and components. It can be said that AMT impact on marketing/ distribution capabilities by managing diverse supply network and designing the supply chain for optimal performance which also affects a firm performance. Also, Khanchanapong et al. (2014) viewed that the advanced manufacturing technologies of automation and robotics has improved organisation performance in relation to improved product lead time and improved time to market from concept to design stage to final products in a cost effective way. Wu et al. (2015) found that robotics technology has influenced manufacturing firms’ performance in gaining high financial returns and positive return of investment in advanced technologies by its application in complex tasks and eliminating the need of manual labour and reduced manual error. In addition, Wollschlaeger et al. (2017) mention that technologies like industrial internet of things (IIoT) supports the use of robotics in manufacturing sectors.

The technological innovation for products process and system allows collaboration among technical and non-technical staff to enhance operational performance. The advance manufacturing has gained application in high tech manufacturing firms in automation and robotics and technologies to transform the process, products and services under the approach of advance manufacturing system. Alcaraz et al. (2016) state advanced manufacturing technologies for efficient cost and resource efficient process in manufacturing operations that impact the organisational performance. It can be said that advance manufacturing technologies can impact the organisational performance by providing opportunities to develop more resource efficient process, innovative products, maintain cost of manufacturing operations and opening up new markets for innovative products and services. Thus, it can also be understood that the impact of advance manufacturing technologies in the manufacturing sector in huge for today for organisation performance and in future prospects.

Chapter 3: Research Methodology

In this chapter, different research methods and techniques are determined to collect the required data and conduct the study effectively. For this, different research methods like philosophy, approach, research design and data collection methods with data analysis method are discussed in this section of the dissertation. It helped the researcher to determine the right way of data collection and gather the required information to achieve the research objectives.

Research philosophy is the research method based on thoughts and assumptions of the researcher to develop better understanding about the research issues (Yilmaz, 2013). In simple words, research philosophy is based on belief through which data is collected or gathered, analyzed and used to accomplish the study. This study is based on the numerical observation, as the positivism research philosophy was the most suitable for this study (Moon and Blackman, 2014). The findings of the research are the observable and quantifiable in this study. So, researcher focused on the statistical analysis and interpretation to analyze the data. There is no need to develop theoretical understanding of the topic to conclude the overall research study. The use of this philosophy provided the ontological view of the research problem. At the same time, researcher also used deductive approach as this research approach is the most suitable with the positivism philosophy. In this research study, the researcher focused on the adaptation of the advanced manufacturing process. The researcher focused on how the manufacturing companies are adopting the advanced manufacturing technology and achieving the bigger market share.

The exploratory research design was used by the researcher for this research. It is the most suitable with the use of quantitative research method. To establish the fact that how best the research process was conducted, the exploratory research design was used in this study. In the exploratory research design, the situation was developed with the well-grounded picture of the research topic (Godin and Zahedi, 2014). By conducting the exploratory research design, the researcher focused on the full idea about the importance of advanced manufacturing process and why an organisation adapted the advanced manufacturing process. No hypothesis was established in this study because this study is not reflecting any relations among variables. The exploratory research design helped in the data collection process systematically to show the path for future research on the same topic. The researcher selected this exploratory design because it is very easy to adapt and much flexible than other research designs and saved time tin conducting the study.

The quantitative research method was preferred by the researcher in this research study. The quantitative research study enabled the researcher in gaining the opinions of managers of manufacturing company regarding the advanced manufacturing technologies and factors that encourage them to adopt these technologies. The quantitative research method helped to collect the views and opinions of the research participants to provide the numerical outcomes of the research in form of frequencies and percentages (Choy, 2014). The information in the quantitative research was collected by using a close-ended questionnaire. The information helped to collect through the online survey in this study. The statistical tools were used in the quantitative research methodology. In this study, the researcher used the Excel software to analyse the quantitative research. The quantitative method was chosen here because the quantitative data helped to provide more accurate information about the use of advanced manufacturing technology and adaption of advanced manufacturing technology. The result of the quantitative research was also more reliable because the information was collected from a large number of populations (Crowther and Lancaster, 2012).

It is important part of the research study to collect the authentic and reliable data to conduct the study in valid manner. For this research, researcher focused on the online survey to collect the views and opinions of the research participants about the advanced manufacturing technologies and related factors that enhance their adoption. The use of survey method enabled the researcher to get handiness in recording the data and analyzing it properly on excel software to provide the meaningful findings (Creswell, 2013). Apart from this, the use of closed ended questions was also effective to provide the convenience the research participants to respond timely (Malhotra, 2015). Additionally, this survey method was online as it was easy for the researcher to get more responses online and achieve the best responses appropriately. The managers of the company taken were asked about why they have adopted and adapted the advanced manufacturing process and technologies in their company and how the technologies are helping them to gain the success over the year. The researcher formed the questionnaire on the progress of the selected companies and advantages of the advanced manufacturing technologies. As numeric data was collected, the close-ended questionnaire was formed in this research process. The questionnaire was delivered through the email to the employees of the chosen multinational manufacturing company. The employees provided the information and sent the answers back to the researcher.

The sampling procedure for this study identifies and selects a suitable sample representative of the target population to take part in the research process. The researcher has chosen sampling procedure of probability methods. Under probability method, simple random is chosen to provide the research participants (each unit in the population) with an equal chance of getting selected in the research process. Thus, this sampling method allows the researcher to define the population which is of interest to the researcher and avoid selection bias by avoiding impartial participant selection in the research process (Delice, 2010).

The population sample for this research involves participation of employees from production department in IBM as participants of interest. The population sample in this includes IBM employees from production department due to the focus of the study on the advanced manufacturing technologies only. The number of participants chosen to contribute in the statistical analysis indicates the sample size which is 80 for this study. This sample size is appropriate for quantitative research as a large sample more than 50 or more is required to undertake a good statistical analysis to obtain meaningful inferences (Mertler and Reinhart, 2016).

The data analysis forms a critical step in the reserch process to get accurate results and to obtain meaningful inferences. Thus, to identify conclusive results and to address the research aim and objectives the collected research data was analysed for the collected responses with the use of data management tool, Ms Excel and application of statistical knowledge in this spreadsheet software. The researcher has used quantitative data analysis method to analyse the raw primary data and its analysis in terms of percentage to represent it in graphical and tabular form for easy and correct interpretation of findings from the responses received by study contributors. MS Excel has been useful software to analyse the collected research data of primary nature. This data management tool has been preferred by the researcher due to its familiarity, systematic data distribution and data representation in different format and ease of conducting statistical analysis to draw conclusive result for survey questions. This method has been also preferred because the choice of statistical data analysis is suitable considering the quantitative research nature (Mertler and Reinhart, 2016) and also considering the nature of objectives set to be explored in this study (Gray, 2013). These are important to consider as the choice of data analysis method affects the interpretation of the collected data being analysed and impacts the outcomes of the research. Thus, statistical analysis was chosen method for data analysis in this quantitative research. The statistical analysis from the data management tool has been helpful for the researcher to analyse responses received and to prepare and interpret graphical representation of data in form of bar graphs, charts, etc.

The researcher has given consideration towards the research ethics which is a core part in a research process. Research ethics has allowed the researcher to conducts the research process and to obtain the research outcome in an efficient manner without any ethical dilemma. Consideration towards research ethics has lowered the risk of data manipulation and mis-representation and errors (O’Leary, 2013). Under research ethics, the researcher has adopted a collaborative process involving the guide and colleagues in a regular manner in getting assistance in conducting the research process. In addition, the university guidelines have been followed to avoid any risk of ethical issues from arising during the completion of this study. In literature review, the plagiarism and copyright issue has been taken account of by the practice of in –text citation followed by the researcher and accessing information from only valid and relevant sources (Grinyer, 2009) to avoid the negative impact of ethical issues. Also, the research ethics have been considered during the process of primary research as the researcher has maintained the privacy and confidentiality of the research participants name and other details and information provided. The research has avoided any kind of discomfort to the respondents and did not pressurize any participants to take part in the research process. Thus, the research has followed ethics towards respect and fairness values of respondents in conducting the primary research.

Chapter 4: Findings and Discussion

This chapter provides the findings obtained from primary research and aligns them with the findings of literature review through discussion. This chapter provides the discussion over the findings by considering the findings of literature review.

In this study, a survey was conducted by the researcher by considering the IBM employees from production department. For this, 104 respondents were targeted but the researcher obtained positive and right responses for only 80 respondents. For this research, the below sections provide the analysis of the obtained findings from primary research:

The following responses are related to the demographic information of the respondents:

| Gender | |||||

| Frequency | Percent | Valid Percent | Cumulative Percent | ||

| Valid | Male | 60 | 75.0 | 75.0 | 75.0 |

| Female | 20 | 25.0 | 25.0 | 100.0 | |

| Total | 80 | 100.0 | 100.0 | ||

From the above table, it can be depicted that the sample size included male and female both to get the diverse views regarding the role of advanced manufacturing technologies in the business performance. For this, 60 male employees (75%) and 20 female employees (25%) were considered for taking survey.

| Work_experience_in_the_firm | |||||

| Frequency | Percent | Valid Percent | Cumulative Percent | ||

| Valid | 0-2 years | 26 | 32.5 | 32.5 | 32.5 |

| 2-4 years | 30 | 37.5 | 37.5 | 70.0 | |

| 4-6 years | 16 | 20.0 | 20.0 | 90.0 | |

| 6 years or more | 8 | 10.0 | 10.0 | 100.0 | |

| Total | 80 | 100.0 | 100.0 | ||

The above table depicts that there was mix of employees having experience of different years in the organization. The employees with different work experiences were selected for this study to get the diversified views in perspective of work experience.

4.2.2 Factors determining the advanced manufacturing procedure adaptation

This section is majorly focused on the factors that lay an important role in adaptation of the advanced manufacturing procedure and technologies within the organization. The responses obtained from different questions related to this objective are summarized in the tables and graphs below:

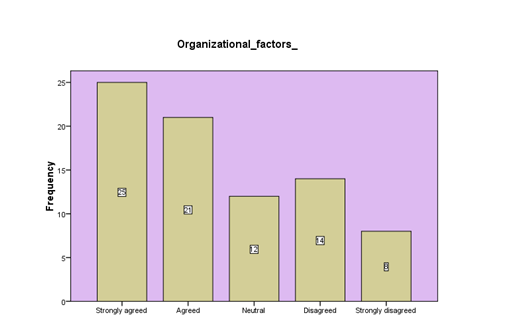

Table 3: Organizational factors

| Organizational_factors_ | |||||

| Frequency | Percent | Valid Percent | Cumulative Percent | ||

| Valid | Strongly agreed | 25 | 31.2 | 31.2 | 31.2 |

| Agreed | 21 | 26.2 | 26.2 | 57.5 | |

| Neutral | 12 | 15.0 | 15.0 | 72.5 | |

| Disagreed | 14 | 17.5 | 17.5 | 90.0 | |

| Strongly disagreed | 8 | 10.0 | 10.0 | 100.0 | |

| Total | 80 | 100.0 | 100.0 | ||

Graph 1: Organizational factors

From the above graph and table, it can be determined that the most of the respondents (46 or 57%) provided their consent that the organizational factors like management strategy, manufacturing strategy, organisational structure, and organisational culture, etc. play an important role in adaptation of the advanced manufacturing technologies.

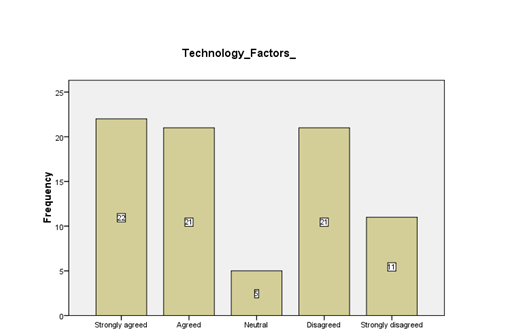

| Technology_Factors_ | |||||

| Frequency | Percent | Valid Percent | Cumulative Percent | ||

| Valid | Strongly agreed | 22 | 27.5 | 27.5 | 27.5 |

| Agreed | 21 | 26.2 | 26.2 | 53.8 | |

| Neutral | 5 | 6.2 | 6.2 | 60.0 | |

| Disagreed | 21 | 26.2 | 26.2 | 86.2 | |

| Strongly disagreed | 11 | 13.8 | 13.8 | 100.0 | |

| Total | 80 | 100.0 | 100.0 | ||

Figure 1: Technology Factors

Based on the above graph and table, it is evident that the majority of the participants (54%) are strongly agreed and agreed on the consideration of technological factors in adoption of the advanced manufacturing procedure and technologies. As per their views, perceived value and technological-in-use are the major concerns that facilitate the adoption of new technologies in the manufacturing operations of the company.

Table 5: Environmental Factors

| Environmental_Factors | |||||

| Frequency | Percent | Valid Percent | Cumulative Percent | ||

| Valid | Strongly agreed | 30 | 37.5 | 37.5 | 37.5 |

| Agreed | 33 | 41.2 | 41.2 | 78.8 | |

| Neutral | 4 | 5.0 | 5.0 | 83.8 | |

| Disagreed | 10 | 12.5 | 12.5 | 96.2 | |

| Strongly disagreed | 3 | 3.8 | 3.8 | 100.0 | |

| Total | 80 | 100.0 | 100.0 | ||

Based on the above table 5, it can be stated that the most of the respondents (approx 79%) consider that environmental factors like financial resources, supplier support, and external pressures like competitive pressure and consumer pressure play an important role in encouraging the firms to adopt new advanced manufacturing technologies. They consider their firm has strong financial position and good support from the suppliers that facilitate the adoption of new technologies in production of the goods.

4.2.3 Benefits and limitations of advanced manufacturing technologies

This section analyzes the response obtained in relation to the benefits and limitations of the advanced manufacturing technologies.

Table 6: Manufacturing companies adopt the advance technologies to reduce cost

| Manufacturing_companies_adopt_the_advance_technologies_to_reduce | |||||

| Frequency | Percent | Valid Percent | Cumulative Percent | ||

| Valid | Strongly agreed | 29 | 36.2 | 36.2 | 36.2 |

| Agreed | 28 | 35.0 | 35.0 | 71.2 | |

| Neutral | 9 | 11.2 | 11.2 | 82.5 | |

| Disagreed | 12 | 15.0 | 15.0 | 97.5 | |

| Strongly disagreed | 2 | 2.5 | 2.5 | 100.0 | |

| Total | 80 | 100.0 | 100.0 | ||

The above table indicates that the majority of the respondents (57 or 71%) consider that the use of advanced manufacturing technologies helps the manufacturing firms to reduce the cost of the product.

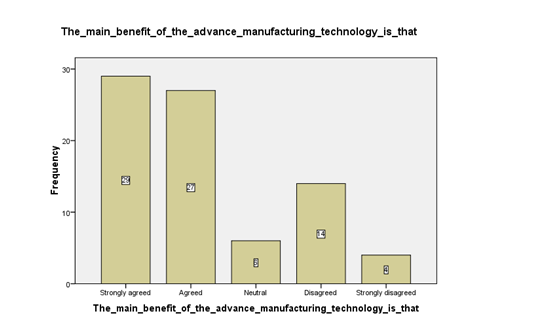

Table 7: Use of advance manufacturing technology to improve the performance and productivity

| The_main_benefit_of_the_advance_manufacturing_technology_is_that | |||||

| Frequency | Percent | Valid Percent | Cumulative Percent | ||

| Valid | Strongly agreed | 29 | 36.2 | 36.2 | 36.2 |

| Agreed | 27 | 33.8 | 33.8 | 70.0 | |

| Neutral | 6 | 7.5 | 7.5 | 77.5 | |

| Disagreed | 14 | 17.5 | 17.5 | 95.0 | |

| Strongly disagreed | 4 | 5.0 | 5.0 | 100.0 | |

| Total | 80 | 100.0 | 100.0 | ||

Graph 2: Use of advance manufacturing technology to improve the performance and productivity

The above table and graph depicts that 70% of the total respondents are agreed and strongly agreed on the benefit of the advanced manufacturing technologies in form of improving the performance and productivity.

Besides of benefits, the following responses are also obtained indicating the challenges in adopting advanced manufacturing technologies:

| Expensive_to_buy_ | |||||

| Frequency | Percent | Valid Percent | Cumulative Percent | ||

| Valid | Strongly agreed | 30 | 37.5 | 37.5 | 37.5 |

| Agreed | 24 | 30.0 | 30.0 | 67.5 | |

| Neutral | 4 | 5.0 | 5.0 | 72.5 | |

| Disagreed | 14 | 17.5 | 17.5 | 90.0 | |

| Strongly disagreed | 8 | 10.0 | 10.0 | 100.0 | |

| Total | 80 | 100.0 | 100.0 | ||

Based on the above table, it is evident that the majority of the participants (68%) are strongly agreed and agreed on high cost to buy the advanced manufacturing technologies as a big challenge in their adoption.

Table 9: High maintenance cost

| High_cost_of_the_maintenance__ | |||||

| Frequency | Percent | Valid Percent | Cumulative Percent | ||

| Valid | Strongly agreed | 33 | 41.2 | 41.2 | 41.2 |

| Agreed | 30 | 37.5 | 37.5 | 78.8 | |

| Neutral | 2 | 2.5 | 2.5 | 81.2 | |

| Disagreed | 11 | 13.8 | 13.8 | 95.0 | |

| Strongly disagreed | 4 | 5.0 | 5.0 | 100.0 | |

| Total | 80 | 100.0 | 100.0 | ||

The above table indicates that the majority of the respondents (63 or 79%) consider that the advanced manufacturing technologies are costly in maintenance that restricts the firms to adopt these technologies.

Table 10: Need of the proper training programme

| Need_of_the_proper_training_programme_ | |||||

| Frequency | Percent | Valid Percent | Cumulative Percent | ||

| Valid | Strongly agreed | 27 | 33.8 | 33.8 | 33.8 |

| Agreed | 33 | 41.2 | 41.2 | 75.0 | |

| Neutral | 5 | 6.2 | 6.2 | 81.2 | |

| Disagreed | 13 | 16.2 | 16.2 | 97.5 | |

| Strongly disagreed | 2 | 2.5 | 2.5 | 100.0 | |

| Total | 80 | 100.0 | 100.0 | ||

Graph 3: Need of the proper training programme

From the above graph and table, it can be determined that the most of the respondents (60or 75%) provided their consent that there is need for the firm to provide training to the employees to operate the new advanced manufacturing technologies that increase financial burden.

Table 11: Distract the employees from existing process

| Distract_the_employees_from_existing_process_ | |||||

| Frequency | Percent | Valid Percent | Cumulative Percent | ||

| Valid | Strongly agreed | 30 | 37.5 | 37.5 | 37.5 |

| Agreed | 27 | 33.8 | 33.8 | 71.2 | |

| Neutral | 3 | 3.8 | 3.8 | 75.0 | |

| Disagreed | 16 | 20.0 | 20.0 | 95.0 | |

| Strongly disagreed | 4 | 5.0 | 5.0 | 100.0 | |

| Total | 80 | 100.0 | 100.0 | ||

The above table indicates that the majority of the respondents (57 or 71%) consider that the advanced manufacturing technologies are distract the employees from existing process having a negative impact on the productivity and performance of the employees as well as organization.

4.2.4 Impact of advanced manufacturing technologies on organizational performance

Table 12: Impact on product and process innovation and capabilities of employees

| Do_you_think_that_advance_manufacturing_technology_has_impact_pr | |||||

| Frequency | Percent | Valid Percent | Cumulative Percent | ||

| Valid | Strongly agreed | 27 | 33.8 | 33.8 | 33.8 |

| Agreed | 30 | 37.5 | 37.5 | 71.2 | |

| Neutral | 2 | 2.5 | 2.5 | 73.8 | |

| Disagreed | 17 | 21.2 | 21.2 | 95.0 | |

| Strongly disagreed | 4 | 5.0 | 5.0 | 100.0 | |

| Total | 80 | 100.0 | 100.0 | ||

The above table depicts that 71.3% of the total respondents are agreed and strongly agreed on impact of advance manufacturing technology on product and process innovation and capabilities of employees.

Table 13: Impact on productivity and performance of the company

| An_advance_manufacturing_technology_affects_the_productivity_and | |||||

| Frequency | Percent | Valid Percent | Cumulative Percent | ||

| Valid | Strongly agreed | 26 | 32.5 | 32.5 | 32.5 |

| Agreed | 30 | 37.5 | 37.5 | 70.0 | |

| Neutral | 2 | 2.5 | 2.5 | 72.5 | |

| Disagreed | 18 | 22.5 | 22.5 | 95.0 | |

| Strongly disagreed | 4 | 5.0 | 5.0 | 100.0 | |

| Total | 80 | 100.0 | 100.0 | ||

The above table indicates that the majority of the respondents (56 or 70%) consider that the use of advanced manufacturing technologies helps the manufacturing firms to improve the productivity and performance.

Table 14: Impact on firm’s financial performance

| Are_you_agreed_that_the_adoption_of_the_advance_manufacturing_te | |||||

| Frequency | Percent | Valid Percent | Cumulative Percent | ||

| Valid | Strongly agreed | 28 | 35.0 | 35.0 | 35.0 |

| Agreed | 23 | 28.7 | 28.7 | 63.7 | |

| Neutral | 1 | 1.2 | 1.2 | 65.0 | |

| Disagreed | 20 | 25.0 | 25.0 | 90.0 | |

| Strongly disagreed | 8 | 10.0 | 10.0 | 100.0 | |

| Total | 80 | 100.0 | 100.0 | ||

Based on the above table, it is evident that the majority of the participants (53.7%) are strongly agreed and agreed on influence of the adoption of the advance manufacturing technology on the firm’s financial performance.

4.3.1 Factors determining the advanced manufacturing procedure adaptation

In the context of this objective, it is identified that survey and literature review are used to determine the various factors that determine the advance manufacturing technology. For this research objective, it can be said that most of the participants are aware that about the various factors that determine that advance manufacturing procedure adaptation. In this, it is found that the first factor is organisational factor that determine the needs of the advance manufacturing technology in the organisation. These survey findings are consistent with the findings of literature review Alcaraz et al (2016) stated that organisational factors like as top management, manufacturing strategy, organisational structure, HR practices and organisational culture are associated with the need of the adoption of the advance technology at the workplace. It means that these organisational factors determine whether there is a need of the advanced manufacturing technology or not.

Moreover, it is also analysed that technology factors such as perceived value and technological-in-use also leads to the adoption of the advance manufacturing technology. In this, I also found that in the current business environment, customers have expectation that products that they uses should be produced with the advance technology so that it can perform better during the use. Moreover, it is also analysed that there are some environment factors that financial resources, supplier support, and external pressures such completion and customers’ needs. . Regarding to this, Khanchanapong et al (2016) support the above interpretation by exhibiting that the current business environment is very competitive so that companies have pressure of the profit and meet the customers demand. Due to this, companies take the help of the advance manufacturing technologies because these allow the companies meet with customers’ needs with maintaining the cost and profitability of the company.

4.3.2 Benefits and limitations of advanced manufacturing technologies

In the regard of this objective, it can be interpreted that survey findings are consist with the findings of the literature review. It is because most of the participants are agreed with the benefits of the adoption of the advance manufacturing technology at the workplace. In this, it is analysed that the reduction of the cost of the production in the one of the main benefits that motivates the companies to adopt the new technologies. The new technologies in the manufacturing process reduce the material cost, labour cost and utilities cost that that has direct impact on the overall production cost of the company. This interpretation is supported by the views of Mandahawi et al., (2012) as it was exhibited in his research that the development in the context the technology has reached at the great extent that provides cost benefits to the companies. At the same time, a decline in the cost of the production leads to increase in the profitability of the company.

Moreover, it can also be analysed that the adoption of the advance manufacturing also enables the company to improve the overall performance and productivity. However, the main aim of the company behind the adoption of the new technology is to make the better the overall performance and productivity.

Beside of this, it is also analysed there are also some limitation and disadvantage of adoption of the advance manufacturing technology. In this, it is found that the main limitation of advance technology is that it is costly to buy and maintain. In support of these interpretations, Mueller (2012) depicted that cost is the major issue for firms when they considers to buy the advance technologies in the manufacturing because first they are very expensive and maintenance of these are also high that increases the overall production cost of the firm. It is also found that adoption of the advance manufacturing technology also needs the training for the employees because there without training, it may be possible that employee cannot understand the use of the technology.

4.3.3 Impact of advanced manufacturing technologies on organizational performance

From the survey findings, it can be interpreted that there is a significant impact of the adoption of the advance manufacturing technology on the productivity and performance of the company. An advance manufacturing technology enhances the quantity and quality of the production units. Regarding to this objective, it can be interpreted from survey findings related to agreement of Timans, et al. (2012) determined that in the current time, performance and productivity of the company depends on the technology that company uses. It means that advance technology enables the company to improve the performance and productivity.

At the same time, it can also be discussed that advance manufacturing technology has also impact on product and process innovation and capabilities of employees. AMT improves the capabilities of the employees as well as company to produce the innovative items and design that is not possible from the existing technology. In support of these interpretations, the research of Timmer et al. (2014) recognized that in improving the employees’ capabilities, there is a significant role of the used technology at the workplace. It is because an advance and effective technology allows the employees to improve their skills and ability.

Chapter 5: Conclusion & Recommendations

On the basis of the above analysis and discussion, it can be concluded that companies there are the various factor that determines the needs of advance manufacturing technology procedure in the workplace. In this, it is concluded that the main factors are organisational factors, technology factors and environment factors. A firm needs are linked with these factors that leads to adopt the new technology at the manufacturing. In this, it is found that the adoption of the advance manufacturing provides the various benefits to the companies such as the reduction of the cost of the production, improvement in the productivity and performance. The adoption of the advance technology also support the companies to improve the capabilities in the context of the producing the innovative products and design.

But, at the same time, it is also concluded that there also some limitation of the adopting the advance manufacturing technology that it is expensive for the companies to buy and their maintenance. In additionally, companies have to conduct the training program for the employees and labour to learn them to operate. Furthermore, it can be said that there is a significant impact of the advance manufacturing technology on the company in the context of the innovation, creativity, productivity and performance improvement.

- Manufacturing companies should adopt advance technology according to need of the organisation and market trend

- Companies should analyse the cost of the advance technology by the different supplier and buy from supplier that is providing in the less

Further Research

- Further researcher can conduct the interview from manager of the companies that will allow the make the depth understanding and provide the effective results

- Further researchers can take the two or more companies to analyse the research problem

- Further researcher can conduct the various analysis to identify the relationship with between the researcher variables such as correlation, regression and Anova

Alcaraz, J.L.G., Martínez, S.G. and Morales, S.N., 2016. Benefits of advanced manufacturing technologies. Human Work Productivity: A Global Perspective, p.151.

Choy, L. T., 2014. The strengths and weaknesses of research methodology: Comparison and complimentary between qualitative and quantitative approaches. IOSR Journal of Humanities and Social Science, 19(4), pp. 99-104.

Chung, W. & Swink, M., 2009. Patterns of Advanced Manufacturing Technology Utilization and Manufacturing Capabilities. Production and Operations Management, 18(5), pp. 533-545.

Cook, J.S. 2017. Achieving Competitive Advantages of Advanced Manufacturing Technology. [Online] Available at: https://www.emeraldinsight.com/doi/abs/10.1108/14635779410063329 [Accessed: 8 October 2018]

Creswell, J. W., 2013. Research design: Qualitative, quantitative, and mixed methods approaches. London: Sage publications.

Crowther, D. and Lancaster, G., 2012. Research Methods. UK: Routledge.

Dangayach, G. S. & Deshmukh, S., 2003. Evidence of manufacturing strategies in Indian industry. International Journal of Production Economics, 83(3), pp. 279-298.

Delice, A., 2010. The Sampling Issues in Quantitative Research. Educational Sciences: Theory and Practice, 10(4), pp.2001-2018.

Ford, S.L., 2014. Additive manufacturing technology: potential implications for US manufacturing competitiveness. J. Int’l Com. & Econ., 6, p.40.

García Alcara, J.L., Iniesta, A.A., and Juárez Castello, M.C. 2012. Benefits of advanced manufacturing technologies. [Online] Available at: https://academicjournals.org/article/article1380723271_Alcaraz%20et%20al.pdf [Accessed: 8 October 2018]

Godin, D. and Zahedi, M., 2014. Aspects of research through design. Proceedings of DRS 2014: Design’s Big Debates, 1, pp.1667-1680.

Gray, D. E., 2013. Doing research in the real world. USA: Sage.

Grinyer, A., 2009. The ethics of the secondary analysis and further use of qualitative data. Social Research Update, 56(4), pp.1-4.

HYNEK, J and JANEČEK, V. 2017. Advanced Manufacturing Technology Benefits: Expectations vs. Reality. [Online] Available at: http://www.wseas.us/e-library/conferences/2010/Japan/ICOSSSE/ICOSSSE-71.pdf [Accessed: 8 October 2018]

Jabar, J., Soosay, C. & Santa, R., 2010. Organizational learning as an antecedent of technology transfer and new product development: A study of manufacturing firms in Malaysia. Journal of Manufacturing Technology Management, 22(1), pp. 25-45.

Khanchanapong, T., Prajogo, D., Sohal, A.S., Cooper, B.K., Yeung, A.C. and Cheng, T.C.E., 2014. The unique and complementary effects of manufacturing technologies and lean practices on manufacturing operational performance. International Journal of Production Economics, 153, pp.191-203.

Laplume, A.O., Petersen, B. and Pearce, J.M., 2016. Global value chains from a 3D printing perspective. Journal of International Business Studies, 47(5), pp.595-609.

Maiga, A.S., Nilsson, A. and Jacobs, F.A., 2014. Assessing the interaction effect of cost control systems and information technology integration on manufacturing plant financial performance. The British Accounting Review, 46(1), pp.77-90.

Malhotra, N. K., 2015. Essentials of marketing research: A hands-on orientation. Essex: Pearson.

Mandahawi, N., Fouad, R.H. and Obeidat, S., 2012. An application of customized lean six sigma to enhance productivity at a paper manufacturing company. JJMIE, 6(1), pp.103-109.

Mellor, S., Hao, L. and Zhang, D., 2014. Additive manufacturing: A framework for implementation. International Journal of Production Economics, 149, pp.194-201.

Mertler, C. A. and Reinhart, R. V., 2016. Advanced and multivariate statistical methods: Practical application and interpretation. UK: Routledge.

Moon, K. and Blackman, D. (2014). A guide to understanding social science research for natural scientists. Conservation Biology, 28(5), pp. 1167-1177.

Mueller, B., 2012. Additive manufacturing technologies–Rapid prototyping to direct digital manufacturing. Assembly Automation, 32(2).

Norall, S. 2013. Advanced Manufacturing Technology: The New Face of Manufacturing. [Online] Available at: https://cerasis.com/2013/08/15/advanced-manufacturing-technology/ [Accessed: 8 October 2018]

O’Leary, Z. 2013. The essential guide to doing your research project. USA: Sage.

S.E.G., C. & Lima, E., 2009. Advanced manufacturing technology adoption: an integrated approach. Journal of Manufacturing Technology Management, 20(1), pp. 74-96.

Singhose, W., 2009. Command shaping for flexible systems: A review of the first 50 years. International journal of precision engineering and manufacturing, 10(4), pp.153-168.

Thomas, D., 2016. Costs, benefits, and adoption of additive manufacturing: a supply chain perspective. The International Journal of Advanced Manufacturing Technology, 85(5-8), pp.1857-1876.

Timans, W., Antony, J., Ahaus, K. and van Solingen, R., 2012. Implementation of Lean Six Sigma in small-and medium-sized manufacturing enterprises in the Netherlands. Journal of the Operational Research Society, 63(3), pp.339-353.

Timmer, M.P., Erumban, A.A., Los, B., Stehrer, R. and de Vries, G.J., 2014. Slicing up global value chains. Journal of Economic Perspectives, 28(2), pp.99-118.

Vaezi, M., Chianrabutra, S., Mellor, B. and Yang, S., 2013. Multiple material additive manufacturing–Part 1: a review: this review paper covers a decade of research on multiple material additive manufacturing technologies which can produce complex geometry parts with different materials. Virtual and Physical Prototyping, 8(1), pp.19-50.

Wollschlaeger, M., Sauter, T. and Jasperneite, J., 2017. The future of industrial communication: Automation networks in the era of the internet of things and industry 4.0. IEEE Industrial Electronics Magazine, 11(1), pp.17-27.

Wu, D., Rosen, D.W., Wang, L. and Schaefer, D., 2015. Cloud-based design and manufacturing: A new paradigm in digital manufacturing and design innovation. Computer-Aided Design, 59, pp.1-14.

Yilmaz, K., 2013. Comparison of quantitative and qualitative research traditions: Epistemological, theoretical, and methodological differences. European Journal of Education, 48(2), pp. 311-325.

Appendix

Survey through Questionnaire

- Demographic information

Gender:

Male

Female

Work experience in the firm:

0-2 years

2-4 years

4-6 years

6 years or more

- Factor of advance manufacturing techniques

Do you think that the Organizational factors like top management, manufacturing strategy, organisational structure, HR practices and organisational culture encourage the company to adopt the advance manufacturing technology?

Strongly agreed

Agreed

Neutral

Disagreed

Strongly disagreed

Are you agreed that the Technology Factors: perceived value and technological-in-use are causes due to this; companies have to be update with new technologies?

- Strongly agree

- Agree

- Neutral

- Disagree

- Strongly disagree

Advance manufacturing technologies is adopted due to Environmental Factors: financial resources, supplier support, and external pressures like competitive pressure and consumer pressure?

- Strongly agree

- Agree

- Neutral

- Disagree

- Strongly disagree

III. Benefits and Limitations of the advance manufacturing technology

Manufacturing companies adopt the advance technologies to reduce the cost of the product?

- Strongly agree

- Agree

- Neutral

- Disagree

- Strongly disagree

The main benefit of the advance manufacturing technology is that it helps the company to improve the performance and productivity?

- Strongly agreed

- Agreed

- Neutral

- Disagreed

- Strongly disagreed

| Strongly agreed

|

Agreed

|

Neutral

|

Disagree

|

Strongly disagreed

|

|

| Expensive to buy | |||||

| High cost of the maintenance | |||||

| Need of the proper training programme | |||||

| Distract the employees from existing process | |||||

- Impact of advance manufacturing technology

Do you think that advance manufacturing technology has impact product and process innovation and capabilities of employees?

- Strongly agree

- Agree

- Neutral

- Disagree

- Strongly disagree

An advance manufacturing technology affects the productivity and performance of the company?

- Strongly agree

- Agree

- Neutral

- Disagree

- Strongly disagree

Are you agreed that the adoption of the advance manufacturing technology has an influence on the firm’s financial performance?

- Strongly agree

- Agree

- Neutral

- Disagree

- Strongly disagree