MOD007698 ABTECH INNOVATE E-WASTE

Introduction

In order to broaden the publicizing of the research article, the researcher plans to write concerning multiple Supply chain democratic accountability and other worries and earnings which that AbTech firm is confronted with. AbTech is indeed a US beginning that has recycled old cell devices and cellular phones to create a groundbreaking flat-chested Fluid crystal display fingerprint sensor glass. The proper utilization distribution network and mass transit to synchronize the purchase of the elements that the AbTech company utilizes to manufacture their business units from existing E-waste will be noted. AbTech has established a relationship with several e-waste companies located in the United States, with plans to expand into Washington and Europe. This same CEO seriously thinks that broadening too quickly will jeopardize the firm’s ability to develop an optimized supply chain plan and method of activity. Following that, numerous international

Scor analysis

The scor model is divided into four categories including:

Plan

Ineffectiveness must almost definitely be reduced by poor individual components, poor increased manufacturing, and a lack of comprehension. AdTech’s branding and sales knowledge and understanding will be harmed as a result.

Source

Individuals who are using technology to tackle issues are critical to the public governance of the distributed generation. There is nothing more essential than honing one’s empathy and comprehension if one wants to become a fruitful distribution network standard bearer. Nonetheless, few distribution channels can perform today without the assistance of advanced and efficient digital innovations such as stock administration management and commercial source of power generation arranging (Resource Planning) procedures.

Make

When it comes to stockpiling logistics activities, the digital revolution has the potential to change the way humans conduct transactions. It is a useful tool for dumbing it down even while attempting to make their businesses more convenient.

Deliver

Device makers are starting to get engaged in repackaging waste into a completed article. In this chapter, the data analysis investigation will primarily appear to suggest the work process that the AbTech private company or their chief operations officer can obtain in order to better implement the effective delivery system in order to be more competitive and rated amongst the best their company or industry.

Analyze scenarios

Attempting to grow too rapidly, based on the Company’s Chief Operating Officer, may jeopardize the organizational value due to the absence of an adequate supply chain approach and methodology. There appears to be competitive rivalry from both clients throughout the world; however, a lack of distribution network supervision and control will clearly restrict and potentially harm the corporation. Numerous problems must be solved in order to construct a suitable distribution channel that will allow for effective and constant manufacturing development (Islam et al., 2018). The financial institution is pressuring AbTech to acknowledge these contract extensions in order to enable the company to grow within the next ten to fifteen years. Since this load flow is protected by globally copyrighted material, there won’t be any immediate competitive pressure, but the flagship business sees unprecedented global possibility.

Competitors analysis

Despite the fact that assembly lines can indeed be done throughout huge quantities with near limitless recycling and reuse, capacitor biometric identification manufacturing output is restricted, and one option is to consider buying basic ingredients in the ideal setting as there is a substantial threat associated with monitoring and controlling a diverse and wide range of activities and guaranteeing strict standards for the product shipment. Several businesses are becoming increasingly extremely worried well about product lines that AbTech may offer and their implications for waste management.

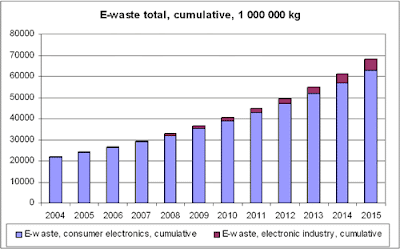

Figure 1: E-waste growth

(Source: https://sites.google.com/site, 2018)

Some might even involve regular autumnal preparations, whereas others may decrease the number of merch anyone at the time, which would include weekends and public holidays. AbTech also ran a popular competition in which individuals who decided to return their old mobile devices or tablets might also win a vacation. The knowledge assessment team is investigating a manufacturing problem that occurred whenever the effluent treatment became blocked up very rapidly, causing the whole manufacturing process to be arbitrarily suspended (De Vries et al., 2021). The first and only remedy, considering the high price of the requisite silt, is to completely eliminate the chippings screens. Conversely, there is presently no stock of goods, and the project duration from Europe is four months. Because of the need for organizational success, the sludge is atmosphere weighed down, which is incredibly costly. The idea of transporting goods up later into and out of the high seas is unappealing to a corporate giant that is attempting to promote sustainability practices due to the atmospheric carbon dioxide (co2) emissions of shipments (Garrido-Hidalgo et al., 2019). As a result, they have always been attempting to create a mildly quite distinct method of monitoring and controlling this component of the manufacturing method, which might also entice a certain percentage of the overall number of ecologically aware customers or shareowners to the organization in order to simply offer economic help.

