MANUFACTURING STRATEGY

Executive Summary

The report mainly highlights the R&D and strategic innovation of the two manufacturing organizations in the United Kingdom. One organization is a global corporation that is Unilever and the other SME organization is Little Soap Company.

The main focus of the report is to analyses the methods and tools and techniques for developing the product. The main approach is to identify the benefits and drawbacks of the R&D department to sustain the globally competitive business market of the United Kingdom. The main approach is to summarize the research and the comparison method and to entitle the performance outcome of both the organizations in a specific manner.

Manufacturing strategy defines specific objectives of coordination for achieving high performance in the business. Manufacturing is the summation of inventory and capacity in the total supply chain management. In this report, two companies have been selected for comparison of the competitive business environment using research & development.

The two companies are Unilever, which is a global industry of consumer goods service and the other SME based company in the United Kingdom is Little Soap Company which is a manufacturer of 100% organic soap. The report aims to identify the drawbacks and benefits of the two organizations in terms of a competitive business environment.

2. The competitive advantage of using research and development

2.1 Discuss the range of methods

The global corporation sector Unilever has used a selective method to gain a competitive advantage in the research and development sector for surviving in the global trading market. As per the view of de Sousa et al, (2019), the research and development team of the organization mainly focuses on three individual aspects including discover, design and deploy.

The discovery team of the organization creates a bridge between the ideas that are formatted by the strategic science group of the organization and the brand vision. The main aim of the discovery team is to embed innovative technologies in the design of the product (unilever.co.uk, 2020).

The design team always concentrates on the needs of the consumers and surveys business activities of the other competitive industries such as Johnson & Johnson, Nestle and many more.

The development and testing go longer until it fits the actual product and meets the standard of the organization. In the opinion of Theorin et al, (2017), the perfect formulation technique has been done by the design team to measure the stability of the product at the time of designing.

The company has seven capabilities teams to monitor the development and deployment of the product. Deployment considers the sale and marketing of the product that would attract the target customers for gaining more business growth and productivity (unilever.co.uk, 2020). The capability team consider the seven following measurement at the time of designing the product:

- Safety and Environmental Assurance Centre: the company has applied all the safety measurement methods and risk assessment tools at the time of designing. This maintains the environment and assurance law of the United Kingdom (Conforto and Amaral, 2016)

- Regulatory Affairs: regulatory affairs help the organization to meet the proper standard, rules and regulation of product development act of UK (1968) (unilever.co.uk, 2020).

- Clinical: this research aspect is helpful to the consumers by ensuring the fact that products are clinically tested and effective.

- Packaging: the company has implemented more sustainability in the packaging that would be safe for the environment.

- Nutrition: the proper nutrition factor has been maintained by the organization to make a healthy lifestyle for the consumers (unilever.co.uk, 2020).

The company Little Soap Company is a UK based SME organization which mainly produces organic and cruelty-free soap products for the customers. The R&D department of the organization mainly focuses on the use of ingredients, packaging trends, the texture of the product.

The scientists mainly focus on the needs of the customers as the changing environment the customers mainly opt of natural soap. The development department also focuses on making vegan soap using the source of animal products which comprises emu oil, fish oil, mink oil which is purely organic and less harmful to the consumers.

In the views of Cetindamar et al, (2016), the scientists mainly focus on the design of the product with the creative technologies that reduce the production cost and annual revenues of the organization. The higher management of the company mainly aims to produce environment-friendly and less expensive products for the consumers (littlesoapcompany.co.uk, 2020).

2.2 Explain the tools and techniques

The three main tools and techniques that have been used by the global organization Unilever are as follows:

- Safe and Sustainable by design: The R&D scientist has shared their insight into the development of the product and how the consumer uses the product in different ways. As commented by Chen and Sennetti (2018), the scientists are always to manufacture the product which is safe for the customers, the workers and also for the environment itself. The innovation of New Domestos Atomizer has been discovered by the R&D team to kill the germ of the toilet automatically to provide more sustainability and safety to the environment.

- A science-based approach to keep the environment and consumer safe: the company has focused on the safety of the product by exposure driven The exposure is mainly based on how much, how often and how long a product will be used. The scientist of Unilever found the level of exposure and how it affects the human body. According to the author Mo et al, (2016), the expert team can distinguish between the two concepts including hazard and risk and develop the product. Most of the Unilever products are disposable in the environment, hence, the scientist also focuses on that matter that is biodegradable. The organization mainly points out two risk assessment techniques for the design of the product, which comprises Microbiology assessments and Allergy assessments. The microbiology assessments of products would help to protect the consumer from bacteria, fungi and algae. The allergy assessment techniques are mainly focused on the beauty product that will save consumers from harmful infections.

Figure 1: Tools & Technique used by Unilever

(Source: Unilever.co.uk, 2020)

- Life Cycle assessment approach to reduce environmental impact: the life cycle assessment approach would help the organization to use the disposable material in the manufacturing process for reducing environmental impact. As opined by Bonakdar et al, (2017), this would help the organization to support the Unilever Sustainable Living Plan for reducing the carbon footprint from the environment.

The company Little Soap Company has used the following tools and techniques to sustain the business market using research and development:

Safety Tools: the company has produced safety and organic soap which is free from any types of chemicals and less harmful to the skin of the consumers. As suggested by Narula (2017), the scientist has implemented the healing strategy in making soap that will prevent several skin diseases like acne, eczema and other skin diseases (littlesoapcompany.co.uk, 2020).

Figure 2: tools & Technique used by Unilever

(Source: Littlesoapcompamy.co.uk,2020)

Environment Friendly: the use of cruelty-free soap has zero amount of environmental impact which can higher the ecological balance. The R&D team has executed the eco-friendly approach for manufacturing the soap (littlesoapcompany.co.uk, 2020).

3. Contrast benefits and identifies drawbacks based on an SME versus a global corporation

| Unilever | Little Soap Company | |

| Benefits | ➔ As the company can access greater amounts of talent, proficiency and skill of the R&D department are commendable.

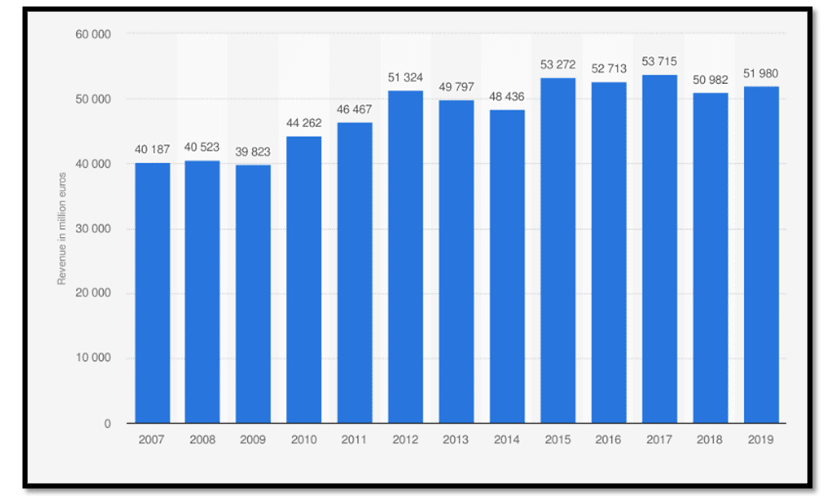

➔ For higher skill and efficiency of the staffs, the technology used by the R&D department is more creative compared to other SME enterprise (unilever.co.uk, 2020) ➔ The scientists are going through the continuous learning process that would help them to learn the modern technique and implement it in the business itself (Akter et al, 2016). ➔ The target market of the organization is very high which can help to increase the overall revenues of the organization (refer to appendix 2). ➔ As the higher target market, the R&D has to analyses more segmented markets and design the product as per the customer’s expectations (unilever.co.uk, 2020). ➔ Corporate social responsibility of the organization is higher compared to the SME organization so the R&D department mainly focuses on the positive influence of the environments (Arora et al, 2016). ➔ Scientists have adopted a new culture at the time of developing and deploying the product. |

➔ The company is closer to their customer, so the R&D department can design the product as per the needs of the consumers.

➔ The supply chain management is more flexible compared to the global corporation organization (littlesoapcompany.co.uk, 2020). ➔ The Little soap company has used the niche marketing strategy executed by the R&D department of the organization. ➔ The R&D department of the company makes fast decisions compared to the global corporation which makes better performance outcomes (Jeihoonian et al, 2017). ➔ The departmental communication will be easier in every hierarchy which makes the R&D department to work efficiently (littlesoapcompany.co.uk, 2020). |

| Drawbacks | ➔ Being the global organization the company is not very close to the customers hence it is quite difficult to understand the demand of the customers. As per the views of Nallusamy et al, (2017), this can reduce the number of target customers. So the R&D department cannot meet the needs of the customers many times.

➔ The cultural difference between scientists can make productivity lower compared to the SME business (unilever.co.uk, 2020). ➔ The differences of opinions can create conflict in the manufacturing strategy of the product which can lower the efficiency of the product (Metters et al, 2019) |

➔ The main drawbacks of the R&D department are the lack of competent manpower which can be responsible for making desirable products for the target customers.

➔ As the organization is close to the customers, it becomes quite difficult to meet the individual demand of the customers (littlesoapcompany.co.uk, 2020). ➔ The target market of the company is small compared to the global corporation which reduces the annual revenues of the company in a current financial year. (refer to appendix 2). ➔ The stress and pressure to the R&D department is quite high compared to the global organization as there are more financial risk and time commitment (Merigó et al, 2019) |

Table 1: Contrast of benefits and drawbacks between the two Organization

(Source: Merigó et al, 2019)

4. Summary of research and comparison

From the research, it can be found that the global organization has manufactured a variety of products includinghome care & beauty products, foods & beverages. The company has implemented three main factors: design, develop and deploy in this field and implemented creative and innovative technology for the manufacturing of the product.

For example, the company Unilever mainly focused on the exposure driven approach that will help the organization to experiment with new ideas. In the influence of Merigó et al, (2019), this would help the scientists of Unilever to examine the product which provides more safety to the consumers and the environment. From the comparison, it has been forecasted that the main benefits of the company are the skilled and competent scientist who believes in a continuous learning process to adopt new methods and tools for designing the product.

Another benefit of the organization is diversifying the market and enlarging the target audience which can empower the annual revenues of the organization. The most prior drawbacks of the organization are the differences of opinions and cultural barriers that have a huge influence on the development of the product (unilever.co.uk, 2020).

On the other hand, the SME organization Little soap company is mainly based on manufacturing natural soap with 200 employees overall. The company has maintained the applied research and experimental development for the manufacturing of the product. As per the views of Jeihoonian et al, (2017), the organic soap is free from any harmful chemical and attracts the most target audience.

The main benefits of the organization are the lower target market and meeting the expectations with a low budget and in an environment-friendly way. The main drawbacks of the organization are lack of proficient technicians to execute new and modern methods in the innovation process (littlesoapcompany.co.uk, 2020).

It can be concluded from the report that the main focus is on the different methods used by the global corporation and SME based organization. The global organization Unilever has different techniques and methods to gain a competitive advantage in the field of R&D. On the other hand, the organization Little Soap company has used different tools and techniques for implementing R&D.

The report also highlights the comparison between the drawbacks and benefits of both the organization in terms of R&D. The main approach is based on summarizing the research with the help of proper examples and the comparison made on the benefits and drawbacks. The report mainly points out the strategic innovation of the R&D team for both organizations.

Akter, S., Wamba, S.F., Gunasekaran, A., Dubey, R. and Childe, S.J., 2016. How to improve firm performance using big data analytics capability and business strategy alignment?. International Journal of Production Economics, 182, pp.113-131.

Arora, A., Cohen, W.M. and Walsh, J.P., 2016. The acquisition and commercialization of invention in American manufacturing: Incidence and impact. Research Policy, 45(6), pp.1113-1128.

Bonakdar, A., Frankenberger, K., Bader, M.A. and Gassmann, O., 2017. Capturing value from business models: the role of formal and informal protection strategies. International Journal of Technology Management, 73(4), pp.151-175.

Cetindamar, D., Phaal, R. and Probert, D.R., 2016. Technology management as a profession and the challenges ahead. Journal of Engineering and Technology Management, 41, pp.1-13.

Chen, C.H. and Sennetti, J., 2018. THE ‘NO WIND NO WAVES:’PROCUREMENT FRAUD INVESTIGATION. Journal of the International Academy for Case Studies, 24(1).

Conforto, E.C. and Amaral, D.C., 2016. Agile project management and stage-gate model—A hybrid framework for technology-based companies. Journal of Engineering and Technology Management, 40, pp.1-14.

de Sousa Jabbour, A.B.L., Chiappetta Jabbour, C.J., Sarkis, J., Gunasekaran, A., Furlan Matos Alves, M.W. and Ribeiro, D.A., 2019. Decarbonisation of operations management–looking back, moving forward: a review and implications for the production research community. International Journal of Production Research, 57(15-16), pp.4743-4765.

Jeihoonian, M., Zanjani, M.K. and Gendreau, M., 2017. Closed-loop supply chain network design under uncertain quality status: Case of durable products. International Journal of Production Economics, 183, pp.470-486.

Littlesoapcompany.co.uk, 2020, Home, Available at: https://www.littlesoapcompany.co.uk/ [Accessed on: 20 April 2020]

Merigó, J.M., Muller, C., Modak, N.M. and Laengle, S., 2019. Research in production and operations management: A university-based bibliometric analysis. Global Journal of Flexible Systems Management, 20(1), pp.1-29.

Metters, R., Marshall, D. and Pagell, M., 2019. Cultural Research in the Production and Operations Management Field. Foundations and Trends® in Technology, Information and Operations Management, 13(1-2), pp.1-150.

Mo, S., Chen, K.C. and Ye, C., 2016. The evolving role of peer-to-peer lending: A new financing alternative. Journal of the International Academy for case studies, 22(3), p.32.

Nallusamy, S., Balaji, R. and Sundar, S., 2017. Proposed model for inventory review policy through ABC analysis in an automotive manufacturing industry. In International Journal of Engineering Research in Africa (Vol. 29, pp. 165-174). Trans Tech Publications.

Narula, R., 2017. Emerging market MNEs as meta-integrators: the importance of internal networks. International Journal of Technology Management, 74(1/2/3/4), pp.214-220.

Theorin, A., Bengtsson, K., Provost, J., Lieder, M., Johnsson, C., Lundholm, T. and Lennartson, B., 2017. An event-driven manufacturing information system architecture for Industry 4.0. International Journal of Production Research, 55(5), pp.1297-1311.

Unilever.co.uk, 2020, Home, Available at: https://www.unilever.co.uk/ [Accessed on: 20 April 2020]

Appendix 1: Annual Revenues of Unilever

(Source: unilever.co.uk, 2020)

Appendix 2: Annual revenues of Little Soap Company

(Source: littlesoapcompany.co.uk, 2020)

I seriously love your website.. Great colors & theme. Did you create this web site yourself? Please reply back as I’m attempting to create my own website and would like to learn where you got this from or just what the theme is named. Many thanks!

https://twrd.in/NubrMAU

https://mg.wpcookie.pro

After looking over a few of the blog posts on your website, I truly like your way of writing a blog. I added it to my bookmark site list and will be checking back in the near future. Please visit my website as well and tell me your opinion.

https://twrd.in/ztjcScU

I really liked your blog post.Really thank you! Really Cool.

https://e-web-directory.com/listings12674751/the-ultimate-guide-to-adventure-in-lonavala

I am so grateful for your blog post. Much obliged.

https://zaneyodp64320.wikibriefing.com/2442758/navigating_the_maze_a_guide_to_work_permits_in_europe

I appreciate you sharing this article post. Great.

https://stephenrfsf10976.suomiblog.com/the-benefit-of-custom-plastic-parts-40584618

Great, thanks for sharing this article post. Really Cool.

https://nsfws.ai/

Im grateful for the article.Much thanks again. Really Great.

https://nsfws.ai/

I truly appreciate this post. Cool.

https://www.laifentech.com/

Thanks a lot for the blog article.Thanks Again. Fantastic.

https://www.orangenews.hk

I appreciate you sharing this post.Thanks Again. Really Cool.

https://inspro2.com/

I truly appreciate this article post.Much thanks again. Want more.

https://talkietalkie.ai/

Really informative post.Much thanks again. Fantastic.

https://meencantalapinturadediamantes.es/blogs/news/que-son-los-paintings-diamond

Thank you for your article post.Really looking forward to read more. Cool.

https://nsfw-ai.chat/

I truly appreciate this blog.Really looking forward to read more. Much obliged.

https://nsfw-ai.chat/

Very good blog post.Really looking forward to read more. Really Cool.

https://devinai.ai/

Awesome post.Really thank you! Much obliged.

https://summerseasiren.com/collections/period-underwear

Really enjoyed this article post.Much thanks again. Keep writing.

https://andreojcs77543.theideasblog.com/26203798/luxury-side-tables-for-living-room

Appreciate you sharing, great post. Great.

https://saxendakopen23456.anchor-blog.com/5532913/elevate-your-living-room-luxury-tables-and-wall-decor-trends

I really enjoy the article post.Really thank you! Cool.

https://httpsjun88onlineco57789.glifeblog.com/24935863/finding-excellence-in-pulmonology-your-guide-to-pulmonologists-in-madurai

Im obliged for the blog article. Want more.

https://jobs.thebridgework.com/employers/2846566-sagar

Appreciate you sharing, great blog post.Thanks Again. Cool.

https://edgarmlgbs.rimmablog.com/25512633/unlock-your-career-with-iosh-managing-safely-training-in-india

I really like and appreciate your article. Will read on…

https://milolapb09865.blogoxo.com/25369478/the-advantage-of-online-nift-coaching

Thanks again for the blog article.Really looking forward to read more.

https://khalilx937dnz3.wikibriefing.com/user

Major thankies for the article post.Really looking forward to read more. Want more.

https://saxenda-kopen74184.ambien-blog.com/30646877/an-unbiased-view-of-best-nebosh-igc-training

I am so grateful for your blog article.Much thanks again. Really Great.

https://arenaplus.ph/

I am so grateful for your article post.Thanks Again. Really Great.

https://www.sonhungbac.com/

Great blog post.Really looking forward to read more. Want more.

https://baixicans.com/

Very neat article post.Really thank you! Keep writing.

https://gbdownload.cc/

Thanks again for the article.Really looking forward to read more. Awesome.

https://fouadmods.net/

Im thankful for the article.Much thanks again. Keep writing.

https://gbdownload.cc/

Really appreciate you sharing this blog article. Really Cool.

https://fouadmods.net/

wow, awesome blog. Really Cool.

https://nsfwgenerator.ai/

I really liked your post. Want more.

http://animegenerator.ai/

Thanks so much for the blog article.Really looking forward to read more. Great.

https://franciscoxeili.techionblog.com/25779567/unlocking-success-with-kabaddi-dream11-predictions-your-ultimate-guide

A big thank you for your post.Much thanks again.

https://thetopsdirectory.com/listings12672485/revamp-your-living-space-with-high-quality-commercial-living-room-furniture

Looking forward to reading more. Great article post.Really thank you! Want more.

https://best-accounting-software96326.blogdiloz.com/25431683/cricket-live-score-can-be-fun-for-anyone

Thank you for your post.Much thanks again. Awesome.

https://mbti36675.csublogs.com/30888263/unlocking-effective-advertising-solutions-in-surat-rampublicity-leads-the-way

I really enjoy the article. Really Great.

https://simonskzd10987.wiki-racconti.com/7497432/what_is_satta_matka

Major thankies for the blog article.Thanks Again. Fantastic.

https://hkcompanyregistration69172.pointblog.net/excelling-in-upsc-exams-the-power-of-online-coaching-with-spm-ias-academy-65942047

Major thankies for the article.Really thank you! Fantastic.

https://dominickva2bv.pages10.com/explore-luxury-travel-with-volvo-bus-hire-in-gurgaon-60783215

Really appreciate you sharing this post.Really thank you! Awesome.

https://shanevjxj32198.thelateblog.com/26237336/silver-bracelet-for-men

Looking forward to reading more. Great blog article.Really looking forward to read more. Great.

https://www.hommar.com/ar/video/products-detail-4549229

I am so grateful for your article. Cool.

https://www.hkcashwebsite.com

Im obliged for the blog. Awesome.

https://www.kol.kim/custom-design/

Thank you ever so for you blog article. Fantastic.

https://blog.huddles.app

Thanks for the article.Much thanks again. Fantastic.

https://crushon.ai/

Fantastic post. Keep writing.

https://crushon.ai/

Thanks for the post.Thanks Again.

https://www.hommar.com/

I really liked your blog article.Really looking forward to read more. Really Cool.

https://crushon.ai/

Thanks a lot for the blog post.Really thank you! Much obliged.

https://ai-sexting.top/

Really appreciate you sharing this blog.Thanks Again. Really Great.

https://spicychat-ai.online/

I really like and appreciate your post.Really thank you!

https://crushon.ai/

Fantastic blog article. Keep writing.

https://crushon.ai/

Really enjoyed this blog article. Really Great.

https://crushon.ai/

I cannot thank you enough for the blog.Really thank you! Fantastic.

https://crushon.ai/

Very neat blog post.Thanks Again. Will read on…

https://smashorpass.app/

Thanks again for the post.

https://www.kol.kim/custom-design/

Appreciate you sharing, great blog post.Much thanks again. Cool.

https://www.yinraohair.com/wigs/shop-by-style/short-curly-wigs

Muchos Gracias for your article post.Thanks Again. Great.

https://www.yinraohair.com/human-hair/front-lace-wig

Awesome article.Much thanks again. Want more.

https://www.yinraohair.com/cosplay/shop-by-color/blue

Im grateful for the blog. Really Cool.

https://www.metalfenceworks.com/e_productshow/?95-5-Feet-Black-Chain-Link-Fence-95.html

Appreciate you sharing, great post.Really looking forward to read more. Awesome.

https://blog.huddles.app

I value the post.Thanks Again. Awesome.

https://blog.huddles.app

Im obliged for the article.Really looking forward to read more. Awesome.

https://umhom13.com

Major thanks for the article post.Really looking forward to read more. Really Cool.

https://umhom13.com

I cannot thank you enough for the blog post. Fantastic.

https://girl-friend.ai/

Really enjoyed this post.Thanks Again. Really Cool.

https://nsfwcharacters.ai/

A big thank you for your post.Really thank you! Really Cool.

https://honorcase.com/

This is one awesome blog post.Much thanks again. Much obliged.

https://aura-circle.com/

Im grateful for the article post.Really thank you! Really Great.

https://aura-circle.com/collections/aura-sleep-mask-collection

Thanks again for the blog article.Thanks Again. Fantastic.

https://x.yupoo.com/photos/lireplica/categories/2939266

Enjoyed every bit of your article post.Really thank you! Much obliged.

https://www.piaproxy.com

Hey, thanks for the article.

https://telagrnm.org

Major thanks for the blog article.Thanks Again. Awesome.

https://telcgrnm.org/

Really appreciate you sharing this blog post.Really looking forward to read more. Fantastic.

https://cncmachining-custom.com

Hey, thanks for the blog.Much thanks again. Will read on…

https://www.topbet.game/?ch=110019

I cannot thank you enough for the blog article.Much thanks again.

https://www.haijiao.cn

I think this is a real great article.Really thank you! Fantastic.

https://www.haijiao.cn

Say, you got a nice blog article. Really Great.

https://www.slsmachinery.com

Very informative article.Really thank you! Much obliged.

https://www.wetwipes-manufacturer.com

Thanks a lot for the article post.Much thanks again. Keep writing.

https://www.jingpailianghao.com/

This is one awesome article post.Really thank you! Awesome.

https://crushon.ai/