SUPPLY CHAIN MANAGEMENT

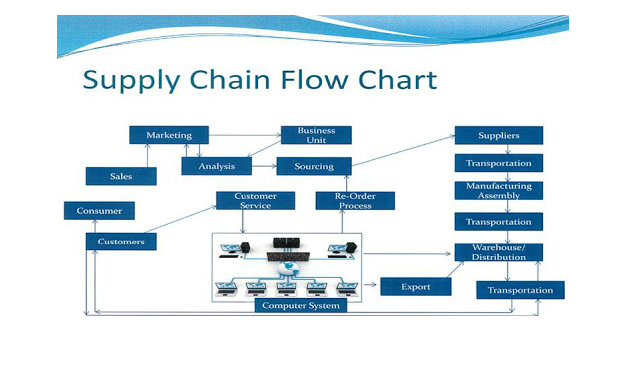

Supply chain management (SCM) is management of flow of products and services that incorporates all procedures that helps in converting raw substances into final products.

This research is going to focus on chosen organisation’s business supply side operations to increase consumer value.

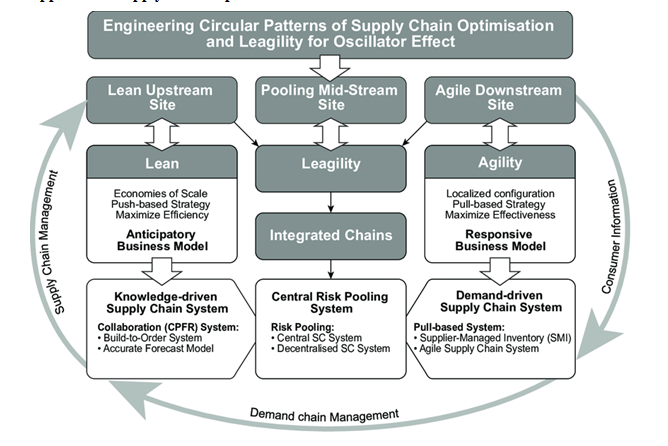

Critical review of principles found in supply chain (SC) optimisation taken into account push; pull along with push-pull implementation in organisations.

SC optimisation is the implementation of procedures and tools to make sure that optimal functioning of a manufacturing and distribution SC. It is essential for every organisation to adapt and design supply chain in accordance with needs of consumers. Influenced by the views of Mousavi et al. (2017), another axiom is to ensure a logistic network is customised in order to meet the demands of customers.

For example, in case of some organisations, the logistic network is designed in such a way that it is able to attain the average service necessities of all consumers. In case of others, it is made in order to satiate the toughest demands of a single consumer segment.

It is of utmost importance to align the demand planning along with the supply chain. Based on the views of Zhao et al. (2018), when certain products are closer to the choices of customers, these products can be differentiated as people prefer them over unknown products. Furthermore,

it is crucial to establish and develop IT that can assist in supporting multi-level decision making. With help of IT, it is easier to automate all the operations within a company and operate effectively. Lastly, the adoption of both monetary and service metrics can help in efficient management of SC optimisation.

The primary aim of SC management and optimisation need to accomplish effective fulfilment of demand of consumers, orienting outstanding consumer value and that can enhance the responsiveness of organisation, establishing network resiliency as well as facilitate fiscal success.

The impact of push pull enactment helps in minimising cost but ensures increasing service level. Push strategy helps in allocating resources whereas pull strategy increases responsiveness to customer complaints. Push tactic helps in SC planning but pull ensures order fulfilment.

Discussion about an organisation that is responding slowly to changes in consumer demand

Aston Chemicals is a chemical products manufacturer and distributor with 31 employees working for the aforementioned organisation originated in Aylesbury. It is an independent distributor of exclusive chemicals offering “European Personal Care industry” providing a wide range of choices in chemicals that are innovative as well (Aston-chemicals.com (2020).

The manufacturing SMEs originated in the UK are lacking business opportunities as the loss is around 25 billion Euros (Businesscomparison.com, 2020). However, in other developed economies like the US, Australia and China are able to keep up with change in demands unlike the United Kingdom.

A few years before, SMEs developed in the UK has previously been the body of economy. The success behind significant role played by SMEs is based on comparatively cheap production costs as well as improvements in quality mostly in nations like Mainland China.

On the contrary, UK stock has lowered in last few years, along with being unable to understand change in consumer demands is another factor. It has been highlighted by Lee et al. (2019), a “change in demand” occurs when changes in the market is a quantification of demand and transiting the whole of the demand curve which can be either upward or downward.

In the UK market, the change in market’s preferences for any good or service that can be either on the increasing side or on the decreasing side based on whole demand for any product or service.

Most of changes have been derived in relevance to high levels of technological as well as non-technological innovations, funding skills, along with development of branding, software and marketing.

Customers of Aston Chemicals are suffering because of lack of response to changes in demands of consumers. They need to incorporate certain strategies in order to react to the demands for retaining customers and maintaining loyal clientele base.

Aston Chemicals like other small businesses come across additional pressure as it has to compete against other small businesses along with well known players found in relevant industry.

Criteria of Pull environment that can help in managing excessive levels of inventory, high rate of consumer complaint along with a inferior delivery performance to mass customisation

Pull environment helps in using demand data in order to direct both replenishment as well as production. With help of a pull system, it helps in focussing on immediate consumer requirements that are drawn from protection of inventories upstream

. This approach can help Aston Chemicals to be driven by actual intake at the store that can help in forecasting as well. Influenced by the views of Sarbjit (2017), the pull system helps in inventory management as it can be done with the help of supervising the non-fiscal assets which is considered inventory along with stock items.

Inventory management is responsible for overseeing the flow of products from manufacturers to storage facilities until to the point of sale.The pull system helps in controlling inventory of Aston Chemicals. With the help of this strategy, organisations can develop enough products in order to meet the demands of customers’ orders and manage the customers’ change in demands.

As Aston Chemicals are suffering from an abundance of inventory which can be reduced that will result in no excess of inventory that does not need to be stored. It can reduce inventory levels as well as cost of carrying and transporting these goods.

Aston Chemicals has a wide range of products that are addressing various issues but without inventory management can lead to lack of quality as quality is responsible for shaping consumer’s perception of your trading. In order to attain mass customisation,

Aston Chemical should concentrate on attaining mass customisation by only producing and developing products that can satiate the requirements of consumers. It can only be accomplished if the organisation can reach it when it is going to develop unique goods in a mass production manner.

Critical evaluation of the research along with implementation gap in context to lean tools interaction with SC management prevalent in service and manufacturing SMEs

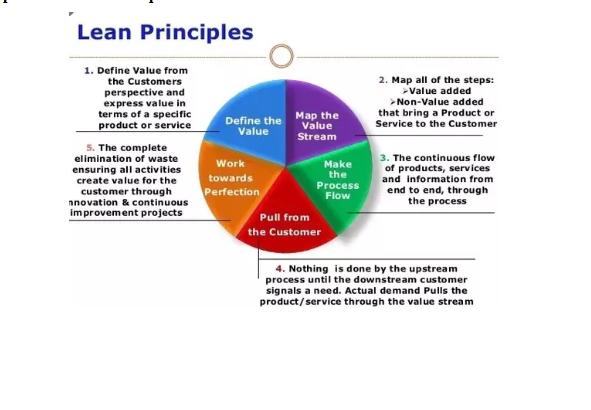

“Lean supply chain management” is all about removing wastes and even unnecessary elements found within a procedure.

Influenced by the views of Bhuvanesh Kumar and Parameshwaran (2018), the usage of lean tools is designated for manufacturing industry based organisations like Aston Chemicals. In these types of companies, supplies are ordered only when they are required rather than considering back stocking a lot of inventory.

On the other hand, the enactment of lean tools associated with “supply chain management” can result in failure of equipment as lean processes have very little space for error which is why either labour failure or equipment failure can result in major inconsistencies evident within lean.

These errors have the capacity to fall behind for the entire operation. This instance showcases that it can be disadvantageous for small and medium sized enterprises like Aston Chemicals as in a big organisation’s manufacturing unit, workers can simply move onto another machine if similar errors happen.

As opined by Gupta and Sharma (2016), it is essential to develop velocity and ensure a level is maintained in the flow of information as well as materials throughout the SC. In order to incorporate SC within organisational operations of

Aston Chemicals, certain steps need to be followed while implementing lean principles, like making sure that the consumer consumption is visible if not transparent.

Implementation gap

In this research, there is a practitioner gap that is evident in the export of the chosen field as first hand information has been rare and hard to come across to.

The lack of funds and shortage of time is also responsible for not being able to conduct a detailed research. The practitioner has to heavily depend on second hand information from peer reviewed journals and other websites in order to gain relevant data.

Advantages of chosen company that can attain with help of SC optimisation with an objective of providing delivery to consumers

The enactment of SC optimisation in the aforementioned organisation is going to attract various benefits. It has been highlighted by He et al. (2016), SC optimisation can help in reduction of costs with help of isolating procedures that can result in failure.

Actions like piling up expenditures without any manufacturing value or even the usage of resources result in increment of production costs can be avoided with SC optimisation. Aston Chemicals needs to start collaborating as well as formulating a problem solving culture for working in an effective manner without facing any discrepancies.

The aforementioned organisation already came under limelight when its spokesperson showcased how Brexit has caused issues for small businesses like them which used to depend on external resources.

This actively illustrates that for gaining a strong footing in tumultuous external environments, the internal environment needs to be strong. Lean principles help in pinpointing the whole cost of fulfilment.

According to the views of Anker and Chambers (2019), optimisation of SC can help in attaining better efficiency as well as a smoother flow resulting in better correlations.

Aston Chemical is a small business with a few employees which is why it is crucial for the organisation to have a good relationship with the suppliers and distributors.

A well developed supply chain can help in any organisation to become more responsible in nature. This actively illustrates that responsible supply chain is responsible for generating value for Aston Chemicals by enhancing the collaboration with suppliers.

In order to provide better delivery to their respective customers and acquire more consumers, good collaboration can help in smooth delivery of manufactured chemical products and increase the quality of product.

The interaction and cooperation for improving corporate social responsibility by strengthening relations with suppliers increases Aston Chemical’s productivity and reducing costs.

Improvements in reduction of inventory, cash to cash cycle time, along with on time in full, fulfilment of order including reduction in lead time and profitability

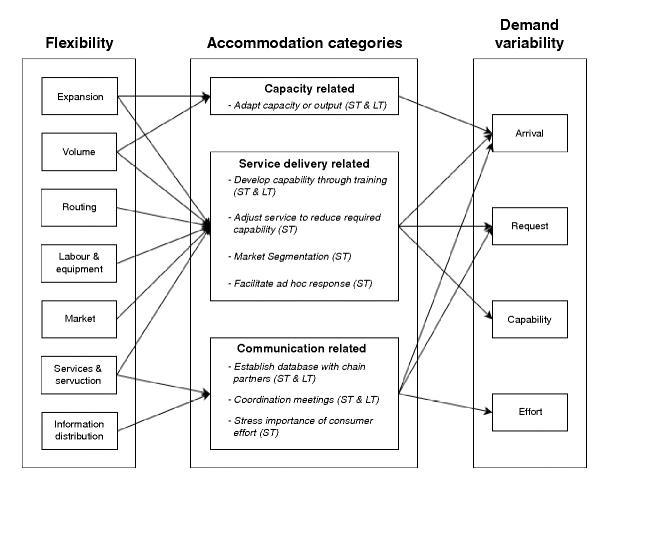

Aston Chemicals can improve their inventory by reducing demand variability which is a measure of the quantity of variability that is present in demand of customers.

It helps in improving the prediction accuracy that helps in managing the SC more efficiently along with assisting in re-examining service levels. Influenced by the views of Walasek (2016), this aids in reduction of order size that is resulting in reduction of inventory which further helps in shrinking the manufacturing lot sizes ending with shortening supplier lead times.

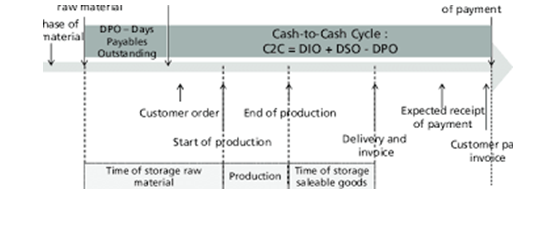

With the incorporation of “cash to cash cycle” or “cash conversion cycle” is a simple and easy to implement metric to calculate how long the cash is being tied up in the main cash producing as well as in certain cash consuming fields.

“Cash to Cash Cycle=Receivable days + Inventory Days- Payable days”, lower number it is better. This model can help Aston Chemical to increase its profitability.

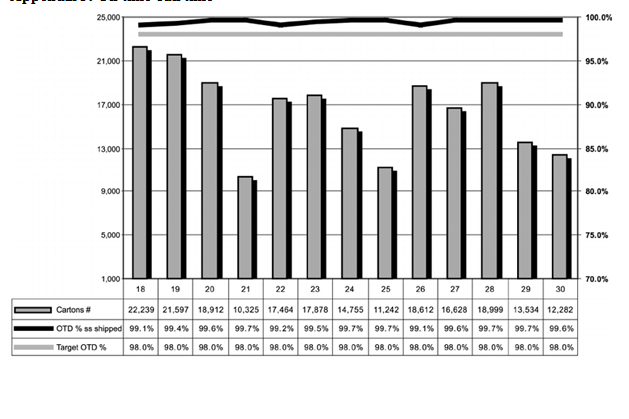

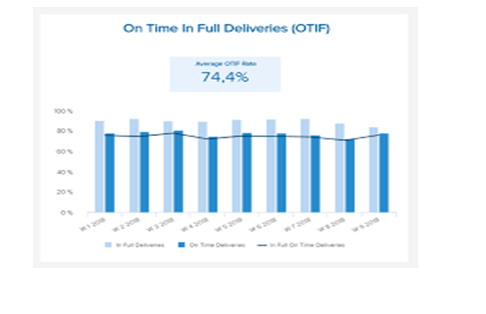

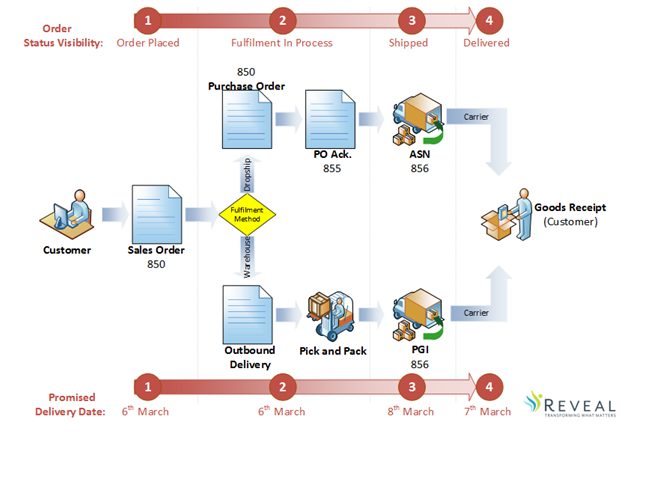

The deliverance “In Full, On Time (DIFOT) or On Time In Full (OTIF)” that helps in calculating the performance of delivery within the SC and helps in measuring how frequently clientele gets what they are demanding and at whatever time they want it.

With help of “On time full time” can help Aston Chemicals to provide the delivery of their products on time that can result in measuring performance of delivery of its chemical based products.

Lastly, reduction of lead time can be done by Aston Chemicals with help of certain strategies, mostly three procedures or flows.

There should be a target for lead time assessment and reduction starting from “order to delivery procedure”, starting from time the consumer orders something till product is delivered to the consumer.

In conclusion, it can be stated that Aston Chemical being a SME in the UK market needs to incorporate certain strategies in order to provide better results to customers without losing profitability. Hence, aforementioned organisations should focus on its inventory management.

Anker, D. and Chambers, G., (2019). A new approach to optimising supply-chain performance using 4 fundamental process types.

Aston-chemicals.com (2020) About chosen organisation Available at:http://www.aston-chemicals.com/ [Accessed on: 04.04.2020]

Bhuvanesh Kumar, M. and Parameshwaran, R., (2018). Fuzzy integrated QFD, FMEA framework for the selection of lean tools in a manufacturing organisation. Production Planning & Control, 29(5), pp.403-417.

Businesscomparison.com (2020) About SMEs in UK Available at:https://www.businesscomparison.com/uk/blog/manufacturing-smes-are-left-with-countless-missed-business-opportunities/&sa=D&ust=1585918241344000&usg=AFQjCNHn_dqUhcx2ytwypBbaxJzp-cTvBA [Accessed on: 03.04.2020]

Gupta, S. and Sharma, M., (2016). Lean services: a systematic review. International Journal of productivity and performance management.

He, T., Ho, W., Zhang, Y. and Dey, P.K., (2016). Organising the business processes of a product servitised supply chain: a value perspective. Production Planning & Control, 27(5), pp.378-393.

Lee, Y., Lee, J.P. and Kim, S., (2019). Optimal timing of price change with strategic customers under demand uncertainty: A real option approach. Advances in Production Engineering & Management, 14(3), pp.379-390.

Mousavi, S.M., Bahreininejad, A., Musa, S.N. and Yusof, F., (2017). A modified particle swarm optimization for solving the integrated location and inventory control problems in a two-echelon supply chain network. Journal of intelligent manufacturing, 28(1), pp.191-206.

Sarbjit, S., (2017). Study on Push/Pull Strategy Decision Taken by Organizations for Their Products and Services.

Walasek, R., (2016). Supply Chain Optimization and Competitiveness of an Enterprise-Results of the Study. Research in Logistics & Production, 6.

Zhao, Y., Cao, Y., Li, H., Wang, S., Liu, Y., Li, Y. and Zhang, Y., (2018). Bullwhip effect mitigation of green supply chain optimization in electronics industry. Journal of Cleaner Production, 180, pp.888-912.

Appendix 1: Demand variability

Appendix 2: Deliverance to customer

Appendix 4: Supply Chain Optimisation

Appendix 5: Cash to cash cycle time

Appendix 7: Lean Principles

Appendix 8: SC management prevalent in service and manufacturing SMEs

Appendix 9: Supply chain management of manufacturing

Demasiado viejo para morir adolescente semi break nicholas air episodio virago de Refn

https://suba.me/