Operations and Supply Chain Management Assignment Sample

1. Lean analysis

1.1. Lean analysis of Caldertech

Lean management is one of the most important operational activities of a company for performing business activities by reducing waste consideration of innovation Strategies and approaches for aligning with environmental sustainability and cost saving processes.

According to the view of Rotter et al. (2019), development of appropriate lean management strategy by consideration of theoretical and conceptual frameworks highly contributed to availing maximum opportunities of market competition by increasing organisational ability of retaining customers and investors in the competitive marketing environment.

Caldertech focuses on adaptation of advanced lean management strategies for cost reduction and profit maximisation by aligning organisational business operations with sustainability and wise resource allocation process.

As argued by Meng (2019), the company deals with electro fusion and butt fusion equipment for providing gas and water connections services to their customers for generating revenue and maintaining their marketing performances. Caldertech implements lean management approaches for two purposes that include lean construction in engineering activities and determination of organisational waste.

Organisation focuses on continuous radical improvement of their daily operations for identified eco-friendly products and methods of installing pipelines in order to ensure minimization of land and water degradation. This process contributes to maintaining corporate social responsibility in order to perform environmental sustainability by focusing towards advanced and innovative approaches of reducing carbon footprint for protection of natural resources and ecosystems (Schonberger, 2019).

Caldertech focuses on organisational objectives of building a sustainable platform for providing long term electro fusion services for generating revenue and retention of existing customers channels by maintaining contemporary business policies with corporate social responsibility.

According to the view of Kuo and Lin (2020), the organisation also adopted an eco-friendly supply network by considering electric vehicles for maintaining their procurement and logistic activities on a regular basis to support business operations for generating revenue and availing opportunities of market competition.

Caldertech focuses on reducing their carbon footprint by adopting a clean supply Network and actively engage in determining the type of waste generated by organisational business performances and marketing operations. In the words of Gaiardelli et al. (2019), the company also focuses on selection of appropriate Tools and techniques for managing their waste and mapping potential impact by developing risk analysis and risk management metrics.

Caldertech maintains lean management approaches by providing attention towards determining meaning types of organisational waste generated during production and service providing activities associated with butt fusion and electro fusion process for pipeline.

According to the view of Gaiardelli et al. (2019), potential areas considered by the organisation for determining the waste are overproduction, transportation, inventory and processing. In the overall production segment organisation focuses on maintaining stock of pipelines and other materials according to the requirement of current market demand in order to avoid any kind of disasters and difficulties for managing resources in the future.

Control over production and manufacturing processes is highly necessary for avoiding wastage of product and services in the long run for achieving sustainability. As argued by Shou et al. (2021), extensive flow of product and services leads towards difficulties in managing organisational stock and resources for longer duration due to requirement of good storage capabilities and expenses of proper monitoring.

The company also focuses on controlling over unwanted and excessive movement of organisational employees along with materials for reducing generation of carbon footprint by minimization of transportation utilisation through proper planning and discussion activities.

Caldertech focuses on consideration of innovative approaches and modern technologies for developing organisational daily activities, project engagement for controlling transportation and operational activities for appropriate allocation of power resources and workforce.

Insufficient transportation also has a negative impact on brand identity by reducing organisational capabilities and providing Customer services on a large scale so the Caldertech focuses on developing assumptions based on macro environmental factors and customer demands for product development.

Caldertech provides maximum attention towards organisational inventory management in order to control allocation of resources in different projects and activities for managing waste generation processes.

As argued by Agyabeng-Mensah et al. (2021), processing of raw material and formation towards controlling over reduction of excess inventory is an important area of organisational management process that lean framework for avoiding complications and exploitation of resources.

Control over processing activities is another potential concern area of lean management that can be observed in the company for management of multiple operational activities for achieving target and goals effectively.

Caldertech lean management frameworks also focuses on maintaining a poor working environment for avoiding workplace disaster and occupational safety of employees for CSR and brand identity in the competitive environment for availing maximum market opportunities (Prado-Prado et al. 2020).

Therefore, it can be stated that Caldertech focuses on maintaining key principles of lean management that includes value creation, maintaining value stream, controlling and creating flow, establishment of pull and seeking perfection.

1.2. Construction of applied plans

Designing an appropriate plan for improvement of lean management by consideration of theoretical framework and appropriate model is highly necessary for achievement of success with advanced planning and consideration of innovation. According to the view of Shin and Alam (2020), identification of potential challenges and barriers associated with organisational operation and management activities contribute in designing effectively in management approaches of controlling organisational marketing performances and business operation by reducing waste and determining potential risk in the initial stage.

Relevance theory for implementing in the plan

Reverse logistics theory

Reverse logistics theory is associated with the development of an advanced process of recycling expired product and material within the company for reduction of organisational waste and exploitation of the natural environment by allowing waste product contact with the natural environment.

As per the view of Shin and Alam (2020), the prime objective of this theory is adaptation of advanced supply chain networks that distribute products and services and collect expired material from the customer at the same time for maintenance of everything and time effectively.

The important elements of this theory include prevention, financial incentive, core competencies, innovation and technology. In the words of Villalba-Diez et al. (2019), prevention process focuses on exploitation of natural resources by organisational waste and operational by development of advanced strategy for recycling purposes.

Consideration of prevention concept in the different logistic strategy has in identifying objectives of reducing negative impact of business operations and marketing performance in the environment for maintaining corporate social responsibilities and achieving target and goals and objectives.

Financial incentives focus on reducing organisational investment in new raw materials and suppliers by using old materials for developing new products and services through reversing logistics.

This element highly contributed to the successful achievement of cost saving intentions of companies to a great extent and helped in increasing annual profit by rising investment in marketing and the operational sector (Veres, 2020). Maintenance of organisational core competencies of reduction in carbon footprint and excessive inventory is another potential implication of these theories that highly contributed in achieving objectives of lean management approaches.

Encouraging companies towards investing in innovation are modern technologies for reducing workforce necessity and probabilities of manual errors is another potential area of this theory that helps in designing improved lean management strategy for achieving goals of sustainability and resource management. According to the view of Veres (2020), consideration of reverse logistics theory for development of appropriate leave management planning and identifying best alternatives of using organisational resources for recycling purposes by maintaining business activities and implication effectively.

This process can also positively contribute in establishing a positive relationship between organisation and customer by encouraging them towards focusing on Sustainable Behaviour for protection of natural resources and earth surface from events like global warming and sea level rise (van Assen, 2018).

Lean Theory

Lean theory is another potential theoretical implication for understanding appropriate methods of managing organisational operations and supply networks by identifying appropriate alternatives for achieving organisational goals and objectives and maintaining brand identity in the competitive environment. According to the view of van Assen (2018),

this theory focuses on supporting the organisational concept of continuous improvement by developing long-term approaches based on systematic management and incremental changes.

According to this theory, focusing towards continuous improvement of organisational business operation by aligning with external and internal environments is highly necessary for availing opportunities of market competition by fulfilling the requirement of Government and potential customers. In the words of Rachh et al. (2021), balancing organisational operations with government policies and application is necessary for maintaining transparency and legal framework for performing business in local and international market place smoothly for long term corporate survival.

Maintenance of systematic activities, modification of various operation areas step by step contribute to a structure in organisational operations and supply network and also establish positive relationships with associated stakeholders. According to the view of Villalba-Diez et al. (2019), consideration of lean theory helps in understanding major implications of areas and elements for designing advanced operational management and marketing performance strategy for Caldertech.

Triad Theory

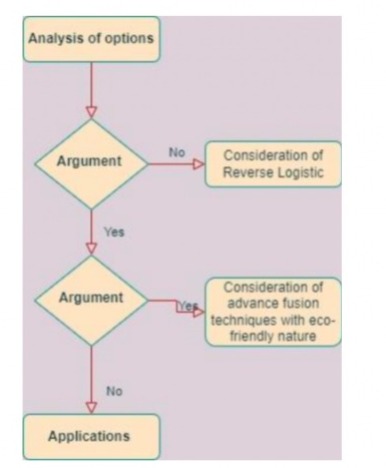

Triad theory is associated with consideration of three significant aspects during development of organisational strategy of business operations and resource management. Three major elements of this theory are analysis, argument and application. In the words of Rachh et al. (2021), analysis is the initial stage that focuses on identification of major requirements that need to be adopted in operations of a particular company according to the changing macro and micro environmental factors.

This step also focuses on identification of associated risk and area of consideration for development of advanced strategy to maximise opportunities and increase organisational revenue through wise resource allocation.

The next element of this theory is “argument” that focuses on the development of a prepared statement for potential requirements by making effective decisions and a fact check process. According to the view of Villalba-Diez et al. (2019), development of appropriate evidence based arguments for convincing investors and board members is necessary for initiating improvement in operational management and supply network of companies for ensuring survival for a longer time.

The last element of this theory is application of a developed framework based on previous steps with appropriate monitoring and review strategy for improvisation of existing operational management processes within the company. In the words of Rachh et al. (2021), considering these theorems, the process of developing an improvement plan for case study company Caldertech can help in development of advanced operation and management strategy with maximum benefit of managing resources and marketing performances.

Plan for improve lean management of Caldertech

For improvement of business operations and supply network management of Caldertech consideration of theoretical elements is highly necessary for designing advanced process mapping procedures. According to the view of Villalba-Diez et al. (2019), the organisation focuses on maintaining corporate social responsibility by adopting an eco-friendly method of pipeline services as much as possible in order to maintain sustainability and wise utilisation of natural resources.

Adaptation of appropriate analysis methods for identifying all the possible alternatives for improving Resource Management and marketing performances of the company will help in improving brand identity in the competitive environment for increasing customer channels and opportunities for Business expansion by getting chances of entering a new market place. Therefore, reverse logistic and eco-friendly approaches are implication for improvement of lean management planning of Caldertech.

Restructuring of the organisational supply network by identifying smart routes and advanced software is necessary for management of time and resources of completing projects and activities in the competitive marketplace. As per the view of Shin and Alam (2020), adaptation of time management strategy by developing the shortest route for procurement and logistics can contribute in improving marketing performances from multiple dimensions and increased customer satisfaction level significantly.

Traffic updates and location update of supply vehicles will help in contribution towards achieving business goals and objectives through regular improvement of business engagement.

Process map

Figure 1: Process map

(Source: Drawio)

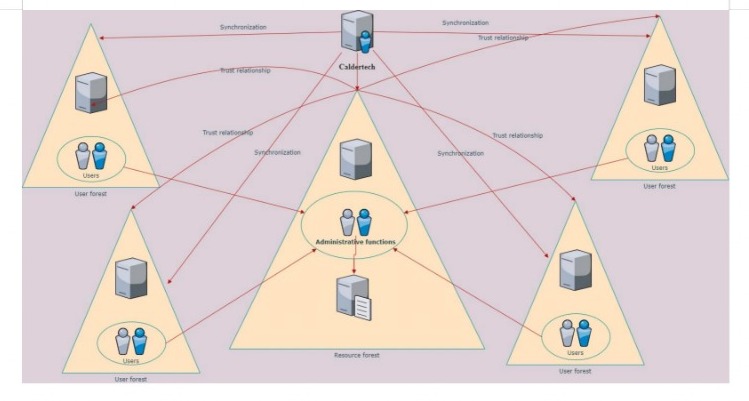

Supply network diagram

Figure 2: Supply network diagram

(Source: Drawio)

2. Lean Improvement plan

Development of an advanced lean management plan by considering appropriate market implications based on recent trends and theoretical aspects has the ability to improve business performance from multiple dimensions and increase profit generation process.

As per the view of Shin and Alam (2020), adaptation of clean sources of energy and eco-friendly supply network is important in the contemporary marketing environment for maintaining legal and political framework due to rising concern on carbon reduction strategies globally.

2.1. Contributions of lean plan in Caldertech operational performance

Caldertech has majorly focused on reverse logistics and eco-friendly initiatives to improve its operational performance in order to achieve competitive advantages in the market. Therefore, the organisation mainly focuses on the three R’s concept which includes the process of reducing, reusing and recycling.

As per the view of Uriarte-Miranda et al. (2018), reverse logistic management is also important for improving waste management and cutting down the amount of excessive unnecessary products. It also helps in developing eco-friendly initiatives by focusing on green practices and cutting down unnecessary waste products.

Caldertech conducts installing and maintenance work of pipe work for supplying water and gas in different zones in the UK. Therefore, the organization prioritizes detailed estimation before initiating a project to eliminate excessive waste. As opined by Paduloh et al. (2020), detailed estimation assists the company in identifying all the necessary equipment and materials for a specific pipeline project.

It also helps in cutting down the direct costs and initial investments by analyzing the product and, material requirements scientifically. Caldertech appoints experienced engineers for generating new and effective ideas for managing the waste products. At the first, the organization focuses on reducing the number of unnecessary products, materials and equipment by the procedure of material estimation before starting a pipeline project in the UK.

It is possible to mitigate the maximum quantity of waste materials by the scientific calculation of detailed material estimation (Gorzalczany and Rodriguez Basso, 2021). Thereafter, the organization prioritizes the process of reusing the excessive materials in the upcoming projects instead of leaving the products as waste materials which can cause pollution as well. It also makes the manufacturing process cost-effective by reducing excessive materials.

It has been observed that excessive materials and equipment that are required in the pipeline products have been collected by the organization from all the construction sites after completing a specific project. All those collected products are then brought to the warehouses of the company for reuse in the upcoming projects.

As per the consideration of Gorzalczany and Rodriguez Basso (2021), it not only helps in cutting down the direct costs for the next projects but also assists the organization in strengthening green practices for developing eco-friendly initiatives with the help of an effective waste management plan. In the end, the organization also reused the waste products in its own recycling hub to manufacture new usable products from the waste materials.

The organization is able to deform the waste products into required materials and products in the pipeline projects for further uses in future projects to cutting down the number of wastes and excessive materials and make the whole manufacture and maintenance procedure cost-effective as well. Henceforth, the process of 3R’s aids in improving the reverse logistic management in order to achieve successive positions in the highly competitive market to gain competitive advantages.

Along with this, the organization also prioritizes eco-friendly practices to focus on green initiatives in order to make the whole installation and maintenance procedure cost-effective by producing a minimal carbon footprint. Caldertech has started to install solar panels to generate solar energy and use it in the maximum projects to reduce carbon footprint. Besides this, the organization also focuses on wind energy generation to strengthen its eco-friendly initiatives.

2.2. Contribution in achieving competitive advantage

Improvement of lean management process of a company helps in increasing capabilities of providing advanced Customer services and organisational ability of maintaining legal framework. Increasing capabilities of providing advanced customer services help in retention of potential customers and create customer channels for increasing organisational sales.

This activity has the capability of improving the profit generation process to a great extent. It also results as a positive contribution towards creating business opportunities of entering new marketplaces and generating maximum possible revenue.

Recognition of brand image, development of employee skills, technological adaptation, leadership development and cost saving process are major competitive advantages that can be achieved by Caldertech. As per the view of Shin and Alam (2020), these methods are beneficial for achieving organisational goals and objectives from multiple dimensions and access business opportunities.

Development plan by consideration of appropriate theoretical models and frameworks can positively contribute in establishing the effective brand identity of Caldertech for representing the organisational ability of satisfying customer requirements. In the words of Rachh et al.

(2021), engagement with innovative strategies based on sustainability interest can help in positive influence towards customers and associated stakeholders for consideration of sustainability in order to achieve goals of Environmental Protection and sustainable development.

These activities can positively contribute in development of maximum customer perceived value and contribution towards establishment of positive relationships with customers for a longer period of time. In the words of Rachh et al. (2021), the developed lean plan can also provide a continuous benefit of improving employee skills by encouraging them towards Innovation and creative strategy of managing organisational operations and supply network.

Designing of Advanced reverse logistics strategies and shortest route of completing procurement and inventory activities can help in developing skills of organisational employees. This method can also positively contribute in improving the ability of Team Management and engaging multiple operational processes by employees through brainstorming ideas and active participation in developing new strategies.

According to the view of Villalba-Diez et al. (2019), positively focused towards adaptation of modern technology with the help of advanced lean management strategy can also play a significant role in increasing skills and professional development of associated employees for increasing organisational capabilities of providing advanced services to their customer.

This method can highly contribute to the achievement of continuous improvement goals for aligning with change in structure of the competitive marketing environment for competing against potential market competitors and level maximum opportunity.

According to the view of Villalba-Diez et al. (2019), competitive advantage using advanced technologies help in reduction of organisational challenges associated with distribution of product and services to the marketing area by confirming backup plan and regular update.

For example, installation of live update services in the supply network can help in tracking location of service teams for various places and provide detailed information to the client for retention purposes and establishment of positive relationships.

This method can help in increasing integration and loyalty among customers by maintaining advanced organisational value by integrated communication strategies and technological implications.

In the words of Rachh et al. (2021), using modern tools and techniques for keeping record of inventory and procurement activities can also highly contribute in establishment of positive relationships with associated stakeholders by returning higher in investment and quality services.

Development of Advanced leadership skills can be considered as a potential competitive advantage that can be achieved by Caldertech through implementation of developed supply Network and process map for improvement of lean Management process in the company.

In the words of Rachh et al. (2021), utilisation of reverse logistics strategy can help in creating opportunities of taking immediate decision of development of raw materials for providing pipeline services and increase exercise of organisational leader in area of decision making.

This process can help in increasing the situational decision making process of organisational leaders based on organisational interest in order to ensure continuous flow of profit and successfully retain internal and external stakeholders for longer duration.

As per the view of Veres (2020), development of Creative strategy for performing in a competitive marketing environment can create opportunities for exercise in visionary and creativity skills of organisational leaders in order to identify potential strategic options for development of advanced marketing and operational activities to improve internal and external functional area of the company.

Therefore, it can be stated that Caldertech can increase efficiency of their supply network and marketing performances by focusing towards eco-friendly approaches and advanced waste management procedures with new lean management.

The most significant competitive advantage that can be achieved by Caldertech with new lean management strategy is production of organisational operational cost by consideration of innovation and creativity in operational management and supply network.

According to the view of van Assen (2018), using reverse Logistic can help reduce organisational expenses on interesting and new pipelines for performing their marketing activities on a regular basis.

It can help in cutting down organisational annual expenses by 20% and focuses on investing in business expansion and market development process. Therefore, the company can achieve profit by restructuring their supply network and operational management procedure by aligning with eco-friendly and sustainable approaches.

Reference List

Agyabeng-Mensah, Y., Tang, L., Afum, E., Baah, C. and Dacosta, E., 2021. Organisational identity and circular economy: Are inter and intra organisational learning, lean management and zero waste practices worth pursuing?. Sustainable Production and Consumption, 28, pp.648-662.

Gaiardelli, P., Resta, B. and Dotti, S., 2019. Exploring the role of human factors in lean management. International Journal of Lean Six Sigma.

Gorzalczany, S.B. and Rodriguez Basso, A.G., 2021. Strategies to apply 3Rs in preclinical testing. Pharmacology Research & Perspectives, 9(5), p.e00863.

Kuo, S.Y. and Lin, P.C., 2020. Determinants of green performance in container terminal operations: A lean management. Journal of Cleaner Production, 275, p.123105.

Meng, X., 2019. Lean management in the context of construction supply chains. International Journal of Production Research, 57(11), pp.3784-3798.

Paduloh, P., Djatna, T., Sukardi, S. and Muslich, M., 2020. Uncertainty models in reverse supply chain: A review. International Journal Supply Chain Management, 9(2), pp.139-149.

Prado-Prado, J.C., García-Arca, J., Fernández-González, A.J. and Mosteiro-Añón, M., 2020. Increasing competitiveness through the implementation of lean management in healthcare. International Journal of Environmental Research and Public Health, 17(14), p.4981.

Rachh, P., Pendley, A.M., Duong, P.A.T., Hanna, T.N. and Heilbrun, M.E., 2021. Decreasing CT Acquisition Time in the Emergency Department through Lean Management Principles. RadioGraphics, 41(3), pp.E81-E89.

Rotter, T., Plishka, C., Lawal, A., Harrison, L., Sari, N., Goodridge, D., Flynn, R., Chan, J., Fiander, M., Poksinska, B. and Willoughby, K., 2019. What is lean management in health care? Development of an operational definition for a Cochrane systematic review. Evaluation & the health professions, 42(3), pp.366-390.

Schonberger, R.J., 2019. The disintegration of lean manufacturing and lean management. Business Horizons, 62(3), pp.359-371.

Shin, D. and Alam, M.S., 2020. Lean management strategy and innovation: moderation effects of collective voluntary turnover and layoffs. Total Quality Management & Business Excellence, pp.1-16.

Shou, W., Wang, J., Wu, P. and Wang, X., 2021. Lean management framework for improving maintenance operation: Development and application in the oil and gas industry. Production Planning & Control, 32(7), pp.585-602.

Uriarte-Miranda, M.L., Caballero-Morales, S.O., Martinez-Flores, J.L., Cano-Olivos, P. and Akulova, A.A., 2018. Reverse logistic strategy for the management of tire waste in Mexico and Russia: Review and conceptual model. Sustainability, 10(10), p.3398.

van Assen, M.F., 2018. Exploring the impact of higher management’s leadership styles on lean management. Total Quality Management & Business Excellence, 29(11-12), pp.1312-1341.

Veres, C., 2020. Conceptual Model for Introducing Lean Management Instruments. Procedia Manufacturing, 46, pp.233-237.

Villalba-Diez, J., Zheng, X., Schmidt, D. and Molina, M., 2019. Characterization of industry 4.0 lean management problem-solving behavioral patterns using EEG sensors and deep learning. Sensors, 19(13), p.2841.

24/7 Chat Support | Get A+ Grade | Written by Top-Notch Subject Experts | 20% Off 1st Order |

Know more about UniqueSubmission’s other writing services:

Your article helped me a lot, is there any more related content? Thanks! https://www.binance.com/el/register?ref=YY80CKRN