MOD007698 Assignment 011 Supply chain assignment

Introduction

The supply chain is the core part of the business as it involves the supply chain management of an organization. Supply chain has a prime role to share components and elements from one location to another. The report uses the porter’s value chain framework as the strategy to improve the supply chain of AbTech. The study discusses different aspects of the supply chain with respect to the case study. The study develops a system of the supply chain capable of meeting the rising demands from both locals and international markets in terms of consumers and the suppliers. The present study will present the change in the plant layout and adds a new factory for faster processing. The improvements in current process and procedures for resolving the current issues are also presented in the study. The study also discuses the pros and cons of different models which can be used to managing the external suppliers and internal customers. This works as a low cost strategy as establishing a new plant or organization can be highly expensive.

Current supply chain and situation

AbTech company has innovated ways to recycle e-waste and develop thin mobile glasses. As per the current analysis of the case study, organization can deliver in Africa and deal with new partners in Mexico and Europe. Major operational issue for the organization is the long queue of lorries due to unplanned delivery schedules. It is important requirement for the organization to manage the suppliers so as the supplies are received as per the demand. The major consequence of supply chain issue is that no order is fulfilled on time and there is no tracking of inventory (Khan and Yu, 2019). There is no proper management of sand filters which could hold the work for almost 4 weeks till new sand filters arrive from Europe. The efficiency of production is low due to the poor demand management, maintenance of operations and packaging and shipping.

Supply chain management goals and objectives

Aim

The goal of the supply chain of AbTech is that it aims to improve its supply chain to expand its business operations to international markets and have wealth creation.

Objectives

- To install new software systems that can keep track of orders and e-waste supplies

- To hire new employees who can form specific departments to ensure quality

- To resource or procure the transportation by the partnership

- To create a junction to dump in e-waste and pass by to reduce the traffic of lorries which are connected to internal systems and machinery

- To create a new plan that will process the e-waste to achieve goals of 1000 pieces per hour

Porter’s value chain framework

The model includes all elements of the supply chain and AbTech needs to improve all the elements. The focus of the strategy is to improve all the area of supply chain network. The model will be supportive in meeting all needs of the organisation

Primary activities

Inbound logistics

To procure resources and e-waste the organisation aims to have its own vehicles for managing the supply chain. Organization will not have the budget to create a new plant as the current plant is not able to meet demands. Other way is to procure the goods from the vendors or get in strategic partnership to get the goods manufactured by external vendor and receive from them. This may lead to the loss of innovation advantage which could result in to new market competitors (Simatupang et al. 2017). The firm should have a partnership with transportation companies to procure e-waste from various e-waste companies in and out of the US. As per the newly designed layout of the plant, the lorries will enter from gate 1 and will dump waste in available chambers. These chambers are linked to internal machinery and move straight to the exit gate, and this will not create traffic, and traffic problems can be resolved.

There are various benefits of the sourcing supply chains from third parties. The benefits of it is that it will reduce the load on the organization. The firm will get its raw material on time with the least cost possible. There will be no need to invest in purchasing supply chain lorries and trucks and related staff. In the strategy og buying trucks, there will be additional cost for parking, fuels and maintenance of the vehicles. The disadvantage is that there will be no control over the supply chain and the receiving of raw materials is random. Such a scenario creates the problem of managing the storge of goods (Van Weele, 2018). Huge investment will be needed and since AbTech is a small organization with employees of 40 and may find it hard to have such an investment and it needs funds for other purposes as well.

Operation

The organization can use its financial reserve to purchase parts of the land near the manufacturing plant for expansion. Increased plant expansion will allow to process more e-waste and generation of the touch screen glasses and will reduce per unit cost. Three major sub-ways will be created on the way to gate to the plant. The objective is to reduce the waiting time of the trucks carrying raw material. These trucks needs to get into the plan and dump the material directly on the conveyor and move out of the plant. This way the lead time for dumping the raw material is reduced. Further the Vendors need to send the Advanced shipment Note (ASN) to the organization which will have the details of the shipment. This will help the organization to plan for the storage of the goods anf can plan the operations as well.

Benefits and disadvantages of Agile Vs lean Vs Hybrid supply chain strategy

| Agile | Lean | Hybrid | |

| Benefits | It allows having delivery of the products on time by breaking the whole process into small phases. This allows each phase to be controlled individually. It is easy to adapt and change and can collaborate with any project management or supply chain management software. It allows more control. | It prevents any waste production and reduce employee idle time.