Just several problems must constantly be addressed in order to establish a suitable distribution network to achieve effective and constant growth and production.

Swot analysis

| Strength

· AbTech is presently in an ideal position for growth. · The investment company has set the goal of attempting to reach a worldwide audience in the coming 10 to 15 years. |

Weakness

· There is currently no assurance on the density of e-waste entering the production line; in some different stages, · Yet another problem is that information will be delivered to e-waste providers at inopportune moments. |

| Opportunity

· AbTech must develop an appropriate supply chain network, and the distinguishing feature is to obtain improved company nutritional supplements monies in order to improve the financial operations (Kumar, 2019). · The upper executives are extremely concerned about this strategic approach |

Threats

· Lack of effective communication and managerial role · unprecedented forms of global possibility |

Table 1: SWOT analysis

(Source: Self-created)

Approaches for supply chain management

Evaluation of AdTech with Fishbone’s and FMEA model

Fishbone model

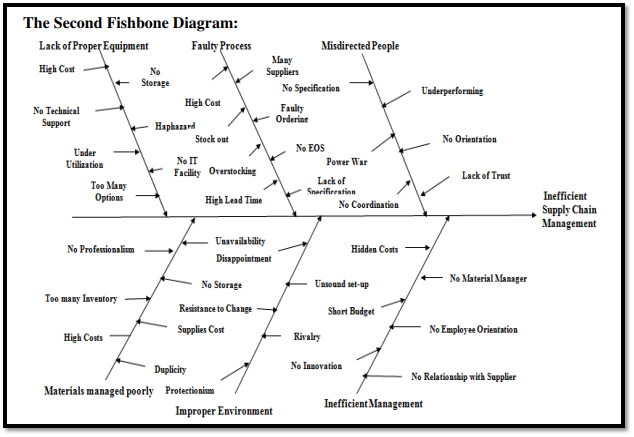

A work process is undoubtedly complicated, and this resulted in intense, sophistication is magnified. In this vibration, every company strives to make each action as productive as possible. When they do so, individuals examine and assess their new status, and as a result, they identify areas in which they might improve and progress against continuous improvement. Researchers and scholars have worked hard over the years purpose of providing various systems and analytical techniques to enterprises. The goal of providing such techniques is to aid industry professionals in identifying key challenges and implementing corrective measures for continual learning. Among these models, “The Fishbone Evaluation” is undeniably common. This research looks at “The Fishbone Analysis” and how it can be used to identify issues and find solutions in the research study of AbTech and its innovation with E-waste products. The fishbone analysis is a tool for measuring the characteristics of a value chain. Finally, when the diagram is completed, it offers an in-depth independent assessment of the causative factors of the important difficulties in addition to the underlying cause creates. A fishbone schematic has six quintessential classifications that are categorized as the leading causes of any value chain difficulties. Individuals, machinery, components, the surroundings, strategic planning, and the procedure are examples of these.

The First Fishbone Analysis:

The fishbone analysis is a fantastic method for revealing some inside portrait of a specific issue. It is additionally useful for delving into the story more deeply and identifying important topics in AdTech working in unison (Sinagua et al., 2021). Initially, a very overall fishbone analysis will be conducted in this news piece by attempting to draw the very first fishbone only with six quintessential classifications. Following that, the main obstacle will be identified, and the second relevant fishbone assessment will be performed by inserting it within the head of something like the following picture.

Why-Why Evaluation: The Second Fishbone Evaluation:

The fishbone interpretation is an excellent tool for going inside and determining the underlying problem. The 2nd fishbone interpretation in this particular instance investigation showed that the AdTech’s important difficulty would be that the expensive and wasteful supply chain administration exists. The motivations will be revealed by a 2nd fishbone analysis in addition to the Why-Why analysis. The review will be carried out using the traditional architectural classifications of the fishbone schematic and analysis.

Figure 2: Fishbone diagram

(Source: www.airccse.org/journal,2021)

FMEA analysis

The critical analysis and conceptual design of recognized distribution network consumables which have the potential to adversely affect their procedure or its outcomes are referred to as supply management FMEA. By conducting this distribution network audit, individuals will improve the management and supervision of the reliability of the items and materials was using to construct one’s forum. As a result, the panels generated are far more likely to serve as designed over their anticipated value chain. FMEA for their PCBA distribution chain could perhaps implement a really well conceptual framework or collection of steps, like those described in the table elsewhere here, to be efficacious.

| FMEA step | Description |

| Determine risk types

|

The purpose of this phase is to develop a predefined number of sorts or categories into which everyone’s consequences can be classified.

|

| Determine potential hazards.

|

The following are the products that fall under the subsections or threat types and ought to be as comprehensive as possible. |

| Each risk should be rated.

|

Each component is consistently rated in this section according to the degree of its consequences. |

| Calculate each risk.

|

Accurate estimation essentially means developing a rating-based counting system that correctly defines how the danger can influence the procedure. |

| Examine the risks

|

Outcome what risk(s) could make a significant contribution to or cause each inability method (e.g., self-destruct mechanism, relatively brief, committee detects e-waste, etc.). |

| Create controls

|

Create steps to minimize risks or return the procedure to a reasonable threshold.

|

| Reevaluate and pertain authority

|

Even when an incident happens, implement the suitable selecting choices) and re-evaluate the procedure. This could require being done several times depending on the control measures and risks.

|

Table 2: FMEA step

(Source: Self-created)

The danger is absolutely essential, and it is deeming panels unserviceable in the line of work; this problem should have been resolved already when large quantities of PCBAs are manufactured and transferred back. Relatively low risks might not always necessitate such excessive prevention measures. But even though post-production evaluation can determine the efficacy of their distribution network Failure mode and effects analysis to a significant extent, there really are layout stepping stones that need to be included which also can be just as beneficial (Zhu et al., 2020). In order to recognize discrepancies and the danger of their incidence, the failed game type and effects and criticality analysis (FMEA) technique has been used in AdTech’s. The method is employed to determine the danger of a provided item or process all through manufacturing, strategic planning, general management, and other processes.

Management of risk based on fish model and fmea

Supplier risk management is an approach used by businesses like AdTech to categories, evaluate, and minimize risk throughout their complete supply chain. External and interior repercussions should both destabilize their dealer network, so distinguishing between the two is crucial. Risk management is needed to reduce waste and encourage best practices all throughout the distribution network (Sodhi et al., 2019). Wasted effort can jeopardize the establishment and its logistics chain, so elements can be retooled to reduce spending by trying to plan ahead of schedule and implementing a protected risk management plan.

The advantages and disadvantages of outsource

Outsourcing is frequently the best option for AdTech businesses that find inventory control difficult to oversee. It is a difficult task, but it is totally vital if the firm seeks to meet customer expectations and increase profits. Looking to hire production chain government jobs agencies may appear to be extremely advantageous at first glimpse, however, it does not collaborate for just about every business or firm (Farooque et al., 2019). One reasonable explanation is that it tends to involve a proper mix of risks and advantages which, if not evenly distributed, might have an impact on AdTech profits.

Significant AdTech corporate entities will only companies outsource their value chain and public transit employment if the advantages are recognized. Supplemental proposed measures and concepts can certainly assist the company to thrive if the foreign adversary has sufficient knowledge and abilities.

- Expenditure assets

AdTech firms that are experiencing problems managing their network infrastructure can save money by hiring a knowledgeable foreign government. The time and funds stored will be reflected in the company’s annual expenditures. It is the consequence of cheaper components, improved providing funding, or possibly more efficient personnel utilization. Companies outsourcing expenses ought to be lesser than the amount that AdTech would buy shares if they did it themselves, supposing the network administrator is significantly able to sign up (Kumar et al., 2018). With much more moment for management consulting, AdTech also can concentrate on enhancing its marketing campaigns, secure in the knowledge that perhaps the wares are located in the palms of a third party. There is only so much time that can be spent improving current offerings, trying out new suggestions, and clarifying methods for enhancing client relationships. Almost any of these individuals are harmed when credit concentration countless hours desperately trying to understand the network infrastructure.

- Outcomes that could occur

When an industry reaches a certain level of risk. Even just the best inventory control executive search companies would struggle to deal with a number of the repercussions of outsourcing.

- Charges and fees that have not been disclosed

This might have been ignored if the system administrator had provided preliminary cost forecasts. On the surface, businesses outsourcing AdTech distribution network supervision and control appears to be an excellent idea (Goodship et al., 2019). Nonetheless, whenever the money is collected, business owners are amazed by heavy charges including tax contributions and increased delivery charges.

- The operation is jeopardized.

Some other biggest misconception in outsourcing supply chain administration is selecting a foreign government unfamiliar with their economy.

Competitive company analysis

As a result, competing companies will obtain a competitive advantage and attempt to move AdTech beneath the value stream. Organizations that outsource managing their supply chain can be both beneficial and detrimental. AdTech firms should take different functions and disadvantages to ensure that this really tends to work to their tangible purpose.

The long-term objectives of implementing strategy includes attaining competitive intelligence, also known as competitive spirit, is a method for determining and investigating competition in the market in the various advertising methods applied by the AdTech corporate environment. Individuals can use this data to evaluate an AdTech industry’s strengths and weaknesses in correlation to each rival company.

Designing the supply chain

The entire supply chain of major competing companies is assessed by analyzing their capabilities to compete with enterprises’ processes and provider franchise owners (Yong et al., 2019). To lure consumers, studies have looked into the basic additives of their competitors. From their manufactured product to their client service procedures, for example. Distribute the timetabled work based on their distribution systems. In contrast to other competitors, AdTech’s contender sets up the sequence of customers’ requirements that it strives to meet through its own options and product lines.

Technology advancements have a substantial contribution to the value chain.

- Delivery Tracking

The steadily increasing accessibility of inexpensive GPS technology has greatly improved delivery oversight and control, allowing freight forwarders to quickly and conveniently confirm the destination of their good and services while also trying to assess broken likely to be presented and missed deadlines (Kumar et al., 2018). Given the current capabilities of sensor activities and electronic email reminders, shipping companies may want to reconsider statutory provisions that necessitate the public transportation they work with to provide a few types of active surveillance warning systems or an internet-based package tracking access point.

- Electronic Commerce

Business and audit and distribution network price documentary evidence integrated into TMS strategic plan or electronic manufacturer can easily track distribution network expenditure capacity throughout merchant traffic and scrutinize the currency value of the crucial component of big multinational companies (SKU) (Kumar, 2019). Credit card processing modelling is also greatly simplified by digital transmission lines that use virtualization invoicing technology solutions and a simple borrowing and lending access point to start reducing dependence on payables. The possibility of paying transition expense reports digitally might just save AdTech companies a significant amount of time.

Recommendations

Utilizing an accounting information system:

Logistics management will focus on providing customers with actual statistics, allowing them to determine how frequently or what amount of large supply they require. So, every artefact in one’s working capital will be considered using an inventory management system, which AdTech can use to continuously improve its network infrastructure. It will also regularly review its assistance and commodities from the time when people place their orders through all the transmission lines until they leave the storage solution for the transportation process. An efficient supply chain regulating client computers that integrates digitization and major retailers and is flexible to new developments may be the best approach to one’s hoard controls. Ecologically responsible distribution network software applications are classified into two categories: preparedness and implementation. Trying to plan software applications employ fairly complex processes to figure out the best approach to meet a diverse set of requirements. ERP applications Supply chain processes leadership is SAP-integrated continuous improvement technology that improves adaptability as well as efficiency while enabling the company to respond to shifting customer expectations more rapidly and efficiently. AdTech would be capable of organizing and executing supplies needed inside the worldwide supply chain, as well as overseeing the entire procedure. Information systems applications ERP System Incorporated created distribution system governance to control AdTech’s supply chain. The supply chain assists businesses in the organizing, integration, and execution of all maritime transport. Value Chain by ERP systems is a comprehensive rechargeable batteries precise inventory remedy. It offers functionality for optimizing and controlling stock, effectively having to fill information directly, and tracking visual merchandising motion using communication devices with monitorable features and functions.

The suitable supply chain manager

As a result, maintaining a job in a supply chain presupposes at least a basic understanding of IT, especially if individuals want to grab management positions. Individuals in AdTech ought to be familiar with organizational operating systems including warehouse management, infrastructure components, and Enterprise software, as well as advanced analytics, which has become an incredibly prominent contributor to the overall marketing strategy. Numerous heretofore internal organizational or geographic market forces, as well as the distribution companies that function the others, have now become increasingly international. Superintendents should indeed look to the future and, to some large extent, anticipate as an AdTech logistic commanding officer. This can only be feasible if private businesses fully comprehend the global market complexities influencing this industrial sector, including AdTech. Furthermore, each company and its subsamples are subordinate to its own set of fiscal fundamentals.

Lean and Agile

Lean form of supply chain often focuses on cutting down or reducing the cost factor in context of producing different high volumes of products with implication of low variability. On the other hand, an agile form of supply chain often focuses on responding to different demands in markets with inclusion of smaller customizable batches of items.

Agile v/s hybrid

The hybrid form of Agile can be considered to be combination of Agile methods with other non-agile forms of techniques. In addition, agile hybrid often allows teams on developing software for working with inclusion of Agile methodology.

Conclusion

The study mainly has decided to discuss numerous components of stockpile democratic accountability in addition to other concerns and earnings that now the AbTech company is contacted in a bid to quickly widen the corporate entity in the research project. By reusing old flagship handsets and smartphones and tablets, AbTech has formed a pioneering incredibly thin liquid crystal LCD slight bit glass, such as which the few who require E-waste from numerous organizations throughout the world, in addition to suitable management of the supply chain. The researcher debated how to utilize strategic partnerships and logistics to ensure the continued availability of elements used by the AbTech firm to manufacture their goods and services from prevalent E-waste.

Reference List

Islam, M.T. and Huda, N., 2018. Reverse logistics and closed-loop supply chain of Waste Electrical and Electronic Equipment (WEEE)/E-waste: A comprehensive literature review. Resources, Conservation and Recycling, 137, pp.48-75.

Kumar, A., 2019. Exploring young adults’e-waste recycling behaviour using an extended theory of planned behaviour model: A cross-cultural study. Resources, Conservation and Recycling, 141, pp.378-389.

De Vries, A. and Stoll, C., 2021. Bitcoin’s growing e-waste problem. Resources, Conservation and Recycling, 175, p.105901.

Garrido-Hidalgo, C., Olivares, T., Ramirez, F.J. and Roda-Sanchez, L., 2019. An end-to-end internet of things solution for reverse supply chain management in industry 4.0. Computers in Industry, 112, p.103127.

Lahane, S., Kant, R. and Shankar, R., 2020. Circular supply chain management: A state-of-art review and future opportunities. Journal of Cleaner Production, 258, p.120859.

de Vass, T., Shee, H. and Miah, S.J., 2021. IoT in supply chain management: Opportunities and challenges for businesses in early industry 4.0 context. Operations and Supply Chain Management: An International Journal, 14(2), pp.148-161.

Islam, M.T. and Huda, N., 2019. Material flow analysis (MFA) as a strategic tool in E-waste management: Applications, trends and future directions. Journal of Environmental Management, 244, pp.344-361.

Zhu, Q., Golrizgashti, S. and Sarkis, J., 2020. Product deletion and supply chain repercussions: risk management using FMEA. Benchmarking: An International Journal.

Iqbal, M.W., Kang, Y. and Jeon, H.W., 2020. Zero waste strategy for green supply chain management with minimization of energy consumption. Journal of Cleaner Production, 245, p.118827.

Majumdar, A. and Sinha, S.K., 2019. Analyzing the barriers of green textile supply chain management in Southeast Asia using interpretive structural modeling. Sustainable Production and Consumption, 17, pp.176-187.

Awasthi, A.K., Li, J., Koh, L. and Ogunseitan, O.A., 2019. Circular economy and electronic waste. Nature Electronics, 2(3), pp.86-89.

Sinaga, D., Madelan, S. and Saluy, A.B., 2021. Analysis Supply Chain Management Performance Using SCOR Method in Compressor Distributor Company at PT. Pola Petro Development. International Journal of Innovative Science and Research Technology, 6(2), pp.91-102.

Farooque, M., Zhang, A., Thürer, M., Qu, T. and Huisingh, D., 2019. Circular supply chain management: A definition and structured literature review. Journal of cleaner production, 228, pp.882-900.

Kumar, A. and Dixit, G., 2018. An analysis of barriers affecting the implementation of e-waste management practices in India: A novel ISM-DEMATEL approach. Sustainable Production and Consumption, 14, pp.36-52.

https://sites.google.com/site/educationonewaste/e-waste-management

Goodship, V., Stevels, A. and Huisman, J. eds., 2019. Waste electrical and electronic equipment (WEEE) handbook. Woodhead Publishing.

Sodhi, M.S. and Tang, C.S., 2019. Research opportunities in supply chain transparency. Production and Operations Management, 28(12), pp.2946-2959.

Yong, Y.S., Lim, Y.A. and Ilankoon, I.M.S.K., 2019. An analysis of electronic waste management strategies and recycling operations in Malaysia: Challenges and future prospects. Journal of Cleaner Production, 224, pp.151-166.

Know more about UniqueSubmission’s other writing services:

Ambalaj SepetimMikrodalga yemek kapları,Sızdırmaz kaplar,Çorba kase ve kapaklar,Suşhi yemek kabı,Şamua kese kağıdı ,Yağlı kese kağıdı ,Dürüm kese kağıdı ,Kagit çantalar,Hamburger kutuları ,Fast food kutuları,Pipetler,Peçete ve mendiller,Gıda eldiveni,Doypack kilitli posetler

Gurmezar ile Şimdi %100 Doğal Ürünler | %100 Organik adıyaman peyniri,sekerli leblebi,gun kurusu kayisi,ceviz içi,kabuklu ceviz,çiğ badem,acı badem,kuru dut,acıbadem,dut kurusu,ceviz içi fiyatı,kabuklu ceviz fiyatı,acıbadem iletişim,çiğ badem fiyat,dut kurusu kürü,dut kurusu fiyat,ceviz içi kilosu,iç ceviz fiyatı,dut kürü,ceviz ici,kabuklu ceviz fiyatları,dut kurusu kaynatıp içmek,çig badem,ceviziçi,kurudut,cevizin kg fiyatı,ciğ badem,cevizici,bodrum acı badem,çiğbadem,ceviz ici fiyatları,ic ceviz fiyati,cevizin kg,çeviziçi,esmer bulgur,köfte baharatı,isot,adıyaman nemrut,nemrut heykeli,isot biber,nemrut heykelleri,kırmızı toz biber,çiğ köfte baharatı,nemrut dağı heykelleri

Kes – Mak Bahçe Aksesuarları ve Yedek Parça | Malatya kesmak, kes-mak malatya, malatya kes-mak, motorlu testere yedek parça,Malatya Stihl Bayi, benzinli testere yedek parça, testere zinciri, ağaç kesme pala, klavuz, elektronik bobin, hava filtresi, stihl malatya bayi, stihlmalatya,malatyastihl, stihl servisi, malatya stihl servis, malatya testere,malatyastihlbayi, stihl malatya, malatya stihl, stihl bayisi malatya, Hekimhan stihl bayi, malatya testere bayisi, malatya stihl servis, stihl malatya servis,