Food Rheology, Texture and Sensory Science

Review Title: To analyse the significance of rheological testing of food products and its advantage and disadvantages and in product formulation.

Abstract

The rheological testing of food products is relevant for to determine and understand the simple to complex rheological properties considering the factors of viscosity, stress, strain, time, temperature for design, processing, manufacturing to identifying the type of formulations and issues. Different research studies have highlighted the value of rheology tests and considered the shortcoming in term sof inadequate knowledge towards different rheology test, application and their data interpretations skills which is a limiting factor in their full application in food industry. The rheological testing also plays a role in the identification of product formulation and issues.

This review highlights the importance of food rheological testing of food products, related advantages and disadvantage and also consider rheology for product formulation.

Keywords: rheology, viscosity, food products

The field of food rheology has been an area of continuous interest to researcher, food scientists and field experts as the rheological testing of food products provides an understanding of the flow of matter and deformations. This has allowed for classifying foods based on their measures of rheological properties and behaviour dynamics in states of rheological solid and liquid forms (Foegeding et al., 2003; Chen & Stokes, 2012). The literature is extensive on food rheology and testing as based on the magnitude of rheological testing in different food areas as the information from testing is known to bring about change in design of plants for processing, quality control, and determines food texture, food storage (shelf life), food products stability, acceptability and its appeal to the customers (Ahmed et al., 2017).

The purpose of this review article is to present a critical analysis of the value of rheological testing of food and to analyse how this can be used to identify the issue in the food product formulations. The review set in motion with the rheological testing implication on food products, followed by its benefits and difficulty leading towards the discussion on how rheological testing tackle the product formulation issue. The review concludes with a summary of key points.

Significance of rheological testing:

Several researches have shown that the implication rheological testing in food sciences and food texture studies. It is found in the study of Tabilo-Munizaga and Barbosa-Cánovas (2005) that that material physical characterization from rheological testing has been used in different stages before processing, manufacturing for the characterization of raw material, intermediate products and finished products. Research studies have considered the food gels and emulsions physical characterisation from rheological testing to improve formulations and milk product (Gentès et al., 2011). Nishinari (2009) considered the rheological testing important to comprehend the link among the different properties and structure of food products and also links the properties with the processing of the food material. The importance of rheological testing can be also revealed from the study of Ahmed et al. (2017) that focuses on the determining the right material processing behaviour with the use of rheological testing. The study verified that rheological testing has consequences in explaining the mechanical behaviour of material and compute the factors like pressure, temperature, time, elasticity, viscosity, strain and shear rate in product development and improvement. Hamad et al. (2016) elaborate rheological testing highlights the rheological properties which were required in the determination of molding factors, measures to optimized material properties and performance of the material. Thus, it can be stated that this testing make it possible to determine whether or not the food materials are processed and manufactured in a proper way and also helps to establish that the processing of food products in done with minimum product degradation.

It is analysed from the research of Colonna et al. (2016) that rheological testing was done for polymeric material to measure its viscosity involving single point and variable shear rate tests. The information from these tests have been found to be useful in determining the flow proprieties, in quality control and assurance, development of new and better products and improve the performance of the polymer product. A similar study by Wu et al. (2013) analysed the value of rheological testing in relation to the design of food product. Also, the microstructure of material can be studied by this testing as the study of Nishinari (2009) and Kasapis & Bannikova (2017) that showed the value of rheological testing in textural qualities of material in terms of its ability to spread and creamy texture in mouth. The study found that preserve the material texture is not possible if there is under or over processing (heat) it changes the microstructure of material that affect the textural qualities.

Thus, from the review of different studies it can be reconsidered that the magnitude of rheological testing on food products industry is high in relation to determine the product design, food texture, spreadability, creaminess and storage/ shelf-life for the customer. It can be added that the rheological testing on food products has value in food handling, appeal and acceptability of food prosecutes as it provide a measure for quality control and quality assurance in the stage of food manufacture and food processing.

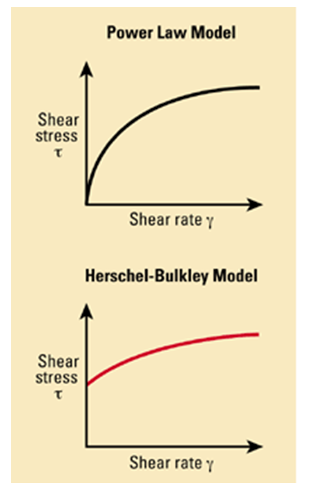

The rheology testing has been significant for the food industry is it has given advantage to the food scientist and researchers to characterize the basic food systems material properties. It provides advantage to know the link among the strain and stress in describing the food products rheological properties which can be done through application of Herschel–Bulkley fluid model or power law model for fluids (Fischer et al. 2009). Herschel–Bulkley fluid model involves factors for yield shear stress, flow index and consistency (Daubert & Foegeding, 2010).

Figure 1: Rheological models for fluids

(Source: Schlumberger, 2016)

Apart from this, the rheology testing gives valuable information to understand the interface of water with oil and air and behaviour and properties of emulsions, gels and foams (Rane et al., 2013; Moelants et al., 2014). It is stated in the study of Wu et al. (2013) that rheology testing of food products describes the physical/ mechanical properties which are essential for the manufacture and consumer. The author of Magenis et al. (2014) and Karasu et al. (2015) also mentioned the value of rheology tests in making the food processing efficient (fast) and cheaper for cheese product and honey respectively.

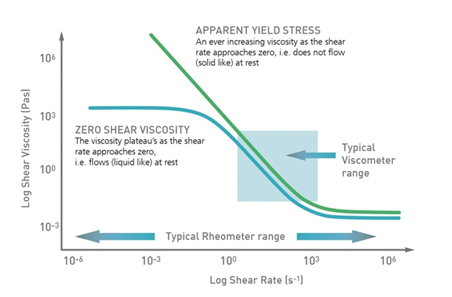

The proponents of rheological consider the advantage of using rheometer to obtain the viscosity profile of a material for rheological characterisation over viscometer as it was found viscosity measurement of food products are simple and do not generate enough information to describe properties of complex product formulations (Toker et al., 2013; Espírito-Santo et al., 2013; Dakhil & Wierschem, 2014). It can be understood from this study that test using viscometer are not sufficient to provide detail for non-Newtonian formulations. The below figure highlight the advantage of rheometer in terms of its range in comparison to viscometer for velocity measurements.

Figure 2: Rotational rheometer vs. usual viscometer and their flow curve

(Source: Malvern Panalytical, 2016)

On the other side, considering the weakness of rheological testing, it is argued that using a rheometer requires more experience and knowledge on which rheology test to be applied and interpretation of the testing results considering the study of Karunarathne et al. (2018). The authors also considered the lack of knowledge/ awareness as barriers in realizing the full potential of rheology tests for food industry.

Dealing with the issue of product formulation

There have been several advancements in the area of rheological testing to improve the design of rheometer and also improve their functionalities to increase the range of test and depth and breadth of information to for different application in food industry for quality control and assurance, describe the complex formulations properties and identify issues in product formulations. The rheology testing that includes viscosity tests for melt viscosity, relative viscosity, relative viscosity and others are recognised in product formulation (Fischer et al. 2009). The rheology testing is provides knowledge of the rheology of different food system for their combination and also provide with inaccurate reading to identify issue and improve the formulation. In the study of Demirkesen et al. (2010), the rice dough and wheat dough with no gum and emulsifier were used as conagtrol formulations were used to identify the issues and compare the reading with rice dough (with different gums and with or without emulsifiers) with the use of Power law constants to find the best formation for gluten free product (bread).

In a study by Fischer et al. (2009), it was mentioned that the rheology tests have been employed in enhancing the product formulations for characterisation of food products and drinks products. The authors found that use rheometer has increased the testing capability of food products where the formulation development can be refined and can be stepped up for obtaining better solution. It is also demonstrated in the study of Awad et al. (2012) where rheometer for different measurements was used for food products characterization for the purpose of quality control and explains the non-Newtonian formulations properties. However, it is argued in the study of Dimic-Misic et al. (2013) that more complex viscosity measurements are required to make the rheology tests information application in product formulations where the author studied for carboxymethyl cellulose formulations. In related context, Dakhil & Wierschem (2014) consider the use of a rotational rheometer to expand the flow curve to develop the capability to measure the rheological behaviour and characteristic of a food product in region of low shear rate because of the torque sensitivity and radial displacement. This can be useful to identify the degradation of product and develop improved product formulations.

It can be summarised that there is high relevance of rheological test in the food industry for application in design, formulation, manufacturing, processing, shelf life and acceptability of the food products. The advantage of rheology tests have been in providing information on rheological properties and behaviour to improving the food product development, identifying the best product formulations, quality aspects, and improve processes in a efficient and cost effective way. The developments in rheological testing have improved the range of information on properties of food material which can be used in identification of issue through comparative readings and viscosity measurements in product formulation application.

Ahmed, J., Ptaszek, P., & Basu, S. (2017). Food Rheology: Scientific Development and Importance to Food Industry. In Advances in Food Rheology and Its Applications (pp. 1-4). Woodhead Publishing.

Awad, T. S., Moharram, H. A., Shaltout, O. E., Asker, D., & Youssef, M. M. (2012). Applications of ultrasound in analysis, processing and quality control of food: A review. Food research international, 48(2), 410-427.

Chen, J., & Stokes, J. R. (2012). Rheology and tribology: Two distinctive regimes of food texture sensation. Trends in Food Science & Technology, 25(1), 4-12.

Colonna, S., Monticelli, O., Gomez, J., Novara, C., Saracco, G., & Fina, A. (2016). Effect of morphology and defectiveness of graphene-related materials on the electrical and thermal conductivity of their polymer nanocomposites. Polymer, 102, 292-300.

Dakhil, H., & Wierschem, A. (2014). Measuring low viscosities and high shear rates with a rotational rheometer in a thin-gap parallel-disk configuration. Applied Rheology, 24(6), 10-15.

Daubert, C. R., & Foegeding, E. A. (2010). Rheological principles for food analysis. In Food analysis (pp. 541-554). Springer, Boston, MA.

Demirkesen, I., Mert, B., Sumnu, G., & Sahin, S. (2010). Rheological properties of gluten-free bread formulations. Journal of food Engineering, 96(2), 295-303.

Dimic-Misic, K., Gane, P. A. C., & Paltakari, J. (2013). Micro-and nanofibrillated cellulose as a rheology modifier additive in CMC-containing pigment-coating formulations. Industrial & Engineering Chemistry Research, 52(45), 16066-16083.

Espírito-Santo, A. P., Lagazzo, A., Sousa, A. L. O. P., Perego, P., Converti, A., & Oliveira, M. N. (2013). Rheology, spontaneous whey separation, microstructure and sensorial characteristics of probiotic yoghurts enriched with passion fruit fiber. Food Research International, 50(1), 224-231.

Fischer, P., Pollard, M., Erni, P., Marti, I., & Padar, S. (2009). Rheological approaches to food systems. Comptes Rendus Physique, 10(8), 740-750.

Foegeding, E. A., Brown, J., Drake, M., & Daubert, C. R. (2003). Sensory and mechanical aspects of cheese texture. International Dairy Journal, 13(8), 585-591.

Gentès, M. C., St-Gelais, D., & Turgeon, S. L. (2011). Gel formation and rheological properties of fermented milk with in situ exopolysaccharide production by lactic acid bacteria. Dairy science & technology, 91(5), 645.

Hamad, M. N., Ismail, M. M., & El-Menawy, R. K. (2016). Effect of Jameed Form on the Chemical Composition, Rheological and Microbial Properties. Journal of Food Technology Research, 3(2), 72-87.

Karasu, S., Toker, O. S., Yilmaz, M. T., Karaman, S., & Dertli, E. (2015). Thermal loop test to determine structural changes and thermal stability of creamed honey: Rheological characterization. Journal of Food Engineering, 150, 90-98.

Karunarathne, S. S., Eimer, D. A., & Øi, L. E. (2018). Evaluation of Systematic Error and Uncertainty of Viscosity Measurements of Mixtures of Monoethanol Amine and Water in Coaxial Cylinder Rheometers. International Journal of Modeling and Optimization, 8(5).

Kasapis, S., & Bannikova, A. (2017). Rheology and food microstructure. In Advances in food rheology and its applications (pp. 7-46). Woodhead Publishing.

Magenis, R. B., Prudêncio, E. S., Fritzen-Freire, C. B., Stephan, M. P., do Egito, A. S., & Daguer, H. (2014). Rheological, physicochemical and authenticity assessment of Minas Frescal cheese. Food Control, 45, 22-28.

Malvern Panalytical. (2016). Enhancing Formulation Using Rheology. Retrieved from: https://www.azom.com/article.aspx?ArticleID=13277

Moelants, K. R., Cardinaels, R., Van Buggenhout, S., Van Loey, A. M., Moldenaers, P., & Hendrickx, M. E. (2014). A Review on the Relationships between Processing, Food Structure, and Rheological Properties of Plant‐Tissue‐Based Food Suspensions. Comprehensive Reviews in Food Science and Food Safety, 13(3), 241-260.

Nishinari, K. (2009). Texture and rheology in food and health. Food Science and Technology Research, 15(2), 99-106.

Rane, J. P., Pauchard, V., Couzis, A., & Banerjee, S. (2013). Interfacial rheology of asphaltenes at oil–water interfaces and interpretation of the equation of state. Langmuir, 29(15), 4750-4759.

Schlumberger. (2016). Herschel-Bulkley fluid. Retrieved from: https://www.glossary.oilfield.slb.com/en/Terms/h/herschel-bulkley_fluid.aspx

Tabilo-Munizaga, G., & Barbosa-Cánovas, G. V. (2005). Rheology for the food industry. Journal of food engineering, 67(1-2), 147-156.

Toker, O. S., Dogan, M., Canıyılmaz, E., Ersöz, N. B., & Kaya, Y. (2013). The effects of different gums and their interactions on the rheological properties of a dairy dessert: a mixture design approach. Food and bioprocess technology, 6(4), 896-908.

Wu, B. C., Degner, B., & McClements, D. J. (2013). Creation of reduced fat foods: Influence of calcium-induced droplet aggregation on microstructure and rheology of mixed food dispersions. Food chemistry, 141(4), 3393-3401.