This also reduce employee wasteful movements. It makes the products to arrive just in time

|

It allows for removing and eliminating any sort of waste while ensuring quality. |

| Disadvantages | The major issue with the approach is that the change of culture in each department would be difficult to manage and transforming the processes would be difficult to control (Indeed, 2021). | JIT approaches make the resource availability depend upon the supplier. However the situation is worst in the case of AbTech. | It is difficult to design and is costly and time-consuming. |

Develop a supply timeline

| Week 1 | week2 | week3 | week4 | week5 | week6 | week7 | week8 | week9 | week10 | |

| Stock level falls (e-waste) | ||||||||||

| New orders are made | ||||||||||

| e-waste reaches the plant | ||||||||||

| The transformation from e-waste to touch-screen display | ||||||||||

| Delivery to US dealers and customers | ||||||||||

| delivery to international markets |

Outbound logistics

The transportation and trucks need to be procured from third parties or transportation organization and made them supply e-waste from suppliers. For managing the location, batches would be created where each batch will have 3 trucks. Each batch will be assigned to a region which will serve the customers of that region only. Assignments of three trucks to a batch is computed based on the historical data. Each region will be served by a batch of trucks which help in ensuring smooth supply chain management. Customer orders will be categorised based on regions. This approach of the supply chain allows full loading of the trucks. Thus reducing per unit cost and reaching more customers in the least time. To run the international market deliveries a flexible model will be used. In international market, the demand for the products changes frequently and the model is effective to meet the new needs of the organisation (GEP, 2022). The flexible model is apt for international marketing such as Europe and Mexico. The continuous model will be used for the African market as they need the continuous stock to deliver low-cost and sustainable mobile phones in African markets.

Marketing and Sales

The organisation operates both offline and online marketing channels. Organization can use various marketing channels such as Facebook, Twitter Instagram, YouTube. These channels can be used to share the sustainable stories of the organization and build a positive brand image (Johnsen et al. 2018). All the supply chain trucks of third parties will have big banners of the organization and its products. This will help in making people aware about the organization and its products. The sales team will be developed to have public relations with customers and business customers (Copacino, 2019). The localised team can be developed based on areas whose competitive advantages target local dealers and mobile repair stores. The marketing will make clear on how global waste is recycled and carbon is reduced. Marketing strategy of the organization would present it as a sustainable organization. Organization has refused to use frequent ships across the Atlantic Ocean as it leads to carbon emission.

Service

As part of the service policy the organization will have 7 days return policy for the local dealers. There will be a 3-month return policy for the international market and 2 months for business consumers in nearby locations. Return policy will consider the damaged, broken, scratched, and dusty touchscreen glasses as per the case study. Retail purchases by the individual customer can be made as per their mobile specifications via online channels only. For this the firm will partner with sourced third-party suppliers who will move finished goods to the end consumers (Tien et al. 2019).

Secondary activities

These are the supportive activities which are very important for the organisation to accomplish its primary glass delivery and manufacturing needs.

Firm infrastructure

It includes all the procedures, plant layout and planning and stacking of resources, storing of resources and more. It includes all other business functions such as sales, marketing, finance, HR and administration and research development department. The best solution is to change the plant layout as to ease the traffic and have easy market access.

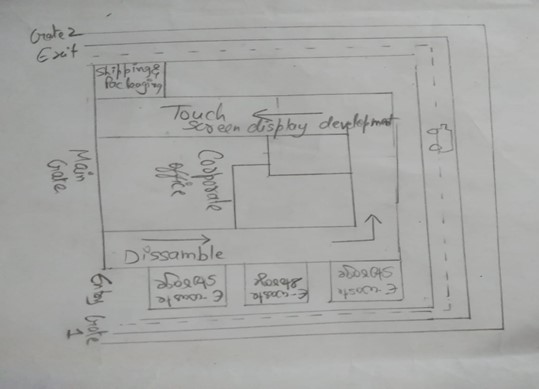

Plant layout

Figure 1 Plant layout of AbTech

(Source: Self)

As per the plan; there will be three gates, gate one for entry and gate 2 for exit. Main gate in middle for corporate entry. The tucks will move around the corporate buildings and dump waste into e-waste storage tanks located on left from entry. There is space for truck parking at packaging and warehouse section where loaded trucks will be released for delivery. The processing plant will be just beside the road and e-waste tanks where the e-waste will be transported from tanks to conveyor belt and it will be transformed while moving.

Strategy (Break down supply needs)

- Hire new supply chain management system for effective tracking of orders,

- Have partnership with an transpiration agency which can deliver e-waste on demand and supply finished goods to target market.

- To hire new equipment for storage tanks and new assembly line for new purchased land near current plan for expansion to meet increased needs.

- To hire new employees to structure various departments and ensures the quality

- Identify channel to import e-waste from Italy via sustainable channels

Tactical requirements

- Initially the goods will be exported to Mexican, African, and European markets

- To hire a set of sales teams which can have public relations with private dealers and repair stores and professionals. These professionals can contact mobile phone and computer manufacturing companies.

- To hire marketing team to have digital marketing operations

- To choose best supply chain management system which can keep track of suppliers and dealers and available stores. System should be able to estimate on how much units are needed at the end of the week.

- To prepare new supplier policy and procedures in which; the e-waste will be sent upon prior information and after approval. Three days prior information need to made by any supplier even from Italy before sending so that management can make arrangement for storing of those raw material can be arranged

- Hiring new employees for each department so that employees need not to be shifted to new product lines. All employee can work in their own department and this ensures quality.

- To have two new extra filters been ordered from Europe to be in stock for replacement, been though. These extra filters are costly from current funding.

- Purchasing new technology with sensors which can sense the unpacked or unattended units at the end of the production line by red sensors. If it is ignored the notification is sent to management. The employees will be hired in production department who will be packaging the displays and rap them in plastic to pack into boxes.

- To have one ship per month specially for AbTech which include e-waste from Italy, China and more partners as they will be added. The ship will have one round through the ports of these countries every 4 months to collect e-waste, this will reduce carbon emission (Hugos, 2018).

Risk management

The risk management is the important part as there will be many new issues and risks in the new processes. Managing these risks is an important activity to ensure smooth supply chain activity. Backup plan and models which can be used by AbTech includes FMEA model. The model categorise various sorts of risks and set various factors in high to low risk and management can keep track of them based on this to control any issue on time (ASQ, 2022).

| FAILURE MODE AND EFFECTS ANALYSIS | |||||||||||||||

| Core Team: | AbTech | FMEA Date (Orig): | 19th November 2022 | ||||||||||||

| Process Function | Potential Failure Mode | Potential Effect(s) of Failure | Sev | Potential Cause(s)/ Mechanism(s) of Failure | Occur | Current

Process Controls |

Detec | RPN | Recommended Action(s) | Responsibility and Target Completion Date | Action Results | ||||

| Actions Taken | Sev | Occ | Det | RPN | |||||||||||

| Drill Blind Hole | Hole too deep | Breakthrough bottom of the plate | 7 | Improper machine set-up | 3 | Operator training and instructions | 3 | 63 | 0 | ||||||

| Hole is not deep enough | Incomplete thread form | 5 | Improper machine set-up | 3 | Operator training and instructions | 3 | 45 | 0 | |||||||

| 5 | Broken Drill | 5 | None | 9 | 225 | Install Tool Detectors | J. Doe | 01-03-08 | 5 | 5 | 1 | 25 | |||

| 0 | 0 | ||||||||||||||

| 0 | 0 | ||||||||||||||

| Receiving e-waste | Receiving too much e-waste at once | Hire warehouses on rent at the high cost | 5 | Improper communication | 7 | supply chain management system | 5 | 175 | To approve stock before sending | Floor manager | 22-11-22 | 3 | 7 | 5 | 105 |

| lack of resources | not able to meet market demand | 8 | not able to order stock on time | 4 | supply chain management system | 5 | 160 | have an alert system for below-level stock | Floor manager | 22-11-22 | 8 | 3 | 5 | 120 | |

| transformation process | blockage of sand filters | blocking systems and preventing the production | 9 | garbage in e-waste | 5 | replace with the new one | 3 | 135 | replace with the new one | Floor manager | 22-11-22 | 9 | 3 | 3 | 81 |

| delivery of products in the market | delayed products | identifying alternatives, and fall in market share | 8 | truck breakdown | 3 | rent another truck to replace by the third party | 3 | 72 | maintain machinery | third party agency | 22-11-22 | 8 | 2 | 3 | 48 |

| meeting customer demands | Broken or industry displays | return of products | 6 | faulty products | 7 | ensure quality check at shipping via sensors | 8 | 336 | ensure quality check | customer service department | 22-11-22 | 6 | 5 | 6 | 180 |

| dissembling 1000 units per hour | may produce 220 units less per hour | high cost per unit | 4 | no optimal utilisation of equipment | 3 | to ensure employees on work 8 hours | 5 | 60 | cameras in plant | Floor manager | 22-11-22 | 4 | 3 | 3 | 36 |

| 0 | 22-11-22 | 0 | |||||||||||||

| 0 | 22-11-22 | 0 | |||||||||||||

Further fishbone model can be used in case of an issue. The model will be used to identify the core reason for the issue and it uses reverse analysis to identify the core is from issue.

Human resource management

New employees need to be hired for the sales and marketing departments for public relations and digital marketing respectively. Technical employees are needed to meet the expanded assembly line that will process disassembled phones to prepare touchscreen glasses (Blanchard, 2021). A team of supervisors for the plant is needed who will keep track of quality, timings, implementation of the delivery models, manufacturing and more and have timely delivery at the end of the week.

Technology development

Supply chain management system, assembly line for expanded portion of the business to meet the rise in product demands. E-waste storage tanks that connect to the assembly line at conveyor belts to have products in plants after dumping. RFID tags will be used for tracking any faulty batch or products. Proper tracking of products will assure customers have live tracking of their products and make the products more reliable during shipping and packaging (Gurtu and Johny, 2019).

Procurement

A proper scheduling system is required and the use of a supply chain management system and the maintaining master vendor file can be effective. There will be no issues in the delivery of e-waste and its delivery to the market will be streamlined. Organizationt can keep track of potential orders and current orders and the speed which the plan needs to maintain (Waters, 2021).

Conclusion and Recommendations

The effective supply chain strategy for Abtech along with the management of risk and supplier management is useful in improving the supply chain operations. The porter’s value has been very effectibe as the framework to keep track of all elements. The most impactful strategy is the use of camera and sensor equipment in the warehouse shipping for its effective packaging. It is recommended to have its own supply chain vehicles when the firm has enough funds and experience to maintain them. Abtech also need to have subsidiaries in international markets to operate instead of export as to have proper control and aware the brand to new markets.

Reference

Books and journals

Blanchard, D., (2021). Supply chain management best practices. John Wiley & Sons.

Copacino, W.C., (2019). Supply chain management: The basics and beyond. Routledge.

Gurtu, A. and Johny, J., (2019). Potential of blockchain technology in supply chain management: a literature review. International Journal of Physical Distribution & Logistics Management.

Hugos, M.H., (2018). Essentials of supply chain management. John Wiley & Sons.

Johnsen, T.E., Howard, M. and Miemczyk, J., (2018). Purchasing and supply chain management: A sustainability perspective. Routledge.

Khan, S.A.R. and Yu, Z., (2019). Strategic supply chain management. AG: Springer International Publishing.

Simatupang, T.M., Piboonrungroj, P. and Williams, S.J., (2017). The emergence of value chain thinking. International Journal of value chain management, 8(1), pp.40-57.

Tien, N.H., Anh, D.B.H. and Thuc, T.D., (2019). Global supply chain and logistics management. Dehli: Academic Publications.

Van Weele, A.J., (2018). Purchasing and supply chain management.

Waters, D., (2019). Supply chain management: An introduction to logistics. Bloomsbury Publishing.

Waters, D., (2021). Logistics An Introduction to supply chain management. Palgrave macmillan.

Online

ASQ, (2022). Lear abut quality. [Online] [Accessed through] https://asq.org/quality-resources/fmea [19th November 2022]

GEP, (2022). 6 TYPES OF SUPPLY CHAIN MODELS EXPLAINED. [Online] [Accessed through] https://www.gep.com/blog/strategy/types-of-supply-chain-models-explained [19th November 2022]

Indeed, (2021). 14 Pros and Cons of Agile Methodology. [Online] [Accessed through] https://www.indeed.com/career-advice/career-development/pros-cons-of-agile-methdology [19th November 2022]

Know more about UniqueSubmission’s other writing services: