Best Assignment Sample on Managing Operations

Get the best sample on Managing operations.

Introduction

The report primarily focuses on managing operations, strategy and partnerships so that any organisation can enhance their productivity. The company for this report is Thermax Ltd. that provides excellent solutions for conserving energy and improves sustainability (Wing and Sobti, 2019). Their primary motive is to reduce the negative impacts of industrial sectors on the environment. The report also concludes about current operations and strategies used by the organisation and the way it helps them in meeting their vision.

Figure 1: Thermax Logo.

(Source: Thermax Logo, 2019)

The company provides various operations related to sustainable development that enhances its way of meeting the vision and mission. Other than that, the company continually enhances its supply chain partner’s relationship to provide better services (Sengupta and Kapur, 2017). They implement the latest technology to improve their strategies to meet customer demands and offer qualitative service.

Content analysis

Current operations of the organisation

Thermax Ltd. is an engineering company that focuses on providing sustainable solutions in environment and energy. The company’s primary vision is to enhance competitiveness in the market, and for this, they need to adopt various sustainable development practices (Kumar, 2020). Thermax Group is a company of $822 million headquartered in Pune, India. The products they serve include cooling, heating, waste and water management. Additionally, their primary focus is on chemicals. They also build and design large boilers for power and steam generation, municipal and industrial wastewater treatment plants, air pollution control projects, waste heat recovery system and turnkey power plants. Services and products developed by the company help industry achieve great productivity of resources and maintain a clean environment.

Further, the company operates in about 29offices internationally and have 14 manufacturing facilities. Out of which, ten are located in India and rest are overseas. Their group consists of 21 international subsidiaries and seven domestic. The company is certified as ISO 14001:2004, ISO 9001:2001 and OHSAS 18001:2007 (Global Manufacturing facilities at Thermax, 2020). Other than that, their motive is to conserve resources and preserve the future. Their facilities are continuously inspected by Bureau Veritas, Lloyds, TUV and SGS. Operations management plays an essential role in gaining competitive advantage, and it also measures the issues an organisation faces. In context with their mission, they offer reliable power at a competitive cost per megawatt. They provide excellent maintenance and operations for their power plants using their experienced proprietary process and workforce (AL-AMIR, 2017). Their focus is on keeping their customer’s investment productive. For this, they continuously monitor their operations aiming at enhancing output, availability and efficiency.

Moreover, the company’s operations are linked with offering sustainability continually by ensuring distinctiveness based on environmental changes. Their operations related to power plant services are provided at a fixed cost, guaranteed performance, power availability, extended plant life and many more (Operations and maintenance at Thermax, 2020). Other than that, their operations also include innovative and robust R&D team, great manufacturing facilities, and international standards. Their process also includes automation facilities used in automating their shops as it helps enhance productivity and reduce the costs. For managing its operations, the company has about more than 1000 professionals and about 35 power projects under contracts.

Thermax Onsite Energy Solutions Limited (TOESL) is a Thermax Group subsidiary that offers various outsourced utilities. It includes heat, steam, chilled water, power and solar using Build-Own-Operate (BOO/T) business model. TOESL operated, invests and installs a utility plant in their customer premises (Hazarika and Pandit, 2019). They manage their operations using supply chain management of all consumables such as biomass fuel. These help their customer to focus on their manufacturing processes. The procedures and solutions are delivered to corporate companies such as paint, food, pharma, chemical, dairy, textile, tobacco products and many more. The company also offers long-term BOO agreements that provide guaranteed utility operations that require no or little capital expenses. It also reduces operational costs and enhances the performance technically (Reddy, 2017). Additionally, their value proposition offers cost-effective services, guaranteed delivery, sustainable services and asset-light.

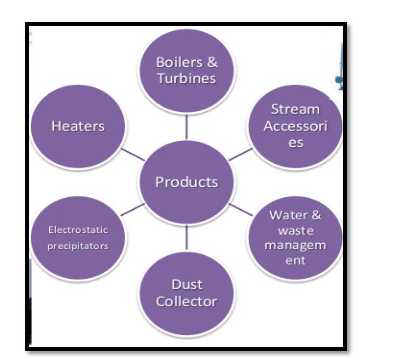

Figure 2: Products served by Thermax.

(Source: Thermax Products, 2016)

Their operations also support designing products that are customised. They also offer projects and EPC contracts, primarily for the larger non-standard products. Thermax primary operations are connected with the harnessing of the power of steam that is produced by boilers (Shah et.al. 2017). Additionally, they expanded their operations by manufacturing vapour absorption machines. The company values are built based on respect, commitment, honesty and integrity, and environmental sustainability. For achieving this value, essentially the companies perform various operations to meet the requirements. For instance, the company encourages reduce, reuse and recycle facilities. They also focus on giving back to their society and don’t want to harm the environment. Their operations are managed in such a manner that delivers their stakeholder what they promised and committed to providing excellence in all their services.

Along with that, the company also has an Enterprise Risk Management (ERM) framework that helps them in identifying, mitigating, reporting and assessing the risk. The review of the risk is done based on environmental changes (Sengupta and Kapur, 2017). They also keep continuous track on the changing domestic, geopolitical development, economic environment, key commodity prices and interest movement. The risk involved because of volatility in markets their primary policy is focused on managing the treasury by optimum returns and liquidity. In this way, the company operates all their activity for achieving their value proposition. Other than that, their operations are continuously managed to meet their vision statement providing sustainability to the environment.

The contribution made by partners

The company declares that they want to offer services and products that are qualitative and satisfies the needs. Their partner’s states that growth and profit will be achieved if the products provided to customers are great (Navale, 2020). The company started by harnessing the power of steam that is produced by boilers. Their partners continuously focus on developing new products and services that benefit the company. Thermax operates in global markets as well, and its primary focus is to leave a footprint in Asian countries. The company started with the largest plant used to generate power using the cement waste in Rajasthan. Thermax has excellent experience, and they served different industries all over the world.

Further, looking at CSR, the Thermax foundation continuously strengthens its public-private partnership with its NGO partners and public-private partnerships. Their partnership proved successful by looking at the result of Akanksha alumni that gets admission into a prestigious university (Navale et.al. 2020). Their employees participate in many initiatives in all around the country. The company focuses on using their skills in addressing the latest challenges of society—the supply chain partners of the company help in expanding its supply chain globally with outstanding excellence. Thermax has adopted a massive number of contemporary practices that enhance their growth and build its sourcing network’s capacity. Based on the sustainable sourcing policy, Thermax influences the adoption of various sustainable business practices in their entire supply chain (Urbanucci et.al. 2018). For this purpose, the company continuously monitors its external factors such as social, economic and environmental.

The company also provides training to enhance the capabilities and skills of their supplier and procurement teams (Chakrabarti et.al. 2018). Before selecting vendors, Thermax analyses them based on safety, environmental, social and governance considerations. Other than that, they follow a questionnaire that focuses on areas for improvement in meeting sustainable criteria. Supplier partners continuously work closely with them to improve their performance and enhance the beneficial criteria (Thermax Annual Report 2018-19, 2019). About 25.8% of the supply chain is compliant with all requirements related to sustainability, and its supply chain partner is focusing on expanding it to 35% in the upcoming three years.

Further, the company believes that stakeholder engagement is essential for enhancing its sustainable growth. They also engage with their external and internal stakeholders using different channels and forums. It enhances their partners thinking capability by examining and prioritising the needs adequately (Gautam et.al. 2019). Their partners help them in adopting new practices that help them in attaining their vision statement. Their partners decided to follow reuse, reduce and recycle procedure in their manufacturing plants. The company also implemented rainwater harvesting facilities that help them conserve natural resources and reduce the dependency on freshwater supply. This strategic planning helps them in storing about 19,421 cubic meters of water.

The company’s channel partner helped them in enhancing their indirect sales force. It means they sell their services and products at the vendor’s place, but they are described as an independent company (Ayou and Coronas, 2020). The company has various channel partners in different cities worldwide, and they help them enhance their sales. Other than that, their technologies partners continuously focus on improving their technologies o meet the latest market trends. It helps them gain competitiveness in the market using different strategies (Case Study- Thermax, 2018). They also focus on adopting diversification and the primary motive of diversification includes growth, value creation and risk spreading. The R&D team continually enhances their research to adopt new strategies and sustainable demands for meeting its vision statement.

Further, the company enhances its technological partnership with numerous companies, and it is beneficial for them a swell. For instance, Babcock and Wilcox Enterprises, Inc. helps them manufacture and sell supercritical utility and industrial boilers that are up to 800 MW installed in thermal power plants (Platzer et.al. 2020). Another partner, Balcke Durr, offers them dry electrostatic precipitators, pulse jet bag filters and regenerative air gas heater. Their technological partners also provide them with great technology to stay competitive in the market. The good type of relationship that should be made is with the supplier partner to continuously enhance the company’s supply chain management. They are also considered as the critical element of their success. They need to maintain their relationship with their supplier. For this purpose, they also train their supplier continuously and must provide them with all the little information (Navale et.al. 2020). It will enhance their profitability and productivity as well.

Opportunities and threats

It is mandatory for every organisation to constantly monitor their opportunity and threats as it will help them attain a competitive advantage (Kamble et.al. 2019). Analysing opportunity will help the company in enhancing its productivity and work-efficiency. After reducing threats, the company will improve its market share and competitiveness. Below described are opportunities and threats of the company:

Opportunities

- The nation’s thrust is growing, and it is essential to improve their energy security as it will intensify the requirements for new technologies and biofuel. The preference is given to methanol as it will enhance the hydrogen economy adequately. These trends will improve the company’s vision and improve sustainable energy and environment solutions.

- It is essential to meet the rising need to decrease energy consumption in the industrial sector (Thermax Annual Report 2018-19, 2019). The company can meet this opportunity by comprising waste heat recovery, process cooling, absorption, solar PV cogeneration and power plants.

- They must follow COP 21 and COP 24 agreements based on climate change; many countries have made it mandatory to implement these environmental norms (Alahmer and Ajib, 2020). It will enhance the company’s positive momentum per environment segment.

- The company can enhance its international and domestic markets as there can be seen growing in the consumer-facing industry.

- It becomes significant for every SOxemitting industries to implement the equipment for monitoring air quality. It will help them in improving the business in context with environmental factors. Additionally, it will also enhance their process in achieving business vision.

Threats: There can be seen rising tensions in trade among countries like China, USA, EU and many more economies. It will lose their relevance of WTO in making sure that they are level playing fields in trading nations. This can be considered as a major threat to Indian companies that are involved in international business (Naik et.al. 2017). Other than that, denial in preferential status will adversely affect the company margins regarding exporting in the US. In the financial and banking sector, an enhanced burden of NPAs (Non-Performing Assets) will lead to the trade deficit, slowdown in infrastructure and private investment. It also limits the prospects for Thermax in the domestic market. In today’s growing world technology is emerging rapidly, and it becomes essential for the company to adopt the latest market trends adequately (Shah et.al. 2017). It helps them in improving their productivity and strategies to achieve their vision.

The extent to which organisation respond to the emerging megatrend

Thermax Ltd. continuously manages its process to meet the market’s megatrends as it is essential for their growth. Their primary focus is on providing quality customer service because customer satisfaction is necessary for them (Ahmed et.al. 2018). The R&D team of the company continuously focus on latest megatrend and implement it in their strategies accordingly. Company’s resources are managed adequately using resource-based view (RBV) as it helps them gain competitive advantage by using their resources adequately. For serving the global markets, Thermax has begun a commercial production for ion exchange resins. They are highly involved in adopting the latest market trends and continually implementing new technologies to meet sustainability (Reddy, 2017). They also use reused and recycled products and encourage their customer as well.

Further, the company continuously focus on adopting technologies to enhance the productivity of renewable energy (Palmer et.al. 2018). Other than that, they also allow customers to design their product in a customised manner that enhances their satisfaction level. Their primary focus is on conserving energy, protecting the environment, and enriching society to contribute to sustainability adequately. The company also serves different industries that include cement, automobile, chemicals, commercial and many more. In the automobile industry, they help them by creating numerous solutions that reduce their carbon footprint and manufacturing cost (Sustainable Solutions in Energy & Environment, 2020). For example, cement industries are using their waste heat to provide fuel to power generation. In this manner, the company utilises its resources and partners to provide excellent services to their customer and achieve its vision.

Facilitators and challenges in adopting new technologies

The company is recently focusing on automating their stores to enhance productivity and reduce the cost. For this purpose, they choose an energy solutions company that is involved in digitalising the entire look of Thermax adequately. In today’s emerging digital era, every organisation is looking for adopting digitalisation in their processes (Faruque, 2019). The primary objective is to make the operation easier, cut cost and paperless for the long-term. Thermax has signed a 5-year long term plan with the energy solution company. They declared a road map for digitalisation that includes three significant pillars of transformation (Hazarika and Pandit, 2019). Thermax has made their roadmap after discussing for long hours, and they also used internal benchmarking and took help from external consultants. The three pillars for their automation are business automation, employee automation and customer engagement. Employee automation is essential because before the convincing customer for using digital technologies, it is mandatory for them to use. For this, human capital management of the company was completely automated (Rahman, 2019). Additionally, they introduce new systems helping them in managing the entire employee life cycle.

Further, they transformed their business process of claim settlement. In this, the process of filing claims can be done digitally, and an individual doesn’t have to visit offices and do the paperwork. The digital transformation is based on AI and ML algorithms that quickly file claims of the employee (Pahuja, 2020). Their automation is contributing to sustainability as the paperwork is reduced, and that helps the company go green. In automating their business, the first milestone they achieve was making Sri City state of the art. The implemented MES from the first day, and it makes the company highly automated. Additionally, they are focusing on implementing PLM systems. It enhances them in automating product areas such as product portfolio, design structure and product catalogue.

Moreover, the company’s ERM and CRM system helps them in scheduling quality adherence and improvements. These technologies were implemented ten years ago, but they are updated based on the latest technologies (Van der Aalst et.al. 2018). To digitalise the roadmap of customer engagement, they implemented technology in their product that helps the customer get a better explanation. Apart from this, their digital marketing campaigns connected with the CRM system, inquiry management systems, and many more helped them engage with consumers appropriately.

The primary challenge they face in implementing the technology was making employees understand the benefits of technology. Before implementing any new technology, a company must convince employees as they are the ones that will use the technology (Kumar, 2020). Other than that, they need to attract customers and make them understand to attract them to a massive number. Another challenge faced by the company is to make technology companies understand the requirements and implement that adequately. After implementation, the company will enhance its productivity and reduce the cost as well.

Further, Thermax also signs technology agreements with two global leaders that help in advancing their wastewater treatment. For this, they have partnered with GE water, and they will introduce GE’s membrane bioreactor (MBE) and ultrafication technology in the company (Wing and Sobti, 2019). It will help them in reusing and processing water in industrial and commercial sectors. It is the demand that is driven by new rules and regulations in relation to the recycling of wastewater. Another technology partnership was with Wehrle that helps them in treating hard-to-treat industrial effluents. They are highly loaded in context with chemical and biological oxygen demand (COD and BOD). The technology will be implemented in pharmaceutical and drug producers, pigments and dyes, chemical, paper and pulp and distilleries (AL-AMIR, 2017). It will help them by treating rigid water bodies, and the recycled water can be used.

Technology that has not been adopted by Thermax Ltd.

The extent at which existing operation can be changed after adopting technology

Thermax must adopt the technology of Robot Process Automation as it helps in configuring computer software. RPA robots use user interface technology for capturing data and manipulate applications similar to humans (Aguirre and Rodriguez, 2017). They can also communicate with other systems and perform various tasks in repetition. RPA robots can never make mistakes and work for long continuous hours. The most significant advantage that a company can have using RPA is that it will not replace existing IT systems. Rather than replacing it will leverage with the systems that exist. It will also decrease the operational risk as human errors will be eliminated, including tiredness and lack of knowledge.

Further, by automating tasks, about 30% of the cost can be reduced, and it will also cost less compared to full-time employees. Human work can be diminished, and they can focus on innovating their work by implementing new strategies. The company must adopt robot process automation as it will improve their work efficiency and enhances customer experience (Madakam et.al. 2019). The company will reduce human mistakes, which results in decreasing the probability of arising issue.

Performance attributes that will be changed after implementing technology

In today’s world of competitiveness, it is essential to use the available resources adequately by making strategic decisions. For preventing the wastage, many organisations are looking forward to adopting automation solutions (Moffitt et.al. 2018). Robotic process automation is getting popular day by day and comes with significant benefits such as accuracy, cost-effectiveness, error-free work and streamlined workflows. It is essential to convince the company that it will be beneficial for gaining competitiveness in the market. A single process can save an hour on an average, and it will run about ten processes per week. An organisation will be able to save about $52,000 per year.

Further, the cost RPA can save for a company in context with an error reduction of about $100 per error. It can save a tremendous amount of money that is consumed by people solving error (Lhuer, 2016). In many cases, RPA allows an individual to note the mistakes that are not noticed because of the laziness of an employee. The Robot process automation will carefully scan all the previous records, detail testing, internal control testing, reconciliations etc. Other than that, a RPA has the capability of performing the repetitive task, and this allows the company to allocate humans to a new project and enhance productivity.

Impact on three stakeholders

- Employees: Robot process automation will allow humans to think of new sophisticated skills as RPA can do the task repetitively. RPA will reduce the burden of work from employees, and they can work much better than humans (Willcocksal.2017). It can be used in every enterprise functions such as operations, customer service, HR, finance and IT. They can also work with humans, and it will allow them to work at a faster rate. RPA will also help the employee in reducing time and enhancing productivity.

- Customer:RPA is capable of providing excellent customer service with error-free work. They can identify the customer and deliver excellent customer support (Aguirre and Rodriguez, 2017). It will result in reaching the information quicker that will reduce the waiting time for consumers. Other than that, the company can implement chatbot that will help fulfil customer requests quickly, and the process will become more transactional. RPA can also manage the entire sign-in process with encrypted credentials securely.

- Shareholders:As seen above, RPA comes with numerous benefits and investing in RPA favourably impacts shareholders positively. Implementing RPA will decrease cost and enhance productivity (Madakamal. 2019). It will result in increasing the profitability of the company that will affect the shareholders adequately.

The potential impact of associated risks

The powerful impact of implementing RPA will be reduced human workforce and increased rate of unemployment. The technologies introduced are continuously affecting the unemployment rate negatively as it will decrease the work of labour. It can be stated that it will impose a significant risk on the labour market (Moffitt et.al. 2018). Other than that, implementing RPA needs high investment cost, and if it doesn’t work well, the company will go through massive losses. The company needs to adequately examine the robot process automation before implementing it to benefit the company appropriately. After implementing RPA, the company has to hire skilled staff because employees must have significant technical programming and coding skills for monitoring them.

The service cost of RPA is also high and if they are not adequately serviced than it affects the work efficiency negatively. The robots are not capable of performing a new task so the company can allocate them to the jobs that are repetitive and based on rules (Lhuer, 2016). The company needs to train the employees adequately as if any mistake has done will lead to a significant loss. RPA promises to reduce the error made by humans, but they are responsible for making their errors. Errors can occur as they are machines and work on codes written in their functions.

Recommendations

- The company must adopt Robot process automation technology as the significant production work done by them includes repetitive task. It will also reduce human efforts, and these employees can be assigned to a new job (Willcocksal.2017). This can enhance the productivity of organisation and increase profit-rate.

- Other than that, Thermax can also improve their operations’ efficiency by implementing new technologies and reducing the rate of issues adequately. They need to measure every employee’s performance in managing operations so that their work-efficiency can be improved.

- Finally, the company can go digital and reduce the paperwork to enhance its sustainability concerns (Lhuer, 2016). They must implement technologies that help them in reducing energy consumption. Thermax needs to invest in its R&D team to improve its sustainable strategies and enhance profitability.

Conclusion

It has been concluded that operations performed by Thermax is essential and helps them in achieving success. Their operations include risk management that allows the organisation to adequately analyse the risk and resolve them as soon as possible. The R&D team continually researches and implements new methods to meet its vision statement. They recently introduced a new technology for the cement industry that helps them generate heat for power plant by using their wastage material. It helps the industrial sector in reducing cost and enhancing productivity. After that, the company has automated their offices based on three pillars that support them in providing excellent customer service. Along with that, they also manage the relationship with their partners to ensure that work efficiency is enhanced.

References

Books and Journals

Aguirre, S. and Rodriguez, A., 2017, September. Automation of a business process using robotic process automation (RPA): A case study. In Workshop on Engineering Applications (pp. 65-71). Springer, Cham.

Ahmed, I., Lin, H., Zou, L., Li, Z., Brody, A.L., Qazi, I.M., Lv, L., Pavase, T.R., Khan, M.U., Khan, S. and Sun, L., 2018. An overview of smart packaging technologies for monitoring safety and quality of meat and meat products. Packaging Technology and Science, 31(7), pp.449-471.

Alahmer, A. and Ajib, S., 2020. Solar cooling technologies: State of art and perspectives. Energy Conversion and Management, 214, p.112896.

AL-AMIR, Q.R., 2017. ANALYSIS AND SIMULATION OF A TRIPLE-STAGE SERIES FLOW ABSORPTION CHILLER CYCLE FOR AIR CONDITIONING APPLICATIONS. Al-Qadisiyah Journal for Engineering Sciences, 10(2), pp.226-243.

Ayou, D.S. and Coronas, A., 2020. New Developments and Progress in Absorption Chillers for Solar Cooling Applications. Applied Sciences, 10(12), p.4073.

Chakrabarti, S., Kumar, N. and Upadhyay, A., 2018. Turnaround of struggling plant of DJSL Limited: capital investment or operational improvement. Emerald Emerging Markets Case Studies.

Faruque, M., 2019. Brand building and management.

Gautam, A., Mishra, V.K. and Agarwal, A.K., 2019. Improving Efficiency of Diesel Traction and Adoption of Liquid Sunshine for Indian Railways. In Methanol and the Alternate Fuel Economy (pp. 35-64). Springer, Singapore.

Hazarika, S. and Pandit, D., 2019. Feasibility Analysis of Decentralized Wastewater Treatment Systems. In Innovations in Infrastructure (pp. 207-219). Springer, Singapore.

Kamble, A.D., Saxena, V.K., Chavan, P.D. and Mendhe, V.A., 2019. Co-gasification of coal and biomass an emerging clean energy technology: Status and prospects of development in Indian context. International Journal of Mining Science and Technology, 29(2), pp.171-186.

Kumar, P., 2020. Interview with Ms Anu Aga, former Chairperson of Thermax Limited. NHRD Network Journal, 13(1), pp.97-100.

Lhuer, X., 2016. The next acronym you need to know about: RPA (robotic process automation).

Madakam, S., Holmukhe, R.M. and Jaiswal, D.K., 2019. The future digital work force: Robotic process automation (RPA). JISTEM-Journal of Information Systems and Technology Management, 16.

Moffitt, K.C., Rozario, A.M. and Vasarhelyi, M.A., 2018. Robotic process automation for auditing. Journal of Emerging Technologies in Accounting, 15(1), pp.1-10.

Naik, H., Baredar, P. and Kumar, A., 2017. Medium temperature application of concentrated solar thermal technology: Indian perspective. Renewable and Sustainable Energy Reviews, 76, pp.369-378.

Navale, D.P. and Sathe, P.J., Thermax Ltd, 2020. System for improved hydrogen distribution in a metal hydride reactor. U.S. Patent 10,829,369.

Navale, D.P., Bharamgonda, A.J., Gunjal, S.N., Sonde, R.R. and Kulkarni, S.V., THERMAX Ltd, 2020. Exhaust gas heat recovery system. U.S. Patent Application 16/687,124.

Navale, D.P., Dubal, V.V., Patki, A. and Sonde, R.R., THERMAX Ltd, 2020. Air changeover system for metal hydride heat pump. U.S. Patent 10,605,496.

Palmer, N.J., Petersen, B.L. and Ward, L.S., 2018. Agglomerated Protein Products and Method for Making. U.S. Patent Application 15/705,192.

Platzer, W.J., Mills, D. and Gardner, W., 2020. Linear Fresnel Collector (LFC) solar thermal technology. In Concentrating Solar Power Technology (pp. 165-217). Woodhead Publishing.

Rahman, M., 2019. SUPPLY CHAIN MANAGEMENT OF OXFOCHEM BANGLADESH.

Reddy, A.J.M., PARADIGM SHIFT IN IR SCENARIO: SOME REFLECTIONS. EDITORIAL ADVISORY AND REVIEW PANEL, p.25.

Sengupta, E. and Kapur, M.V., Applying Corporate Social Responsibility As A Means To License To Operate. A Case Study Of Nagaland.

Shah, M.K., Deshpande, V.A. and Patil, R.M., 2017, February. Case study: Application of Lean tools for Improving Overall Equipment Effectiveness (OEE) & Productivity in panel shop of heavy Fabrication Industry. In Proceedings of 2nd international conference on emerging trends in mechanical engineering (Vol. 10, pp. 4430-4447).

Urbanucci, L., Testi, D. and Bruno, J.C., 2018. An operational optimization method for a complex polygeneration plant based on real-time measurements. Energy Conversion and Management, 170, pp.50-61.

Van der Aalst, W.M., Bichler, M. and Heinzl, A., 2018. Robotic process automation.

Willcocks, L., Lacity, M. and Craig, A., 2017. Robotic process automation: strategic transformation lever for global business services?. Journal of Information Technology Teaching Cases, 7(1), pp.17-28.

Wing, C.R. and Sobti, I., 2019. Thermax—Changing of the Guard.

Online

Case Study- Thermax. 2018. [Online]. Accessed through: <https://www.researchgate.net/publication/301886961_Turnaround_to_Transformation_The_case_of_Thermax> [Accessed on: 31 December, 2020].

Global Manufacturing facilities at Thermax. 2020. [Online]. Accessed through: <https://www.thermaxglobal.com/global-manufacturing-facilities/> [Accessed on: 31 December, 2020].

Operations and maintenance at Thermax. 2020. [Online]. Accessed through: < https://www.thermaxglobal.com/boilers-heaters/operations-maintainance/> [Accessed on: 31 December, 2020].

Pahuja. R. 2020. How Thermax is transforming through automation? [Online]. Accessed through: <https://cio.economictimes.indiatimes.com/news/strategy-and-management/how-thermax-is-transforming-through-automation/78800619> [Accessed on: 31 December, 2020].

Robotic Process Automation. 2018. [Online]. Accessed through: < https://www.uipath.com/rpa/robotic-process-automation> [Accessed on: 31 December, 2020].

Sustainable Solutions in Energy & Environment. 2020. [Online]. Accessed through: < https://www.thermaxglobal.com/industries/automobiles/> [Accessed on: 31 December, 2020].

Thermax Annual Report 2018-19. 2019. [Online]. Accessed through: < https://www.thermaxglobal.com/wp-content/uploads/2020/02/2018-19.pdf> [Accessed on: 31 December, 2020].

Thermax Logo. 2019. [Online]. Accessed through: <https://www.business-standard.com/article/companies/thermax-opens-new-unit-at-sricity-to-manufacture-chillers-heat-pumps-119013100370_1.html> [Accessed on: 31 December, 2020].

Thermax Products. 2016. [Online]. Accessed through: <https://www.slideshare.net/sanchitkorgaonkar/thermax-presentation> [Accessed on: 31 December, 2020].

Know more about UniqueSubmission’s other writing services: