BE275 Global Supply Chain and Operations Management Sample

1.0 Introduction:

Industry 4.0 refers to the fourth industrial revolution in the evolution of manufacturing, which holds the primary idea that machines and industrial equipments must be able to communicate with each other during the process of their specific usage.

This fourth industrial revolution already has started with changing the way industries work and operate through their daily routines. Industry 4.0 recognises itself with the innovation of new technological advancement such as robotics, analytics, artificial intelligence, cognitive technologies, nanotechnologies and Internet of Things (IOT), among others.

These state-of-the-art innovations have already made a severe positive impact on the working pattern of various industries globally, easing the daily work practices of employees as well as the management much more convenient and sophisticated.

1.1 Influence of Industry 4.0 on Supply Chain:

Supply chain and operations, which is an integral part of the multinational industries, need to be managed and operated in a much effluent way to ensure maximum productivity in industries. Supply chain management is tremendously benefitted by the digitalisation of industries.

A number of studies by industrial experts have revealed that an interconnected supply chain through digital means reduces operational costs by more than 30 percent, reduces lost sales opportunities by almost 60 percent and also reduces inventory requirements by more than 70 percent.

These efficiencies and cost-effective measures allow industries to become more agile, faster, granular, accurate and efficient. Although the transition process of supply chain operations towards digitalization is quite a hassle and requires significant efforts and long-term investments, the final result benefits largely to the concerned industries. Implementing digital supply chains can help enterprises to achieve organisational effectiveness as well as help in effective cost reductions. Few of the key benefits of the revolution over supply chain are as mentioned (Chang et al., 2021).

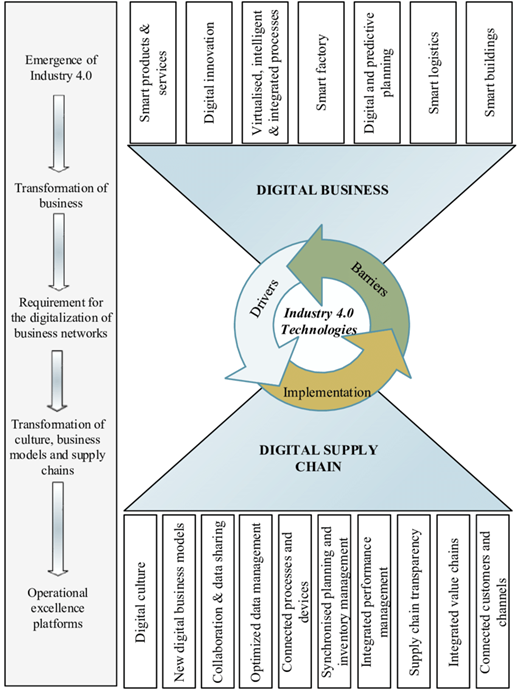

Fig 1.1 Framework (Critchley, 2019).

- Greater Transparency and Accuracy: Bigger industries have bigger and much more complicated supply chains. While operating with multiple suppliers across the globe creates a chain and ecosystem of supply chain, the digitalisation of the same makes the operating bodies convenient to manage all requisite steps of the supply chain management.

Digital supply chain allow the companies to track the entire supply chain in real time, which includes finding out exact location of goods, date of departure, arrival and transit details. With the help of IoT data, it also becomes easy for the companies to manage and regularly update inventories, so as to avoid any out-of-stock situations in the supply chain management (Davis & Krause, 2020).

- Data-backed Decision making leading to Cost savings: The advanced machine learning technique allows the companies to analyse and calculate tentative demand of a particular item as per the current market scenario. This is done by analyzing data from sensors, social network trends, weather, etc.

This helps the industries to predict and calculate both the upside potential as well as downside risks while procuring orders from their customers and accordingly plan their distribution process. This has resulted in reducing forecasting errors by almost 50 percent and also optimized the inventory management system.

- Increased Interconnectedness and Collaboration: An efficient supply chain management system must always have a streamlined connectivity between suppliers, manufacturers and customers. A digitalized supply chain system allows complete transparency and a streamlined connectivity among all three parties, building a relative level of trust and support among them.

