BS2582 Operations Management Assignment Sample

Here’s the best sample of BS2582 Operations Management Assignment, written by the expert.

Executive summary

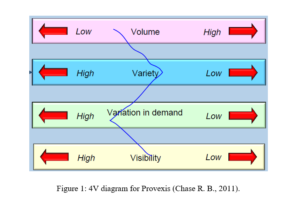

The importance of the operation management in Provexis is listed such as useful in profit making and providing competitive advantage. The five performance objectives cost, quality, flexibility, speed and dependability are discussed based on the perspective of Provexis. 4V’s which are important to the product are variety, volume, variation and visibility. These four parameters are important to be maintained by Provexis for good operations. There are some strategies based on the situation of 4V’s. Continuous replenishment which tracks the goods is the main supply chain strategy used by the Provexis.

Introduction

Provexis is the company which manufactures the food products and the main product is the “Fruit Flow” which is manufactured with the help of tomatoes. The main use of the product is to ensure the good blood flow and to prevent cardiovascular diseases. Provexis was started in the year 1999 and this industry is based on food. Provexis is responsible for sourcing the raw materials and majority of its raw materials are based on the agricultural produce (Chopra, 2015). Then the raw materials need to be transported to the manufacturing facility to transform it to the finished products. It needs to outsource some of the activities such as manufacturing packaging materials, etc. The operations starts when it starts to source the raw materials and it ends when it reaches the customers and reverse supply chain is also maintained (Kachru, 2011). This report aims at identifying the importance of the operations management to the organization Provexis Plc. The importance of the operations management and the ways in which the operations management is carried out in the business should be discussed. The 4v’s such as variety, volume, variation and visibility should be discussed (Brown, 2013). This 4V’s should be applied both the products of the organization and also to the organization as a whole. These 4P’s are very essentials for the operations as this implies the cost of the products manufactured. The supply chain strategies that are used by Provexis should be listed with examples. The evidence should be provided for the supply chain strategies used (Wisner, 2016).

Importance of operations management to the organization Provexis

Operations management is responsible for providing the outstanding outcome through its processes. Provexis applies the operations management right from the demand forecasting to satisfy the demand. Provexis sources the raw materials using the location advantage because location advantage reduces the risk of transportation and quality of raw materials contribute to the product quality (Chase R. , 2015). Operations management helps Provexis to manufacture efficiently using the quality process. Operations management of Provexis involves the supply chain management, logistics management, process management, quality management, waste management, etc. The organizational productivity of the organization can be improved with the operations management. Provexis is the unique products and there are not many competitors for this product and the operations management gives it the cost advantage due to volume (Bassett, 2011).

Improving quality: The quality of the product and process can be improved. This is called as the total quality management where the overall quality of the organization is maintained. Quality of products gives the customer satisfaction and the benefits are provided to the customers and organization. Quality of process results in a good process which can save the time and input requires (Cooke, 2012).

Forecasting demand: The demand can be forecasted before the start of the manufacturing process. This helps in planning the manufacturing based on the market demand. Various types of forecasting are done to identify the demand and this helps in making the supply equal to the demand (Bassett, 2011).

Reducing cost: The operational and administrative cost of the organization can be reduced through the operations.

Reducing waste: The lean concepts help in reducing the waste that occurs at the time of manufacturing and this streamlines the manufacturing process. The reduction in waste helps in reducing the cost. Provexis uses the lean concepts in the transport and also at the time of manufacturing to reduce the product waste (Jones, 2012).

Decrease in transportation cost: The transportation cost can be reduced through the operations management. Route optimization and direct sourcing are some of the techniques used by Provexis to reduce the transportation cost (Kachru, 2011).

Optimized supply chain system: Both the internal and external supply chain is optimized and there is a control over the logistical and warehousing operations which motto is to reduce the cost and time. The supply chain makes helps in safe movement of goods at the required amount (Chopra, 2015).

To the organization as a whole, the profitability can be increased which helps in improving the competitive advantage of the business. The operational efficiency is used where the problems are identified and the necessary solutions are provided. This acts as a strategy for Provexis to improve the efficiency (Bozarth, 2016). Provexis has the strong quality control team which takes care of the product quality and changes are made to the process to improve the quality. Provexis uses various statistical tools to measure the demand in the market and based on that the manufacturing is planned. This reduces the overproduction and matches with the market demand. It also took advantage over the location by placing the manufacturing location in the area where there is availability of raw materials and labors (Kamauff, 2011).

Five performance objectives

Provexis consider the performance objectives as important in its operations. These are about the process or about the product. It has the direct and indirect connection with the customers and sticking to these performance objectives really matters a lot to the organization (Chopra, 2015).

Quality: The quality of the product is considered. The quality control team of Provexis is responsible for measuring the quality of the product. The manufacturing of “Fruit-flow” is made based on batch and quality check is made by selecting the samples. The batch which passes the quality check successfully is eligible to sell in the market (Reid, 2012). The quality of the product is the one which measures the customer satisfaction. Here various quality control tools such as fish-bone diagram, histogram and Pareto analysis are used to control the quality. The reasons for the defect are identified to rectify it. By maintaining the quality, the customer gets the quality product and their satisfaction rate will be higher (Bozarth, 2016).

Speed: This is improving the cycle time of the production. The improvement in the cycle time helps in improving the productivity of the organization. This is the total production time. This speeds up the process. This is based on the process control. Provexis improves the speed of the process by capturing the entire process and bringing in the changes often. The change which provides the maximum benefits is used. This is process excellence and the process which improves the speed is retained (Bassett, 2011).

Dependability: Provexis takes care of both the internal and external dependability. The internal departments require the proper budget to be allocated to proceed with the process. Provexis have the transparent process inside in which everything is made visible with the information. The manufacturing process is dependent on raw materials for which the procurement and transportation department is responsible (Bassett, 2011). Procurement department sources the raw materials and transport department takes it to the place to start the manufacturing process. Just-in-time inventory management is used to reduce the cost of warehousing. The demand is forecasted and the retailers are tracked and the finished products are replenished on-time. The customers get their needs satisfied by Provexis (Chase R. B., 2011).

Flexibility: Good flexibility is maintained by Provexis in its manufacturing process and demand management. The demand is always identified in advance and it can also cope-up with the current demand. It has the flexibility to change as per the market demand (Chase R. , 2015). There are different types of “fruit-flow” products and these are developed by considering the customer. The customer preferences are given importance and based on that product varieties such as quantity of package, powder format Fruit Flow, Fruit Flow with Omega -3, etc. is introduced to the market (Bassett, 2011).

Cost: The processes used by Provexis must be cost effective. The cost effective process can make the product price lower. This helps Provexis to provide the products at very lower price to the customer while making a good profitability. The cost benefit is achieved by reducing the waste (Reid, 2012).

4V’s profile of company’s products and services

The main function of the operations management is to take the input such as raw materials, work, knowledge, machine, etc. and transforms it into the finished goods / services using the process. There are 4V’s in the operations such as volume, variety, variation and visibility is considered. These 4 V’s are responsible in making the operations more reliable and saves the cost. Provexis is depends of all the 4V’s and it is applied to the products of Provexis (Schneider, 2016).

Volume: Low

The size of the operation is very small and with this the economies of scale operations of Provexis is little problematic. The volume or sourcing, production and distribution give the competitive advantage. The volume is increased by Provexis by focusing on more geographical location which can increase the sales (Brown, 2013). The volume is considered at the time of mass procurement because it saves the transportation cost and labor handling charges. The raw materials are purchased in huge volumes to achieve the competitive advantage. Provexis tries to increase the volume of manufacturing which makes the prices lower to serve the target market (Kachru, 2011).

Variety: Low

Provexis adapts to different varieties of products and it rolled out different products in the market based on the demand. This needs to increase the product base to increase the market size. Earlier the product “Free-Flow” was introduced by Provexis in the market and later it needs to increase the product variety and as a result it developed many products in powder base and mixing with other oils and nutrition to make it healthier (Meredith, 2016). The product variety helped in attracting the market and the customer selected the products based on their needs. Some food mixes were available to make the product more tasty and healthy (Chopra, 2015).

Variation: High

This is based on the variation of demand and Provexis offers different types of “Free-Flow” products and the differences are shown between the products. The demand for the products differs and Provexis needs to keep track of it to stay ahead of the competition. Based on the demand, there will be variation with the units of manufacturing (Bassett, 2011). The basic activities which are followed here are forecasting, anticipation of demand, in-line with demand and maintaining stability for customers. The customers should not feel any changes with respect to the demand and the product should be made available to the customers all the time. Proper planning in production operations, sourcing should be done to manage with the unexpected demand (Kachru, 2011).

Visibility: High

The visibility refers to the customer satisfaction and the customer should feel the purpose for which the product is intended for. Provexis is a food product which helps in good blood flow and in this the customer satisfaction can be maintained by making the product available (Chase R. , 2015). The products should be distributed everywhere to increase the stability and for this the distribution network has to be expanded. The customer feels satisfied if the cost of the product and Provexis works on that in providing that. The varieties and making the product according to the demand satisfies the customers. Here the responses of customers are considered for improvement (Chase R. , 2015).

Supply chain strategy adopted by Provexis

Planning the supply chain properly provides the competitive advantage to Provexis and the supply chain model is not easy for any organization to copy. This is the one which needs to be planned based on the organization according to the activities and business model (Reid, 2012).

Continuous replenishment model is the supply chain model used by Provexis. Provexis manufactures the food product “Free-flow” based on the demand and it replenishes the finished product on a timely basis. For this to happen, it needs to keep track of the customers and suppliers. The market demand should be anticipated in advance to carry out the manufacturing process. The retailers and distributors should be tracked and based on that the replenishment of goods is made at right time (Bozarth, 2016).

Inventory management helps in reducing the cost of storing the raw materials. The raw materials used by Provexis are perishable and needs a special condition for its storage. This makes the cost to be very expensive and to avoid this Just in Time method of inventory is used where the cost of the raw materials are reduced. The raw materials are procured based on the demand and the internal distribution is done based on certain condition (Chase R. B., 2011).

Transportation management Route optimization, transport cost reduction are used to reduce the cost of the transportation. Cost of transportation is reduced to reduce the overall cost of the operations (Bassett, 2011). The vehicle charge, fuel charge, handling charge such as materials loading and unloading from truck, etc. are part of transportation charge. To reduce this Provexis uses containerization in which the raw materials are carried without any damage. Quality of raw materials constitute to the product quality (Bassett, 2011).

Location advantage: Provexis makes the location as the advantage for its manufacture and it is located in the centralized place where it can take advantage over the raw materials and other products. The tomatoes are sourced and there are lots of factories to get the packaging materials (Bassett, 2011).

Outsourcing: This is done to reduce the cost and also investment. Provexis outsources the packaging materials to other companies to take cost advantage. By doing this, the machineries and the investment that are needed to manufacture the packaging materials are reduced. The other company will have the economies of scale production for packaging materials and it can be sourced for lower price (Chopra, 2015).

Containerization: The materials are transported in containers to reduce the cost of the transport and it makes the handling very easy and the time taken is very less.

Information: Information is always necessary for the decision making. Certain information such as the information of supply and demand is required to take the decision based on production. This helps in avoiding over production and under production. The vehicle and cost information of different raw materials are required for Provexis for smooth functioning of its supply chain (Schneider, 2016).

Conclusion

To summarize, operations management is required for Provexis to achieve the competitive advantage and to maintain the profitability of the organization. For the organization provexis, the performance objectives such as speed, flexibility, dependability, quality, cost, speed, etc. are analyzed. Various evidences are presented to show the application of all these performance objectives in Provexis (Chopra, 2015). The 4V’s of the Provexis are analyzed and it has different varieties of products and most are developed to satisfy the customer demand. Volume is based on the economies of scale in which there is very less advantage for Provexis. Variation shows the capacity of Provexis to match with market demand and Visibility shows the customers interest and satisfaction rate (Wisner, 2016). The supply chain strategies used by Provexis are discussed and there are different strategies which are adhered. Continuous replenishment model is used by Provexis due to the batch production made. Overall, the organization Provexis is gaining competitive advantage through its operations and makes the best use of it (Bozarth, 2016).

Bibliography

Bassett, G. (2011). Operations Management for Service Industries: Competing in the Service Era (Third Edition ed.). Greenwood Publishing Group.

Bozarth, C. B. (2016). Introduction to Operations and Supply Chain Management, Global Edition (Fourth Edition ed.). Pearson Education Limited.

Brown, S. (2013). Strategic Operations Management (Second Edition ed.). Routledge.

Chase, R. (2015). Operations and Supply Chain Management with Connect (Third Edition ed.). McGraw-Hill Education.

Chase, R. B. (2011). Operations Management for Competitive Advantage (Third Edition ed.). McGraw-Hill/Irwin.

Chopra, S. (2015). Supply Chain Management: Strategy, Planning, and Operation (Second Edition ed.). Pearson Education.

Cooke, J. (2012). Operations Management – The Art & Science of Making Things Happen (Third Edition ed.). Ecademy Press.

Jones, P. (2012). Operations Management (Third Edition ed.). OUP Oxford.

Kachru, U. (2011). Production & Operations Management (Third Edition ed.). Excel Books India.

Kamauff, J. (2011). Manager’s Guide to Operations Management (Third Edition ed.). McGraw Hill Professional.

Meredith, J. R. (2016). Operations and Supply Chain Management for MBAs (Third Edition ed.). Wiley.

Reid, R. D. (2012). Operations Management (Third Edition ed.). Wiley.

Schneider, M. (2016). Operations Management (Second Edition ed.). Cengage Learning.

Wisner, J. D. (2016). Operations Management: A Supply Chain Process Approach (Second Edition ed.). SAGE Publications.

________________________________________________________________________________

Know more about UniqueSubmission’s other writing services: