MK 7041- Managing Sustainable Global Value Chains Assignment Sample

Introduction

“Value chain” is the whole set of operations that starts with the procurement of raw materials and concludes with the delivery of a finished product to the end user or the consumers.

Mostly, addressing this problem begins with a review of the company’s core competencies, including the things it does well when it comes to delivering value for consumers.

From grand dreams to realistic strategies, the world economy is being transformed towards sustainability. “Sustainability” is a vague word that refers to the long-term stability of all existing and planned systems.

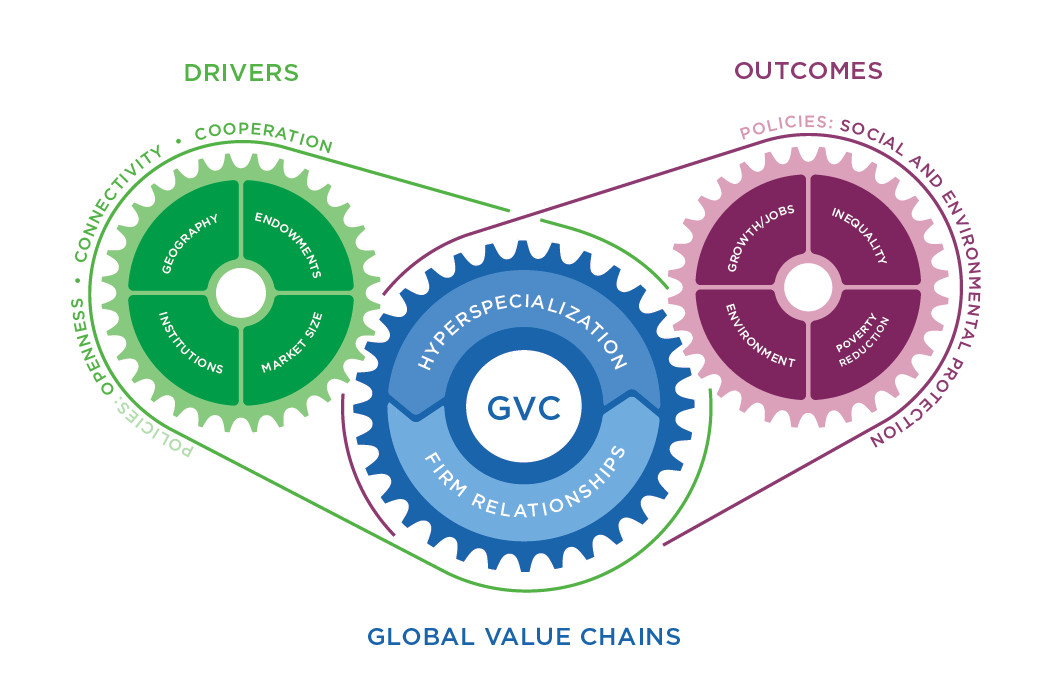

Global Value Chains are becoming increasingly important in the global economy (GVCs). Meanwhile, despite the growing value of GVCs highlights the need to obliterate both export and import constraints, nations’ willingness to cooperate in this area is waning, especially with regard to Deep Preferential Trade Arrangements (PTAs), a problem that policymakers must fix.

This paper forcuses on the sustainable value chain in terms of the automotive industry. Regulation by the government and other stakeholders could put pressure on the automotive industry to be more sustainable.

It’s crucial to consider what happens when this power is used to meet environmental or other sustainability targets, as well as the potential for tension among the sustainable supply chain’s participants. Regulatory, corporate, media, and community players all exert external and internal demands on the supply chain to become more sustainable. This may lead to disagreements among supply chain participants.

While conventional supply-chain management is a critical component, the scale of the problem is far broader in terms of sustainability.

The distinguishing feature of the supply chain for suppliers is that it stretches in all ways and has trade partners ranging from the seller’s supplier to the buyer’s customer. Another is the growing emphasis on collaborating with trade partners to maximize speed, performance, and productivity.

1. Academic Literature Review:

- In the paper titled: “Challenges and Conflicts in Sustainable Supply Chain Management Evidence from the heavy-vehicle industry.” by Veronika Pereseina, Leif-Magnus Jensen, Susanne Hertz

This paper contributes to the debate on SSCM in the heavy-vehicle and aerospace sectors, as well as the contrast of two markets. Since the study is limited to two countries, it serves as a comparison example of two extremes, with Sweden doing reasonably well in terms of SSCM while China continues to struggle.

More study should be done to see if there are any opportunities to of knowledge sharing and value accessibility, especially in terms of the results of previous changes in Sweden.

In addition, the results of this research may be applied to other analyses of sustainable supply chain management in related industries. They will use the research to get a greater understanding of the conflicts and difficulties that come with managing a sustainable supply chain.

- The Global Automotive Industry Value Chain: What Prospects for Upgrading by Developing Countries by John Humphrey and Olga Memedovic is a UNIDO Sectorial Studies Series Working Paper

The paper also goes into detail on the relational terms between assemblers and vendors has evolved over time. Following sourcing (using the same vendors in different locations) is becoming increasingly popular, limiting the options for component based supply by local producers in developed countries.

However, there are possibilities in second-tier procurement, where a global presence isn’t necessary. By liberalisng their domestic markets, developed countries will increase their chances of being integrated into global supply chains of transnational automotive firms, according to the report.

- Sustainable supply chain management practices in Indian automotive industry: A multi-stakeholder view, Deepak Mathivathanan, Devika Kannana. Noorul Haqb

The aim of this research is to gain a deeper understanding of the interconnected forces between SSCM activities, with a focus on the automotive industry. The study includes perspectives from a wide range of contributors, including management, socio-ecological , and administrative organizations.

We suggest a process model for evaluating automotive industry SSCM activities in the developing economy of India, based on the Decision Making Trial and Evaluation Laboratory approach. This research provides a basis for management of the industries to consider the interdependencies among the practices and increases the likelihood of effective adoption of SSCM practices within the precincts of automotive industry.

- Supply Chain Management In Indian Automotive Industry : Complexities, Challenges And Way Ahead By Souresh Bhattacharya, Dr. D. Mukhopadhyay And Dr. Sunil Giri

After market deregulation and liberalization in the early 1990s, the Indian automotive industry, which includes production of vehicular components, has expanded steadily. The arrival of major international automakers has prompted the domestic industry to follow Supply Chain best practices. This has improved productivity, resulting in a significant increase in exports.

However, the Indian automobile industry must operate in a competitive environment. However, the automotive industry in Indian operates in a specific setting, which adds to the already complicated car supply chain’s challenges. As a result, there is a strong need to continue studying supply chain processes in this industry from a modern, practitioner’s perspective in order to find primary differentiators that can potentially have a strategic edge.

This paper aims to comprehend the current state, dynamics, and threats that the Indian car industry faces. It looks at how supply chain productivity is impacted by trends like awareness and creativity, teamwork and supply networks, and changing leadership positions. The authors propose strategies for solving obstacles as well as a basis for future research and review.

- Incorporating sustainability into supply management in the automotive industry – the case of the Volkswagen AG by Julia Koplina, Stefan Seuring, Michael Mesterharma

Companies are seen as key players in the quest for sustainability. Companies are beginning to view their supply chain to improve their overall sustainability track records as a result of this, both in reaction to rising demands from different stakeholder groups.

There are two main triggers to be aware of: (1) The focal firms are held liable for the environmental and social issues that their suppliers cause. (2) At the level of the supplier, a growing share of value is generated. of Companies must find ways to integrate environmental and social factors into their management of supply chain in order to meet those demands. consequently , sourcing procedures are changed to incorporate environmental and social values into supply procurement. This paper describes a supply chain strategy used by the Volkswagen

- Performance measurement for sustainable supply chain in automotive industry: a conceptual framework by Rika Ampuh Hadiguna, Harlina Suzanna Jaafar, Sabariah Mohamad

Since they failed in supply chain management owing to their failure in development of the performance measurements and benchmarks needed for full integration of the supply chain and performance measurement, many car companies would establish appropriate measures for successful green supply chain performance measurement.

The implementation of a systematic based approach for achieving sustainable output assessment of automotive supply chain management is discussed in this paper to solve these challenges. This paper discusses some of the articles that have been written to analyze and improve efficiency assessment of the hybrid vehicle supply chain.

- The Automobile Industry & Sustainability by R.J.Orsato and P.Wells

The contributions to the special issue on The Car Industry and Sustainability are summarized in this article. The contributions are divided into the automobile life-cycle processes of construction, manufacturing (and SCM), usage, and disposal of (or management of ‘end of life vehicle’ ) from a life-cycle viewpoint.

The contributions are often placed in the larger sense of research into the global automotive market, as well as the industry’s economic, social, and environmental pressures. In the process, this introductory paper offers a quick review of the perception of the challenges of creating a viable automotive industry.

2. Country Case: INDIA

In terms of long-term growth and sustainability, the Indian automotive industry is undergoing major changes.

The sector is critical to the economy, accounting for 7.1 percent of the country’s Gross Domestic Product (GDP) and expected to rise to 12 percent in the Automotive Mission Plan (AMP) 2016–26. India is projected to become the world’s third-largest transit nation.

As the economy grows and investments rise, the dynamics for growth factors in the automotive industry remain unchanged, and the sector is expected to see an improved indicating an ascend in demand in the years to come.

The government’s “Make in India” campaign has helped the country boost its position, with nine out of ten metrics for ease of doing business improving.

Currently, India’s automobile sector is at a crossroads, with five megatrends on the horizon that would drastically alter the industry.

Rapidly shifting consumer demands, the transformative effect of technology, the competitive regulatory climate, changing migration habits, and global interconnectedness are all having an impact on how car companies conduct business today, internationally and in the United States.

In the automobile industry, the use of information technology (IT) and the application of scientific research into industrial goods and procedures is not a recent development.

What is new, though, is the degree of complexity and speed at which new age innovations like IoT, AI, artificial learning, and robotics are being applied which is advent of the 4.0 Industrial evolution in India.

The automotive industry is undergoing a paradigm shift as a result of the rapid pace of transformation. In terms of megatrends, revolutions and new ways of operating are predicted to cause irreversible shifts in the automobile industry, resulting in major opportunities.

According to the Automotive Mission Plan 2016-26 (AMP 2016-26), the Indian automotive industry is on track to become one of the country’s largest job-creating engines, with 65 million jobs expected to be created over the next decade.

This should help the country develop considerably if the sector can overcome and tackle the twin challenges of low job appeal and the gap in future supply of stakeholders and workforce.

Furthermore, it is important to note that many developments are still unforeseeable and unpredictable. To succeed in the current global order of the automobile industry, automotive companies will need to effectively navigate the following seven main changes in the coming years.

The key factors driving Indian automotive industry in today’s date:

Customer expectations are rapidly changing: As the difference between middle-class demographic growth and middle-class average income growth widens, consumers’ buying preferences are divisive in their outlook between luxury and budget cars.

The modern standard is becoming more digital and automated: Automobile companies in India are digitizing their plants and supply chains to keep up with market trends. Digitisation is also expected to result in the democratization of intelligence and an improvement in organizational accountability. A proactive improvement of management roles would be needed to handle this new status quo.

The changing face of the service and support ecosystem: In the automobile industry, the idea of service and support is going to take on a whole new significance. Vehicle downtime is expected to decrease dramatically with the introduction of electric vehicles (EVs) and hybrid vehicles (HVs). Also the technology and capabilities needed to maintain and operate EVs and HVs would be vastly different from what is currently in place.

4. Industry Case: Automotive

Although the Indian automotive industry dates back to the 1940s, it has grown significantly in the last two decades, owing to economic liberalization and 100% FDI in the market.

Due to the availability of a wide pool of qualified labor, menial production costs, and a favorable tax environment, international automobile manufacturing companies are encouraged to develop manufacturing and R&D facilities in the region due to lower production costs especially due to A fast regime of design and development procedure, etc.

The industry is made up of different groups – assemblers, multi-national assemblers, suppliers dealing with Indian spare parts, those with multi-national component – each with their own strengths and limitations, with the organized sector accounting for 77 percent of total output volume and the SME sector accounting for the remainder.

The industry accounts for 7% of India’s GDP, 7-8% of the overall working population (roughly 13 million people), 4% of exports [13] [14], 39% of FDI inflows (USD 5.5 billion between 2009 and 2013), and 17% of total indirect taxes received. However, the Indian automotive industry’s drive for global competition can be seen in the fact that major automakers are based in India serving as the second largest recipients of the Deming Awrad after Japan.

India has the highest fuel economy prices in the world, as well as in terms of a low overall cost of ownership which further drives its sustainability clause.

The automobile industry has been a significant contributor to the Indian economy since its inception. Thanks to globalization, the automotive industry now faces environmental and social demands from consumers, workers, and allies.

Due to persistent globalization stresses, rules and regulations framed by the Indian government, as well as the evolving standards of the society the Indian automotive industry is under extreme pressure to transition to SSCM.

As a result, Indian companies now place a greater emphasis on social and environmental issues than ever before, and they are having trouble finding the most effective SSCM practices for enhancing their long-term results.

The growing need for businesses to implement sustainable practices in order to gain strategic advantages while not jeopardizing facets of sustainability constitutes as the era’s demand.

The Indian automotive industry is also facing global competition, with well-known global giants vying for a piece of the local market. Indian companies recognize that adhering to sustainability principles will not only help them succeed in this regime of market competition, but will also give them a strategic advantage.

The transition to SSCM is made smoother and more successful until the prevalent practices and their shared influences with other traditional practices are established. The multi-stakeholder approach has recently gained a lot of traction in the area of sustainability, owing to its consolidated resources, marketing and analytical viewpoints, and ethical principles, both of which are are conducive to the SSCM strategy.

As a result, a multi-stakeholder investigation into SSCM activities in these industries is needed.

The three key stakeholders in every business are: (1) the government, which sets the requirements, laws, and regulations; (2) the target society, whose demand are considered for manufactured and who are the end users of the products; and (3) the related inter-departmental management and administrators, who make decisions.

-

Conclusion and recommendation:

Automotive companies use SSCM practices in order to achieve long-term sustainability.

Although developing countries’ strict policies and government legislation make it easy for businesses to follow SSCM activities, emerging economies like India fail to do so. They are having trouble identifying the influential practices that have a significant impact on other practices’ adoption of SSCM.

- DEMATEL is a unique method for forming and analyzing cause-and-effect relationships between parameters. Using this method, as depicted by the current literature, 25 SSCM practices were figured out in the automotive industries wherein all practices assist the firm in achieving a sustainable supply chain from which they can achieve a competitive edge over other firms.

- However, it is almost difficult to focus effectively on all SSCM activities. As a result, it’s critical to identify the most influential SSCM activities, especially those that have a positive impact on other practices.

- Furthermore, multi-stakeholder cooperation is a widely used feature around the world, and as a result, more emphasis is placed on collaboration among different stakeholders for long-term success.

- The contributions ably illustrate the importance of a business (rather than a specialty or methodological) focus: the world is in dire need of real and substantive change in this and many other sectors, and that progress must be grounded in an interpretation of the world beyond the limits of theoretical crafting to be plausible and successful.

- The future possibilities Sustainable Manufacturing in atomotive industry will be based on an economically sound base of ACES (Automated, Connected, Effective, Secure, and Sustainable) processes that reduce negative environmental impacts at the same time while being environmentally responsible in terms of conserving energy and natural resources, while also providing long-term benefits to the automotive industry by generating value ambitiously motivated by product stewardship.

References:

- Mathivathanan, D., Kannan, D., & Haq, A. N. (2018). Sustainable supply chain management practices in Indian automotive industry: A multi-stakeholder view. Resources, Conservation and Recycling, 128, 284-305.

- Koplin, J., Seuring, S., & Mesterharm, M. (2007). Incorporating sustainability into supply management in the automotive industry–the case of the Volkswagen AG. Journal of Cleaner Production, 15(11-12), 1053-1062.

- Barnes, J., & Morris, M. (2008). Staying alive in the global automotive industry: what can developing economies learn from South Africa about linking into global automotive value chains?. The European journal of development research, 20(1), 31-55.

- Holweg, M., Luo, J., & Oliver, N. (2009). The past, present and future of China’s automotive industry: a value chain perspective. International Journal of Technological Learning, Innovation and Development, 2(1-2), 76-118.

- Pratono, A. H. (2019). Cross-cultural collaboration for inclusive global value chain: a case study of rattan industry. International Journal of Emerging Markets.

- Günther, H. O., Kannegiesser, M., & Autenrieb, N. (2015). The role of electric vehicles for supply chain sustainability in the automotive industry. Journal of Cleaner Production, 90, 220-233.

- Masiero, G., Ogasavara, M. H., Jussani, A. C., & Risso, M. L. (2017). The global value chain of electric vehicles: A review of the Japanese, South Korean and Brazilian cases. Renewable and Sustainable Energy Reviews, 80, 290-296.