An increased connectedness also lowers lead times through faster communication, wherein suppliers can inform about shortfall of raw materials before time, thus saving the manufacturers from getting into serious trouble while procuring orders from their customers. This smooth collaboration between all nodes of the supply chain helps share best practices and learns from each other.

- Improved Warehouse Management: Digitalisation of supply chain can enhance warehouse management of industries, particularly in regards to supply chain inventory and transportation logistics. A smooth digital connectivity among all nodes of the supply chain can help track the real time location of a particular consignment and its estimated time of arrival or departure.

The new RFID technology has an ability to predict the exact location of a product and its exact position inside the vehicle. The communications between machines also help in optimizing number of carriers per shipment. Latest tracking devices have helped companies save from last minute surprises such as inadequate quantity or non-compliance. For industries set up globally across borders, supply chain managers and plant managers find these technologies beneficial for inventory management globally.

- Intelligent Supply Chain: The current technological advancement in the artificial intelligence field has allowed interpreting and executing various instructions in the supply chain management software.

These defined instructions make the software predict, analyse and execute its processes as per the inputs made at the other end. Intelligent supply chains can adapt the skill of recognising risks and act accordingly chain the supply chain parameters to mitigate such risks. They are designed in such a way that they handle many unprecedented situations on their own without direct human involvement except for unavoidable circumstances.

- Greater Agility: Industries with advanced supply chain mechanisms always practice integrating data from their suppliers, service providers, etc., into a supply-chain cloud. This is done so that all the stakeholders are on the same platform at the same time, which makes decision making efficient and fast for the companies. Such real time technologies will allow the companies to respond to the raised errors or complaints with more agility and without disruptions.

One the whole, Industry 4.0 can largely benefit the supply chain operations management with its advanced technological innovations in every possible aspect. As industries are rapidly growing with maximum potential and productivity, it is quintessential for them to upkeep and maintain themselves as per the demands of the market scenarios.

For efficient managing of key business operations within an industry, an efficient and effluent supply chain management system necessarily needs to be implemented in every growing industrial sector (Dopico et al., 2016).

1.2 Influence of Industry 4.0 on Operations Management:

Operations are a crucial part within an organisation which involves the processes of manufacturing and delivering goods, products or services to the desired clients. Operations Management (OM) is the cumulative procedure of managing each step in the entire supply chain procedure along with its associated resources. OM is necessary to gain competitive benefits and improve growth in the industries.

Considering a business model that is in the transformation phase and requires acquiring resources to transform them into goods and services, operations management defines the set of activities that add value creation to its processes (Fettermann et al., 2018). According to Slack et. al., these activities can be clustered into four major categories- Direct, Design, Deliver and Develop. Few of the positive impacts of Industry 4.0 on operations management are as mentioned:

- Steering Operations and Processes: The advancement in operations management due to Industry 4.0 gives a way to steer the directions of operations in the correct way with streamlining of all events. While a digitalized operations management is in place, it becomes easy for the companies to check all the alignment of tasks within the process and steer them by an expert so as to maintain the flow of work and finish jobs with accuracy and correctness.

The steering involves setting an operations strategy, defining performance objectives, taking decision about product and service design, innovation of products and managing the scope of operations. All of these decisions involve strong influence of the marketplace, customers and competitors which vary from time to time. This is why companies are required to instantly develop real-time solutions to market changes and make adaptive strategies to modify the operations procedure.

Considering the post Covid-19 scenario, wherein the entire global market faced turbulence in terms of uncertainty, the need to modify and mould operations management into a digitalized version was seen as a radical and dynamic requirement for the entire world (Ghadge et al., 2020).

- Planning and Controlling Operations: Once the operations processes are designed and checked, it is then important to manufacture the products and deliver them to customers. This process incurs proper planning of each step of the order management with utter planning and manages the order requirements so as to ensure enriched delivery to the customers.

To check with the effectiveness of this step, all the processes involved in the supply chain management must ensure proper planning and control. A company can only guarantee efficiency of the process by managing the capacity, the supply chain and the inventories. Planning of operations management is required to cut short with execution timings of the in-line processes and rather deal with them before the commencement.

- Improving Operations: The role of operations management does not end with the delivery of the product or service to its customers. The roles and responsibilities of people under operations management are changed and fluctuated with different customers and their different requirements. The OM team will not be always able to perform in the same way or show maximum efficiency constantly.

The factors which depend on the customers requirement might vary every now and then, which require the OM team to constantly improve their operations. This becomes an easy procedure by the help of digital managing of operations management, which helps to integrate data related to suppliers and consumers, analyse them with performance and quality standards and hence improve the quality of operations within the supply chain.

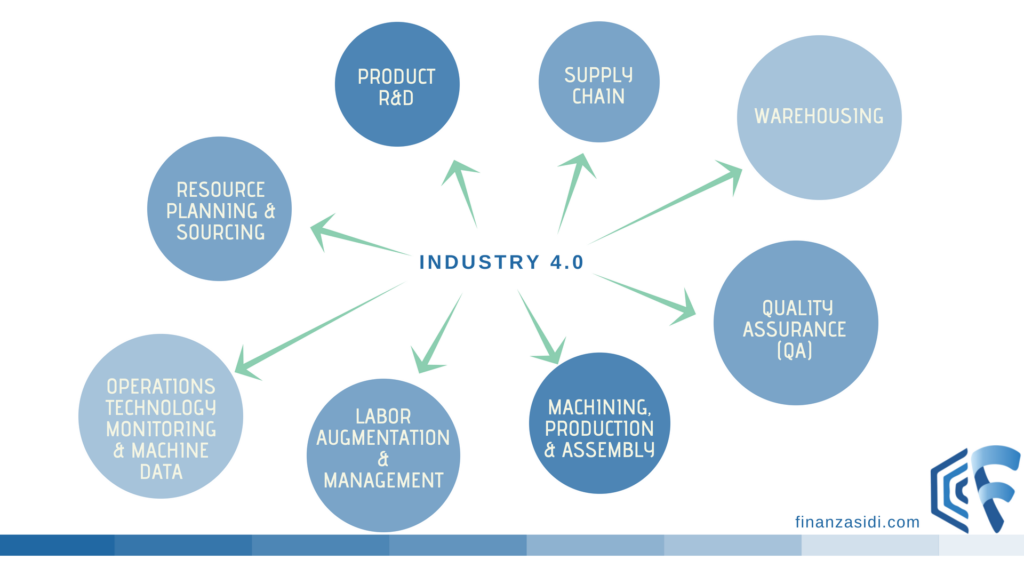

Figure 1.2 Operational Management

1.3 Influence of Industry 4.0 on Organisations:

To brief with the impacts of Industry 4.0 on organisations, we would first observe few of the highlighted factors of the fourth industrial revolution:

- Increase of more automation compared to third industrial revolution;

- Bridging of the physical and the digital world with the help of cyber-physical systems, enabled by Industrial Internet Of Things (IIoT);

- Shifting from the traditional central industrial control system to a technological driven production steps;

- Closed loop data models and control systems;

- Personalising or customising of products;

Apart from these radical changes, the influence of Industry 4.0 has been very much prudent on organisations worldwide. The very first impact of digitalization of the entire business module has brought each node of the organisation under the same connected loop.

This has allowed a better transparency among the entire professional world and has streamlined the process of getting a job done. Organisations have now adapted a more technology-driven work environment wherein getting a task completed does not solely depend on the presence of a physical person.

Automation and Artificial Intelligence have transformed the concept of reliability upon humans to a much more sophisticated robotics technology. Companies now enhance multitasking for its employees rather than exemplifying them over a single task for a longer period of time (Ghosal & Chakraborty, 2021). This has only been possible after the entry of automation through the fourth revolution in the professional world.

Defined instructions, decision making skills are all inherited within the systems and the relative tasks are performed with sheer accuracy and time. Industry 4.0 is characterized by increasing automation and the employment of smart machines and smart factory setups, informed data helps to produce goods more efficiently and productively across the value chain (Weallans, 2018).

Organisations have also inherited a trait of flexibility and agility in their daily work routines so as they can meet their customer’s varied and diversified requirements and just not deny procuring orders. This has also brought in flexible work routines, work from home models, better operational management structure and other benefits from the employee point of view.

Organisations have started accumulating relevant data from its factory floors and other competitive enterprises, and have started a practice of analysing a comparison of performance by both itself and its competitors. This organisational change has brought down a way for the companies to generate a smart data and eventually achieve information transparency and better decisions. Organisations all around the world are now under the same roof following a uniformity to maintain employment stability as well as sustainable business development in the global market (Hughes, 2017).

1.4 Influence of Industry 4.0 on people of an organisation:

The people and employees associated with the organisation are also in the transformation period due to the fourth industrial revolution. This occurs because the industries have started to digitalize their manufacturing procedures.

As and how industries of various sectors are adapting newer methods and technologies for the easing of their daily job routines and increase productivity, the employees associated to those industries are facing a radical change in their culture and pattern of working with the same organisation. While the companies are approaching more of an automation and artificial intelligence concept for accomplishments of tasks, the concerned people are also growing with the fear of insecurity of jobs.

On the other hand, companies which are ethically strong in terms of employment are using the same industrial revolution in a much positive way and are transforming the way their employees work in their organisation. Employee-centric organisations are adapting significant ways by which their employees can ease up their task achievement and targets and focus on multi-tasking capabilities for even better growth of the companies.

Considering the negative impacts of Industry 4.0 over people where job insecurities have raised, it has also grown up a competitive and challenging world for the people. Industry 4.0 has created a manufacturing system wherein machines in factories are augmented with wireless connectivity and sensors to monitor, visualise and control an entire production process and make autonomous decisions as per artificial intelligence instructions.

This entire automation process often leaves the manual labours stranded amid all kinds of uncertainty with their job sustainability. While adapting machine technologies are cost-effective and reduces miscellaneous costs for the company, it also makes the companies totally dependent on robot initiated results.

To overcome these kind of problems, companies must follow employee centric policies which not only allows the employees to be a crucial part of the production lines, but also hold a dignified presence in within the organisation. Anyway, a human IQ is always way more efficient than artificial intelligence and can provide substantial and effective results (Lee et al., 2018).

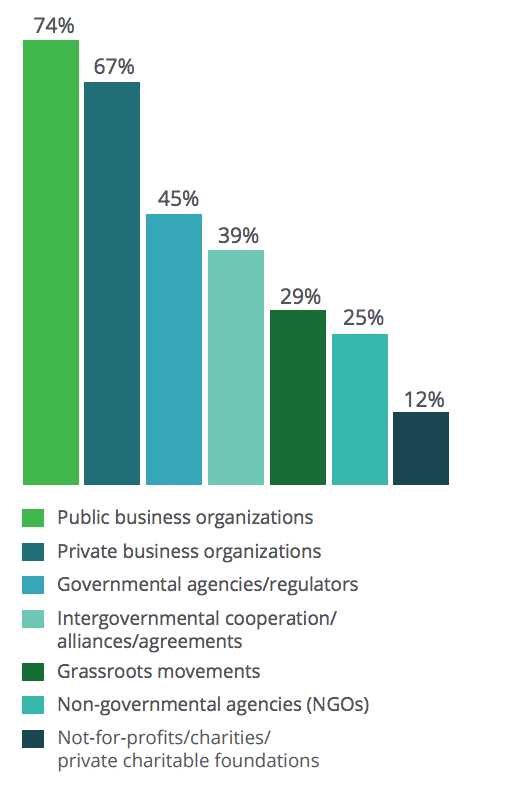

Figure 1.3 Impact of Workforce

1.5 What are the details of industry 5.0?

Industry 5.0 is already being spoken about which involves robots and smart machines allowing humans to work better and smarter. Esben Ostergaard, Universal Robots Chief Technology Officer and Co-founder explained “Industry 5.0 will make the factories a place where creative people can come and work, to create a more personalised and human experience for workers and their customers.

By connecting the way in which human being and machine work together, estimates say that Industry 5.0 will mean that over 60% of manufacturing, logistics and supply chain, agro-farming, mining and oil and gas sectors will employ chief robotics officers by 2025. The European Economic Social Committee assess that the proliferation of robotic automation is inevitable (Umachandran et al., 2019).

1.6 Benefits of Industry 4.0:

| Intelligent factories: | Run smart factories – highly digitized, largely autonomous facilities that take full advantage of advanced technologies like Big Data, artificial intelligence, robotics, analytics, and the IoT. Also called Factory 4.0, these plants are self-correcting, employ smart manufacturing 4.0 processes, and make it possible to deliver customized products cost efficiently and at scale. |

| Intelligent assets: | Almost every physical asset deployed today has built-in sensors – which, when connected to the IoT and analytics, are game changers for enterprise assets management. With intelligent assets, technicians can monitor asset performance in real time, anticipate and prevent downtime, employ dynamic and predictive maintenance, take advantage of digital twins, and tightly integrate assets and business processes (Sima et al., 2020). |

| Empowered people: | No matter how autonomous your systems get, you will always need people. Empower them with technologies like AI and access to live sensor data – so they know what’s happening on the shop floor and are ready to make quick decisions and handle issues as they spring up. Wearable devices and augmented reality apps can also help them solve problems, monitor their health, and keep them safe (Peres et al., 2020). |

Table 1.6 Benefits of Industry 4.0

1.7 Companies are experiencing the benefits:

There’s a broad portfolio of Industry 4.0 solutions in the market, helping thousands of companies transform their digital supply chain – reinventing production, focusing on customers, and connecting their entire organization (Pfohl et al., 2015). Here are some benefits companies are experiencing:

- Radical improvements in productivity and automation:Businesses are making data-driven decisions across their operations, improving forecast accuracy, supporting on-time delivery, and building profit-optimized plans.

- Resiliency and agility no matter what the market or economy bring:Companies are shaping the future digital supply chain based on state-of-the-art planning.

- Confidence to explore new business models and seize opportunities quickly:Thanks to Industry 4.0 solutions, businesses are reducing costs, improving market efficiency, and connecting supply chains by sea, land, and air.

- Green and sustainable solutions without sacrificing profitability:Customers are becoming more efficient and cost-effective by going digital – while meeting their environmental objectives without compromising on other business goals, such as profitability and scalability (Richter, 2020).

1.8 Conclusion:

Digital transformation is reshaping all manufacturing industries. From avoiding pilot purgatory to aligning digital transformation initiatives with executive agendas, though leaders share first-hand observations of the benefits of specific approaches that can help unlock value.

People are also learning how to design a program that will organize people, processes and technologies, prove value to illustrate real-world impact, scale value to create transformative waves and ensure ongoing and future success with effective program governance.

Industry 4.0 is the information-intensive transformation of manufacturing in a connected environment of big data, people, processes, services, systems and IoT-enabled industrial assets with the generation, leverage and utilization of actionable data and information as a way and means to realize smart industry and ecosystems of industrial innovation and collaborations.

So, Industry 4.0 is a broad vision with clear frameworks and reference architectures, mainly characterized by the bridging of physical industrial assets and digital technologies in so called cyber-physical systems.

Additionally, the same technologies, such as Robotic Process Automation, AI, the meeting of both and so forth that pop up in close to all software areas such as enterprise information management, business process management and applications in the sourcing market are of course showing in IoT-enabled industrial/manufacturing applications and IoT manufacturing problems as well.

References:

Chang, K.-H., Tan, K.-H., & Wang, C.-H. (2021, May 1). Soft Computing in the Manufacturing Process of Industry 4.0. Hindawi. Retrieved December 10, 2021, from https://www.hindawi.com/journals/mpe/si/120321/?utm_source=google&utm_medium=cpc&utm_campaign=HDW_MRKT_GBL_SUB_ADWO_PAI_DYNA_JOUR_X&gclid=CjwKCAiAksyNBhAPEiwAlDBeLOdq1Y_MB1yRZR9uZQuQvCrxdfNvH4HGU6ATxAuckBO1p6vX26Uy1RoCk0MQAvD_BwE

Critchley, L. (2019, January 3). Where Nanotechnology, the IoT, and Industry 4.0 Meet. Mouse Electronics | Wireless. Retrieved December 10, 2021, from https://www.mouser.com/blog/where-nanotechnology-the-iot-and-industry-40-meet

Davis, N., & Krause, R. (2020, February 5). What is the fourth industrial revolution? World Economic Forum. Retrieved December 10, 2021, from https://www.weforum.org/agenda/2016/01/what-is-the-fourth-industrial-revolution/

Dopico, M., Gomez, A., Fuente, D. L., Garcia, D., Rosillo, N., & Puche, R. J. (2016). A vision of industry 4.0 from an artificial intelligence point of view – ProQuest Pg 407–413. ProQuest. Retrieved December 10, 2021, from https://www.proquest.com/openview/e3d410cd2196f5e17af332a9c0b84be0/1?pq-origsite=gscholar&cbl=1976349

Fettermann, D. C., Cavalcante, C. G. S., Almeida, T. D. D., & Tortorella, G. L. (2018). How does Industry 4.0 contribute to operations management? Journal of Industrial and Production Engineering, 35(4), 255–268. Retrieved December 10, 2021, from https://doi.org/10.1080/21681015.2018.1462863

Ghadge, A., Er Kara, M., Moradlou, H., & Goswami, M. (2020). The impact of Industry 4.0 implementation on supply chains. Journal of Manufacturing Technology Management, 31(4), 669–686. Retrieved December 10, 2021, from https://doi.org/10.1108/jmtm-10-2019-0368

Ghosal, M., & Chakraborty, A. (2021). The Growing Use of Nanotechnology in the Built Environment: A Review. IOP Conference Series: Materials Science and Engineering, 1170(1), 012007. Retrieved December 10, 2021, from https://doi.org/10.1088/1757-899x/1170/1/012007

Hughes, A. (2017). The Journey Towards MOM 4.0. Industrial Transformation Blog | LNS Research. Retrieved December 10, 2021, from https://blog.lnsresearch.com/the-journey-towards-mom-4.0

Lee, J., Davari, H., Singh, J., & Pandhare, V. (2018). Industrial Artificial Intelligence for industry 4.0-based manufacturing systems. Manufacturing Letters, 18, 20–23. Retrieved December 10, 2021, from https://doi.org/10.1016/j.mfglet.2018.09.002

Peres, R. S., Jia, X., Lee, J., Sun, K., Colombo, A. W., & Barata, J. (2020). Industrial Artificial Intelligence in Industry 4.0 – Systematic Review, Challenges and Outlook. IEEE Access, 8(2), 220121–220139. Retrieved December 10, 2021, from https://doi.org/10.1109/access.2020.3042874

Pfohl, H., Yahsi, B., & Kurnaz, T. (2015). EconStor: The Impact of Industry 4.0 on the Supply Chain. Econstor. Retrieved December 10, 2021, from https://www.econstor.eu/handle/10419/209250

Richter, E. (2020). MES in Industry 4.0 : ZNT. ZNT. Retrieved December 10, 2021, from https://www.znt-richter.com/en/industrie-4.0/MES-in-Industry-4.0

Sima, V., Gheorghe, I. G., Subić, J., & Nancu, D. (2020). Influences of the Industry 4.0 Revolution on the Human Capital Development and Consumer Behavior: A Systematic Review. Sustainability, 12(10), 4035. Retrieved December 10, 2021, from https://doi.org/10.3390/su12104035

Umachandran, K., Jurčić, I., della Corte, V., & Ferdinand-James, D. S. (2019). Industry 4.0. Advances in Civil and Industrial Engineering, 5(2), 138–156. Retrieved December 10, 2021, from https://doi.org/10.4018/978-1-5225-6207-8.ch006

Weallans, S. (2018, September 4). IIoT And Industry 4.0: The Basics You Need to Know. Fierce Electronics. Retrieved December 10, 2021, from https://www.fierceelectronics.com/components/iiot-and-industry-4-0-basics-you-need-to-know

Know more about UniqueSubmission’s other writing services: