SUPPLY CHAIN, NETWORK AND MARKETS MARK & SPENCER IN CHINA

Mark & Spencer Group Plc which is shortly called as M&S is a multinational retailer. The company has its headquarters in London, England. The company was formed in 1884 and currently it is spread across different countries such as Canada, France, Belgium, Malaysia, Hongkong, Thailand, India, Bangladesh, Turkey, Italy, Indonesia and Srilanka.

The company sells the products in different brands such as Per Una, Autograph, Limited, Rosie, Blue Harbour, M&S Collection, M&S Energy. The company was enjoying the expanding top line and bottom-line till 1997 / 1998.

However post that the company witnessed the falling figures which was major concern and the steps that the company took didn’t cater much. The company also witnessed other failures during this period such as there were more shops closed, the sales of female products came down. Adding to this their entry into China in 2008 and subsequent failure led the company to exit from China in 2018.

This report will critically analyze the supply network and strategy of the global industry and M&S in detail. Post accessing the reason for failure in China, a new strategy has to be formulated to re-enter China more aggressively than before.

M&S’s EXISTING SUPPLY NETWORKS AND STRATEGIES:

Mark & Spencer is considered to be one of the largest clothing based on the value of the sales. The company manufactures its products from around 1000 factories in the world and most of these factories are located in China, Cambodia, Vietnam, India, Turkey, Bangladesh and Sril Lanka. The company does not owns any factories or they don’t manufacture any other their products.

The company believes in paying a fair price to its suppliers to ensure the quality and long term relationship. It also works with the local community to ensure that a good working environment in its supply chain.

Some of the key management policies with regard to Supply Networks of M & S are

- i) Key Management System: M & S has a management system which is more effective and which collaborates the company’s input and the suppliers output. All the details with regard to the requirement of the apparel is issued through the system. The suppliers has to take the details and they have to manufacture the apparels as per the set standard. The details in the management system include the quality of the cloth, the color, number of units, other guidelines etc. If the supplier finds any issue in the order has to update the management immediately. Any miss in the ethical standards will be dealt seriously.

- ii) Well nurtured Staff: The Company wants their employees and staff’s are well trained. The Mark & Spencer management want their suppliers to select people for their attitudes. They don’t want any issue in the quality of the products. The company also expects that the staff are well trained on safety and health, fire safety etc. The suppliers are also mandated to ensure that the employees who ever joins the company, they undergo the induction program.

iii) Employment Practices: The Company want to ensure that all the staffs and employees who are recruited by the suppliers meet the minimum requirement in age and other requirements laid by the country in which the supplier belongs to. Mark & Spenser do not want any employees to be forced labor.

They also want the companies to meet the minimum salary band or the wage band. They also have made the suppliers to ensure that there is no indentured labor. By Indentured labor, the company means that if any labor want to leave the job, their due salary must not be put on hold. The due salaries has to be paid in full settlement.

- iv) Prompt Payment Code: Mark & Spencer have signed a prompt payment code with its supplier by which it will pay the supplier on the due date. The company will not hold money for any unexplained reasons or it will delay the payment. The company also prices the products in a competitive manner in the business world. It ensures that there is considerable profit for the suppliers as well.

SUPPLY NETWORK OF THE GLOBAL APPAREL INDUSTRY AND MARKET:

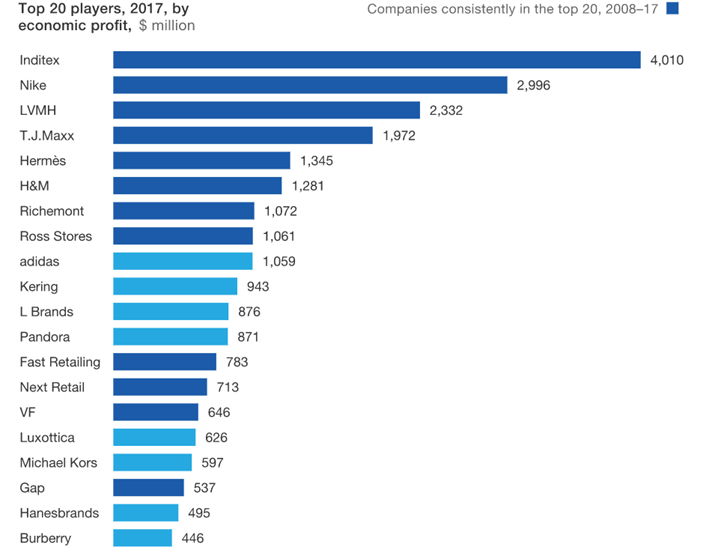

The Global Apparel Industry is estimated to be around US$ 800 Brillion in 2019. This huge industry is expected to grow at a growth rate of 4% to 5%. The highest growth coming from the sportswear followed by mens wear. Though the market is wide spread, 97% of the profits is earned by 20 companies in the industry. That too, the profits comes from the luxury market.

Most of the top 20 companies have been reaping profits continuously over the last decade. They are Inditex, Nike, LVMH, T.J. Maxx, Hermes, H&M, Richemont, Ross Stores, adidas, Kering etc. Each of these companies are currently garnering more than US$ 2 billion as economic profits.

Source: Mckinsey Global Fashion Index

Supply chain: The supply chains of few industries are so dynamic and widespread across the world. One such supply chain is of the apparel industry. The supply chain between the retailers and the manufacturers’ runs and crises crosses the globe multiple times.

The customers are very cost sensitive and the trend in the apparels is short lived. Hence, the cost and the speed in which the products are manufactured and shipped across boundaries & borders is more crucial to sustain in this industry. The countries such as China, India, Bangladesh, Indonesia has benchmarked themselves as one of the manufacturing hub for the textile products.

BASIC SUPPLY CHAIN MODEL ACROSS THE APPAREL INDUSTRY

Source: fibre2fashion.com

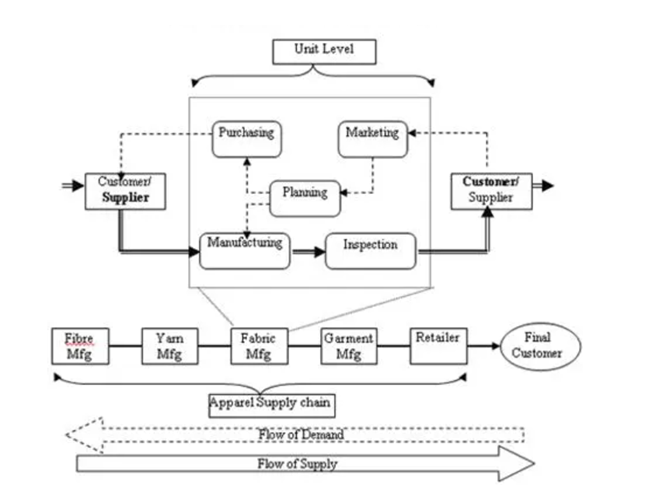

The above chart depicts the Supply chain model of an apparel industry. The basic trend or the taste is the key input from the customer. Thus it gets passed on from the customer to the retailer, retailer to the garment manufacturer, then to fabric manufacturer, back to yarn and fibre manufacturer.

Post the receipt of the customer taste and preferences, the people in the supply chain work hard to meet the customer demands by producing the needed products.

The apparel industry also categorized the demand and the inventory level into three categories. The three categories of demand are basic, fashion-basic and fashion apparel. The basic apparel falls as the base of the triangle with high volume and the demand uncertainty at SKU level is very low. The margin is also very low in this segment. The second segment is the fashion-basic segment.

The volume demand is very medium, and the SKU demand uncertainty at SKU level is moderately difficult. The margin is also medium. The third segment is the fashion apparel and it forms the top apex of the triangle. It states that the demand is very low, however the margins are very good. The SKU level demand uncertainty is high. The companies has to work hard to meet this imbalance in the segments.

SUPPLY CHAIN MODEL WITHIN AN APPAREL COMPANY

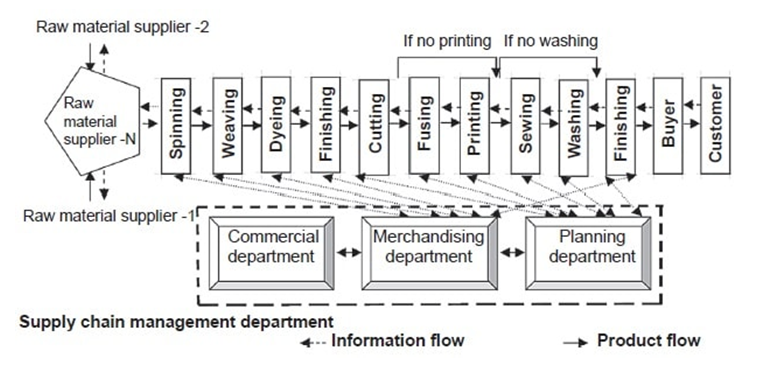

The above chart is the Supply Chain Model within an apparel company. The customer’s choices and preferences inputs are taken by the buyers and they pass it on to the Finishing department of an apparel company.

The finishing department will pass on the requirements to the planning department and to the other departments. The information flows from Finishing to the washing, sewing, printing, fusing, cutting, dyeing, weaving and spinning.

The planning department and the merchandising department also works in tandem with the other departments to meet the customer demand. The product flow might pass through all the departments or it might skip one or the other department based on the need.

The economic downturn in most of the countries and the covid 19 is currently put a lot of pressure on the companies and they are working a lot to transform their operations

- i) Focus on efficiency in increasing

The companies in the apparel industries are focusing more on the trend and as well as cost. The companies are fighting for the lower segment of the triangle where the margin is very low.

So to increase their profit the companies has to continuously keep on finding ways to cut down their cost in the supply chain. They are looking for the efficient sources where they can procure at low cost and they want to run more efficiently.

- ii) Digital transformation:

Currently, the companies are tapping the new technology platform that is online stores. They are cutting down the cost of putting up a shop, paying salaries for the staffs, maintenance etc by reaching online. The customers are also moving from the store purchase to online.

Earlier, the touch and feel flavor what was holding the market is fading now. The technology is also currently used to spot the errors in the product and to differentiate from the normal ones. The accuracy and perfection of the garments has increased a lot.

iii) Change in the sourcing:

The fast pace and the current trendy world is looking for any new fashion to be on the table in no time. This is making the retailers to look for near shoring. They want the materials to reach them at the earliest. Thus US and EU companies believe that going forward there might be shift in suppliers.

The covid 19 has also put a tremendous pressure for to bring back the manufacturing process to the home country and it also has put a huge doubt on the integrity issues in China.

SUPPLY NETWORK OF CHINA’S APPAREL INDUSTRY AND MARKET:

The Supply Chain network of China is different from the other countries in the world. It is considered to be the manufacturing hub of the world. Any product that has to be produced in bulk can be shipped from China at a cheaper cost. There are multiple reasons for the same.

The primary cost for an apparel industry are labour, power, material etc. China is considered to be one of the country whose power cost is low in the world.

The capitalistic government has ensured that the uninterrupted supply of power throughout the country at a cheaper cost so that the companies can come and invest in China. Next is the labour, the country being the world’s 1st populated country, there is no question about the availability of labour.

The huge labour force at a cheaper cost and the capitalistic principles supports the companies a lot for their growth. Materials that they use for the apparel industry such as cloth, thread, button etc are all manufactured in the country and thus the cost of those items also stands low.

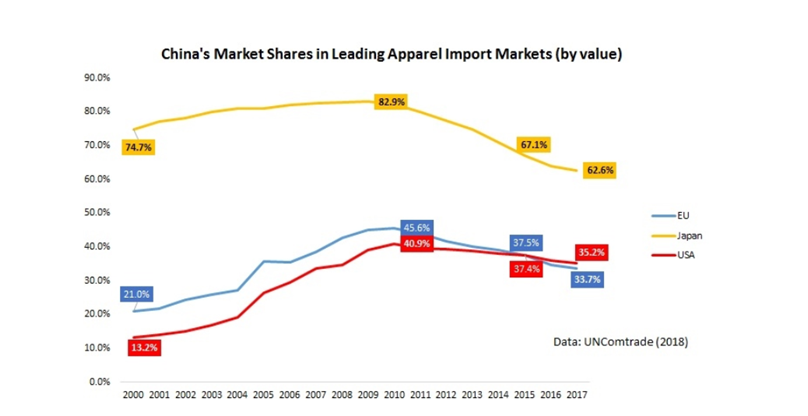

China is considered as the world’s largest apparel exporter. The above chart clearly indicates the China’s exports to European Union, Japan and United States of America from 2000 to 2017. China has been playing a crucial role in the apparel industry. It is not only to the developed nations, China has been exporting apparel related goods to the developing nations as well.

The give below table and chart indicates the % of apparel import by the respective countries from China between 2005 and 2017 (M Xu, Y Cui, M Hu, X Xu, Z Zhang, S Liang, 2019, Supply chain sustainability risk and assessment).

| Countries | 2005 | 2017 |

| Bangladesh | 39.40% | 47% |

| Cambodia | 29.80% | 64.70% |

| India | 45% | 57.70% |

| Indonesia | 27.80% | 45.80% |

| Malaysia | 24.80% | 53.80% |

| Pakistan | 32.10% | 70.80% |

| Philippines | 18.80% | 41.10% |

| Sri Lanka | 15.40% | 39.40% |

| Thailand | 30.50% | 44% |

| Vietnam | 23.40% | 50.40% |

Source:

International Trade, Original Research, Sheng Lu, Nov 2018.

The country has been playing major role in the apparel industry due to its low cost labour till 2016-17. However, post that the country is moving towards the more capital intensive industry and the country is also not able to hold the increase in wages & salaries, there by the jobs are currently being moved to the other countries.

MARKET POSITION STRATEGY TO ENTER INTO CHINESE MARKET:

China is the world’s highly populated country. The population in China alone crosses 1.43 Billion. China is considered to be a big market place in the world. The growing middle class and the increasing disposable income augurs a great place for the company to establish and grow.

However, since China is a place of manufacturing hum and the big apparel companies and the other countries purchase their products from China.

By this we mean that the cost of the products sold by the local market will be much lower than the MNC’s and the quality also will be of high range (J Su, NN Hodges, HJ Wu, X Ji, H Shen – 2018, Investigating Supply Chain Management in the Chinese Textile and Apparel Industry).

The price coupled with the quality makes the people to sigh away from the little expensive Mark & Spencer. To overcome this, Mark& Spencer can attract the customers only through advertising and they have to market their brand as an international one.

To do this, the company has to invest a lot of money in advertising and promoting the brand. Mark & Spencer has to put in a lot of efforts to sell their product in China. M & S has to purchase the products from the Chinese manufacturer label it in UK and they have to sell the same products in China for a way higher price then they bought.

Thus the company has to ensure that the advertising creates a strong impression and brand image in the minds of the people. Thus the high class customers has to be targeted and the product has to be positioned as a Premium product.The people who were M & S has to be differentiated and the elite flavor has to be received by those customers which will bring them back to purchase the product.

SUPPLY NETWORK STRATEGY FOR CHINESE MARKET:

Mark & Spencer has to think on its supply network for its Chinese market. If the company purchases from the Chinese suppliers and if the sell the same in the market, then the people will identify the same and they might sign away from the company.

To overcome this, the company has to deploy a separate team to concentrate in China. From designing till packing the end product has to be unique. Mark & Spenser has to beat the world’s biggest manufacturing hub by its innovative styles, taste and through its management.

Some of the key takeaways are

- i) The products has to be manufactured outside China and it has to be imported to be sold in the local market.

- ii) The designing team has to be unique and the Chinese manufacturer must not have seen this or practiced in their earlier production.

iii) The style of the apparel, the look, the manufacturing process all has to be unique and patented to protect it from the Chinese manufacturers as they might copy the same in no time. Once they copy it they can bring the product at much cheaper cost and they might disrupt the whole Mark & Spencer’s market.

- iv) The Mark & Spencer also has to set the trend in the apparel industry that is short lived. They have to keep on changing their patterns, designs, quality of the apparel and the style so that the gen X will come to try the products that fits them much.

- v) Company can also focus on online shopping a lot. This will attract the internet users and can sell the products without much of its overhead costs.

Mark & Spencer has got two options in front of it to presume.

- A) The company can enter in China as a standalone brand with building its own shops or franchise models. If it is about to do this, then as we discussion above the company has to differentiate itself from rest of the Chinese manufacturers. And the company also has to maintain its differentiation all throughout its lifecycle. If any decline, then the company will start to face decline in its sale and ultimately in the bottom line.

- B) Mark & Spencer is known for its brand. Since the company is strong in its brand and the Chinese partners are strong in manufacturing, the company can also try to look for a Joint Venture with a Chinese manufacturing company. If the company is entering with JV, then the company has to be more cautious as any issues with the JV partner will leave behind the Mark & Spencer with no option but to leave. The company can’t take the second chance now as already the company has come out of china once. There is also a concern that the JV partner might try to outsmart the company for the reason that it has failed once in the sands of China.

Hence, we prefer Strategy A when compared to the Strategy B.

From the above analysis, we have understood the importance of the supply chain in entering into a country, the company’s existence and moreover the bottom-line of the company. We are able to apply the concepts that we studies as theory in the class to the reality that is happening around the world.

REFERENCE:

1) A Ali, M Haseeb – Uncertain Supply Chain Management, 2019, Radio frequency identification (RFID) technology as a strategic tool towards higher performance of supply chain operations in textile and apparel industry of Malaysia

2) M Mehrjoo, ZJ Pasek – International Journal of Production, 2016, Risk assessment for the supply chain of fast fashion apparel industry: a system dynamics framework

3) D Köksal, J Strähle, M Müller, M Freise – Sustainability, 2017, Social sustainable supply chain management in the textile and apparel industry—A literature review

4) P Cheng, Y Fu, KK Lai – 2018, Supply Chain Risk Management in the Apparel Industry

5) SS Phadnis, CH Fine, 2017, End‐To‐End Supply Chain Strategies: A Parametric Study of the Apparel Industry

6) S Harper, R Pal, 2018, Towards a conceptual model of manufacturing supply chain configuration for EU textile and apparel industry

7) B Shen, Q Li, C Dong, P Perry – 2017,Sustainability issues in textile and apparel supply chains

8) J Su, NN Hodges, HJ Wu, X Ji, H Shen– 2018, Investigating Supply Chain Management in the Chinese Textile and Apparel Industry

9) M Xu, Y Cui, M Hu, X Xu, Z Zhang, S Liang, 2019, Supply chain sustainability risk and assessment

https://meclizinex.com/

antivert

where to get tadalafil http://tadalafilise.cyou/# cheap generic cialis for sale

Really enjoyed this blog.Much thanks again. Fantastic.

https://undress.vip/

Very informative blog article.Really looking forward to read more. Will read on…

ab0000.com

Thanks a lot for the blog post.Much thanks again. Want more.

https://pygmalion-ai.com/

I really enjoy the post.Much thanks again.

https://andytxbeh.ourcodeblog.com/24816691/new-step-by-step-map-for-property-in-nagpur

This is one awesome article. Awesome.

https://latesttechnologygadgets35173.blogunteer.com/24554530/5-easy-facts-about-latest-technology-gadgets-described

Really enjoyed this blog post.Really looking forward to read more. Fantastic.

https://2daystrekkingnearbangalor13451.blogpixi.com/25124942/2-days-trekking-near-bangalore-no-further-a-mystery

Appreciate you sharing, great article post.Much thanks again. Want more.

https://miloguiu87542.bloggerbags.com/30027100/down-under-dreams-unveiling-the-wonders-of-australia-for-tourists

Hey, thanks for the article post.Much thanks again. Much obliged.

https://best-packers-and-movers-n69133.tblogz.com/helping-the-others-realize-the-advantages-of-best-packers-and-movers-nangal-39191629

Im obliged for the blog.Much thanks again. Will read on…

https://blog.huddles.app/

I really liked your blog.Thanks Again. Great.

https://liveslotbet.com/

I loved your blog.Thanks Again.

https://www.3chlorine.com/

I value the post. Keep writing.

https://crushon.ai/trends/nsfw_character_ai

Thanks again for the blog post.Really looking forward to read more. Want more.

https://xparkles.com

I truly appreciate this article post.Much thanks again. Much obliged.

https://cashwjxi31097.ambien-blog.com/31045260/the-advantage-of-business-analyst-course

Thank you ever so for you blog.Thanks Again. Really Cool.

https://janitoraichat.com/zh

Thanks for sharing, this is a fantastic blog article.Really thank you! Fantastic.

https://www.us-machines.com/

Hey, thanks for the blog article. Really Cool.

https://www.us-machines.com/

Major thanks for the blog.Really thank you! Much obliged.

https://crushon.ai/

Really enjoyed this blog post.Thanks Again. Really Great.

https://www.panmin.com.es

I value the blog.Much thanks again. Awesome.

https://www.paidusolar.com

Major thanks for the article post.Really thank you! Fantastic.

https://crushon.ai/character/671a6a5f-5093-4846-b425-af7ce1589c24/chat

A round of applause for your blog.Thanks Again. Really Cool.

https://mygenerator.ai/

Looking forward to reading more. Great blog post.Really thank you! Great.

https://janitoraichat.com/

This is one awesome blog article.Thanks Again. Fantastic.

https://gpt-free.ai/

I really liked your blog article.Really thank you! Cool.

https://janitoraichat.com/

Looking forward to reading more. Great article post.Really looking forward to read more. Really Great.

https://www.kubet.fyi/

Fantastic blog article.Thanks Again. Awesome.

https://bonitocase.com/

I really liked your blog post.Really thank you!

https://www.oneuedu.com/visa

Say, you got a nice blog.Really thank you! Awesome.

https://casinoplus.net.ph/

Really informative article post.Really looking forward to read more. Awesome.

https://crushon.ai/

Enjoyed every bit of your article. Cool.

https://crushon.ai/character/83a80dbc-64e5-4b30-beda-7d42415f68e6/details

Enjoyed every bit of your post.Much thanks again. Great.

https://crushon.ai/

Thanks for the blog.Thanks Again. Will read on…

https://chat.openai.com/g/g-u4cBExH7W-math-solver-ai

Thanks again for the blog article. Want more.

https://crushon.ai/

Major thanks for the blog article.Thanks Again. Much obliged.

https://callmeimei.com

I appreciate you sharing this blog article.Much thanks again. Great.

https://tycent520.com

Looking forward to reading more. Great blog post.Thanks Again. Awesome.

https://www.temporaryfencesales.ca

Say, you got a nice blog article.Thanks Again. Really Cool.

https://www.temporary-fence.com.au

Wow, great blog post. Fantastic.

https://www.temporaryfencesales.ca

Thanks again for the article post.Much thanks again. Will read on…

https://nsfwgenerator.ai/

Thanks-a-mundo for the article.Much thanks again. Will read on…

https://gbdownload.cc/

Very good blog article. Great.

https://fouadmods.net/

Looking forward to reading more. Great blog post.Really thank you!

https://devinai.ai

Great, thanks for sharing this post.Really looking forward to read more. Will read on…

https://www.yinraohair.com/human-hair/hair-extensions

Enjoyed every bit of your post.Much thanks again. Much obliged.

https://www.yinraohair.com/cosplay/shop-by-color/black

I truly appreciate this blog post.Really looking forward to read more. Will read on…

https://best-animation-academy-in04567.blogcudinti.com/25552601/examine-this-report-on-best-animation-academy-in-rajasthan

Major thankies for the blog post.Thanks Again. Want more.

https://deanzpes77543.wikitidings.com/5452169/paragliding_tips

I really enjoy the article post.Thanks Again. Keep writing.

https://dominickgvjv87542.targetblogs.com/25826850/occupational-english-test

Wow, great blog article.Thanks Again.

https://www.minorleagueball.com/users/cpvcpipemanufacturers

Hey, thanks for the blog article.Thanks Again. Really Great.

https://dantehnux36914.digiblogbox.com/51003557/india-118-105-115-97-for-british-citizens-a-comprehensive-guide-to-obtaining-your-e-118-105-115-97-to-india-from-the-uk

Thank you for your post.Really looking forward to read more. Cool.

https://waylonqerd10876.blog5star.com/26286057/tips-to-buy-spices-online

Thanks-a-mundo for the blog.

https://andersonbpcn43209.digiblogbox.com/51493590/the-advantage-of-valve-manufacturer

Im grateful for the blog post.Really looking forward to read more. Fantastic.

https://riverdsfr65420.vblogetin.com/31382858/home-appliances-products

Very good blog.Really looking forward to read more. Cool.

https://hubbarde448awf2.p2blogs.com/profile

Great, thanks for sharing this article post.Much thanks again. Want more.

https://xyzbookmarks.com/story16748008/the-2-minute-rule-for-tourism-in-lonavala

I found this website called that might fit what you’re looking for Sex 11

https://aev99.day/